Professional Documents

Culture Documents

Black Magic SFT SLSH Hires

Uploaded by

Bilal RashidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Black Magic SFT SLSH Hires

Uploaded by

Bilal RashidCopyright:

Available Formats

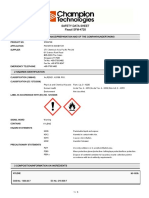

BLACK MAGIC

SFT spotting fluid

Lower NPT with a sacked fishing

tool that can be prepared at a rigsite

Brought by WellServe OilField annulus. In addition, approximately Applications

Service 10 to 15 bbl (1.19 to 1.79 m3) of BLACK-

MAGIC SFT fluid should be left in the pipe.

•• Stuck pipe

BLACK MAGIC™ SFT spotting fluid from

While working to free the differentially

Baker Hughes, a GE company (BHGE), is

stuck pipe, 0.5 to 1 bbl (0.060 to 0.12 m3)

a dry, powdered mixture of optimum-sized Benefits

of BLACK-MAGIC SFT fluid should be

air-blown asphalt, lime, fatty acids, and

dispersants for building variable-density

pumped every 30 minutes. ••Single-sack solution

spotting fluids used for stuck pipe. with small footprint

−−Builds a complete

After the BLACK MAGIC SFT fluid is spotted Mixing procedure oil/mud/spotting fluid that

to the location of the differential sticking,

1. Clean mixing pit and flush can be prepared at the rig

circulation stops and the BLACK MAGIC SFT

pumps and lines. −−Provides all properties

fluid begins working to remove the filter cake

through wetting and flocculation. After the 2. Add required amount of base oil. required for suspension-

filter cake is removed, the BLACK MAGIC 3. Add BLACK MAGIC SFT fluid of-weight material

SFT fluid deposits a thin tough wall cake to through the hopper with agitation. −−Can easily be weighted to

minimize differential pressures. In addition, 18.0 lbm/gal (2160 kg/m3)

4. Add water and agitate

the BLACK MAGIC SFT fluid lubricates the −−Stores more conveniently

until smoothly blended.

hole to reduce torque and drag, allowing the than compounded liquid

pipe to be jarred free so that drilling 5. Add the BHGE MIL-BAR™ additive

drum products

can resume. and agitate until a smooth blend.

••Reduced risk and losses

6. To increase viscosity add more −− Minimizes nonproductive time

BLACK MAGIC SFT fluid.

Determining pill volumes 7. To decease viscosity, add more base oil.

−−Reduces unplanned sidetracks

−−Lessens wear and tear on

The amount of BLACK-MAGIC SFT fluid to

be used for freeing differentially stuck pipe

drilling equipment (jarring)

should be based on building enough volume −−Avoids lost tool

to cover the bottomhole assembly in the

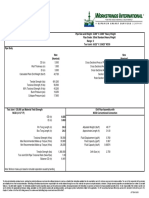

Spotting procedure Environmental information Typical physical properties

8. Spot the leading edge of the pill at For information concerning

Appearance Grayish powder

the stuck point, leaving 24 bbl (2.86 environmental regulations applicable to

m3) in the drill string. this product, contact the Health, Safety, Hygroscopic No

9. Allow 30 minutes of soak time and Environment department of BHGE.

prior to working pipe.

10.Pull tension and torque the Safe handling

pipe every 30 minuntes.

recommendations

11. After working pipe pump 0.5 to 1 bbl

Use normal precautions for employee

of the pill every 30 to 60 minutes.

protection when handling chemical

12.Continue this cycle until the products. Use of appropriate

pipe becomes free. respirator, gloves, and goggles.

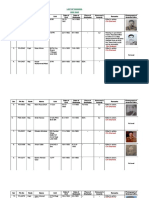

The tables below shows the recommended concentrations of products used to build the spotting fluid for different mud

weights. The weighting material could be MIL-BAR or MIL-CARB additives.

