Professional Documents

Culture Documents

2015-05-25 LESA-2 CT Cement Squeeze Contaminant Rev 0.0

Uploaded by

Pratama RuliandryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2015-05-25 LESA-2 CT Cement Squeeze Contaminant Rev 0.0

Uploaded by

Pratama RuliandryCopyright:

Available Formats

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

PT. ELNUSA Tbk

Coiled Tubing Services – Drilling & Oilfield Services

Graha Elnusa 6th Floor, Jl. TB. Simatupang Kav 1B, Jakarta 12560

CT Cement Squeeze Contaminant

Version 0.0

Date : 25 May 2015

Well: LESA-2

Prepared for : Prepared by:

Kristianto Wibowo Azhar Maulana

Agung Arief Wijaya

Pertamina Hulu Energi – ONWJ Elnusa

PHE Tower, 8th Floor PT Elnusa Tbk

Jl. TB Simatupang, Kav 99, Jakarta Graha Elnusa 6th Floor, Jl. TB.

12560 Simatupang Kav 1B, Jakarta

12560

Indonesia Indonesia

+62811 1830 797 +62812 1256 3181

+62856 9178 3437

kristianto.wibowo@pertamina.com azhar.maulana@elnusa.co.id

agung.wijaya01@pertamina.com

Rev 0.0 Page 1 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Table of Contents

GENERAL INFORMATION ........................................................................................................ 5

1 INTRODUCTION & OBJECTIVE .......................................................................................... 5

2 DESIGN DATA ...................................................................................................................... 5

THE FOLLOWING PAGES INDICATE THE DATA GATHERED FOR DESIGN PURPOSES .................. 5

2.1 CLIENT SUPPLIED DATA ........................................................................................................ 5

DESC COMPILED / USED DATA ........................................................................................................ 6

2.2 WELL PROFILE ...................................................................................................................... 7

2.3 COMPLETION DIAGRAM ........................................................................................................ 8

3 OPERATIONAL SUMMARY & PROCEDURE ............................................................................ 9

3.1 OUTLINE PROCEDURE ......................................................................................................... 10

3.2 DETAILED PROCEDURE ......................................................................................................... 12

3.3 CONTINGENCY PLAN ......................................................................................................... 14

3.4 SAFETY ...................................................................................................................................... 15

4. EQUIPMENT REQUIREMENTS ........................................................................................................ 16

4.1 CT equipment ...................................................................................................................... 16

4.2 Pumping equipment ........................................................................................................ 16

5. FLUID CONSUMPTION ....................................................................................................... 17

5.1 15.8 lb/gal Cement Squeeze Slurry ........................................................................................... 17

5.2 Mud Pill ..................................................................................................................... 17

5.3 Contaminant Fluid ....................................................................................................... 17

6. ATTACHMENTS ....................................................................................................................... 19

6.1 RIG-UP FOR CT ....................................................................................................................... 19

6.2 ENGINEERING ANALYSIS ......................................................................................................... 20

6.3 BHA DIAGRAM ....................................................................................................................... 24

6.4 Laboratory Report ......................................................................................................... 25

Rev 0.0 Page 2 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Approval Sheet

Designed By Azhar Maulana ELNUSA CTU

DESC Engineer

Reviewed By Muryono Hadi ELNUSA CTU

Tech. Representatives

Approved By Agung Arief Wijaya PHE ONWJ

Well Intervention Eng

Kristianto Wibowo PHE ONWJ

Well Intervention Eng

Rev 0.0 Page 3 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Barkah Widyantoro PHE ONWJ

Well Intervention Supt.

Rev 0.0 Page 4 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

1 INTRODUCTION & OBJECTIVE

LESA-2 well is a well in KLA field area that equipped with 9-5/8” previous casing from surface to 800’

md, 7” current liner to 5192’ md and 3-1/2” production from surface to 7904’md. Open Hole section

from 5192’ md to 7904’ md.

It has been request to isolate zone KL-37A (5610’ – 5622’ md), KL-38B (5738’ -5749’ md) and KL-39

(5819’ – 5846’ md) with lenght of total perfotation 50 ft by using 1.5” coiled tubing.

Well Profile

Rev 0.0 Page 5 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

2 DESIGN DATA

The following pages indicate the data gathered for design purposes.

Notes

2.1 Client Supplied Data

Client Engineer Kristianto Wibowo

Agung Arief Wijaya

Field KLA

Well No LESA-2

Well Type (Oil / Gas / W.I. etc) Gas Producer

Job Type CT Cement Squeeze

Contaminant

Job Date-Projected Start May 2015

Completion Diagram As attached

Deviation Survey Deviated well

Last Well Entry Year 1999

Max Inclination 52.4 deg @ 4170’ MD

Max DLS 6.224 deg/100 ft @ 1061’

Total Depth 7904’ md

SIWHP N/A Based on PHE ONWJ information

Fluid level N/A Based on PHE ONWJ information

Rig Data

Certifying Authority Teras Conquest 4 Operating using CTU-501 1.5” CT

DESC Compiled / Used Data

Fluid type to be pumped 15.8 lb/gal cement slurry, Mud Pill, contaminant fluid, filtered

water

Pump rates 1 bpm

Nitrogen rate N.A

Max pump pressures 5,000 psi

CT size 1.5”

Lab tests required No

Rev 0.0 Page 6 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

2.2 Completion Diagram

Rev 0.0 Page 7 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

3 OPERATIONAL SUMMARY & PROCEDURE

NOTES: I. All operations must be carried out in accordance with Safety Standards.

