Professional Documents

Culture Documents

Cold Rolled Steel Strip Voestalpine en 111021

Uploaded by

Shailendra SharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cold Rolled Steel Strip Voestalpine en 111021

Uploaded by

Shailendra SharmaCopyright:

Available Formats

PREMIUM QUALITY

WITH REDUCED

CARBON FOOTPRINT

COLD-ROLLED

STEEL STRIP

Range of supply

November 2023

voestalpine Steel Division

www.voestalpine.com/steel

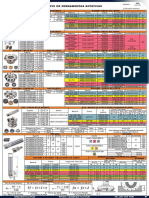

Yield Tensile Total Yield Tensile Total

Norms and strength strength elong. r value n value BH2 Norms and strength strength elong. r value n value BH2

specifica- Test Rp0.2 Rm A80 min. min. min. min. specifica- Test Rp0.2 Rm A80 min. min. min. min.

Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed

Mild steels Micro-alloyed steels

EN 10130 Re Rm A80 r90 n90 BH2 E EN 10268 Rp0.2 Rm A80 r90 n90 BH2 E

DC01 EN 10130 Trans. 140 - 280 270 - 410 28 - - - HC260LA EN 10268 Trans. 260 - 330 350 - 430 26 - - - -

DC03 EN 10130 Trans. 140 - 240 270 - 370 34 1.3 - - HC300LA EN 10268 Trans. 300 - 380 380 - 480 23 - - - -

DC04 EN 10130 Trans. 140 - 210 270 - 350 38 1.6 0.18 - HC340LA EN 10268 Trans. 340 - 420 410 - 510 21 - - - -

DC05 EN 10130 Trans. 140 - 180 270 - 330 40 1.9 0.20 - HC380LA EN 10268 Trans. 380 - 480 440 - 580 19 - - - -

DC06 EN 10130 Trans. 120 - 170 270 - 330 41 2.1 0.22 - HC420LA EN 10268 Trans. 420 - 520 470 - 600 17 - - - -

DC07 EN 10130 Trans. 100 - 150 250 - 310 44 2.5 0.23 - HC460LA EN 10268 Trans. 460 - 580 510 - 660 13 - - - -

VDA 239-100 HC500LA EN 10268 Trans. 500 - 620 550 - 710 12 - - - -

Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

and voestalpine special grade

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

CR1 VDA 239-100 Trans. 140 - 300 270 - 410 28 - - - and voestalpine special grade

CR2 VDA 239-100 Trans. 140 - 240 270 - 370 34 1.3 0.16 - CR210LA VDA 239-100 Long. 210 - 300 310 - 410 29 1.0 0.15 - -

CR3 VDA 239-100 Trans. 140 - 210 270 - 350 38 1.8 0.18 - CR240LA VDA 239-100 Long. 240 - 320 320 - 430 27 - 0.15 - -

CR4 VDA 239-100 Trans. 140 - 180 270 - 330 39 1.9 0.20 - CR270LA VDA 239-100 Long. 270 - 350 350 - 460 25 - 0.14 - -

CR5 VDA 239-100 Trans. 110 - 170 260 - 330 41 2.1 0.22 - CR300LA VDA 239-100 Long. 300 - 380 380 - 490 23 - 0.14 - -

CR6 voestalpine Trans. 110 - 170 250 - 330 43 2.3 0.23 - CR340LA VDA 239-100 Long. 340 - 430 410 - 530 21 - 0.12 - -

CR380LA VDA 239-100 Long. 380 - 470 450 - 570 19 - 0.12 - -

Structural steels CR420LA VDA 239-100 Long. 420 - 520 480 - 600 17 - 0.11 - -

DIN 1623 Rp0.2 Rm A80 r90 n10-20/Ag BH2 E CR460LA VDA 239-100 Long. 460 - 580 520 - 680 15 - 0.10 - -

S215G DIN 1623 Trans. ≥ 215 360 - 510 20 - - - - CR800LA voestalpine Long. 800 - 950 830 - 1030 9 - - - -

