Professional Documents

Culture Documents

HT46R066B 12

Uploaded by

Juan CoronelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HT46R066B 12

Uploaded by

Juan CoronelCopyright:

Available Formats

Enhanced A/D Type 8-Bit OTP MCU

HT46R064B/HT46R065B/HT46R066B

Revision: 1.10 Date : October 23, 2012

Contents

Table of Contents

General Description ............................................................................6

Features ...............................................................................................6

CPU Features ........................................................................................................6

Peripheral Features ................................................................................................6

Technical Document ...........................................................................6

Selection Table ....................................................................................7

Block Diagram .....................................................................................7

Pin Assignment ...................................................................................8

Pin Description ....................................................................................9

HT46R064B ...........................................................................................................9

HT46R065B .........................................................................................................10

HT46R066B..........................................................................................................11

Absolute Maximum Ratings .............................................................12

D.C. Characteristics ..........................................................................12

A.C. Characteristics ..........................................................................14

ADC Characteristics..........................................................................15

Power-on Reset Characteristics ......................................................15

IV Characteristic Curve.....................................................................16

VOL vs. IOL1 Over Temperature (VDD=3.0V) ............................................................16

VOL vs. IOL1 Over Temperature (VDD=5.0V) ............................................................16

VOH vs. IOH Over Temperature (VDD=3.0V).............................................................17

VOH vs. IOH Over Temperature (VDD=5.0V).............................................................17

System Architecture .........................................................................18

Clocking and Pipelining ........................................................................................18

Program Counter..................................................................................................19

Stack ....................................................................................................................19

Arithmetic and Logic Unit - ALU ...........................................................................19

Program Memory...............................................................................20

Structure...............................................................................................................20

Special Vectors.....................................................................................................20

Look-up Table.......................................................................................................21

Table Program Example .......................................................................................21

Rev. 1.10 2 October 23, 2012

Contents

Data Memory......................................................................................22

Structure...............................................................................................................22

Special Purpose Data Memory .............................................................................23

Special Function Registers ..............................................................23

Indirect Addressing Registers - IAR0, IAR1 .........................................................23

Memory Pointers - MP0, MP1..............................................................................23

Accumulator - ACC ..............................................................................................25

Program Counter Low Register - PCL..................................................................25

Status Register - STATUS ...................................................................................25

Input/Output Ports and Control Registers .............................................................26

System Control Registers - CTRL0, CTRL1.........................................................27

Wake-up Function Register - PAWK ....................................................................28

Pull-high Registers - PAPU, PBPU, PCPU, PDPU ...............................................28

Software COM Register - SCOMC.......................................................................28

Oscillator............................................................................................28

System Oscillator Overview..................................................................................28

System Clock Configurations................................................................................29

External Crystal/Resonator Oscillator - HXT ........................................................29

External RC Oscillator - ERC ...............................................................................29

Internal RC Oscillator - HIRC ...............................................................................29

External 32768Hz Crystal Oscillator - LXT ...........................................................29

LXT Oscillator Low Power Function ......................................................................30

Internal Low Speed Oscillator - LIRC ...................................................................30

Operating Modes ...............................................................................30

Mode Types and Selection ...................................................................................30

Mode Switching ....................................................................................................31

Standby Current Considerations...........................................................................31

Wake-up...............................................................................................................32

Watchdog Timer ................................................................................32

Watchdog Timer Operation...................................................................................32

Reset and Initialisation .....................................................................34

Reset Functions ...................................................................................................34

Reset Initial Conditions .........................................................................................35

Input/Output Ports.............................................................................38

Pull-high Resistors................................................................................................38

Port A Wake-up ....................................................................................................38

I/O Port Control Registers.....................................................................................40

Pin-shared Functions............................................................................................40

Pin Remapping Configuration - HT46R066B .......................................................40

I/O Pin Structures .................................................................................................41

Programming Considerations ...............................................................................41

Rev. 1.10 3 October 23, 2012

Contents

Timer/Event Counters .......................................................................41

Configuring the Timer/Event Counter Input Clock Source .....................................43

Timer Registers - TMR0, TMR1 ...........................................................................43

Timer Control Registers - TMR0C, TMR1C..........................................................43

Timer Mode ..........................................................................................................43

Event Counter Mode.............................................................................................46

Pulse Width Capture Mode...................................................................................46

Prescaler ..............................................................................................................47

PFD Function .......................................................................................................47

I/O Interfacing.......................................................................................................48

Programming Considerations ...............................................................................48

Timer Program Example.......................................................................................48

Time Base ..........................................................................................49

Pulse Width Modulator .....................................................................50

PWM Operation....................................................................................................50

6+2 PWM Mode ...................................................................................................50

7+1 PWM Mode ...................................................................................................51

PWM Output Control ............................................................................................51

Analog to Digital Converter..............................................................53

A/D Overview .......................................................................................................53

A/D Converter Data Registers - ADRL, ADRH .....................................................53

A/D Converter Control Registers - ADCR, ACSR.................................................53

A/D Input Pins ......................................................................................................56

Summary of A/D Conversion Steps ......................................................................56

Programming Considerations ...............................................................................57

A/D Transfer Function...........................................................................................57

A/D Programming Example ..................................................................................57

Interrupts............................................................................................59

Interrupt Register..................................................................................................59

Interrupt Operation ...............................................................................................59

Interrupt Priority.....................................................................................................60

External Interrupt ..................................................................................................60

Timer/Event Counter Interrupt ..............................................................................63

Time Base Interrupt ..............................................................................................63

Programming Considerations ...............................................................................63

SCOM Function for LCD ...................................................................63

LCD Operation .....................................................................................................63

LCD Bias Control..................................................................................................64

Configuration Options ......................................................................65

Application Circuits ..........................................................................65

Rev. 1.10 4 October 23, 2012

Contents

Instruction Set ...................................................................................66

Introduction ..........................................................................................................66

Instruction Timing .................................................................................................66

Moving and Transferring Data ..............................................................................66

Arithmetic Operations ...........................................................................................66

Logical and Rotate Operations .............................................................................66

Branches and Control Transfer.............................................................................66

Table Read Operations.........................................................................................67

Instruction Set Summary ......................................................................................67

Instruction Definition ........................................................................69

Package Information .........................................................................79

16-pin DIP (300mil) Outline Dimensions ...............................................................79

16-pin NSOP (150mil) Outline Dimensions ...........................................................81

20-pin DIP (300mil) Outline Dimensions ...............................................................82

20-pin SOP (300mil) Outline Dimensions..............................................................84

20-pin SSOP (150mil) Outline Dimensions ...........................................................85

24-pin SKDIP (300mil) Outline Dimensions ..........................................................86

24-pin SOP (300mil) Outline Dimensions..............................................................88

24-pin SSOP (150mil) Outline Dimensions ...........................................................89

28-pin SKDIP (300mil) Outline Dimensions ..........................................................90

28-pin SOP (300mil) Outline Dimensions..............................................................91

28-pin SSOP (150mil) Outline Dimensions ...........................................................92

Product Tape and Reel Specifications ............................................93

Reel Dimensions ..................................................................................................93

Carrier Tape Dimensions ......................................................................................94

Rev. 1.10 5 October 23, 2012

HT46R064B/065B/066B

Enhanced A/D Type 8-Bit OTP MCU

Technical Document

· Application Note

- HA0075E MCU Reset and Oscillator Circuits Application Note

Features

CPU Features · Up to 6-level subroutine nesting

· Operating voltage: · Bit manipulation instruction

fSYS= 4MHz: 2.2V~5.5V · Low voltage reset function

fSYS= 8MHz: 3.0V~5.5V · Wide range of available package types

fSYS= 12MHz: 4.5V~5.5V

· Up to 0.33ms instruction cycle with 12MHz system Peripheral Features

clock at VDD= 5V · Up to 26 bidirectional I/O lines

· Oscillator types: · Up to 8 channel 12-bit ADC

External high freuency Crystal -- HXT

· Up to 2 channel 8-bit PWM

External RC -- ERC

· Software controlled 4-SCOM lines LCD driver with

Internal RC -- HIRC

External low frequency crystal -- LXT 1/2 bias

· Three operational modes: Normal, Slow, Sleep · External interrupt input shared with an I/O line

· Fully integrated internal 4MHz, 8MHz and 12MHz os- · Up to two 8-bit programmable Timer/Event

cillator requires no external components Counter with overflow interrupt and prescaler

· Watchdog Timer function · Time-Base function

· LIRC oscillator function for watchdog timer · Programmable Frequency Divider - PFD

· All instructions executed in one or two instruction

cycles

· Table read instructions

· 63 powerful instructions

General Description

The Enhanced A/D MCUs are a series of 8-bit high per- taining a high level of cost effectiveness. The fully inte-

formance, RISC architecture microcontrollers specifi- grated system oscillator HIRC, which requires no

cally designed for a wide range of applications. The external components and which has three frequency

usual Holtek microcontroller features of low power con- selections, opens up a huge range of new application

sumption, I/O flexibility, timer functions, oscillator op- possibilities for these devices, some of which may in-

tions, power down and wake-up functions, watchdog clude industrial control, consumer products, household

timer and low voltage reset, combine to provide devices appliances subsystem controllers, etc.

