Professional Documents

Culture Documents

Investor Brief - K-SAAT Final

Investor Brief - K-SAAT Final

Uploaded by

Anonymous 48QX0oxy7u0 ratings0% found this document useful (0 votes)

70 views1 pages

Original Title

Investor Brief_K-SAAT Final (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documents

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

70 views1 pageInvestor Brief - K-SAAT Final

Investor Brief - K-SAAT Final

Uploaded by

Anonymous 48QX0oxy7us

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

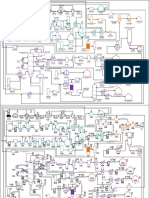

K-SAAT TM

KBR Solid Acid Alkylation Technology

K-SAAT Highlights Why K-SAAT?

Compared a conventional HF or Sulfuric Acid alkylation

• For refiners who wish to increase alkylate production technology, K-SAAT process offers the following

to increase octane for gasoline blending

advantages:

• Because octane requirements are increasing with

• Higher product yield and better product quality

demand for cleaner burning fuels & engine efficiency

• Lower CAPEX and OPEX due to lower equipment and

• Who are dissatisfied with hazardous liquid acid-based energy requirements

alkylation processes and their high cost for acid

• Better feedstock flexibility through improved

handling and maintenance

impurities tolerance

• Our technology K-SAAT is a revolutionary alkylation

• Lowest plot space requirements

process which uses a solid non-hazardous catalyst

• No Safety Concerns due to solid nature of the catalyst

• That delivers a very high yield of specification alkylate

from an unmatched variety of feeds while being Drivers for a K-SAAT unit

inherently safe and low-cost. Also available as • Increase alkylation capacity

modular supply it provides customers a very fast • Retrofit existing liquid acid alkylation units

return on investment.

• Monetize LPG from shale or excess ethylene

What is Alkylation? Growth Markets

• Alkylation is a process that many refineries use to • Demand growth areas – Grassroots Investments:

produce high octane motor and aviation fuels Middle East, China, Asia, Latin America, Russia/CIS

• During the process, light hydrocarbons are combined • Large installed base – Revamps:

in the presence of a catalyst to produce alkylate North America, Europe

What drives Global Alkylate Demand?

Investment / Economics

Global demand for motor fuels continues to rise to

• Average investment of about $60M for 10,000 BPSD

record levels whilst stricter environmental standards

grassroots and $36M for revamp (ISBL USGC 2017)

and oxygenate blend requirements for gasoline place a

• Payback period typically < 3 Years for Grassroots

premium on low Reid Vapor pressure, clean-burning

components. Experience & Selected Recent Successes:

The potential of alkylate is only limited by the costly K-SAAT is a breakthrough technology and has attracted

technology that, until now, was required to produce it. wide industry interest since its market introduction.

KBR has developed a new alkylation process that Dong Ying Haike Ruilin Chemical (2016), Wynnewood

overcomes this challenge. Refining (2018)

© 2019 KBR, Inc. All Rights Reserved

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ECS-5L Engine DiagramDocument8 pagesECS-5L Engine DiagramMartin AguilarNo ratings yet

- ROPERS.08 MV KASHING Bunker Survey Report ProgramDocument7 pagesROPERS.08 MV KASHING Bunker Survey Report ProgramTomas Silva KiharaNo ratings yet

- Biomassa Através Das ErasDocument11 pagesBiomassa Através Das ErasNICOLAS ANDERSON LEAL MORAIS LUNANo ratings yet

- Pid Solnica Philippines IncDocument3 pagesPid Solnica Philippines IncAndreRicamaraNo ratings yet

- CH 7 ExoDocument2 pagesCH 7 ExoHoussam Eddine BENLOUNASSENo ratings yet

- Ibr Arra SolazymeDocument1 pageIbr Arra SolazymeRamakrishnan TamilvaananNo ratings yet

- Changing The Tool: Other Tools Can Be Downloaded From The GHG Protocol WebsiteDocument20 pagesChanging The Tool: Other Tools Can Be Downloaded From The GHG Protocol WebsiteCarolina A. González DíazNo ratings yet

- R2B-P3-206-02-A-FO-00001 - Rev.1 - Operation Philosophy - EngDocument290 pagesR2B-P3-206-02-A-FO-00001 - Rev.1 - Operation Philosophy - Engdaniel contreras0% (1)

- Enhanced Oil Recovery (EOR) Why EOR?Document15 pagesEnhanced Oil Recovery (EOR) Why EOR?Mohanad HussienNo ratings yet

- Amt 224 - Aircraft Fuel Meterin SystemDocument20 pagesAmt 224 - Aircraft Fuel Meterin SystemNino AngobNo ratings yet

- Flash Point Avtur PDFDocument50 pagesFlash Point Avtur PDFAnggya AnggyNo ratings yet

- Production of Bio-Briquette From Biochar Derived From Pyrolysis of Cashew Nut WasteDocument11 pagesProduction of Bio-Briquette From Biochar Derived From Pyrolysis of Cashew Nut WasteDedek KarlinaNo ratings yet

- Ethanol Blending IN INDIA 2020-25: Roadmap ForDocument72 pagesEthanol Blending IN INDIA 2020-25: Roadmap Forabhinav7373No ratings yet

- Biomass Valorization For Converting Fuels and ChemicalsDocument51 pagesBiomass Valorization For Converting Fuels and ChemicalsJuanFleitesNo ratings yet

- IB Chemistry Option C Notes HLDocument64 pagesIB Chemistry Option C Notes HLFadilatu Abdoul ZakouNo ratings yet

- Differences Between Octane Number and Cetane NumberDocument2 pagesDifferences Between Octane Number and Cetane NumberrakeshbiswaNo ratings yet

- Heavy Oil InfoDocument18 pagesHeavy Oil Infonedian_2006No ratings yet

- Enzymatic Biodiesel MagazineDocument4 pagesEnzymatic Biodiesel Magazinerr345No ratings yet

- 33 - Vacuum Distillation UnitDocument136 pages33 - Vacuum Distillation Unitsunggwan kim0% (1)

- 103Document52 pages103Món Quà Vô Giá100% (1)

- What Is Industrial CombustionDocument5 pagesWhat Is Industrial CombustionTrường Tây ĐôNo ratings yet

- 2ndpaper PDFDocument7 pages2ndpaper PDFaysha ghazyNo ratings yet

- Proposed LPG Bottling Plant at POIC Lahad DatuDocument11 pagesProposed LPG Bottling Plant at POIC Lahad Datu96 CKNo ratings yet

- ES Chem 101 Lesson 1 Fuel and CombustionDocument51 pagesES Chem 101 Lesson 1 Fuel and CombustionInstructor JL Cuizon, RChENo ratings yet

- Coordenadas Geograficas de Paises - DesarrolleDocument4 pagesCoordenadas Geograficas de Paises - DesarrolleJim Lucero JooNo ratings yet

- Drawing ListDocument2 pagesDrawing ListRafiahammad ShaikNo ratings yet

- SCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFDocument3 pagesSCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFSEGUNNo ratings yet

- 9th YSF Symposium Proceedings 2020-133-138Document6 pages9th YSF Symposium Proceedings 2020-133-138Udya DevarajaNo ratings yet

- Denso Na Crs Shop DirectoryDocument1 pageDenso Na Crs Shop DirectoryCesar Bayes RamosNo ratings yet

- Compressed Natural Gas in Transport SectorDocument13 pagesCompressed Natural Gas in Transport SectorAnurag RayNo ratings yet