Enameling steels

EN 10209 Re Rm A80 r n10-20/Ag BH2 E

and voestalpine special grade

DC01EK EN 10209 Trans. 140 - 270 270 - 390 30 - - - -

DC04EK EN 10209 Trans. 140 - 220 270 - 350 36 - - - -

DC05EK EN 10209 Trans. 140 - 220 270 - 350 36 1.5 - - -

DC06EK EN 10209 Trans. 120 - 190 270 - 350 38 1.6 - - -

DC07EK EN 10209 Trans. 100 - 170 270 - 350 40 2.0 - - -

DC03ED TiVac voestalpine Trans. 140 - 220 270 - 370 34 1.4 - - -

DC04ED TiVac voestalpine Trans. 140 - 200 270 - 350 38 - - - -

2 COLD -ROLLED S TEEL S TRIP • R A NG E OF SUPPLY • 11/2023 3

Yield Tensile Total Yield Tensile Total

Norms and strength strength elong. r value n value BH2 Norms and strength strength elong. r value n value BH2

specifica- Test Rp0.2 Rm A80 min. min. min. min. specifica- Test Rp0.2 Rm A80 min. min. min. min.

Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed

Bake-hardening steels High-strength IF steels

EN 10268 Rp0.2 Rm A80 r90 n90 BH2 E EN 10268 Rp0.2 Rm A80 r90 n90 BH2 E

HC180B EN 10268 Trans. 180 - 230 290 - 360 34 1.6 0.17 35 HC180Y EN 10268 Trans. 180 - 230 330 - 400 35 1.7 0.19 -

HC220B EN 10268 Trans. 220 - 270 320 - 400 32 1.5 0.16 35 HC220Y EN 10268 Trans. 220 - 270 340 - 420 33 1.6 0.18 -

HC260B EN 10268 Trans. 260 - 320 360 - 440 29 - - 35 HC260Y EN 10268 Trans. 260 - 320 380 - 440 31 1.4 0.17 -

HC300B EN 10268 Trans. 300 - 360 390 - 480 26 - - 35 - VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E

VDA 239-100 Rp0.2 Rm A80 r0 n10-20/Ag BH2 E CR180IF VDA 239-100 Long. 180 - 240 320 - 400 35 1.2 0.19 -

CR180BH VDA 239-100 Long. 180 - 240 290 - 370 34 1.1 0.17 20/30 CR210IF VDA 239-100 Long. 210 - 270 340 - 420 33 1.1 0.18 -

CR210BH VDA 239-100 Long. 210 - 270 320 - 400 32 1.1 0.16 20/30 CR240IF VDA 239-100 Long. 240 - 300 360 - 440 31 1.0 0.17 -

CR240BH VDA 239-100 Long. 240 - 300 340 - 440 29 1.0 0.15 20/30

CR270BH VDA 239-100 Long. 270 - 330 360 - 460 27 - 0.13 20/30 - Carbon-manganese steels

Special voestalpine grade Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

High-strength LC steels HT440CM voestalpine Trans. 280 - 380 ≥ 440 25 - - - -

Special voestalpine grade Rp0.2 Rm A80 r90 n10-20/Ag BH2 E HT590CM voestalpine Trans. 420 - 570 ≥ 590 14 - - - -

HC180LC voestalpine Trans. 180 - 270 300 - 390 32 - - -

HC200LC voestalpine Trans. 200 - 290 310 - 400 31 - - -

HC220LC voestalpine Trans. 220 - 310 320 - 410 30 - - -

4 COLD -ROLLED S TEEL S TRIP • R A NG E OF SUPPLY • 11/2023 5

Yield Tensile Total Yield Tensile Total

Norms and strength strength elong. r value n value BH2 Norms and strength strength elong. r value n value BH2

specifica- Test Rp0.2 Rm A80 min. min. min. min. specifica- Test Rp0.2 Rm A80 min. min. min. min.

Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed

Dual-phase steels Complex-phase steels

EN 10338 Rp0.2 Rm A80 r90 n10-UE BH2 E EN 10338 Rp0.2 Rm A80 r90 n10-UE BH2 E

HCT450X EN 10338 Long. 260 - 340 ≥ 450 27 - 0.16 30 - HCT780C EN 10338 Long. 570 - 720 ≥ 780 10 - - 30 -

HCT490X EN 10338 Long. 290 - 380 ≥ 490 24 - 0.15 30 - HCT980C EN 10338 Long. 780 - 950 ≥ 980 6 - - 30 -