with a huge range of functional options while still main-

Rev. 1.10 6 October 23, 2012

HT46R064B/065B/066B

Selection Table

Program Data 8-bit Time HIRC RTC LCD

Part No. I/O A/D PWM PFD Stack Package

Memory Memory Timer Base (MHz) (LXT) SCOM

16DIP/NSOP,

HT46R064B 1K´14 64´8 18 1 1 4/8/12 Ö ¾ 12-bit´4 8-bit´1 Ö 4

20DIP/SOP/SSOP

16DIP/NSOP,

HT46R065B 2K´15 96´8 22 2 1 4/8/12 Ö 4 12-bit´4 8-bit´1 Ö 6 20DIP/SOP/SSOP,

24SKDIP/SOP/SSOP

16DIP/NSOP,

HT46R066B 4K´15 128´8 26 2 1 4/8/12 Ö 4 12-bit´8 8-bit´2 Ö 6 20DIP/SOP/SSOP,

24/28SKDIP/SOP/SSOP

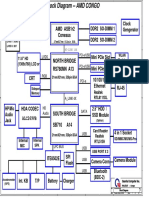

Block Diagram

The following block diagram illustrates the main functional blocks.

T im in g

G e n e r a tio n

L C D P W M P F D I/O

S C O M D r iv e r D r iv e r P o rts

8 - b it

R IS C

M C U

C o re

A /D T im e R O M /R A M

C o n v e rte r T im e r B a s e M e m o ry

Rev. 1.10 7 October 23, 2012

HT46R064B/065B/066B

Pin Assignment

P A 3 /IN T /A N 3 1 2 0 P A 4 /P W M 0

P A 2 /T C 0 /A N 2 2 1 9 P A 5 /O S C 2

P A 3 /IN T /A N 3 1 1 6 P A 4 /P W M 0 P A 1 /P F D /A N 1 3 1 8 P A 6 /O S C 1 P A 3 /IN T /A N 3 1 1 6 P A 4 /P W M 0 /T C 1

P A 2 /T C 0 /A N 2 2 1 5 P A 5 /O S C 2 P A 0 /A N 0 4 1 7 P A 7 /R E S P A 2 /T C 0 /A N 2 2 1 5 P A 5 /O S C 2

P A 1 /P F D /A N 1 3 1 4 P A 6 /O S C 1 V S S 5 1 6 V D D P A 1 /P F D /A N 1 3 1 4 P A 6 /O S C 1

P A 0 /A N 0 4 1 3 P A 7 /R E S P C 0 6 1 5 P C 3 P A 0 /A N 0 4 1 3 P A 7 /R E S

V S S 5 1 2 V D D P C 1 7 1 4 P C 2 V S S 5 1 2 V D D

P B 0 6 1 1 P B 5 P B 0 8 1 3 P B 5 P B 0 /S C O M 0 6 1 1 P B 5

P B 1 7 1 0 P B 4 P B 1 9 1 2 P B 4 P B 1 /S C O M 1 7 1 0 P B 4

P B 2 8 9 P B 3 P B 2 1 0 1 1 P B 3 P B 2 //S C O M 2 8 9 P B 3 /S C O M 3

H T 4 6 R 0 6 4 B H T 4 6 R 0 6 4 B H T 4 6 R 0 6 5 B

1 6 D IP -A /N S O P -A 2 0 D IP -A /S O P -A /S S O P -A 1 6 D IP -A /N S O P -A

P A 3 /IN T /A N 3 1 2 4 P A 4 /P W M 0 /T C 1

P A 2 /T C 0 /A N 2 2 2 3 P A 5 /O S C 2

P A 3 /IN T /A N 3 1 2 0 P A 4 /P W M 0 /T C 1 P A 1 /P F D /A N 1 3 2 2 P A 6 /O S C 1

P A 2 /T C 0 /A N 2 2 1 9 P A 5 /O S C 2 P A 0 /A N 0 4 2 1 P A 7 /R E S

P A 1 /P F D /A N 1 3 1 8 P A 6 /O S C 1 V S S 5 2 0 V D D P A 3 /IN T /A N 3 1 1 6 P A 4 /P W M 0 /T C 1

P A 0 /A N 0 4 1 7 P A 7 /R E S P C 6 6 1 9 P C 5 P A 2 /T C 0 /A N 2 2 1 5 P A 5 /O S C 2

V S S 5 1 6 V D D P C 7 7 1 8 P C 4 P A 1 /P F D /A N 1 3 1 4 P A 6 /O S C 1

P C 0 6 1 5 P C 3 P C 0 8 1 7 P C 3 P A 0 /A N 0 4 1 3 P A 7 /R E S

P C 1 7 1 4 P C 2 P C 1 9 1 6 P C 2 V S S 5 1 2 V D D

P B 0 /S C O M 0 8 1 3 P B 5 P B 0 /S C O M 0 1 0 1 5 P B 5 P B 0 /S C O M 0 6 1 1 P C 3 /P W M 1

P B 1 /S C O M 1 9 1 2 P B 4 P B 1 /S C O M 1 1 1 1 4 P B 4 P B 1 /S C O M 1 7 1 0 P B 4

P B 2 //S C O M 2 1 0 1 1 P B 3 /S C O M 3 P B 2 //S C O M 2 1 2 1 3 P B 3 /S C O M 3 P B 2 //S C O M 2 8 9 P B 3 /S C O M 3

H T 4 6 R 0 6 5 B H T 4 6 R 0 6 5 B H T 4 6 R 0 6 6 B

2 0 D IP -A /S O P -A /S S O P -A 2 4 S K D IP -A /S O P -A /S S O P -A 1 6 D IP -A /N S O P -A

P A 3 /IN T /A N 3 1 2 8 P A 4 /P W M 0 /T C 1

P A 2 /T C 0 /A N 2 2 2 7 P A 5 /O S C 2

P A 3 /IN T /A N 3 1 2 4 P A 4 /P W M 0 /T C 1 P A 1 /P F D /A N 1 3 2 6 P A 6 /O S C 1

P A 2 /T C 0 /A N 2 2 2 3 P A 5 /O S C 2 P A 0 /A N 0 4 2 5 P A 7 /R E S

P A 3 /IN T /A N 3 1 2 0 P A 4 /P W M 0 /T C 1 P A 1 /P F D /A N 1 3 2 2 P A 6 /O S C 1 V S S 5 2 4 V D D

P A 2 /T C 0 /A N 2 2 1 9 P A 5 /O S C 2 P A 0 /A N 0 4 2 1 P A 7 /R E S P C 6 /A N 6 6 2 3 P C 5

P A 1 /P F D /A N 1 3 1 8 P A 6 /O S C 1 V S S 5 2 0 V D D P C 7 /A N 7 7 2 2 P C 4

P A 0 /A N 0 4 1 7 P A 7 /R E S P C 6 /A N 6 6 1 9 P C 5 P C 0 /A N 4 8 2 1 P C 3 /P W M 1

V S S 5 1 6 V D D P C 7 /A N 7 7 1 8 P C 4 P C 1 /A N 5 9 2 0 P C 2

P C 0 /A N 4 6 1 5 P C 3 /P W M 1 P C 0 /A N 4 8 1 7 P C 3 /P W M 1 P D 0 1 0 1 9 P D 3

P C 1 /A N 5 7 1 4 P C 2 P C 1 /A N 5 9 1 6 P C 2 P D 1 1 1 1 8 P D 2

P B 0 /S C O M 0 8 1 3 P B 5 /[IN T ] P B 0 /S C O M 0 1 0 1 5 P B 5 /[IN T ] P B 0 /S C O M 0 1 2 1 7 P B 5 /[IN T ]

P B 1 /S C O M 1 9 1 2 P B 4 /[T C 0 ] P B 1 /S C O M 1 1 1 1 4 P B 4 /[T C 0 ] P B 1 /S C O M 1 1 3 1 6 P B 4 /[T C 0 ]

P B 2 //S C O M 2 1 0 1 1 P B 3 /S C O M 3 /[P F D ] P B 2 //S C O M 2 1 2 1 3 P B 3 /S C O M 3 /[P F D ] P B 2 //S C O M 2 1 4 1 5 P B 3 /S C O M 3 /[P F D ]

H T 4 6 R 0 6 6 B H T 4 6 R 0 6 6 B H T 4 6 R 0 6 6 B

2 0 D IP -A /S O P -A /S S O P -A 2 4 S K D IP -A /S O P -A /S S O P -A 2 8 S K D IP -A /S O P -A /S S O P -A

Note: Bracketed pin names indicate non-default pinout remapping locations.

Rev. 1.10 8 October 23, 2012

HT46R064B/065B/066B

Pin Description

HT46R064B

Pin Name Function OPT I/T O/T Description

PAPU

PA0 ST General purpose I/O. Register enabled pull-up and wake-up.