BLACK BLACK MIL-BAR,

Density, Density Base oil, bbl Base oil, m³ Water, bbl Water, m³ MIL-BAR, kg

MAGIC SFT, MAGIC SFT, 100-lbm

lbm/gal kg/m³

sacks kg sacks

unwtd.(7.5) 898.7 70 11 136 3393 12 1.88 0 0

9 1078.4 66 10 128 3193 11 1.76 81 3674

10 1198.3 64 10 124 3093 10 1.64 135 6123

12 1437.9 61 10 113 2819 7 1.08 244 11068

14 1677.6 56 9 102 2545 6 0.99 350 15876

16 1917.2 54 9 91 2270 3 0.45 459 20820

18 2156.9 48 8 81 2021 3 0.40 565 25628

MIL-BAR (Based on 100-lbm sacks)

BLACK BLACK MIL-CARB, MIL-CARB,

Density, Density Base oil, bbl Base oil, m³ Water, bbl Water, m³

MAGIC SFT, MAGIC SFT, 50-lbm kg

lbm/gal kg/m³

sacks kg sacks

8 958.6 67 11 136 3393 11 1.80 64 1451

9 1078.4 62 10 124 3093 11 1.69 190 4309

10 1198.3 61 10 113 2819 7 1.08 324 7348

11 1318.1 56 9 102 2545 6 1.00 448 10160

12 1437.9 54 9 91 2270 3 0.46 578 13109

13 1557.7 49 8 81 2021 3 0.41 702 15921

MIL-CARB (Based on 50-lbm sacks)

Collected by :Bilal Rashid (F.Eng)

bhge.com

Copyright 2018 Baker Hughes, a GE company, LLC (“BHGE”). All rights reserved.

The information contained in this document is company confidential and proprietary property of BHGE and its affiliates. It is to be used only for the benefit of BHGE and

may not be distributed, transmitted, reproduced, altered, or used for any purpose without the express written consent of BHGE.

Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product described at any time without notice or

obligation. Contact your BHGE representative for the most current information. The Baker Hughes logo, BLACK-MAGIC SFT, and MIL-BAR are trademarks of Baker

Hughes, a GE company, LLC. GE and the GE Monogram are trademarks of the General Electric Company.

78168

You might also like

- 2015-06-05 ZUA-11ST CT Nitrifed Acid Stimulation Rev 0.0Document26 pages2015-06-05 ZUA-11ST CT Nitrifed Acid Stimulation Rev 0.0Pratama RuliandryNo ratings yet

- Standard Operating Procedure - Cementing: 1. PurposeDocument4 pagesStandard Operating Procedure - Cementing: 1. PurposeSeven Knight100% (1)

- 1995 - Ardjuna B FieldDocument8 pages1995 - Ardjuna B FieldGemilangNo ratings yet

- Final Job Program - 9.625 in Intermediate Casing - BJK - CH-6 - 28 FEB22Document39 pagesFinal Job Program - 9.625 in Intermediate Casing - BJK - CH-6 - 28 FEB22Sanjenbam SumitNo ratings yet

- Belt Identification Chart GATESDocument1 pageBelt Identification Chart GATESBenito Ramirez MirandaNo ratings yet

- Cleancut CCB PDFDocument2 pagesCleancut CCB PDFbruce lian100% (1)

- Kompresor: Perancangan Alat Proses Abdul Wahid Surhim 2014Document72 pagesKompresor: Perancangan Alat Proses Abdul Wahid Surhim 2014curlychemNo ratings yet

- Chrome-Extension Mhjfbmdgcfjbbpaeojofohoefgiehjai IndexDocument7 pagesChrome-Extension Mhjfbmdgcfjbbpaeojofohoefgiehjai Indexjangri10980% (1)

- Right Torque at The Connection 5Document4 pagesRight Torque at The Connection 5Shafiqa AlhobaishyNo ratings yet

- Assignment 2 - DiscussionDocument28 pagesAssignment 2 - DiscussionNofril ZendriadiNo ratings yet

- MSDS SFM-4728, FlexoilDocument5 pagesMSDS SFM-4728, FlexoilLeddy ZakarunaNo ratings yet

- Formation Evaluation Log Bumerah-1X Bumerah-1X: Total GasDocument14 pagesFormation Evaluation Log Bumerah-1X Bumerah-1X: Total Gasfahrain2012100% (1)

- Selection of ElastomersDocument3 pagesSelection of ElastomersMaria Jose CuellarNo ratings yet

- 2015-05-25 LESA-2 CT Cement Squeeze Contaminant Rev 0.0Document28 pages2015-05-25 LESA-2 CT Cement Squeeze Contaminant Rev 0.0Pratama RuliandryNo ratings yet