II. The CT Data Acquisition System must be used throughout the operation to record:

Time

Depth Counter

Weight (In and Out)

Coiled Tubing Surface Pressure

WHP (tubing)

Pumping flow rate

III. A pre-job meeting must be held, and to be repeated as necessary during the operation

(i.e. crew change and prior to personnel new to the on-going operation starting work or

when critical stages of the program commence.)

IV. During coiled tubing operation, following parameters must not be exceeded without line

management approval:

Do not exceed CT compressive and tensile limits in any point in the wellbore.

Rev 0.0 Page 8 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

3.1 CT Preparation

1. Perform pre-job Preventive Maintenance Procedure checklist for all equipment

2. Ensure sufficient water and chemicals available prior to starting the job.

3. Hold pre-rig up safety meeting and discuss :

Preventive Maintenance Procedure

Rig-up procedure

Rig-up responsibilities

Muster point

Physical and Chemical hazards

Review JSA

4. Ensure BOP rams are function and pressure tested on boar prior to starting job

5. Confirm the maximum allowable pressure rating of the client master valve.

6. Rig up equipment, BOP, wellhead connection above wellhead master valve and treating line as

per R/U schematics

Note: Perform pressure test as per procedure. Inform Company Representatives if the master

valve is leaking

7. Make up CT connector and perform pull test 20,000 lbs

8. Pressure test CT with filtered water against CT connector. Perform low pressure test and high

pressure test.

9. M/U CT tubing cutter BHA as per diagram at attahment

Note: The Job Supervisor measure the BHA and to keep a full record of every tool run

(OD's/ID’s, lengths). Put BHA diagram, well completion diagram with detailed information

inside control cabin at all times, observe CT weight during RIH and POOH.

10. Rig-up the injector head with complete BHA. Perform low and high pressure test for stripper

and BOP body against the wellhead as per procedure.

11. Perform depth and weight correlation as per procedure

12. Hold pre-job safety meeting and discuss:

Job procedure

Personnel assigned and responsibility defined.

i. CT Supervisor – Job Supervises and responsible for all aspects of Job preparation, and

execution as per Standards procedure with no deviations. Make sure contingency plans in

place. Recognizes risks associated with the operation, and reduces these risks to as low as

reasonably possible. Ensures that all personnel assigned are competent to operate their

assigned equipment.

ii. CT Equipment Operators – responsible for equipment preparation and Preventive

Maintenance Schedule requirements. Perform job execution follow by Job Supervisor.

Rev 0.0 Page 9 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

iii. CT Engineer – responsible to provide engineering support to CT Supervisor and executes

successful jobs as per the design provided and approved by the Client. Identifies any

potential unplanned changes to the job program at the well site, and discussed with client

all of thing that deviated from program.

Ensures that all personnel assigned are competent to operate their assigned equipment.

Radio channels and communications

Physical and Chemical hazards

Job Safety Analysis and Contingency plans

PPE requirements

Rev 0.0 Page 10 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

3.2 Detailed Procedure

3.2.1 Run – 1 : CT Cement Squeeze Contaminant

Note – Refer to PHE ONWJ Program during the operation.

1. Hold TBT prior to commencing work, review and update for the specific location/task all

relevant risk assessments and work method’s as per Elnusa procedures.

Note: Ensure all communication s are in place with all Elnusa/Third Party and PHE ONWJ

representative, check all equipment and complete pre RIH checklist.

2. Make up CT standard BHA and ensure all details have been recorded on BHA checklist.

3. Stab injector onto stack and pressure test stack as per pressure test Matrix.

4. Ensure all communications are in place with the PHE ONWJ Reps, check all equipment and

complete pre RIH checklist.

5. Equalise and open the tree valves as per “Company” procedures.

6. Line up well to take returns.

7. Lines up kill line (if required).

8. Slowly start running coiled tubing carefully watching the weight indicator for obstruction.

Check weight every 1,000 ft and slow down at nipple profiles or tubular restrictions.

9. Continue RIH CT to set plug at 6,441 ft MD. Circulate well slowly with 2% KCl water while RIH.

10. POOH CT to 5,616 ft MD (for KL-37A zone), Close CT annulus and perform Injectivity Test,

started with 0.5 BPM and increased gradually to 0.75 BPM and 1 bbl respectively.