PA0/AN0 PAWK

AN0 AN ¾ A/D channel 0

PAPU

PA1 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA1/PFD/AN1

PFD CTRL0 ¾ CMOS PFD output

AN1 ADCR AN ¾ A/D channel 1

PAPU

PA2 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA2/TC0/AN2

TC0 ¾ ST ¾ External Timer 0 clock input

AN2 ADCR AN ¾ A/D channel 2

PAPU

PA3 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA3/INT/AN3

INT ¾ ST ¾ External interrupt input

AN3 ADCR AN ¾ A/D channel 3

PAPU

PA4 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA4/PWM0 PAWK

PWM0 CTRL0 ¾ CMOS PWM output

PAPU

PA5 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA5/OSC2 PAWK

OSC2 CO ¾ OSC Oscillator pin

PAPU

PA6 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA6/OSC1 PAWK

OSC1 CO OSC ¾ Oscillator pin

PA7 PAWK ST NMOS General purpose I/O. Register enabled wake-up.

PA7/RES

RES CO ST ¾ Reset input

PB0~PB5 PBn PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PC0~PC3 PCn PCPU ST CMOS General purpose I/O. Register enabled pull-up.

VDD VDD ¾ PWR ¾ Power supply

VSS VSS ¾ PWR ¾ Ground

Note: I/T: Input type; O/T: Output type

OPT: Optional by configuration option (CO) or register option

PWR: Power; CO: Configuration option

ST: Schmitt Trigger input; CMOS: CMOS output; AN: analog input

SCOM= software controlled LCD COM

HXT: High frequency crystal oscillator

LXT: Low frequency crystal oscillator

Rev. 1.10 9 October 23, 2012

HT46R064B/065B/066B

HT46R065B

Pin Name Function OPT I/T O/T Description

PAPU

PA0 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA0/AN0 PAWK

AN0 ADCR AN ¾ A/D channel 0

PAPU

PA1 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA1/PFD/AN1

PFD CTRL0 ¾ CMOS PFD output

AN1 ADCR AN ¾ A/D channel 1

PAPU

PA2 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA2/TC0/AN2

TC0 ¾ ST ¾ External Timer 0 clock input

AN2 ADCR AN ¾ A/D channel 2

PAPU

PA3 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA3/INT/AN3

INT ¾ ST ¾ External interrupt input

AN3 ADCR AN ¾ A/D channel 3

PAPU

PA4 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA4/TC1/PWM0

TC1 ¾ ST ¾ External Timer 1 clock input

PWM0 CTRL0 ¾ CMOS PWM output

PAPU

PA5 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA5/OSC2 PAWK

OSC2 CO ¾ OSC Oscillator pin

PAPU

PA6 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA6/OSC1 PAWK

OSC1 CO OSC ¾ Oscillator pin

PA7 PAWK ST NMOS General purpose I/O. Register enabled wake-up.

PA7/RES

RES CO ST ¾ Reset input

PB0 PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB0/SCOM0

SCOM0 SCOMC ¾ SCOM Software controlled 1/2 bias LCD COM

PB1 PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB1/SCOM1

SCOM1 SCOMC ¾ SCOM Software controlled 1/2 bias LCD COM

PB2 PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB2/SCOM2

SCOM2 SCOMC ¾ SCOM Software controlled 1/2 bias LCD COM

PB3 PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB3/SCOM3

SCOM3 SCOMC ¾ SCOM Software controlled 1/2 bias LCD COM

PB4, PB5 PBn PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PC0~PC7 PCn PCPU ST CMOS General purpose I/O. Register enabled pull-up.

VDD VDD ¾ PWR ¾ Power supply

VSS VSS ¾ PWR ¾ Ground

Note: I/T: Input type; O/T: Output type

OPT: Optional by configuration option (CO) or register option

PWR: Power; CO: Configuration option

ST: Schmitt Trigger input; CMOS: CMOS output; AN: analog input

SCOM: Software controlled LCD COM

HXT: High frequency crystal oscillator

LXT: Low frequency crystal oscillator

Rev. 1.10 10 October 23, 2012

HT46R064B/065B/066B

HT46R066B

Pin Name Function OPT I/T O/T Description

PAPU

PA0 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA0/AN0 PAWK

AN0 ADCR AN ¾ A/D channel 0

PAPU

PA1 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA1/PFD/AN1

PFD CTRL0 ¾ CMOS PFD output

AN1 ADCR AN ¾ A/D channel 1

PAPU

PA2 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA2/TC0/AN2

TC0 ¾ ST ¾ External Timer 0 clock input

AN2 ADCR AN ¾ A/D channel 2

PAPU

PA3 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA3/INT/AN3

INT ¾ ST ¾ External interrupt input

AN3 ADCR AN ¾ A/D channel 3

PAPU

PA4 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PAWK

PA4/TC1/PWM0

TC1 ¾ ST ¾ External Timer 1 clock input

PWM0 CTRL0 ¾ CMOS PWM output

PAPU

PA5 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA5/OSC2 PAWK

OSC2 CO ¾ OSC Oscillator pin

PAPU

PA6 ST CMOS General purpose I/O. Register enabled pull-up and wake-up.

PA6/OSC1 PAWK

OSC1 CO OSC ¾ Oscillator pin

PA7 PAWK ST NMOS General purpose I/O. Register enabled wake-up.

PA7/RES

RES CO ST ¾ Reset input

PB0 PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB0/SCOM0

SCOM0 SCOMC ¾ SCOM Software controlled 1/2 bias LCD COM

PB1 PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB1/SCOM1

SCOM1 SCOMC ¾ SCOM Software controlled 1/2 bias LCD COM

PB2 PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB2/SCOM2

SCOM2 SCOMC ¾ SCOM Software controlled 1/2 bias LCD COM

PB3 PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB3/[PFD]/SCOM3 PFD CTRL0 ¾ CMOS PFD output

SCOM3 SCOMC ¾ SCOM Software controlled 1/2 bias LCD COM

PBn PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB4/[TC0]

TC0 CTRL0 ST ¾ External Timer 0 clock input

PBn PBPU ST CMOS General purpose I/O. Register enabled pull-up.

PB5/[INT]

INT CTRL0 ST ¾ External interrupt input

Rev. 1.10 11 October 23, 2012

HT46R064B/065B/066B

Pin Name Function OPT I/T O/T Description

PC0/AN4 PCn PCPU ST CMOS General purpose I/O. Register enabled pull-up.

PC1/AN5

PC6/AN6 ANn ADCR AN ¾ A/D channel 4, 5, 6, 7

PC7/AN7

PC2, PC4~PC5 PCn PCPU ST CMOS General purpose I/O. Register enabled pull-up.

PCn PCPU ST CMOS General purpose I/O. Register enabled pull-up.

PC3/PWM1

PWM1 CTRL0 ¾ CMOS PWM output

PD0~PD3 PDn PDPU ST CMOS General purpose I/O. Register enabled pull-up.

VDD VDD ¾ PWR ¾ Power supply

VSS VSS ¾ PWR ¾ Ground

Note: I/T: Input type; O/T: Output type

OPT: Optional by configuration option (CO) or register option

PWR: Power; CO: Configuration option

ST: Schmitt Trigger input; CMOS: CMOS output; AN: analog input

SCOM: Software controlled LCD COM

HXT: High frequency crystal oscillator

LXT: Low frequency crystal oscillator

Absolute Maximum Ratings

Supply Voltage ...........................VSS-0.3V to VSS+6.0V Storage Temperature ............................-50°C to 125°C

Input Voltage..............................VSS-0.3V to VDD+0.3V Operating Temperature...........................-40°C to 85°C

IOL Total ..............................................................100mA IOH Total............................................................-100mA

Total Power Dissipation .....................................500mW

Note: These are stress ratings only. Stresses exceeding the range specified under ²Absolute Maximum Ratings² may

cause substantial damage to the device. Functional operation of this device at other conditions beyond those listed

in the specification is not implied and prolonged exposure to extreme conditions may affect device reliability.