HCT590X EN 10338 Long. 330 - 430 ≥ 590 20 - 0.14 30 - VDA 239-100 Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

HCT780X EN 10338 Long. 440 - 550 ≥ 780 14 - - 30 - and voestalpine special grade

HCT980X EN 10338 Long. 590 - 740 ≥ 980 10 - - 30 - CR570Y780T-CP VDA 239-100 Long. 570 - 720 780 - 920 10 - - 30 -

VDA 239-100 CR660Y780T-CP voestalpine Long. 660 - 830 780 - 980 10 - - 30 -

Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

and voestalpine special grade CR780Y980T-CP VDA 239-100 Long. 780 - 950 980 - 1140 6 - - 30 -

CR260Y450T-DP voestalpine Long. 260 - 340 450 - 560 27 - 0.16 30 - CR900Y1180T-CP VDA 239-100 Long. 900 - 1100 1180 - 1350 5 - - 30 -

CR290Y490T-DP VDA 239-100 Long. 290 - 380 490 - 600 24 - 0.15 30 - CR950Y1180T-CP voestalpine Long. 950 - 1150 1180 - 1350 5 - - 30 -

CR330Y590T-DP VDA 239-100 Long. 330 - 430 590 - 700 20 - 0.14 30 -

CR360Y590T-DP voestalpine Long. 360 - 460 590 - 700 19 - 0.14 30 - Complex-phase steels high-ductility (cold rolled complex-phase steels with improved formability)

CR440Y780T-DP VDA 239-100 Long. 440 - 550 780 - 900 14 - 0.11 30 - Special voestalpine grade Rp0.2 Rm A80 r90 n10-UE BH2 E

CR500Y780T-DP voestalpine Long. 500 - 620 780 - 900 13 - - 30 - CR780Y980T-CH voestalpine Long. 780 - 950 980 - 1140 10 - - 30 -

CR550Y980T-DP voestalpine Long. 550 - 730 980 - 1130 10 - - 30 - CR900Y1180T-CH voestalpine Long. 900 - 1150 1180 - 1350 7 - - 30 -

CR590Y980T-DP VDA 239-100 Long. 590 - 740 980 - 1130 10 - - 30 - CR1000Y1370T-CH voestalpine Long. 1000 - 1250 1370 - 1550 5 - - 30 -

CR660Y980T-DP voestalpine Trans. 660 - 810 980 - 1130 10 - - 30 -

CR700Y980T-DP VDA 239-100 Long. 700 - 850 980 - 1130 8 - - 30 -

Dual-phase high-ductility steels (cold rolled dual-phase steels with improved formability)

VDA 239-100

and voestalpine special grade Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

CR330Y590T-DH voestalpine Long. 330 - 430 590 - 700 26 - 0.16 30 -

CR440Y780T-DH VDA 239-100 Long. 440 - 550 780 - 900 18 - 0.13 30 -

CR700Y980T-DH VDA 239-100 Long. 700 - 850 980 - 1180 13 - - 30 -

CR850Y1180T-DH voestalpine Long. 850 - 1050 1180 - 1350 13 - - 30 -

6 COLD -ROLLED S TEEL S TRIP • R A NG E OF SUPPLY • 11/2023 7

Yield Tensile Total Yield Tensile Total

Norms and strength strength elong. r value n value BH2 Norms and strength strength elong. r value n value BH2

specifica- Test Rp0.2 Rm A80 min. min. min. min. specifica- Test Rp0.2 Rm A80 min. min. min. min.

Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed Steel grade tions dir. [MPa] [MPa] [%] [-] [-] [MPa] Exposed

Case-hardening and heat-treatable steels in +LC condition (soft-annealed and lightly rerolled) Case-hardening steels in +LC condition (soft-annealed and lightly rerolled)

EN 10132 Rp0.2 Rm A80 r90 n10-20/Ag BH2 E Special voestalpine grade Rp0.2 Rm A80 r90 n10-20/Ag BH2 E

C10E EN 10132 Long. ≤ 345 ≤ 430 26 - - - - 22MnB5 voestalpine Long. ≤ 450 ≤ 650 18 - - - -

C15E EN 10132 Long. ≤ 360 ≤ 450 25 - - - - 27MnB5 voestalpine Long. ≤ 450 ≤ 650 18 - - - -