Note: Injectivity result will dictate cement slurry to be mixed, discuss with company

representative or engineering team for cement volume to be mixed

11. Repeat step no.10 for desired depth at 5,744 ft MD (for KL-38B zone) and at 5,833 ft MD (for

KL -39 zone)

Note: Injectivity result will dictate cement slurry to be mixed, discuss with company

representative or engineering team for cement volume to be mixed

12. Mix the following:

32 bbl of 15.8 ppg mud pill

15 bbl of 15.8 ppg cement slurry

252 bbl of contaminant fluid can be mix per 50 bbl

Note : Take a sample of the cement slurry for onsite lab testing and run for set time on

consistometer

13. After the cement ready to be pumped, RIH CT to 6,441 ft MD, open CT annulus and pump the

following at 1,2 bpm:

32 bbl of 15.8 ppg mud pill

Rev 0.0 Page 11 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

5 bbl of fresh water as spacer ahead

10.7 bbl of 15.8 ppg cement slurry

5 bbl of fresh water as spacer behind

Continue displace with filtered sea water for one coil tubing volume (28.3 bbl + 1.5 bbl

= 29.8 bbl)

Note :

Once 1.3 bbl of 15.8 ppg mud pill out of coil tubing, start POOH CT at 35 fpm to 5,896 ft

MD.

Once 1.3 bbl of 15.8 ppg cement slurry out of coil tubing, start POOH CT at 35 fpm to

4,946 ft MD and then close CT annulus

Hesitate the remaining cement slowly to formation

during hesitation keep pumping below 500 psi

keep pumping pressure below maximum pressure allowed (4,000 psi).

pumping rate dictate coil tubing pick up rate.

Adjust CT pick up and pumping rate at 1:1 speed ratio

if squeeze pressure hold and do not decrease while there still some cement inside CTU

and estimate thickening time has been reached then POOH CT 50 ft from estimate

TOC and circulate out excess cement to surface. Keep backup pressure 500 psi while

circulate out excess cement.

14. After 15 minutes at 500 psi, RIH CT to the TOC at estimated calculated Top of Cement at

5,560 ft MD and contaminates cement with Contaminant Fluid while maintaining back

pressure 500 psi. Circulate out all cement in tubing. Make 5 down passes and 5 up passes at

pumping rate 1 bpm and CT running rate 35 fpm.

15. Leave the well secured. WOC until cement slurry reach 2000 psi compressive strength based

on UCA test result.

16. Perform positive test 500 psi for 10 minutes. Bleed off.

17. If good test observed continue with next program

18. If the cement leaks, re-do cement contaminant

19. Confirm with company representative prior POOH CT to surface.

20. Close lower and upper master valve.

21. Rig down equipment safely.

22. Job Completed

Rev 0.0 Page 12 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

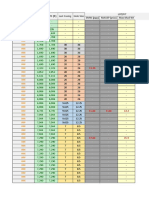

3.2.2 Cement Squeeze Contamination Calculation

Rev 0.0 Page 13 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Cement Squeeze Contaminant Calculation

OD ID Weight Capacity

OH 8,500 in 8,5 in 0,07018 bbl/ft

Casing 7 in 6,28 in 26 lb/ft 0,038262 bbl/ft

Tubing 3 1/2 in 2,99 in 9,2 lb/ft 0,008696 bbl/ft

Cap. Cas to Tub 0,026363 bbl/ft

Cap OH to Tub 0,058286 bbl/ft

Top of Cement 5560 ft MD

EOT 7904 ft MD

KL-37A 5610 - 5622 ft MD 12 ft

KL-38B 5738 - 5749 ft MD 11 ft

KL-39 5819 - 5846 ft MD 27 ft

Bottom of Cement 5896 ft MD

X Plug 6441 ft MD

Float shoe of Tubing 7903 ft MD

Total Perforation 50,00 ft 6 spf

Cement per perforation 0,10 cuft/perf

Cement in Casing 2,92 bbl

Cement in Perforation 5,34 bbl

Excess 30% 2,48 bbl

Total Cement Required 10,74 bbl

Required Mud Pill to fill casing 32 bbl

Length of cement before squeeze 900 ft

Top Of cement before squeeze 4996 ft MD

Number of passes to clean out cement 5 passes

Total trip 8810 ft

CT speed 35 fpm

Time for cement contaminating 251,7 min

Pump rate 1 bbl

Containant fluid volume 251,7 bbl

Contaminant fluid required 251,7 bbl

Rev 0.0 Page 14 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

3.2.3 Pumping Schedule Cemnt Squeeze Contaminant

CT Speed Final CT Depth Pump rate Pump Vol Time Total Vol. counter Total Time Ann