D.C. Characteristics Ta=25°C

Test Conditions

Symbol Parameter Min. Typ. Max. Unit

VDD Conditions

fSYS=4MHz 2.2 ¾ 5.5 V

VDD Operating Voltage ¾ fSYS=8MHz 3.0 ¾ 5.5 V

fSYS=12MHz 4.5 ¾ 5.5 V

Operating Current 3V ¾ 0.8 1.2 mA

IDD1 No load, fSYS=4MHz

(HXT, HIRC, ERC) 5V ¾ 1.5 2.25 mA

Operating Current 3V ¾ 1.4 2.1 mA

IDD2 No load, fSYS=8MHz

(HXT, HIRC, ERC) 5V ¾ 2.8 4.2 mA

Operating Current

IDD3 5V No load, fSYS=12MHz ¾ 4 6 mA

(HXT, HIRC, ERC)

3V No load, fSYS=32768Hz ¾ 5 10 mA

(LXT on OSC1/OSC2,

Operating Current 5V LVR disabled, LXTLP=1) ¾ 12 24 mA

IDD4

(HIRC + LXT, Slow Mode) 3V No load, fSYS=32768Hz ¾ 5 10 mA

(LXT on XT1/XT2,

5V LVR disabled, LXTLP=1) ¾ 10 20 mA

Rev. 1.10 12 October 23, 2012

HT46R064B/065B/066B

Ta=25°C

Test Conditions

Symbol Parameter Min. Typ. Max. Unit

VDD Conditions

Standby Current 3V ¾ ¾ 5 mA

ISTB1 No load, system HALT

(LIRC On, LXT Off) 5V ¾ ¾ 10 mA

Standby Current 3V ¾ ¾ 1 mA

ISTB2 No load, system HALT

(LIRC Off, LXT Off) 5V ¾ ¾ 2 mA

3V No load, system HALT ¾ ¾ 5 mA

5V (LXT on OSC1/OSC2) ¾ ¾ 10 mA

Standby Current

ISTB3

(LIRC Off, LXT On, LXTLP=1) 3V ¾ ¾ 3 mA

No load, system HALT

5V (LXT on XT1/XT2) ¾ ¾ 5 mA

Input Low Voltage for I/O,

VIL1 ¾ ¾ 0 ¾ 0.3VDD V

TCn and INT

Input High Voltage for I/O,

VIH1 ¾ ¾ 0.7VDD ¾ VDD V

TCn and INT

VIL2 Input Low Voltage (RES) ¾ ¾ 0 ¾ 0.4VDD V

VIH2 Input High Voltage (RES) ¾ ¾ 0.9VDD ¾ VDD V

VLVR1 Low Voltage Reset 1 ¾ VLVR = 4.2V 3.98 4.2 4.42 V

VLVR2 Low Voltage Reset 2 ¾ VLVR = 3.15V 2.98 3.15 3.32 V

VLVR3 Low Voltage Reset 3 ¾ VLVR = 2.1V 1.98 2.1 2.22 V

I/O Port Sink Current 3V 4 8 ¾ mA

IOL1 VOL=0.1VDD

(PA, PB, PC) 5V 10 20 ¾ mA

3V -2 -4 ¾ mA

IOH I/O Port Source Current VOH=0.9VDD

5V -5 -10 ¾ mA

IOL2 PA7 Sink Current 5V VOL=0.1VDD 2 3 ¾ mA

3V ¾ 20 60 100 kW

RPH Pull-high Resistance

5V ¾ 10 30 50 kW

SCOMC, ISEL[1:0]=00 17.5 25.0 32.5 mA

SCOMC, ISEL[1:0]=01 35 50 65 mA

ISCOM SCOM Operating Current 5V

SCOMC, ISEL[1:0]=10 70 100 130 mA

SCOMC, ISEL[1:0]=11 140 200 260 mA

VSCOM VDD/2 Voltage for LCD COM 5V No load 0.475 0.500 0.525 VDD

Note: The standby current (ISTB1~ISTB3) and IDD4 are measured with all I/O pins in input mode and tied to VDD.

Rev. 1.10 13 October 23, 2012

HT46R064B/065B/066B

A.C. Characteristics Ta=25°C

Test Conditions

Symbol Parameter Min. Typ. Max. Unit

VDD Conditions

2.2V~5.5V 32 ¾ 4000 kHz

fSYS System Clock ¾ 3.0V~5.5V 32 ¾ 8000 kHz

4.5V~5.5V 32 ¾ 12000 kHz

3V/5V Ta=25°C -2% 4 +2% MHz

3V/5V Ta=25°C -2% 8 +2% MHz

5V Ta=25°C -2% 12 +2% MHz

3V/5V Ta=0~70°C -5% 4 +5% MHz

3V/5V Ta=0~70°C -5% 8 +5% MHz

5V Ta=0~70°C -5% 12 +5% MHz

2.2V~

Ta=0~70°C -8% 4 +8% MHz

3.6V

3.0V~

Ta=0~70°C -8% 4 +8% MHz

5.5V

System Clock

fHIRC

(HIRC) 3.0V~

Ta=0~70°C -8% 8 +8% MHz

5.5V

4.5V~

Ta=0~70°C -8% 12 +8% MHz

5.5V

2.2V~

Ta= -40°C~85°C -12% 4 +12% MHz

3.6V

3.0V~

Ta= -40°C~85°C -12% 4 +12% MHz

5.5V

3.0V~

Ta= -40°C~85°C -12% 8 +12% MHz

5.5V

4.5V~

Ta= -40°C~85°C -12% 12 +12% MHz

5.5V

5V Ta=25°C, R=120kW * -2% 4 +2% MHz

5V Ta=0~70°C, R=120kW * -5% 4 +5% MHz

System Clock Ta= -40°C~85°C,

fERC 5V -7% 4 +7% MHz

(ERC) R=120kW *

2.2V~ Ta= -40°C~85°C,

-11% 4 +11% MHz

5.5V R=120kW *

fLXT System Clock (LXT) ¾ ¾ ¾ 32768 ¾ Hz

2.2V~5.5V 0 ¾ 4000 kHz

Timer Input Frequency

fTIMER ¾ 3.0V~5.5V 0 ¾ 8000 kHz

(TCn)

4.5V~5.5V 0 ¾ 12000 kHz

3V ¾ 5 10 15 kHz

fLIRC LIRC Oscillator

5V ¾ 6.5 13 19.5 kHz

tRES External Reset Low Pulse Width ¾ ¾ 1 ¾ ¾ ms

For HXT/LXT ¾ 128 ¾ tSYS

tSST System Start-up time Period ¾ For ERC/IRC

¾ 2 ¾ tSYS

(By configuration option)

Rev. 1.10 14 October 23, 2012

HT46R064B/065B/066B

Ta=25°C

Test Conditions

Symbol Parameter Min. Typ. Max. Unit

VDD Conditions

tINT Interrupt Pulse Width ¾ ¾ 1 ¾ ¾ ms

tLVR Low Voltage Width to Reset ¾ ¾ 0.25 1 2 ms

RESTD Reset Delay Time ¾ ¾ ¾ 100 ¾ ms

Note: 1. tSYS=1/fSYS

2. *For fERC, as the resistor tolerance will influence the frequency a precision resistor is recommended.

3. To maintain the accuracy of the internal HIRC oscillator frequency, a 0.1mF decoupling capacitor should

be connected between VDD and VSS and located as close to the device as possible.

ADC Characteristics Ta=25°C

Test Conditions

Symbol Parameter Min. Typ. Max. Unit

VDD Conditions

3V

DNL A/C Differential Non-Linearity tAD=0.5ms -2 ¾ 2 LSB

5V

3V

INL ADC Integral Non-Linearity tAD=0.5ms -4 ¾ 4 LSB

5V

Additional Power Consumption 3V ¾ 0.5 0.75 mA

IADC ¾

if A/D Converter is Used 5V ¾ 1.0 1.5 mA

Power-on Reset Characteristics

Test Conditions

Symbol Parameter Min. Typ. Max. Unit

VDD Conditions

VDD Start Voltage to Ensure

VPOR ¾ ¾ ¾ ¾ 100 mV

Power-on Reset

VDD raising rate to Ensure

RRVDD ¾ ¾ 0.035 ¾ ¾ V/ms

Power-on Reset

Minimum Time for VDD Stays at

tPOR ¾ ¾ 1 ¾ ¾ ms

VPOR to Ensure Power-on Reset

V D D

tP O R R R V D D

V P O R

T im e

Rev. 1.10 15 October 23, 2012

HT46R064B/065B/066B

Characteristic Curve

VOL vs. IOL1 Over Temperature (VDD=3.0V)

IOL1 (3V)

0.6

0.5

85

0.4 25

VOL (V)

-40

0.3

0.2

0.1

0

2.5 5 7.5 10 12.5 15 17.5 20 22.5 25

IOL (mA)

VOL vs. IOL1 Over Temperature (VDD=5.0V)

IOL1 (5V)

0.45

0.40

0.35

0.30 85

25

VOL (V)

0.25 -40

0.20

0.15

0.10

0.05

0.00

2.5 5 7.5 10 12.5 15 17.5 20 22.5 25

IOL (mA)

Rev. 1.10 16 October 23, 2012

HT46R064B/065B/066B

VOH vs. IOH Over Temperature (VDD=3.0V)

IOH (3V)

3.25

3.00

2.75

VOH (V) 2.50 -40

2.25

25

2.00

85

1.75

1.50

-2.5 -5.0 -7.5 -10.0 -12.5 -15.0 -17.5 -20.0 -22.5 -25.0

IOH (mA)

VOH vs. IOH Over Temperature (VDD=5.0V)

IOH (5V)

5.00

4.90

4.80

4.70 -40

4.60

VOH (V)

4.50 25

4.40 85

4.30

4.20

4.10

4.00

-2.5 -5.0 -7.5 -10.0 -12.5 -15.0 -17.5 -20.0 -22.5 -25.0

IOH (mA)