16MnCr5 EN 10132 Long. ≤ 420 ≤ 550 21 - - - - 34MnB5 voestalpine Long. ≤ 450 ≤ 650 16 - - - -

C22E EN 10132 Long. ≤ 400 ≤ 500 22 - - - -

C25E EN 10132 Long. ≤ 410 ≤ 510 21 - - - - Martensitic steels

C35E EN 10132 Long. ≤ 430 ≤ 540 19 - - - - VDA 239-100 Rp0.2 Rm A80 r90 n10-UE BH2 E

and voestalpine special grade

CR860Y1100T-MS voestalpine Long. 860 - 1120 1100 - 1320 3 - - 30 -

CR1030Y1300T-MS VDA 239-100 Long. 1030 - 1330 1300 - 1550 3 - - 30 -

Hot-forming steels in +LC condition (soft-annealed and lightly rerolled)

Special voestalpine grade 1) Rp0.2 Rm A r90 n10-20/Ag BH2 E

phs-uncoated 1500 CR unhardened Trans. 300 - 480 480 - 600 18 - - - -

phs-uncoated 1500 CR hardened* Trans. 1050 1500 6 - - - -

phs-uncoated 1500 HR unhardened Trans. ≥ 280 450 - 750 12 - - - -

phs-uncoated 1500 HR hardened* Trans. 1050 1500 6 - - - -

phs-uncoated 2000 CR** unhardened Trans. 300 - 500 450 - 650 17 - - - -

phs-uncoated 2000 CR** hardened* Trans. 1200 1900 5 - - - -

phs-uncoated 2000 HR** unhardened Trans. 280 - 680 440 - 850 10 - - - -

phs-uncoated 2000 HR** hardened* Trans. 1200 1900 5 - - - -

1)

The voestalpine steel grades meet the specifications of VDA 239-500.

* Mechanical parameters and coating properties in hardened condition are standard values achieved in professional processing of flat sheets.

The indicated values are not guaranteed by voestalpine Stahl GmbH

** Indication of preliminary values

8 COLD -ROLLED S TEEL S TRIP • R A NG E OF SUPPLY • 11/2023 9

SURFACES AND FUNCTIONAL DIMENSIONS

SURFACE TREATMENT

Surfaces according to EN 10130 and VDA 239-100 Available dimensions: wide strip (coil)

Norms and Thickness Width Outside diameter Inside diameter

Product variant Normal surface Best surface

specifications [mm] max. [mm] max. [mm] [mm]

EN 10130 A B 0.40 - 3.00 1615 2000 500 / 600

Uncoated cold-rolled strip

VDA 239-100 U E

Available dimensions: slit (slit strip)

Thickness Strip width Outside diameter Inside diameter

[mm] min. [mm] [mm] [mm]

Functional surface treatment

0.40 - 3.00 10 700 - 2000 500 / 600

Oiled

Product variant (e.g. prelube2)

Available dimensions: cut-to-length (sheet)

Uncoated cold-rolled strip

Thickness Width Length Package weight

[mm] min. [mm] [mm] max. [t]

0.40 - 3.00 210 200 - 6700 6

Indicated references are standard values. The available combinations of widths and thicknesses and supply forms vary

depending on the steel grade. Certain limitations possible depending on thickness.

This document provides an overview of the cold-rolled steel strip products supplied by the voestalpine Steel Division. Other

grades are available upon request. Please find further information and downloads under the following link:

Cold-rolled steel strip – greentec steel Edition www.voestalpine.com/steel

Premium quality with reduced carbon footprint

Max. carbon footprint 1.97 kg CO2e per kg of steel 1)

1)

per EN 15804+A2 (EPD methodology) cradle to gate

All products, dimensions and steel grades listed in each voestalpine supply range are available as greentec steel Edition.

The information and product properties contained in this printed material are non-binding and serve the sole purpose of technical orientation.