No Stage Fluid pumped

(ft/min) (ft) (Bpm) (bbl) (min) (bbl) (min) Tubing-CT

RIH while pumping 2% KCl

1 RIH CT to set plug X-niple @ 6441 ft MD 50,00 6441 KCL 2% 0,50 64,41 128,82 64,4 128,82 Open

Injectivity Test

Pump filtered water at varied pumping pressure and

Filtered water

2 record WHP 0,00 953 0.5 - 1.5 Close

Cementing Stage

3 Mixing Cement Slurry 0,00 6441 N.A N.A N.A 30,00 0 30,00 Open

4 Reset bbl control, pump 32 bbl of mud pit 0,00 6441 Mud Pill 1,2 32,00 26,67 32 26,67 Open

5 Pump 5 bbl of water ahead 0,00 6441 Filtered water 1,2 5,00 4,17 37 4,17 Open

6 Reset bbl control, pump 10.7 bbl of 15.8 lb/gal cement slurry 0,00 6441 Cement slurry 1,2 10,70 8,92 47,7 10,70 Open

7 Pump 5 bbl of water behind 0,00 6441 Filtered water 1,2 5,00 4,17 52,7 4,17 Open

Displace & Hesitate Stage

Pumping filtered water 1 CT volume (28.3 bbl) +

8 Filtered water

Line volume (1.5 bbl) 0,00 6441 1,2 29,80 24,83 82,50 24,83 Open

9 Pick up CT to bottom of cement 35,00 5896 N.A N.A N.A 15,57 92,00 15,57 Open

10 Pick up CT to 50' above of TOC 35,00 4946 N.A N.A N.A 27,14 92,00 27,14 Close

11 Hesitate 0,00 4946 Filtered water Var. 5,34 15,00 97,34 15,00 Close

Pumping Contaminant Fluid

12 RBIH CT to top of cement 35,00 5560 ContaminantN.A N.A N.A 17,54 97,34 17,54 Close

13 Circulate cement by contaminant fluid 35,00 Fluid 1,2 252,00 210,00 349,34 210,00 Open

Total Pumping Time 385,79

Thickening Time 437,00

POOH CT

POOH CT to surface while replacing CT volume

14 (1 bbl every 300 ft) -30,00 0 Filtered water 1,0 214,7 214,70 Close

Rev 0.0 Page 15 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

3.3 Contingency Plan

Below are quick steps to be performed during the job in case of critical situation condition occurred in

related to the operation.

If the weight of CT increase suddenly where potential stuck is possible:

Any indication over pull always do close communication with PHE ONWJ representatives

Assess situation, do not stop circulating

Pull up CT without exceed 80% max over pull

Increase pump rate up to maximum pressure limitation, if pump rate restricted proceed to

burst the disk to gain circulation.

Keep POOH CT until the CT return to normal as per forces on string

Continue circulating and move the pipe until return is clean

Assess the situation before proceed with the cleanout

Circulating pressure increase or decrease rapidly:

POOH CT

Observe Coil Tubing Acquisition parameter

Continue pulling out and fully circulate until return is clean

If circulation cannot be established, pressure up to burst the disc (in MHA) up to maximum

surface pressure test (6000 psi)

Assess the situation

Pump Failure:

POOH CT

Prepare the second pump (already primed previously)

Continue pumping

Continue pulling out and fully circulate until return is clean

Repair the first pump

If both pump fails, POOH CT as fast as you can to safe depth

CT Stuck (but can still establish circulation):

Maintain circulation

Calculate stuck point

If CT is stuck at BHA proceed to following steps

Set OPSD to 5000 psi

Stop pumping and close 2x2 plug valve at reel manifold when launching ball (hydraulic

disconnect ball)

Close launcher and pressure up to 1000 psi against 2x2 plug valve

Rev 0.0 Page 16 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Open 2x2 plug valve

Once ball is inside CT increase rate and listen ball moving sounds across CT

Monitor the bbls pumped since ball launching

When ball is expected to be on goose neck decrease pump rate to minimum

When observed increase of pressure, keep pumping at minimum rate until shear pins break and

circulating pressure decreases (sign of hydraulic disconnect have activated)

POOH CT and be prepared to perform BHA fishing

CT Stuck (no circulation, burst disc set at 6000 psi):

Set OPSD to 6000 psi at surface

Pump at low rate until maximum pressure (6600 psi) to burst the disc

Note: Confirm burst disc rating with tool specialist

After burst disc breaks and circulation is established, POOH CT to surface while maintaining

circulation (pumping at constant flow rate)

3.4 Safety

All personnel that are involved with the mixing must read MSDS before handling or mixing any

chemicals.

Always wear proper PPE before handling or operating equipment and mixing chemicals

Visually inspect all equipment for any damage incurred during the transportation

A safety meeting involving all personnel must be held before the job. Mixing procedure and

safety consideration must be discussed. All relevant MSDS sheets must be available. Assign

work team and ensure that everyone understand work objectives and appropriate safety

practices

Only people necessary for the mixing will be in the mixing areas. The personnel involved in the

mixing must wearing proper protective gear, i.e slick suit (make sure the rubber goes outside

your boots), rubber boots, safety goggles, face shields, rubber gloves and respirator on top of

the normal PPE as required by MSDS.

Eye wash bottles, safety shower must be located in the immediate area where the mixing takes

place. Make sure the safety shower is connected to a working water line. The eyewash bottles

must be full of water. It is advisable to have a water hose close by the area also

Follow the procedure described in the next pages when mixing the chemicals

Always be careful in opening and closing valves. Do this slowly to avoid any sudden pressure

changes in the line

During pumping, there must be an assigned person to observe and to operate valves (avoid

pump cavitation)

Ensure proper and sufficient amount of logistics (drill water and chemicals)

Rev 0.0 Page 17 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

4. EQUIPMENT REQUIREMENTS

The equipment that will be required for the operation is as follows:

CT equipment

Equipment

CT Unit with 680 injector head

4” 1/16 side door stripper

4” 1/16 Combi BOP

Tools

Pull test plate

CT BHA as defined in the program

Test bar 1.5”

