Professional Documents

Culture Documents

Cross Bracing Slotted Strut Channel 41x41x2x2256mm PDF

Uploaded by

Yaseen PathanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cross Bracing Slotted Strut Channel 41x41x2x2256mm PDF

Uploaded by

Yaseen PathanCopyright:

Available Formats

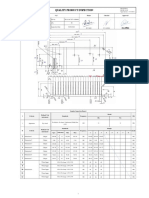

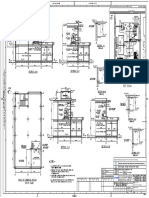

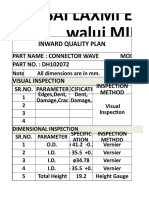

FINAL INSPECTION REPORT

Customer Name:- STERLING AND WILSON, CHENNAI Po Number:-4400116691, dt-29/08/2019 Drawing No:- RS - JIKA - 07

Lot Qty:- 06 Pcs Work Order No;-JIKA 560

Product Description:- Cross Bracing Dispatched Quantity:- 06 Pcs

41X41X2.00X2256 mm Inspected Qty:- 02 Pcs

Note:- Punching As Per Drawing Page 1 of 1

Inspection Observed Parameter

So No. Parameter Specifications Remark

Equipment SA-1 SA-2 SA-3 SA-4 SA-5 SA-6 SA-7 SA-8 SA-9 SA-10 SA-11 SA-12 SA-13 SA-14 SA-15

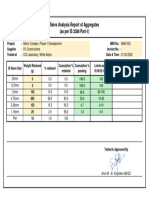

1 Width 41±1mm V.C 0.02 41.28 41.26

2 Height 41±1mm V.C 0.02 41.34 41.56

3 Lip 9.5±1mm V.C 0.02 9.42 9.62

4 Gap 22.3±1mm V.C 0.02 22.34 22.48

5 Thickness 2.00 ±1mm Micrometer 0.01 2.02 2.03

6 Length 2256±1mm M.Tape 1 2256 2256

7 Slot Ø14x29±1mm V.C 0.02 14.06x29.12 14.22x29.14

Checked Ok

Slot Punching 30±1mm V.C 0.02 30.4 30.46

8

Position 30±1mm V.C 0.02 30.3 30.24

9 Punching Center 20.5±0.5mm V.C 0.02 20.4 20.54

Powder Coating

10 Thickness 60 Microns Alcometer 68 70

(Microns)

Peel Off test

11 Peel Off Test No Peel Off OK OK

Equipment.

Details of Inspection Inspection Activities:-

• Scope of Inspection:-Visual (Random), Random Dimension, Material T.C.

Review and Powder Coating Thickness Check. 1) Visual Inspection carried out on offered material for surface finish, surface defect,

Bend found satisfactory.

2) Dimensional Inspection carried out with reference to drawing found in Tolerance ±1

Submission:- mm.

1) Raw Material Test Certificate.

2) Valid Calibration Certificates for Instruments. 3) No Lums on shearing areas, No Camber and twist. No Sectional Bow observed.

Verified & Approved Date:- 24/10/2019

You might also like

- 4-Lembar Pengesahan PengujiDocument163 pages4-Lembar Pengesahan PengujiNico Achmad ZulviansyahNo ratings yet

- Pdir 5PM Ad3532001 - 1a31892004b 04.06.2022Document1 pagePdir 5PM Ad3532001 - 1a31892004b 04.06.2022RohitNo ratings yet

- Amir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)Document3 pagesAmir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)sumit singhNo ratings yet

- Pdi 5Document1 pagePdi 5antNo ratings yet

- Sample Report-HandbagsDocument41 pagesSample Report-HandbagsKhiet PhamNo ratings yet

- Pdir F2L09399Document1 pagePdir F2L09399Shankar JadhavNo ratings yet

- Pdir FMG0599.Document1 pagePdir FMG0599.Shankar JadhavNo ratings yet

- Rev No. 0Document7 pagesRev No. 0DavoodNo ratings yet

- Cs-Rites-Door Link Mechanism (Single Link)Document3 pagesCs-Rites-Door Link Mechanism (Single Link)sohelNo ratings yet

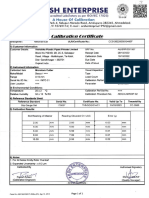

- Customer Details:: Test Reading STD - Reading Error Uncertainty S.NoDocument2 pagesCustomer Details:: Test Reading STD - Reading Error Uncertainty S.NomaniNo ratings yet

- Pre Despatch Inspection Report: FYN2133 Screw Sreekar 04.08.2022 50 Nos 5 NosDocument2 pagesPre Despatch Inspection Report: FYN2133 Screw Sreekar 04.08.2022 50 Nos 5 Nosvee s veeNo ratings yet