They do not replace individual advisory services provided by our sales and customer service teams. The product information and characteristics

set forth herein shall not be considered as guaranteed properties unless explicitly stipulated in a separate contractual agreement. For this rea-

son, voestalpine shall not grant any warranty nor be held liable for properties and/or specifications other than those subject to explicit agree-

ment. This also applies to the suitability and applicability of products for certain applications as well as to the further processing of materials

into final products. All application risks and suitability risks shall be borne by the customer. The General Terms of Sale for Goods and Services of

the voestalpine Steel Division shall apply to all materials supplied by the voestalpine Steel Division and can be accessed using the following link:

www.voestalpine.com/stahl/en/The-Steel-Division/General-Terms-of-Sale

Technical changes are reserved. Errors and misprints are excepted. No part of this publication may be reprinted without explicit written

permission by voestalpine Stahl GmbH.

10 COLD -ROLLED S TEEL S TRIP • R A NG E OF SUPPLY • 11/2023 11

11/2023

voestalpine Steel Division

voestalpine-Straße 3

4020 Linz, Austria

productmanagement@voestalpine.com

www.voestalpine.com/steel

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- Hot-Dip Galvanized Steel Strip: Range of Supply April 2019Document8 pagesHot-Dip Galvanized Steel Strip: Range of Supply April 2019Meme VillacortaNo ratings yet

- Hot-Dip Galvanized Steel Strip Range of SupplyDocument12 pagesHot-Dip Galvanized Steel Strip Range of SupplyvictorNo ratings yet

- Hot Dip Galvanized Steel Strip Voestalpine en 20181002 TwosideDocument5 pagesHot Dip Galvanized Steel Strip Voestalpine en 20181002 TwosideAndy HuffNo ratings yet

- Dual Phase Steels Voestalpine EN 28092018Document4 pagesDual Phase Steels Voestalpine EN 28092018Silverio AcuñaNo ratings yet

- Dual-phase steels data sheet highlights strength propertiesDocument4 pagesDual-phase steels data sheet highlights strength propertiespranayNo ratings yet

- En 10139Document2 pagesEn 10139releone11No ratings yet

- Dual Phase High Ductility Steels Voestalpine EN 12062019Document2 pagesDual Phase High Ductility Steels Voestalpine EN 12062019RhushikeshNo ratings yet

- Dual Phase High Ductility Steels Voestalpine EN 12062019Document2 pagesDual Phase High Ductility Steels Voestalpine EN 12062019Willian FreireNo ratings yet

- Zetty Catalogue 121Document1 pageZetty Catalogue 121ramukolakiNo ratings yet

- DC01 Steel Data Sheet: Mechanical Properties, Chemical Composition, ApplicationsDocument9 pagesDC01 Steel Data Sheet: Mechanical Properties, Chemical Composition, ApplicationsHung NguyenNo ratings yet

- Datasheet-Sandvik-3r60-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-3r60-En-V2020-12-10 07 - 47 Version 1Bruno AlfanoNo ratings yet

- Avk Centric U-Section Butterfly Valve, Pn10 820/20-028: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument2 pagesAvk Centric U-Section Butterfly Valve, Pn10 820/20-028: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- 5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeDocument2 pages5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeMemona FayyazNo ratings yet

- Copper Bussman FusesDocument9 pagesCopper Bussman FusesKhaled BellegdyNo ratings yet

- RuukiDocument20 pagesRuukiproje01No ratings yet

- High Speed HRC Fuses - Continued: Fuses, Circuit Breakers & Consumer UnitsDocument1 pageHigh Speed HRC Fuses - Continued: Fuses, Circuit Breakers & Consumer UnitsVasile DumitruNo ratings yet

- Applications: Type TestedDocument4 pagesApplications: Type TestedFV AllanNo ratings yet

- 2017MEA46 50Hz Copeland CR Compressor Cross Reference - FlyerDocument2 pages2017MEA46 50Hz Copeland CR Compressor Cross Reference - FlyershadNo ratings yet

- Molded RF Inductor: FeaturesDocument2 pagesMolded RF Inductor: FeaturesStuxnetNo ratings yet

- Low Carbon Content SteelsDocument1 pageLow Carbon Content SteelsAntonio ClimaNo ratings yet

- Datasheet-Sanmac-316316l-En-V2017-11-21 13 - 01 Version 1Document7 pagesDatasheet-Sanmac-316316l-En-V2017-11-21 13 - 01 Version 1Pier Paolo MaccioneNo ratings yet

- Cross Reference of STANDARDS For Equivalent Grades of Steel: 1. Bearing Quality Steel: BS DIN IS EN Sae/AisiDocument4 pagesCross Reference of STANDARDS For Equivalent Grades of Steel: 1. Bearing Quality Steel: BS DIN IS EN Sae/AisiManjunath MNo ratings yet