Pumping equipment

Twin pump

2 x 50bbl Batch Mixer

Filtration Unit

Mixing acid tank

Nitrogen converter

Nitrogen tank

Rev 0.0 Page 18 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

5. FLUID CONSUMPTION

5.1 Cement Squeeze Slurry – 15.8 lb/gal

15.8 lb/gal Squeeze Cement Slurry 15 Bbl 630 Gall

Chemical or Product Conc. Unit Required Unit

Fresh Water 3,137 gps 216,7 Gall

Cement Class G 94 lb/sx 69,1 Sx

Dispersant (FR-1L) 0,45 gps 31,1 Gall

Medium Temp Retarder (R-1L) 0,10 gps 6,9 Gall

Fluid Loss Control (FL-1L) 0,80 gps 55,3 Gall

Anti Migration Gas (AMG-1) 1,00 gps 69,1 Gall

Defoamer (AF-1L) 0,05 gps 3,5 Gall

Yield cement slurry 1,219 cuft/sx

5.2 Mud Pill – 15.8 lb/gal

15.8 lb/gal Mud Pill 32 Bbl 1344 Gall

Chemical/Product Conc. Unit Required Unit

Fresh Water 44,2 gal/Mgal 59,4 Gall

SAPP (pH controller) 0 lb/Mgal 0,0 lb

XCD polymer 1,5 lb/Mgal 2,0 lb

Barite 266,7 ppb 8.534,4 lb

Foam Preventer 0,1 gal/Mgal 0,1 Gall

5.3.Contaminant FLuid

Contaminant Fluid 252 Bbl 10584 Gall

Chemical/Product Conc. Unit Required Unit

Fresh Water 996 Gal/Mgal 10.541,7 Gall

HEC-10 30 Lb/Mgal 317,5 Lb

KCl 5 Lb/Mgal 52,9 Lb

Rev 0.0 Page 19 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

6. Attachment

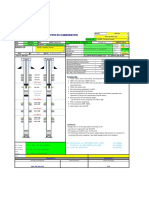

6.1 Rig-Up for CT Acid Stimulation

CT RIG UP

Item Schematic

Client: PHE ONWJ

Field: LESA Field

Well : LESA-2

Min. Restriction: 2,812

Res. Press:

BHST:

Size or Height Weigth Min PSI Elsa or

Item Description

Connection ft kg K 3rd Party

1 Injector Head 680 12,67 6050 10 Elnusa 1

Side Door 4 1/16" 10K

2 2 340 10 Elnusa

Stripper Side Door

2

3 Riser 4 1/16" 10K 4 800 10 Elnusa

3

4 Riser 4 1/16" 10K 6 800 10 Elnusa

5 Dual Combi BOP 4 1/16" 10K 3,3 900 10 Elnusa

4

6 Flow Tee 4 1/16" 10K 1,72 40 10 Elnusa

Single Shear

7 4 1/16" 10K 1,8 700 10 Elnusa 5

Seal BOP

8 x-over 4 1/16" 5K 2 20 5 Elnusa

6

PHE

9 Wellhead 3 1/8" 5K 6 - 3

ONWJ

7

8

Total Height: 39,49 ft 9

Total Weigth: 9650,0 kgs

Min PSI: 3,0 K psi

Double check connections, gaskets, nuts & bolts!!

Rev 0.0 Page 20 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

6.2 ENGINEERING ANALYSIS

Tubing Forces

Rev 0.0 Page 21 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Summary

RIH : CT and BHA can reach the target depth with no lock-up detected

POOH : CT and BHA can be retrieved to surface form the target depth

Normal CT RIH & POOH Tensions

Normal RIH weight expected : 2,306 lbs

Normal POOH weight expected: 11,500 lbs

Max Pull :

Maximum available pick-up at depth : 13,430 lbs; corresponding weight indicator : 33,722 lbs

Max Slack-off:

Maximum slack off on tool at depth : -2,709 lbs; corresponding weight indicator : -1,198 lbs

Rev 0.0 Page 22 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Note :

1. Set alarm on OrionNET at 25,000 lbs during POOH and set alarm at - 500 lbs during RIH

2. Inform immediately to PHE ONWJ Reps if found any indication of CT buckling and or over pull

3. Inform to town if found any indication of CT buckling and over pull

Rev 0.0 Page 23 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Tubing Limit

CT Fatigue

Updated on : May 20th 2015

Rev 0.0 Page 24 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

6.3 BHA Diagram

* BHA Diagram to be confirm again on location before job

BHA SCHEMATIC #2

Item Tool Schematic

Client: PHE ONWJ

Rig/Platform: Teras Conquest-4

Field/Well Number: LESA_LESA_3

Minimum Well Restriction: 2.812 inch

Bottom Hole Temperature: N/A 1

Bottom Hole Pressure: N/A

Wellhead Pressure: 150 psi

BHA Name: CT Squeeze Cementing

Date Drawn: 26-May-15

Item Tool Tool Connections Tool O/D Tool I/D T-Length

Description in Inches in Inches in feet 2

Dimple On

1 1.0 AMMT pin 1,688 0,750 0,280

Connector

1-3/4" OD Motor

2 1.0 AMMT Box-Pin 1,750 0,430 2,170

Head Assembly

1-3/4" OD

3 1.0 AMMT box & pin 1,750 0,630 2,170

Staight Bar

1-1/2" Cement

4 1,125" SA 10 Box 1,500 port 0,500

Nozzle

3

Maxiumum Tool-String OD: 1,75

Minim um Tool-String ID: 0,43

Total Le ngth of BHA in Ft 5,12

Prepared by Azhar Maulana

Rev 0.0 Page 25 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

6.4 Laboratory Report

Rev 0.0 Page 26 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Rev 0.0 Page 27 of 28