Rev. 1.10 17 October 23, 2012

HT46R064B/065B/066B

System Architecture

A key factor in the high-performance features of the Program Counter is incremented at the beginning of the

Holtek range of microcontrollers is attributed to the inter- T1 clock during which time a new instruction is fetched.

nal system architecture. The range of devices take ad- The remaining T2~T4 clocks carry out the decoding and

vantage of the usual features found within RISC execution functions. In this way, one T1~T4 clock cycle

microcontrollers providing increased speed of operation forms one instruction cycle. Although the fetching and

and enhanced performance. The pipelining scheme is execution of instructions takes place in consecutive in-

implemented in such a way that instruction fetching and struction cycles, the pipelining structure of the

instruction execution are overlapped, hence instructions microcontroller ensures that instructions are effectively

are effectively executed in one cycle, with the exception executed in one instruction cycle. The exception to this

of branch or call instructions. An 8-bit wide ALU is used are instructions where the contents of the Program

in practically all operations of the instruction set. It car- Counter are changed, such as subroutine calls or

ries out arithmetic operations, logic operations, rotation, jumps, in which case the instruction will take one more

increment, decrement, branch decisions, etc. The inter- instruction cycle to execute.

nal data path is simplified by moving data through the

For instructions involving branches, such as jump or call

Accumulator and the ALU. Certain internal registers are instructions, two instruction cycles are required to com-

implemented in the Data Memory and can be directly or

plete instruction execution. An extra cycle is required as

indirectly addressed. The simple addressing methods of

the program takes one cycle to first obtain the actual

these registers along with additional architectural fea-

jump or call address and then another cycle to actually

tures ensure that a minimum of external components is execute the branch. The requirement for this extra cycle

required to provide a functional I/O and A/D control sys-

should be taken into account by programmers in timing

tem with maximum reliability and flexibility. sensitive applications.

Clocking and Pipelining

The main system clock, derived from either a Crys-

tal/Resonator or RC oscillator is subdivided into four in-

ternally generated non-overlapping clocks, T1~T4. The

O s c illa to r C lo c k

( S y s te m C lo c k )

P h a s e C lo c k T 1

P h a s e C lo c k T 2

P h a s e C lo c k T 3

P h a s e C lo c k T 4

P ro g ra m C o u n te r P C P C + 1 P C + 2

F e tc h In s t. (P C )

P ip e lin in g

E x e c u te In s t. (P C -1 ) F e tc h In s t. (P C + 1 )

E x e c u te In s t. (P C ) F e tc h In s t. (P C + 2 )

E x e c u te In s t. (P C + 1 )

System Clocking and Pipelining

1 M O V A ,[1 2 H ] F e tc h In s t. 1 E x e c u te In s t. 1

2 C A L L D E L A Y F e tc h In s t. 2 E x e c u te In s t. 2

3 C P L [1 2 H ] F e tc h In s t. 3 F lu s h P ip e lin e

4 : F e tc h In s t. 6 E x e c u te In s t. 6

5 : F e tc h In s t. 7

6 D E L A Y : N O P

Instruction Fetching

Rev. 1.10 18 October 23, 2012

HT46R064B/065B/066B

Program Counter Counter are pushed onto the stack. At the end of a sub-

During program execution, the Program Counter is used routine or an interrupt routine, signaled by a return in-

to keep track of the address of the next instruction to be struction, RET or RETI, the Program Counter is restored

executed. It is automatically incremented by one each to its previous value from the stack. After a device reset,

time an instruction is executed except for instructions, the Stack Pointer will point to the top of the stack.

such as ²JMP² or ²CALL² that demand a jump to a

P ro g ra m C o u n te r

non-consecutive Program Memory address. Note that

the Program Counter width varies with the Program

Memory capacity depending upon which device is se- T o p o f S ta c k S ta c k L e v e l 1

lected. However, it must be noted that only the lower 8 S ta c k L e v e l 2

bits, known as the Program Counter Low Register, are S ta c k P ro g ra m

S ta c k L e v e l 3

directly addressable by user. P o in te r M e m o ry

When executing instructions requiring jumps to

non-consecutive addresses such as a jump instruction, B o tto m o f S ta c k S ta c k L e v e l 6

a subroutine call, interrupt or reset, etc., the

microcontroller manages program control by loading the

Device Stack Levels

required address into the Program Counter. For condi-

tional skip instructions, once the condition has been HT46R064B 4

met, the next instruction, which has already been HT46R065B

6

fetched during the present instruction execution, is dis- HT46R066B

carded and a dummy cycle takes its place while the cor-

rect instruction is obtained. If the stack is full and an enabled interrupt takes place,

the interrupt request flag will be recorded but the ac-

Program Counter knowledge signal will be inhibited. When the Stack

Device Program Counter Pointer is decremented, by RET or RETI, the interrupt

PCL Register

High Byte will be serviced. This feature prevents stack overflow al-

HT46R064B PC9,PC8 lowing the programmer to use the structure more easily.

However, when the stack is full, a CALL subroutine in-

HT46R065B PC10~PC8 PCL7~PCL0 struction can still be executed which will result in a stack

HT46R066B PC11~PC8 overflow. Precautions should be taken to avoid such

cases which might cause unpredictable program

The lower byte of the Program Counter, known as the branching.

Program Counter Low register or PCL, is available for

program control and is a readable and writeable regis- Arithmetic and Logic Unit - ALU

ter. By transferring data directly into this register, a short The arithmetic-logic unit or ALU is a critical area of the

program jump can be executed directly, however, as microcontroller that carries out arithmetic and logic op-

only this low byte is available for manipulation, the erations of the instruction set. Connected to the main

jumps are limited to the present page of memory, that is microcontroller data bus, the ALU receives related in-

256 locations. When such program jumps are executed struction codes and performs the required arithmetic or

it should also be noted that a dummy cycle will be in- logical operations after which the result will be placed in

serted. the specified register. As these ALU calculation or oper-

The lower byte of the Program Counter is fully accessi- ations may result in carry, borrow or other status

ble under program control. Manipulating the PCL might changes, the status register will be correspondingly up-

cause program branching, so an extra cycle is needed dated to reflect these changes. The ALU supports the

to pre-fetch. Further information on the PCL register can following functions:

be found in the Special Function Register section. · Arithmetic operations: ADD, ADDM, ADC, ADCM,

SUB, SUBM, SBC, SBCM, DAA

Stack · Logic operations: AND, OR, XOR, ANDM, ORM,

This is a special part of the memory which is used to XORM, CPL, CPLA

save the contents of the Program Counter only. The · Rotation RRA, RR, RRCA, RRC, RLA, RL, RLCA,

stack is neither part of the Data or Program Memory RLC

space, and is neither readable nor writeable. The acti- · Increment and Decrement INCA, INC, DECA, DEC

vated level is indexed by the Stack Pointer, SP, and is · Branch decision, JMP, SZ, SZA, SNZ, SIZ, SDZ,

neither readable nor writeable. At a subroutine call or in- SIZA, SDZA, CALL, RET, RETI

terrupt acknowledge signal, the contents of the Program

Rev. 1.10 19 October 23, 2012

HT46R064B/065B/066B

Program Memory

The Program Memory is the location where the user Special Vectors

code or program is stored. The device is supplied with

Within the Program Memory, certain locations are re-

One-Time Programmable, OTP, memory where users

served for special usage such as reset and interrupts.

can program their application code into the device. By

using the appropriate programming tools, OTP devices · Reset Vector

offer users the flexibility to freely develop their applica- This vector is reserved for use by the device reset for

program initialisation. After a device reset is initiated, the

tions which may be useful during debug or for products

program will jump to this location and begin execution.

requiring frequent upgrades or program changes.

· External interrupt vector

Structure This vector is used by the external interrupt. If the ex-

ternal interrupt pin on the device receives an edge

The Program Memory has a capacity of 1K´14 to

transition, the program will jump to this location and

4K´16. The Program Memory is addressed by the Pro- begin execution if the external interrupt is enabled and

gram Counter and also contains data, table information the stack is not full. The external interrupt active edge

and interrupt entries. Table data, which can be setup in transition type, whether high to low, low to high or both

any location within the Program Memory, is addressed is specified in the CTRL1 register.

by separate table pointer registers.

· Timer/Event 0/1 counter interrupt vector

Device Capacity This internal vector is used by the Timer/Event Coun-

ters. If a Timer/Event Counter overflow occurs, the

HT46R064B 1K´14 program will jump to its respective location and begin

HT46R065B 2K´15 execution if the associated Timer/Event Counter inter-

rupt is enabled and the stack is not full.

HT46R066B 4K´15

· Time base interrupt vector

This internal vector is used by the internal Time Base.

If a Time Base overflow occurs, the program will jump

to this location and begin execution if the Time Base

counter interrupt is enabled and the stack is not full.