- Rifeng PAP 2Document37 pagesRifeng PAP 2Sota KarunaNo ratings yet

- 05 - 14 Steel RepairsDocument1 page05 - 14 Steel Repairsmaxuya2001No ratings yet

- 05 - 14 Steel RepairsDocument1 page05 - 14 Steel Repairsmaxuya2001No ratings yet

- SP - QCA - 0018 - R00 SP Mechanical ComponentsDocument6 pagesSP - QCA - 0018 - R00 SP Mechanical ComponentsProfRyu11No ratings yet

- Alloy Steel Astm Asme A 335 GR p911 Seamless PipeDocument15 pagesAlloy Steel Astm Asme A 335 GR p911 Seamless Pipemanuelq9No ratings yet

- Alloy Steel Astm Asme A 335 GR p2 Seamless PipeDocument15 pagesAlloy Steel Astm Asme A 335 GR p2 Seamless PipeApurva GuptaNo ratings yet

- A 48 CP, Ap, FPDocument1 pageA 48 CP, Ap, FPMuhammad HannanNo ratings yet

- Reliable wastewater pumps for buildingsDocument4 pagesReliable wastewater pumps for buildingsArmando BarrancoNo ratings yet

- Material Data Sheet for S355J2 and Related Steel GradesDocument3 pagesMaterial Data Sheet for S355J2 and Related Steel GradesRushangNo ratings yet

- Arrancadores General ElectricDocument1 pageArrancadores General ElectricFernando AguíñagaNo ratings yet

- Dammam Housing DT: 01/10/2018 10:50:21.151296 DT: 85383 Microsec - 5.12 Cyc 1440.9222 AS: ONDocument4 pagesDammam Housing DT: 01/10/2018 10:50:21.151296 DT: 85383 Microsec - 5.12 Cyc 1440.9222 AS: ONsivaguruk2No ratings yet

- RPMAB21QKS100-Quick GS SimpleDocument1 pageRPMAB21QKS100-Quick GS SimpleinfoNo ratings yet

- pm3600 SeriesDocument3 pagespm3600 SeriesAli AbbasNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Mild Steels Voestalpine EN 09082019Document5 pagesMild Steels Voestalpine EN 09082019Alma Aliza VillaberNo ratings yet

- 5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332Document2 pages5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332LXCNo ratings yet

- TCE Kronos-Data-Sheet-2019Document1 pageTCE Kronos-Data-Sheet-2019crash2804No ratings yet

- Datasheet Sandvik 6r35 enDocument7 pagesDatasheet Sandvik 6r35 enSimone FerronNo ratings yet

- Table 20210909122524Document4 pagesTable 20210909122524Luiizz MartiinezzNo ratings yet

- 5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052Document3 pages5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052MahfudNo ratings yet

- Ca 50 50Document2 pagesCa 50 50Adrian MartinNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Venvu 116Document1 pageVenvu 116ronaldb322No ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Plastic Package For TransistorsDocument4 pagesPlastic Package For Transistorsvikram80No ratings yet

- Cardápio de Ferramentas Rotativas: WCS503507HDocument2 pagesCardápio de Ferramentas Rotativas: WCS503507HRafael A. CarvalhoNo ratings yet

- Equivalent GradesDocument37 pagesEquivalent GradesUmesh SakhareliyaNo ratings yet

- Material PropertiesDocument4 pagesMaterial Propertiesbratkp100% (1)

- SSR 40daDocument4 pagesSSR 40daMarcus NguyễnNo ratings yet

- Sandvik 2RE69 Stainless Steel DatasheetDocument9 pagesSandvik 2RE69 Stainless Steel DatasheetMuzammilNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, KilledDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, Killedamit kumar sarkarNo ratings yet

- GUIA DE MATERIALES ACERODocument11 pagesGUIA DE MATERIALES ACEROGracielaNo ratings yet

- IXYS HV MOSFETsDocument17 pagesIXYS HV MOSFETsshahinNo ratings yet

- QSC Rmx850 SchematicDocument7 pagesQSC Rmx850 SchematicSergioMastríacoNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Steel in The European Union Vera Trappmann PDFDocument21 pagesSteel in The European Union Vera Trappmann PDFaashima chopraNo ratings yet