Job Proposal

Client Name: Pertamina Hulu Energi - ONWJ REVISION : 0.0

WELL : LESA-2 PREPARED BY : AZH

OPERATION : CT Cement Squeeze ISSUE DATE : 21 May 2015

Contaminant

Rev 0.0 Page 28 of 28

You might also like

- Grant Prideco Field Service For Atlas Bradford ConnectionsDocument12 pagesGrant Prideco Field Service For Atlas Bradford Connectionsnardo_ingNo ratings yet

- BJ SqueezecementingDocument77 pagesBJ SqueezecementingAbdullahAliNo ratings yet

- Water Sprinkler: ManualDocument133 pagesWater Sprinkler: ManualWajdi Jellouli100% (2)

- Design of A Large Scale Solar PV SystemDocument309 pagesDesign of A Large Scale Solar PV SystemArianit Zeqiri67% (3)

- Managed Pressure Drilling & Underbalanced Operations: Platinum SponsorsDocument4 pagesManaged Pressure Drilling & Underbalanced Operations: Platinum SponsorsSyed IrtazaNo ratings yet

- KARAM-10 Perforation ProgramDocument7 pagesKARAM-10 Perforation ProgramAhmed AliNo ratings yet

- Gamma World Rules D20 ConversionDocument183 pagesGamma World Rules D20 ConversionDennis Dillion100% (1)

- Overview of Insulation MaterialsDocument64 pagesOverview of Insulation Materialsnike_y2k100% (3)

- FakinasolDocument17 pagesFakinasolmasgontarNo ratings yet

- JET Manual 04: Basic Oilfield EquipmentDocument88 pagesJET Manual 04: Basic Oilfield EquipmentPratama RuliandryNo ratings yet

- Triplex Slush Pump Service ManualDocument26 pagesTriplex Slush Pump Service ManualActivos FijosNo ratings yet

- Drilling Product CatalogueDocument43 pagesDrilling Product Cataloguemin thantNo ratings yet

- Underbalanced Coiled Tubing Drilled Horizontal Well in The North SeaDocument6 pagesUnderbalanced Coiled Tubing Drilled Horizontal Well in The North Seatarang_tusharNo ratings yet

- 111 Kepner - TregoeDocument12 pages111 Kepner - Tregoeiresendiz100% (1)

- SAP S - 4HANA Embedded EWM-QM Integration Setup-1709 - SAP BlogsDocument32 pagesSAP S - 4HANA Embedded EWM-QM Integration Setup-1709 - SAP Blogspmanikumar100% (4)

- Well: LLB-12 13-3/8" Squeeze Design: Pt. Cosl IndoDocument6 pagesWell: LLB-12 13-3/8" Squeeze Design: Pt. Cosl IndoIbnu HasanNo ratings yet

- Salamat-1 Mud Report 53-27092012Document4 pagesSalamat-1 Mud Report 53-27092012mega87_2000100% (1)

- JFE CasingDocument40 pagesJFE CasingezrawongNo ratings yet

- Drilling Rigs Built in The U.SDocument9 pagesDrilling Rigs Built in The U.SalmirNo ratings yet

- BKDocument1 pageBKmbloexNo ratings yet

- JET 1 Treating EquipmentDocument60 pagesJET 1 Treating Equipmentmasterab100% (3)

- JET Manual 05: Low-Pressure EquipmentDocument66 pagesJET Manual 05: Low-Pressure EquipmentPratama RuliandryNo ratings yet

- C200-047-09-Man Mha 2.125Document18 pagesC200-047-09-Man Mha 2.125Virnando Nainggolan100% (1)

- PBL Operation ProcedureDocument16 pagesPBL Operation Procedurekudturkar100% (1)

- Spec Rig 550 HP TMSDocument21 pagesSpec Rig 550 HP TMSAli AkbarNo ratings yet

- Warehouse Space Rental OpportunitiesDocument6 pagesWarehouse Space Rental OpportunitiesAnonymous 5JrxY4No ratings yet

- (Zaneta&Yurika) Drilling FinalDocument88 pages(Zaneta&Yurika) Drilling FinalRika NazmilaNo ratings yet

- ID Vs Role Based FirefightingDocument12 pagesID Vs Role Based Firefightingcesar.andres9105No ratings yet

- Pertamina EP Asset 4 Poleng BW-021 WO ProgramDocument12 pagesPertamina EP Asset 4 Poleng BW-021 WO ProgramDeddy BramNo ratings yet

