100% found this document useful (1 vote)

4K views7 pagesMaster Formula Card

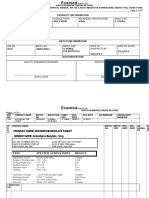

The document provides information on the manufacturing process for a tablet product including:

1. Lists the equipment, materials, and procedures used in production.

2. Details in-process quality checks during granulation, compression, and packing including specifications for tests.

3. Outlines packaging material requirements and instructions for packing operations.

Uploaded by

Trilochan AyurvedaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

4K views7 pagesMaster Formula Card

The document provides information on the manufacturing process for a tablet product including:

1. Lists the equipment, materials, and procedures used in production.

2. Details in-process quality checks during granulation, compression, and packing including specifications for tests.

3. Outlines packaging material requirements and instructions for packing operations.

Uploaded by

Trilochan AyurvedaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Master Formula Card

- Requisition Form

- Standard Operating Procedure

- Personnel Hygiene Machine Cleaning

- List of Equipment

- Weight Variation and Packing

- In Process Checking During Packing