- SIROLL CM Solutions For Cold Rolling Mills enDocument36 pagesSIROLL CM Solutions For Cold Rolling Mills enashbasalNo ratings yet

- BIS Licences for Foreign ManufacturersDocument168 pagesBIS Licences for Foreign ManufacturersKamal T100% (3)

- Material Data Sheet: Material Number Country DesignationsDocument29 pagesMaterial Data Sheet: Material Number Country Designationsdandan29No ratings yet

- RBI FDI Inflows Report TableDocument138 pagesRBI FDI Inflows Report TableRohitSalunkheNo ratings yet

- Simetal BF Vairon enDocument12 pagesSimetal BF Vairon enBharat Bhushan SaxenaNo ratings yet

- Solutions For Sinter Plants enDocument20 pagesSolutions For Sinter Plants enRajat SahuNo ratings yet

- VRSDocument8 pagesVRSCNo ratings yet

- Simetal Meros Plant enDocument8 pagesSimetal Meros Plant enLuigi OlivaNo ratings yet

- VOESTALPINE - Durostat (EN-05062019) 04 - 2019 PDFDocument3 pagesVOESTALPINE - Durostat (EN-05062019) 04 - 2019 PDFSimone PavaniNo ratings yet

- S355 420 460 Toughcore Voestalpine EN 020720Document4 pagesS355 420 460 Toughcore Voestalpine EN 020720Joost de HaanNo ratings yet

- 010 Metals-Magazine 3-2009 Long-Products Plant-ModernizationsDocument108 pages010 Metals-Magazine 3-2009 Long-Products Plant-ModernizationsElafanNo ratings yet

- Voest Alpine Electrical SteelDocument18 pagesVoest Alpine Electrical SteelL Mahender ReddyNo ratings yet

- Structural Steel Data SheetDocument3 pagesStructural Steel Data Sheetmaheshmalaichamy007No ratings yet

- Cold Rolled Steel Strip Voestalpine en 111021Document7 pagesCold Rolled Steel Strip Voestalpine en 111021Shailendra SharmaNo ratings yet

- Voestalpine Folder Durostat EN 20180612Document12 pagesVoestalpine Folder Durostat EN 20180612Kalpesh JainNo ratings yet

- Platts SBB Steel DailyDocument11 pagesPlatts SBB Steel DailydxkarthikNo ratings yet

- Repair and Maintenance Weld Overlay Solutions For Steel MillsDocument28 pagesRepair and Maintenance Weld Overlay Solutions For Steel MillsMike CheNo ratings yet

- UTP Steel+brochure EN 2017 WEBDocument28 pagesUTP Steel+brochure EN 2017 WEBCarlos Anibal OrtizNo ratings yet

- December 2010 Maerz News - Maerz Ofenbau AG PDFDocument12 pagesDecember 2010 Maerz News - Maerz Ofenbau AG PDFWindy Nitaejun HorvejkulNo ratings yet

- List 1Document89 pagesList 1samima khatunNo ratings yet

- Sintering Methods and Products PDFDocument326 pagesSintering Methods and Products PDFlamia97No ratings yet

- Comparison of Steel Standards - VoestalpineDocument14 pagesComparison of Steel Standards - VoestalpineAnonymous 6aGAvbN100% (1)

- Sintering - Methods and ProductsDocument326 pagesSintering - Methods and ProductsJosé Ramírez100% (1)

- APPROVED STEEL MILLS AND PIPE MILLS LISTDocument89 pagesAPPROVED STEEL MILLS AND PIPE MILLS LISTWilliam DaslerNo ratings yet

- 35 110 HwcpresentationactualDocument43 pages35 110 HwcpresentationactualEyock PierreNo ratings yet

- EnergyProcessing 09032009Document40 pagesEnergyProcessing 09032009hamdanribhiNo ratings yet

- Specimen: Advance Payment Guarantee: To Voestalpine Automotive Components Linz GMBH Stahlstraße 47 A-4020 LinzDocument2 pagesSpecimen: Advance Payment Guarantee: To Voestalpine Automotive Components Linz GMBH Stahlstraße 47 A-4020 LinzRAJVIR SINGH PUNIANo ratings yet