- Chevron Indonesia Completion Workover for Well 5G-0302ADocument21 pagesChevron Indonesia Completion Workover for Well 5G-0302ARyan SinagaNo ratings yet

- SPE-175230-MS First Acid Fracturing Unlocks The Production Potential of Tight Tuba Carbonate Reservoir, North KuwaitDocument18 pagesSPE-175230-MS First Acid Fracturing Unlocks The Production Potential of Tight Tuba Carbonate Reservoir, North KuwaitarispriyatmonoNo ratings yet

- Starborn EP Presentation On Bontang PSCDocument18 pagesStarborn EP Presentation On Bontang PSCEugene TanNo ratings yet

- Aerated DrillingDocument7 pagesAerated DrillingHarisma BagusNo ratings yet

- Information Security GovernanceDocument194 pagesInformation Security Governancenaeemupm82% (11)

- Black Platinum announces Dara East Gas Field PPoDDocument3 pagesBlack Platinum announces Dara East Gas Field PPoDWahyudin IlyasNo ratings yet

- Lay Out Plan Rig Nyt#08 Akatara#2Document2 pagesLay Out Plan Rig Nyt#08 Akatara#2Bayu SaputraNo ratings yet

- SO Jasa Survey Topografi Lahan Sumur Kinanti - 5Document2 pagesSO Jasa Survey Topografi Lahan Sumur Kinanti - 5ajaemma288No ratings yet

- 2015-06-05 ZUA-11ST CT Nitrifed Acid Stimulation Rev 0.0Document26 pages2015-06-05 ZUA-11ST CT Nitrifed Acid Stimulation Rev 0.0Pratama RuliandryNo ratings yet

- Well Program CPI BangkoDocument1 pageWell Program CPI BangkoUge HolicNo ratings yet

- Overview Kerja PraktekDocument42 pagesOverview Kerja PraktekAmanda Talia LumentutNo ratings yet

- PolarProp ApplicationDocument4 pagesPolarProp ApplicationCristian BarbuceanuNo ratings yet

- Surat Dukungantender Safekick Limited Dengan PT Andalas Petroleum ServicesDocument9 pagesSurat Dukungantender Safekick Limited Dengan PT Andalas Petroleum Servicesyono DaryonoNo ratings yet

- 3 - Arenas Curables y ActivadoresDocument52 pages3 - Arenas Curables y ActivadoresPablo SotoNo ratings yet

- 00079896Document13 pages00079896JohnSmithNo ratings yet

- Pet P 0010920190516 P KR 03Document23 pagesPet P 0010920190516 P KR 03Ryan SinagaNo ratings yet

- LINERDPDocument1 pageLINERDPscrbdgharaviNo ratings yet

- Manifold ValvesDocument3 pagesManifold ValvesberrouiNo ratings yet

- DOS Matrix Acidizing Treatment PEPA1 BN-45 DOS V1 180119Document28 pagesDOS Matrix Acidizing Treatment PEPA1 BN-45 DOS V1 180119adityawigasNo ratings yet

- One Page Info KalrezDocument2 pagesOne Page Info KalrezDaryoko RispurwantoNo ratings yet

- Drilling Forecast CNLC January 31stDocument1 pageDrilling Forecast CNLC January 31stsault07No ratings yet

- He-E10 Well MontageDocument1 pageHe-E10 Well MontageSaeid OrangiNo ratings yet

- API/IADC recommended makeup torque for oilfield tubular connectionsDocument2 pagesAPI/IADC recommended makeup torque for oilfield tubular connectionsHarsha Chowdary100% (1)

- Topl Full Fleet ListDocument4 pagesTopl Full Fleet ListhaydarburedahNo ratings yet

- Section 11 - Drilling Mud ManualDocument4 pagesSection 11 - Drilling Mud ManualMohamed AbozeimaNo ratings yet

- PetroChina Announces Tender for Purchase of Down-hole Completion ToolsDocument7 pagesPetroChina Announces Tender for Purchase of Down-hole Completion ToolsAmeer BabylonianNo ratings yet

- Final Job Program - 9.625 in Intermediate Casing - BJK - CH-6 - 28 FEB22Document39 pagesFinal Job Program - 9.625 in Intermediate Casing - BJK - CH-6 - 28 FEB22Sanjenbam SumitNo ratings yet

- Santrol Pocket Guide InternationalDocument2 pagesSantrol Pocket Guide Internationalintoyou2007No ratings yet

- ZQ203-125II DRILL PIPE POWER TONG PARTS LISTDocument26 pagesZQ203-125II DRILL PIPE POWER TONG PARTS LISTwaleedNo ratings yet

- Petani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)Document30 pagesPetani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)handokoNo ratings yet

- Well Completions 2111Document2 pagesWell Completions 2111muturabu87No ratings yet

- Mahad3 - WaterLess Fracturing TechnologyDocument48 pagesMahad3 - WaterLess Fracturing Technologycj100% (1)

- Company Profile of PT BPKDocument18 pagesCompany Profile of PT BPKFajri MilanNo ratings yet

- Inside BOP Specs and SizesDocument1 pageInside BOP Specs and SizesWanto SupriyoNo ratings yet