H T 4 6 R 0 6 4 B H T 4 6 R 0 6 5 B H T 4 6 R 0 6 6 B

0 0 H R e s e t R e s e t R e s e t

0 4 H E x te rn a l E x te rn a l E x te rn a l

In te rru p t In te rru p t In te rru p t

0 8 H T im e r 0 T im e r 0 T im e r 0

In te rru p t In te rru p t In te rru p t

0 C H A /D T im e r 1 T im e r 1

In te rru p t In te rru p t In te rru p t

1 0 H T im e B a s e A /D A /D

In te rru p t In te rru p t In te rru p t

1 4 H T im e B a s e T im e B a s e

In te rru p t In te rru p t

1 8 H

3 F F H 1 4 b its

7 F F H 1 5 b its

F F F H 1 5 b its

Program Memory Structure

Rev. 1.10 20 October 23, 2012

HT46R064B/065B/066B

Look-up Table Table Program Example

Any location within the Program Memory can be defined The accompanying example shows how the table

as a look-up table where programmers can store fixed pointer and table data is defined and retrieved from the

data. To use the look-up table, the table pointer must device. This example uses raw table data located in the

first be setup by placing the lower order address of the last page which is stored there using the ORG state-

look up data to be retrieved in the table pointer register, ment. The value at this ORG statement is ²300H² which

TBLP. This register defines the lower 8-bit address of refers to the start address of the last page within the 1K

the look-up table. Program Memory of the HT46R064B microcontrollers.

After setting up the table pointer, the table data can be The table pointer is setup here to have an initial value of

retrieved from the current Program Memory page or last ²06H². This will ensure that the first data read from the

Program Memory page using the ²TABRDC[m]² or data table will be at the Program Memory address

²TABRDL [m]² instructions, respectively. When these in- ²306H² or 6 locations after the start of the last page.

structions are executed, the lower order table byte from Note that the value for the table pointer is referenced to

the Program Memory will be transferred to the user de- the first address of the present page if the ²TABRDC

fined Data Memory register [m] as specified in the in- [m]² instruction is being used. The high byte of the table

struction. The higher order table data byte from the data which in this case is equal to zero will be trans-

Program Memory will be transferred to the TBLH special ferred to the TBLH register automatically when the

register. Any unused bits in this transferred higher order ²TABRDL [m]² instruction is executed.

byte will be read as ²0². Because the TBLH register is a read-only register and

The following diagram illustrates the addressing/data cannot be restored, care should be taken to ensure its

flow of the look-up table: protection if both the main routine and Interrupt Service

Routine use the table read instructions. If using the table

L a s t p a g e o r read instructions, the Interrupt Service Routines may

p re s e n t p a g e

P C x ~ P C 8 change the value of TBLH and subsequently cause er-

P ro g ra m M e m o ry

P C H ig h B y te rors if used again by the main routine. As a rule it is rec-

A d d re s s

D a ta ommended that simultaneous use of the table read

T B L P R e g is te r 1 4 ~ 1 5 b its instructions should be avoided. However, in situations

where simultaneous use cannot be avoided, the inter-

rupts should be disabled prior to the execution of any

U s e r S e le c te d main routine table-read instructions. Note that all table

R e g is te r T B L H

R e g is te r related instructions require two instruction cycles to

H ig h B y te L o w B y te complete their operation.

Table Location Bits

Instruction

b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

TABRDC [m] PC12 PC11 PC10 PC9 PC8 @7 @6 @5 @4 @3 @2 @1 @0

TABRDL [m] 1 1 1 1 1 @7 @6 @5 @4 @3 @2 @1 @0

Table Location

Note: PC12~PC8: Current Program Counter bits

@7~@0: Table Pointer TBLP bits

For the HT46R064B, the Table address location is 10 bits, i.e. from b9~b0.

For the HT46R065B, the Table address location is 11 bits, i.e. from b10~b0.

For the HT46R066B, the Table address location is 12 bits, i.e. from b11~b0

Rev. 1.10 21 October 23, 2012

HT46R064B/065B/066B

Table Read Program Example:

tempreg1 db ? ; temporary register #1

tempreg2 db ? ; temporary register #2

:

:

mov a,06h ; initialise table pointer - note that this address

; is referenced

mov tblp,a ; to the last page or present page

:

:

tabrdl tempreg1 ; transfers value in table referenced by table pointer

; to tempregl

; data at prog. memory address ²306H² transferred to

; tempreg1 and TBLH

dec tblp ; reduce value of table pointer by one

tabrdl tempreg2 ; transfers value in table referenced by table pointer

; to tempreg2

; data at prog.memory address ²305H² transferred to

; tempreg2 and TBLH

; in this example the data ²1AH² is transferred to

; tempreg1 and data ²0FH² to register tempreg2

; the value ²00H² will be transferred to the high byte

; register TBLH

:

:

org 300h ; sets initial address of last page

dc 00Ah, 00Bh, 00Ch, 00Dh, 00Eh, 00Fh, 01Ah, 01Bh

:

:

Data Memory

The Data Memory is a volatile area of 8-bit wide RAM The two sections of Data Memory, the Special Purpose

internal memory and is the location where temporary in- and General Purpose Data Memory are located at con-

formation is stored. secutive locations. All are implemented in RAM and are 8

bits wide but the length of each memory section is dic-

Structure tated by the type of microcontroller chosen. The start ad-

Divided into two sections, the first of these is an area of dress of the Data Memory for all devices is the address

RAM where special function registers are located. These ²00H².

registers have fixed locations and are necessary for cor- All microcontroller programs require an area of

rect operation of the device. Many of these registers can read/write memory where temporary data can be stored

be read from and written to directly under program con- and retrieved for use later. It is this area of RAM memory

trol, however, some remain protected from user manipu- that is known as General Purpose Data Memory. This

lation. The second area of Data Memory is reserved for area of Data Memory is fully accessible by the user pro-

general purpose use. All locations within this area are gram for both read and write operations. By using the

read and write accessible under program control. ²SET [m].i² and ²CLR [m].i² instructions individual bits

Device Capacity can be set or reset under program control giving the

user a large range of flexibility for bit manipulation in the

HT46R064B 64´8

Data Memory.

HT46R065B 96´8

For some devices, the Data Memory is subdivided into

HT46R066B 128´8 two banks, which are selected using a Bank Pointer.

Only data in Bank 0 can be directly addressed, data in

Bank 1 must be indirectly addressed.

Rev. 1.10 22 October 23, 2012

HT46R064B/065B/066B

H T 4 6 R 0 6 4 B H T 4 6 R 0 6 5 B H T 4 6 R 0 6 6 B Indirect Addressing Registers - IAR0, IAR1

0 0 H IA R 0 IA R 0 IA R 0

The Indirect Addressing Registers, IAR0 and IAR1, al-

0 1 H M P 0 M P 0 M P 0 S p e c ia l

P u rp o s e though having their locations in normal RAM register

R e g is te r s space, do not actually physically exist as normal regis-

3 F H ters. The method of indirect addressing for RAM data

4 0 H

manipulation uses these Indirect Addressing Registers

6 4 b y te s and Memory Pointers, in contrast to direct memory ad-

7 F H 9 6 b y te s 1 2 8 b y te s G e n e ra l

P u rp o s e dressing, where the actual memory address is speci-

9 F H R e g is te r s fied. Actions on the IAR0 and IAR1 registers will result in

no actual read or write operation to these registers but

B F H

rather to the memory location specified by their corre-

Data Memory Structure sponding Memory Pointer, MP0 or MP1. Acting as a

pair, IAR0 with MP0 and IAR1 with MP1 can together ac-

Note: Most of the Data Memory bits can be directly

cess data from the Data Memory. As the Indirect Ad-

manipulated using the ²SET [m].i² and ²CLR

dressing Registers are not physically implemented,

[m].i² with the exception of a few dedicated bits.

reading the Indirect Addressing Registers indirectly will

The Data Memory can also be accessed

return a result of ²00H² and writing to the registers indi-

through the memory pointer registers.

rectly will result in no operation.

Special Purpose Data Memory Memory Pointers - MP0, MP1

This area of Data Memory is where registers, necessary Two Memory Pointers, known as MP0 and MP1 are pro-

for the correct operation of the microcontroller, are vided. These Memory Pointers are physically imple-

stored. Most of the registers are both readable and mented in the Data Memory and can be manipulated in

writeable but some are protected and are readable only, the same way as normal registers providing a conve-

the details of which are located under the relevant Spe- nient way with which to indirectly address and track

cial Function Register section. Note that for locations data. MP0 can only be used to indirectly address data in

that are unused, any read instruction to these addresses Bank 0 while MP1 can be used to address data in Bank

will return the value ²00H². 0 and Bank1. When any operation to the relevant Indi-

rect Addressing Registers is carried out, the actual ad-

Special Function Registers dress that the microcontroller is directed to, is the

address specified by the related Memory Pointer. Note

To ensure successful operation of the microcontroller,

that for the HT46R064B device, bit 7 of the Memory

certain internal registers are implemented in the Data

Pointers is not required to address the full memory

Memory area. These registers ensure correct operation

space. When bit 7 of the Memory Pointers for these de-

of internal functions such as timers, interrupts, etc., as

vices is read, a value of ²1² will be returned. Note that in-

well as external functions such as I/O data control. The

direct addressing using MP1 and IAR1 must be used to

location of these registers within the Data Memory be-

access any data in Bank 1. The following example shows

gins at the address ²00H² and are mapped into both

how to clear a section of four Data Memory locations al-

Bank 0 and Bank 1. Any unused Data Memory locations

ready defined as locations adres1 to adres4.

between these special function registers and the point

where the General Purpose Memory begins is reserved

and attempting to read data from these locations will re-

turn a value of ²00H².