- Presentasi Power Pack - Virnando Batu AraDocument17 pagesPresentasi Power Pack - Virnando Batu AraVirnando NainggolanNo ratings yet

- Excel Perhitungan Pompa Sentrifugal Kel.3Document9 pagesExcel Perhitungan Pompa Sentrifugal Kel.3Tonny Dwi YuliantoNo ratings yet

- CASING and TUBING HANGER PDFDocument4 pagesCASING and TUBING HANGER PDFrenjuNo ratings yet

- Soltex Potassium AdditiveDocument2 pagesSoltex Potassium AdditiveKinni ShenoldNo ratings yet

- Artificial Lift (Part 2)Document49 pagesArtificial Lift (Part 2)chegg accountNo ratings yet

- Drilling Forecast CNLC January 31stDocument1 pageDrilling Forecast CNLC January 31stsault07No ratings yet

- Workover Operations (Ok)Document6 pagesWorkover Operations (Ok)Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Bab V Perhitungan: 4.1. Massa Air Yang Teruapkan Dan Kandungan Air AkhirDocument6 pagesBab V Perhitungan: 4.1. Massa Air Yang Teruapkan Dan Kandungan Air AkhirPutri Hanifah SNo ratings yet

- Sucker Rod Pump and Accessories-Huaming EnergyDocument9 pagesSucker Rod Pump and Accessories-Huaming EnergyKevin XuNo ratings yet

- Istilah-Istilah Dalam Drilling Day ReportDocument4 pagesIstilah-Istilah Dalam Drilling Day ReportAdventhy RyaNo ratings yet

- Delhi Center Is Also Responsible For Producing India SentinelDocument2 pagesDelhi Center Is Also Responsible For Producing India Sentinelshivani1912No ratings yet

- 12 Perforating SystemsDocument79 pages12 Perforating SystemsnazgultrNo ratings yet

- POB - Sarulla ProjectDocument8 pagesPOB - Sarulla ProjectRenta SiregarNo ratings yet

- PolarProp ApplicationDocument4 pagesPolarProp ApplicationCristian BarbuceanuNo ratings yet

- MsdsDocument5 pagesMsdsSusan TylersNo ratings yet

- Apdn - 2014Document6 pagesApdn - 2014Poull SteeadyNo ratings yet

- Wellhead - Manual S2100559Document47 pagesWellhead - Manual S2100559Parag PadoleNo ratings yet

- Company Profile PT - PHE-WMODocument30 pagesCompany Profile PT - PHE-WMOHendri Anur100% (2)

- Alur Produksi Gas Benuo Taka WailawiDocument1 pageAlur Produksi Gas Benuo Taka WailawiAbdullahNo ratings yet

- 3 - Arenas Curables y ActivadoresDocument52 pages3 - Arenas Curables y ActivadoresPablo SotoNo ratings yet

- Surat Dukungantender Safekick Limited Dengan PT Andalas Petroleum ServicesDocument9 pagesSurat Dukungantender Safekick Limited Dengan PT Andalas Petroleum Servicesyono DaryonoNo ratings yet

- HP SV EqualizingDocument1 pageHP SV EqualizingGuiver Suarez V.No ratings yet

- Hasil Deepening Gas LiftDocument16 pagesHasil Deepening Gas LiftIrsalina NHNo ratings yet

- Proposal To HalliburtonDocument20 pagesProposal To HalliburtonAchmad Zuelhari MalikNo ratings yet

- Safety Data Sheet: Shell MDS (M) SDN BHDDocument7 pagesSafety Data Sheet: Shell MDS (M) SDN BHDAnonymous VNu3ODGavNo ratings yet

- Pembagian Ruangan Oral Presentation - Rev4 - 20180927Document1 pagePembagian Ruangan Oral Presentation - Rev4 - 20180927Rizal NasutionNo ratings yet

- 103 Camisea Description Norberto BenitoDocument38 pages103 Camisea Description Norberto BenitoJorge LuisNo ratings yet

- Pumps Spec Series5100!8!09Document12 pagesPumps Spec Series5100!8!09Carlos David Lopez TorresNo ratings yet

- CV-Mabexly Sitohang PDFDocument9 pagesCV-Mabexly Sitohang PDFmpsitohangNo ratings yet

