Professional Documents

Culture Documents

Trick Overpull String

Uploaded by

Bilal RashidCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trick Overpull String

Uploaded by

Bilal RashidCopyright:

Available Formats

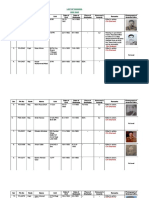

Effective Pull On Stuck Pipe

The first actions taken when the drillstring becomes stuck have a great influence on the chance of success.

The information detailed below give guidance to the correct early response when the pipe becomes stuck.

Effective Pull on Stuck Pipe

When determining the pull on differentially or mechanically stuck drillpipe, the actual weight of the string in air is

to be used and not the indicated weight as recorded by the weight indicator.

For example:

Depth 10,000 ft

Weight of drill collars in air 743 ft of 6-1/2” OD x 3” ID @ 89 lb/ft 66,127 lb

Weight of DP in air 9,257 ft x 19.50 lb/ft 180,512 lb

Total weight of string in air 246,639 lb

Weight indicator reading 220,000 lb

Weight of top drive, hook, blocks, swivel, etc. 50,000 lb

Pull reported at 100,000 lbs. over indicator reading 320,000 lb

Less hook, block, swivel, etc. - 50,000 lb

Effective pull on string 270,000 lb

Assuming that pipe is stuck on bottom, then the effective pull at the 23,361 lb

stuck point = 270,000 - 246,639 (no buoyancy of pipe)

In order to apply a pull of 100,000 lbs. at the bit, the Indicator 396,639 lb

reading would have to be 246,639 + 50,000 + 100,000 lb

This would mean that the pull on the pipe amounts to 346,639 lb

(396,639 lb - 50,000 lb)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Amaal For Laylatul QadrDocument319 pagesAmaal For Laylatul QadrBilal RashidNo ratings yet

- Docit - Tips - Pakistan Army Martyrs A 1965 Indo Pak War Pakistan South AsiaDocument13 pagesDocit - Tips - Pakistan Army Martyrs A 1965 Indo Pak War Pakistan South AsiaBilal RashidNo ratings yet

- Black Magic SFT SLSH HiresDocument2 pagesBlack Magic SFT SLSH HiresBilal RashidNo ratings yet

- Casing ScrapperDocument6 pagesCasing ScrapperBilal RashidNo ratings yet