Rev. 1.10 23 October 23, 2012

HT46R064B/065B/066B

H T 4 6 R 0 6 4 B H T 4 6 R 0 6 5 B H T 4 6 R 0 6 6 B

0 0 H IA R 0 IA R 0 IA R 0

0 1 H M P 0 M P 0 M P 0

0 2 H IA R 1 IA R 1 IA R 1

0 3 H M P 1 M P 1 M P 1

0 4 H

0 5 H A C C A C C A C C

0 6 H P C L P C L P C L

0 7 H T B L P T B L P T B L P

0 8 H T B L H T B L H T B L H

0 9 H W D T S W D T S W D T S

0 A H S T A T U S S T A T U S S T A T U S

0 B H IN T C 0 IN T C 0 IN T C 0

0 C H T M R 0 T M R 0 T M R 0

0 D H T M R 0 C T M R 0 C T M R 0 C

0 E H T M R 1 T M R 1

0 F H T M R 1 C T M R 1 C

1 0 H P A P A P A

1 1 H P A C P A C P A C

1 2 H P A P U P A P U P A P U

1 3 H P A W K P A W K P A W K

1 4 H P B P B P B

1 5 H P B C P B C P B C

1 6 H P B P U P B P U P B P U

1 7 H P C P C P C

1 8 H P C C P C C P C C

1 9 H P C P U P C P U P C P U

1 A H C T R L 0 C T R L 0 C T R L 0

1 B H C T R L 1 C T R L 1 C T R L 1

1 C H S C O M C S C O M C

1 D H P W M 1

1 E H IN T C 1 IN T C 1 IN T C 1

1 F H P W M 0 P W M 0 P W M 0

2 0 H A D R L A D R L A D R L

2 1 H A D R H A D R H A D R H

2 2 H A D C R A D C R A D C R

2 3 H A C S R A C S R A C S R

2 4 H

2 5 H P D

2 6 H P D C

2 7 H P D P U

2 8 H

2 9 H

2 A H

2 B H

2 C H

2 D H

2 E H

2 F H

3 0 H

3 1 H

3 2 H

3 F H

: U n u s e d , re a d a s "0 0 "

Special Purpose Data Memory

Rev. 1.10 24 October 23, 2012

HT46R064B/065B/066B

· Indirect Addressing Program Example

data .section ¢data¢

adres1 db ?

adres2 db ?

adres3 db ?

adres4 db ?

block db ?

code .section at 0 code

org 00h

start:

mov a,04h ; setup size of block

mov block,a

mov a,offset adres1 ; Accumulator loaded with first RAM address

mov mp0,a ; setup memory pointer with first RAM address

loop:

clr IAR0 ; clear the data at address defined by MP0

inc mp0 ; increment memory pointer

sdz block ; check if last memory location has been cleared

jmp loop

continue:

The important point to note here is that in the example shown above, no reference is made to specific Data Memory

addresses.

Accumulator - ACC Status Register - STATUS

The Accumulator is central to the operation of any This 8-bit register contains the zero flag (Z), carry flag

microcontroller and is closely related with operations (C), auxiliary carry flag (AC), overflow flag (OV), power

carried out by the ALU. The Accumulator is the place down flag (PDF), and watchdog time-out flag (TO).

where all intermediate results from the ALU are stored. These arithmetic/logical operation and system manage-

Without the Accumulator it would be necessary to write ment flags are used to record the status and operation of

the result of each calculation or logical operation such the microcontroller.

as addition, subtraction, shift, etc., to the Data Memory With the exception of the TO and PDF flags, bits in the

resulting in higher programming and timing overheads. status register can be altered by instructions like most

Data transfer operations usually involve the temporary other registers. Any data written into the status register

storage function of the Accumulator; for example, when will not change the TO or PDF flag. In addition, opera-

transferring data between one user defined register and tions related to the status register may give different re-

another, it is necessary to do this by passing the data sults due to the different instruction operations. The TO

through the Accumulator as no direct transfer between flag can be affected only by a system power-up, a WDT

two registers is permitted.

time-out or by executing the ²CLR WDT² or ²HALT² in-

struction. The PDF flag is affected only by executing the

Program Counter Low Register - PCL

²HALT² or ²CLR WDT² instruction or during a system

To provide additional program control functions, the low power-up.

byte of the Program Counter is made accessible to pro-

The Z, OV, AC and C flags generally reflect the status of

grammers by locating it within the Special Purpose area

the latest operations.

of the Data Memory. By manipulating this register, direct

jumps to other program locations are easily imple- In addition, on entering an interrupt sequence or execut-

mented. Loading a value directly into this PCL register ing a subroutine call, the status register will not be

will cause a jump to the specified Program Memory lo- pushed onto the stack automatically. If the contents of

cation, however, as the register is only 8-bit wide, only the status registers are important and if the interrupt rou-

jumps within the current Program Memory page are per- tine can change the status register, precautions must be

mitted. When such operations are used, note that a taken to correctly save it. Note that bits 0~3 of the

dummy cycle will be inserted. STATUS register are both readable and writeable bits.

Rev. 1.10 25 October 23, 2012

HT46R064B/065B/066B

· STATUS Register

Bit 7 6 5 4 3 2 1 0

Name ¾ ¾ TO PDF OV Z AC C

R/W ¾ ¾ R R R/W R/W R/W R/W

POR ¾ ¾ 0 0 x x x x

²x² unknown

Bit 7, 6 Unimplemented, read as ²0²

Bit 5 TO: Watchdog Time-Out flag

0: After power up or executing the ²CLR WDT² or ²HALT² instruction

1: A watchdog time-out occurred.

Bit 4 PDF: Power down flag

0: After power up or executing the ²CLR WDT² instruction

1: By executing the ²HALT² instruction

Bit 3 OV: Overflow flag

0: no overflow

1: an operation results in a carry into the highest-order bit but not a carry out of the

highest-order bit or vice versa.

Bit 2 Z: Zero flag

0: The result of an arithmetic or logical operation is not zero

1: The result of an arithmetic or logical operation is zero

Bit 1 AC: Auxiliary flag

0: no auxiliary carry

1: an operation results in a carry out of the low nibbles in addition, or no borrow from the

high nibble into the low nibble in subtraction

Bit 0 C: Carry flag

0: no carry-out

1: an operation results in a carry during an addition operation or if a borrow does not take place

during a subtraction operation

C is also affected by a rotate through carry instruction.

Input/Output Ports and Control Registers high, for an output it must be set low. During program in-

Within the area of Special Function Registers, the port itialisation, it is important to first setup the control regis-

PA, PB, etc data I/O registers and their associated con- ters to specify which pins are outputs and which are

trol register PAC, PBC, etc play a prominent role. These inputs before reading data from or writing data to the I/O

registers are mapped to specific addresses within the ports. One flexible feature of these registers is the ability

Data Memory as shown in the Data Memory table. The to directly program single bits using the ²SET [m].i² and

data I/O registers, are used to transfer the appropriate ²CLR [m].i² instructions. The ability to change I/O pins

output or input data on the port. The control registers from output to input and vice versa by manipulating spe-

specifies which pins of the port are set as inputs and cific bits of the I/O control registers during normal pro-

which are set as outputs. To setup a pin as an input, the gram operation is a useful feature of these devices.

corresponding bit of the control register must be set

Rev. 1.10 26 October 23, 2012

HT46R064B/065B/066B

System Control Registers - CTRL0, CTRL1

These registers are used to provide control over various internal functions. Some of these include the PFD control,

PWM control, certain system clock options, the LXT Oscillator low power control, external Interrupt edge trigger type,

Watchdog Timer enable function, Time Base function division ratio, and the LXT oscillator enable control.