- Presentation - Bit - 001 - IntroductionDocument15 pagesPresentation - Bit - 001 - IntroductionMohamed HamdyNo ratings yet

- JopDocument10 pagesJopAnonymous nHT1rzjmcNo ratings yet

- Cost Bunchpress & Shredder Sunli by BJM 2019 Mei EditDocument1 pageCost Bunchpress & Shredder Sunli by BJM 2019 Mei EditHeryy TanujayaNo ratings yet

- Pompa SelwoodDocument4 pagesPompa SelwoodakkilluaNo ratings yet

- Mpe PresentationDocument26 pagesMpe PresentationarakanoilwatchNo ratings yet

- THC Tubing Pumps: Bore Size Barrel AssemblyDocument1 pageTHC Tubing Pumps: Bore Size Barrel AssemblyDuddi DennisukNo ratings yet

- MKPK Tugas 5Document4 pagesMKPK Tugas 5Tri MitraNo ratings yet

- Stab-In Casing Cementing Job Risk AssessmentDocument2 pagesStab-In Casing Cementing Job Risk AssessmentIbnu HasanNo ratings yet

- 376-20-NFS2-3030E Nico Coco Factory Rev.0Document2 pages376-20-NFS2-3030E Nico Coco Factory Rev.0Christa Desmonda100% (1)

- New Technology of H2S Removal - AK SeriesDocument12 pagesNew Technology of H2S Removal - AK SeriesWaskito SantosoNo ratings yet

- PMBOK Integration - Stake Holder - CommunicationDocument51 pagesPMBOK Integration - Stake Holder - CommunicationGibran WijayaNo ratings yet

- Optimizing Rig Scheduling PDFDocument15 pagesOptimizing Rig Scheduling PDFYoyi YuniasNo ratings yet

- Liquid Loading in A Horizontal Shale Gas Well: Prediction, Prevention & RemediationDocument2 pagesLiquid Loading in A Horizontal Shale Gas Well: Prediction, Prevention & Remediationpablo raffinNo ratings yet

- Wytch Farm Report - AsdDocument6 pagesWytch Farm Report - Asddaul93No ratings yet

- Fracseal (Fine)Document1 pageFracseal (Fine)Jaka TingkirNo ratings yet

- SFT InformationDocument4 pagesSFT Informationfelipecl2106No ratings yet

- Black Magic SFT PBDocument1 pageBlack Magic SFT PBfelipecl2106No ratings yet

- Aamal Mahe RamzanDocument194 pagesAamal Mahe RamzanBilal RashidNo ratings yet

- Docit - Tips - Pakistan Army Martyrs A 1965 Indo Pak War Pakistan South AsiaDocument13 pagesDocit - Tips - Pakistan Army Martyrs A 1965 Indo Pak War Pakistan South AsiaBilal RashidNo ratings yet

- Amaal For Laylatul QadrDocument319 pagesAmaal For Laylatul QadrBilal RashidNo ratings yet

- Using Chemical Formulas 11 KeyDocument9 pagesUsing Chemical Formulas 11 KeyBilal RashidNo ratings yet

- Periodic Table-Color PDFDocument1 pagePeriodic Table-Color PDFMohamed NedalNo ratings yet

- 32-Column Periodic Table PDFDocument1 page32-Column Periodic Table PDFAmna KhanNo ratings yet

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) ConventionalDocument1 page5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) ConventionalAlvaro Garcia acostaNo ratings yet

- VAM Catalog 2011Document116 pagesVAM Catalog 2011Anoop SVNo ratings yet

- 1262128171drillstring DesignDocument1 page1262128171drillstring DesignBilal RashidNo ratings yet

- Vam Tubular StandardsDocument84 pagesVam Tubular StandardsMAHAN4231100% (9)

- Casing ScrapperDocument6 pagesCasing ScrapperBilal RashidNo ratings yet

- HappyDocument1 pageHappyBilal RashidNo ratings yet

- Trick Overpull StringDocument1 pageTrick Overpull StringBilal RashidNo ratings yet

- API Tubing TableDocument6 pagesAPI Tubing TableDavid KusumaNo ratings yet

- SaltDocument1 pageSaltBilal RashidNo ratings yet

- Internal Pressure CutterDocument1 pageInternal Pressure CutterBilal RashidNo ratings yet