- Drilling Program WOEN-5 PDFDocument69 pagesDrilling Program WOEN-5 PDFHouria HouriaNo ratings yet

- Right Torque at The Connection 5Document4 pagesRight Torque at The Connection 5Shafiqa AlhobaishyNo ratings yet

- HCI (S) Top Drive SystemDocument19 pagesHCI (S) Top Drive SystemHugo TejadaNo ratings yet

- Stab-in Cementing Job Risk AssessmentDocument2 pagesStab-in Cementing Job Risk AssessmentIbnu HasanNo ratings yet

- Top Drive HSDocument12 pagesTop Drive HSluis sarmientoNo ratings yet

- Tesco HCS 750 Troubleshooting Guide PDFDocument86 pagesTesco HCS 750 Troubleshooting Guide PDFLuther MoletaNo ratings yet

- Drill 12-1⁄4Document1 pageDrill 12-1⁄4Mohamed AbozeimaNo ratings yet

- 802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2Document11 pages802-CBN-00-PR-CE-LIFTING PROCEDURE-049-A of Civil Construction and Infrastructure Works, Stage 2Agus SupriadiNo ratings yet

- 802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Document12 pages802-CBN-00-PR-CE-LIFTING PROCEDURE-049-B of Civil Construction and Infrastructure Works, Stage 2Agus SupriadiNo ratings yet

- General Manager UIP Nusra SRM Operasi Dan Konstruksi UIP NUSRA PT. PLN (Persero) UPP Timor ArsipDocument31 pagesGeneral Manager UIP Nusra SRM Operasi Dan Konstruksi UIP NUSRA PT. PLN (Persero) UPP Timor Arsiphastaria mannaNo ratings yet

- Modifications To The Mean Maximum Pressure SystemDocument17 pagesModifications To The Mean Maximum Pressure Systemkanteron6443No ratings yet

- Perfecto HT 5 Heat Transfer Oil Data SheetDocument2 pagesPerfecto HT 5 Heat Transfer Oil Data SheetnghiaNo ratings yet

- ENSA Questions AnswersDocument18 pagesENSA Questions AnswersNurul ShakirahNo ratings yet

- Radulescu Clepsydra Astray PDFDocument3 pagesRadulescu Clepsydra Astray PDFAlen IlijicNo ratings yet

- ETS-50!06!08-C1 High-Voltage Components - Current Transformer 400 KV 2000-1000 ADocument7 pagesETS-50!06!08-C1 High-Voltage Components - Current Transformer 400 KV 2000-1000 Araghavendran raghuNo ratings yet

- Pile Target As Per MSP Schedule - RODocument11 pagesPile Target As Per MSP Schedule - ROabir senguptaNo ratings yet

- Uninterrupted DC Power Supply PDFDocument59 pagesUninterrupted DC Power Supply PDFit's DifFerEntNo ratings yet

- HajMissionRepresentativeGuide1 0 PDFDocument68 pagesHajMissionRepresentativeGuide1 0 PDFMohammed Yusuf Mahbub HmNo ratings yet

- BT 2 Elec Plumbing Struc CedarsideDocument14 pagesBT 2 Elec Plumbing Struc CedarsideK4 Printing ServicesNo ratings yet

- Department of Defense: DirectiveDocument11 pagesDepartment of Defense: DirectiveChristopher DorobekNo ratings yet

- Trakr Programming ManualDocument35 pagesTrakr Programming ManualMizi SallyNo ratings yet

- Dear MRDocument2 pagesDear MRVEERAMANINo ratings yet

- Fatigue in The Shell of A Conveyor Drum: Ch. Affolter, G. Piskoty, R. Koller, M. Zgraggen, T.F. Ru TtiDocument15 pagesFatigue in The Shell of A Conveyor Drum: Ch. Affolter, G. Piskoty, R. Koller, M. Zgraggen, T.F. Ru TtiSamir KulkarniNo ratings yet

- Alfa Romeo's rich history and iconic modelsDocument12 pagesAlfa Romeo's rich history and iconic modelsVidysagar Vvec100% (1)

- NB Geotube Highpumpingheights Tcm29-12837Document2 pagesNB Geotube Highpumpingheights Tcm29-12837pjgomezdNo ratings yet

- 2az-Fe Engine Control System Sfi SystemDocument6 pages2az-Fe Engine Control System Sfi SystemMarcelo DecimaNo ratings yet

- MICROWAVE ENGINEERING QUESTION BANKDocument7 pagesMICROWAVE ENGINEERING QUESTION BANKRahul KoshtaNo ratings yet

- JD730 Power Sensor JDPM Operating Guide R1.4Document44 pagesJD730 Power Sensor JDPM Operating Guide R1.4mborazNo ratings yet

- E-Link 1000EXR Datasheet v16 PDFDocument2 pagesE-Link 1000EXR Datasheet v16 PDFjorlugonNo ratings yet

- Siddharth Joshi - 2016 Resume LongformDocument4 pagesSiddharth Joshi - 2016 Resume Longformdrumfiend21No ratings yet

- Mary Wix Resume 2016Document2 pagesMary Wix Resume 2016api-302404484No ratings yet