· CTRL0 Register

¨ HT46R064B

Bit 7 6 5 4 3 2 1 0

Name ¾ ¾ PWMSEL ¾ PWMC0 PFDC LXTLP CLKMOD

R/W ¾ ¾ R/W ¾ R/W R/W R/W R/W

POR ¾ ¾ 0 ¾ 0 0 0 0

¨ HT46R065B

Bit 7 6 5 4 3 2 1 0

Name ¾ PFDCS PWMSEL ¾ PWMC0 PFDC LXTLP CLKMOD

R/W ¾ R/W R/W ¾ R/W R/W R/W R/W

POR ¾ 0 0 ¾ 0 0 0 0

¨ HT46R066B

Bit 7 6 5 4 3 2 1 0

Name PCFG PFDCS PWMSEL PWMC1 PWMC0 PFDC LXTLP CLKMOD

R/W R/W R/W R/W R/W R/W R/W R/W R/W

POR 0 0 0 0 0 0 0 0

Bit 7 PCFG: I/O configuration

0: INT/TC0/PFD pin-shared with PA3/PA2/PA1

1: INT/TC0/PFD pin-shared with PB5/PB4/PB3

Bit 6 PFDCS: PFD clock source

0: timer0

1: timer1

Bit 5 PWMSEL: PWM type selection

0: 6+2

1: 7+1

Bit 4 PWMC1: I/O or PWM1

0: I/O

1: PWM1

Bit 3 PWMC0: I/O or PWM0

0: I/O

1: PWM0

Bit 2 PFDC: I/O or PFD

0: I/O

1: PFD

Bit 1 LXTLP: LXT oscillator low power control function

0: LXT Oscillator quick start-up mode

1: LXT Oscillator Low Power Mode

Bit 0 CLKMOD: system clock mode selection.

0: High speed - HIRC used as system clock

1: Low speed - LXT used as system clock, HIRC oscillator stopped.

For HT46R064B/065B/066B, these selections are only valid if the oscillator configuration options

have selected the HIRC+LXT.

Note: If PWM0/1/2 output is selected by PWMC0/1/2 bit, fTP comes always from fSYS.

(fTP is the clock source for timer0/2 , time base and PWM)

Rev. 1.10 27 October 23, 2012

HT46R064B/065B/066B

· CTRL1 Register

Bit 7 6 5 4 3 2 1 0

Name INTEG1 INTEG0 TBSEL1 TBSEL0 WDTEN3 WDTEN2 WDTEN1 WDTEN0

R/W R/W R/W R/W R/W R/W R/W R/W R/W

POR 1 0 0 0 1 0 1 0

Bit 7, 6 INTEG1, INTEG0: External interrupt edge type

00: disable

01: rising edge trigger

10: falling edge trigger

11: dual edge trigger

Bit 5, 4 TBSEL1, TBSEL0: Time base period selection

00: 210 ´ (1/fTP)

01: 211 ´ (1/fTP)

10: 212 ´ (1/fTP)

11: 213 ´ (1/fTP)

Bit 3~0 WDTEN3, WDTEN2, WDTEN1, WDTEN0: WDT function enable

1010: WDT disabled

Other values: WDT enabled - Recommended value is 0101

If the ²watchdog timer enable² is configuration option is selected, then the watchdog timer will

always be enabled and the WDTEN3~WDTEN0 control bits will have no effect.

Note: The WDT is only disabled when both the WDT configuration option is disabled and when bits

WDTEN3~WDTEN0=1010.

The WDT is enabled when either the WDT configuration option is enabled or when bits

WDTEN3~WDTEN0¹1010.

Wake-up Function Register - PAWK terms of speed and power saving. Oscillator selections

When the microcontroller enters the Sleep Mode, vari- and operation are selected through a combination of

ous methods exist to wake the device up and continue configuration options and registers.

with normal operation. One method is to allow a falling

System Oscillator Overview

edge on the I/O pins to have a wake-up function. This

register is used to select which Port A I/O pins are used In addition to being the source of the main system clock

to have this wake-up function. the oscillators also provide clock sources for the Watch-

dog Timer and Time Base functions. External oscillators

Pull-high Registers - PAPU, PBPU, PCPU, PDPU requiring some external components as well as a two

fully integrated internal oscillators, requiring no external

The I/O pins, if configured as inputs, can have internal

components, are provided to form a wide range of both

pull-high resistors connected, which eliminates the need

fast and slow system oscillators.

for external pull-high resistors. This register selects which

I/O pins are connected to internal pull-high resistors. Type Name Freq. Pins

400kHz~ OSC1/

Software COM Register - SCOMC External Crystal HXT

12MHz OSC2

The pins PB0~PB3 on Port B can be used as SCOM

400kHz~

lines to drive an external LCD panel. To implement this External RC ERC OSC1

12MHz

function, the SCOMC register is used to setup the cor-

rect bias voltages on these pins. Internal High

HIRC 4, 8 or 12MHz ¾

Speed RC

Oscillator External Low OSC1/

LXT 32768Hz

Speed Crystal OSC2

Various oscillator options offer the user a wide range of

functions according to their various application require- Internal Low

LIRC 13kHz ¾

Speed RC

ments. The flexible features of the oscillator functions

ensure that the best optimisation can be achieved in

Rev. 1.10 28 October 23, 2012

HT46R064B/065B/066B

System Clock Configurations frequency are minimised. As a resistance/frequency ref-

There are five system oscillators. Three high speed os- erence point, it can be noted that with an external 120K

cillators and two low speed oscillators. The high speed resistor connected and with a 5V voltage power supply

oscillators are the external crystal/ceramic oscillator - and temperature of 25 degrees, the oscillator will have a

HXT, the external - ERC, and the internal RC oscillator - frequency of 4MHz within a tolerance of 2%. Here only

HIRC. The two low speed oscillator are the external the OSC1 pin is used, which is shared with I/O pin PA6,

32768Hz oscillator - LXT and the internal 13kHz leaving pin PA5 free for use as a normal I/O pin.

(VDD=5V) oscillator - LIRC. V D D

External Crystal/Resonator Oscillator - HXT R O S C

The simple connection of a crystal across OSC1 and P A 6 /O S C 1

OSC2 will create the necessary phase shift and feed- 4 7 0 p F

back for oscillation. However, for some crystals and

most resonator types, to ensure oscillation and accurate

P A 5 /O S C 2

frequency generation, it is necessary to add two small

value external capacitors, C1 and C2. The exact values

External RC Oscillator - ERC

of C1 and C2 should be selected in consultation with the

crystal or resonator manufacturer¢s specification. Internal RC Oscillator - HIRC

Crystal Oscillator C1 and C2 Values The internal RC oscillator is a fully integrated system os-

Crystal Frequency C1 C2 cillator requiring no external components. The internal

RC oscillator has three fixed frequencies of either

12MHz 8pF 10pF

4MHz, 8MHz or 12MHz. Device trimming during the

8MHz 8pF 10pF manufacturing process and the inclusion of internal fre-

4MHz 8pF 10pF quency compensation circuits are used to ensure that

1MHz 100pF 100pF the influence of the power supply voltage, temperature

and process variations on the oscillation frequency are

Note: C1 and C2 values are for guidance only. minimised. As a result, at a power supply of either 3V or

5V and at a temperature of 25 degrees, the fixed oscilla-

Crystal Recommended Capacitor Values

tion frequency of 4MHz, 8MHz or 12MHz will have a tol-

erance within 2%. Note that if this internal system clock

C 1 In te r n a l

O S C 1 O s c illa to r option is selected, as it requires no external pins for its

C ir c u it operation, I/O pins PA5 and PA6 are free for use as nor-

R p R f

mal I/O pins.

T o in te r n a l P A 5 /O S C 2

c ir c u its In te rn a l R C

O S C 2 O s c illa to r

C 2

P A 6 /O S C 1

N o te : 1 . R p is n o r m a lly n o t r e q u ir e d . C 1 a n d C 2 a r e r e q u ir e d .

2 . A lth o u g h n o t s h o w n O S C 1 /O S C 2 p in s h a v e a p a r a s itic N o te : P A 5 /P A 6 u s e d a s n o rm a l I/O s

c a p a c ita n c e o f a r o u n d 7 p F .

Internal RC Oscillator - HIRC

Crystal/Resonator Oscillator - HXT

External RC Oscillator - ERC External 32768Hz Crystal Oscillator - LXT

Using the ERC oscillator only requires that a resistor, When the microcontroller enters the Idle/Sleep Mode,

the system clock is switched off to stop microcontroller

with a value between 24kW and 1.5MW, is connected

activity and to conserve power. However, in many

between OSC1 and VDD, and a capacitor is connected

microcontroller applications it may be necessary to keep

between OSC and ground, providing a low cost oscilla-

the internal timers operational even when the

tor configuration. It is only the external resistor that de-

microcontroller is in the Power-down Mode. To do this,

termines the oscillation frequency; the external

another clock, independent of the system clock, must be

capacitor has no influence over the frequency and is

provided. To do this a configuration option exists to allow

connected for stability purposes only. Device trimming

a high speed oscillator to be used in conjunction with a a

during the manufacturing process and the inclusion of

low speed oscillator, known as the LXT oscillator. The

internal frequency compensation circuits are used to en-

LXT oscillator is implemented using a 32768Hz crystal

sure that the influence of the power supply voltage, tem-

connected to pins OSC1/OSC2. However, for some

perature and process variations on the oscillation

Rev. 1.10 29 October 23, 2012

HT46R064B/065B/066B

crystals, to ensure oscillation and accurate frequency It should be noted that, no matter what condition the

generation, it is necessary to add two small value exter- LXTLP bit is set to, the LXT oscillator will always func-