- Test Result: Sample 1 Sample 2Document14 pagesTest Result: Sample 1 Sample 2yogi arohmanNo ratings yet

- Layout Inspection Report: MY25 Cummins Filtration Expandable Seal As Per Drawing Spec 0 01 4 5 NosDocument2 pagesLayout Inspection Report: MY25 Cummins Filtration Expandable Seal As Per Drawing Spec 0 01 4 5 NosRohitNo ratings yet

- Bearing LSS CoverDocument2 pagesBearing LSS CoverRagul0042No ratings yet

- DC 958Document2 pagesDC 958mkarthiNo ratings yet

- Test Report Mac - PhersonDocument11 pagesTest Report Mac - Phersondeportesaldia2014No ratings yet

- 164-01-01-003 Locating Pin - Dia 3.2Document1 page164-01-01-003 Locating Pin - Dia 3.2cawojNo ratings yet

- PDIRDocument1 pagePDIRShankar JadhavNo ratings yet

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velNo ratings yet

- Long Housing Reports x104Document7 pagesLong Housing Reports x104PACHAIYAPPAN SNo ratings yet

- LQC STDDocument2 pagesLQC STDAstronNo ratings yet

- 3-Microtome Calibration CartificateDocument1 page3-Microtome Calibration Cartificatemba213No ratings yet

- 164-01-01-006 Locating Pin - Dia 2.4Document1 page164-01-01-006 Locating Pin - Dia 2.4cawojNo ratings yet

- Customer Specification Rport 12 FCDocument12 pagesCustomer Specification Rport 12 FCSridharan VenkatNo ratings yet

- Pre-Dispatch Inspection ReportDocument2 pagesPre-Dispatch Inspection ReportPuneet SharmaNo ratings yet

- MMC Hardmetal India Pvt. LTD.: Part Number Part Name Edp No. Inspected DateDocument1 pageMMC Hardmetal India Pvt. LTD.: Part Number Part Name Edp No. Inspected DateshrikantNo ratings yet

- Material Test Certificate: Doc No: A1 FENCE/QAD/QC-FORM-06 Rev No: 00 DTD 20/09/2020Document2 pagesMaterial Test Certificate: Doc No: A1 FENCE/QAD/QC-FORM-06 Rev No: 00 DTD 20/09/2020adipur aartiNo ratings yet

- BULL Lighting-LampDocument9 pagesBULL Lighting-LampMary Jenni Zuluaga MejiaNo ratings yet

- Phiếu OQC KGDK02-07.06.2021Document2 pagesPhiếu OQC KGDK02-07.06.2021long nguyễn vănNo ratings yet

- Scr452 - 20.01.2016 Pdi - Qad-28 Sample Inspection Reportcheck Rail - Machine (Scr-452)Document1 pageScr452 - 20.01.2016 Pdi - Qad-28 Sample Inspection Reportcheck Rail - Machine (Scr-452)azadNo ratings yet

- Customer Details:: Test Reading STD - Reading Error Uncertainty S.NoDocument2 pagesCustomer Details:: Test Reading STD - Reading Error Uncertainty S.NomaniNo ratings yet

- Measurement Data of 3210D704201300Document3 pagesMeasurement Data of 3210D704201300wawan darmawanNo ratings yet

- Mac Pherson GDSTDocument11 pagesMac Pherson GDSTdeportesaldia2014No ratings yet

- Ningbo - Anchor - M20Document1 pageNingbo - Anchor - M20jailani.anwarNo ratings yet

- Inspection Report: V'Groove DetailsDocument4 pagesInspection Report: V'Groove DetailsVijay Makwana VishwakarmaNo ratings yet

- AccreditationDocument40 pagesAccreditationWalid BdeirNo ratings yet

- QAR-QD405-800 Rod As-Hoist CylinderDocument6 pagesQAR-QD405-800 Rod As-Hoist CylinderIrwanto ManafNo ratings yet

- HDPE Pile Wheel SpacersDocument12 pagesHDPE Pile Wheel SpacersGhayas JawedNo ratings yet

- Technical Specification PTP Ennore Part2-2024-02!19!06!07!41Document239 pagesTechnical Specification PTP Ennore Part2-2024-02!19!06!07!41trilokNo ratings yet

- Raw Material Incoming Inspection Report: 0.18 - 0.23 0.30 Max 0.80 - 1.10 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Document1 pageRaw Material Incoming Inspection Report: 0.18 - 0.23 0.30 Max 0.80 - 1.10 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Maintenance Plant 1 & 2No ratings yet

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocument3 pagesVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNo ratings yet

- Board Line: - 022 66595154: As Per Iso 2341Document1 pageBoard Line: - 022 66595154: As Per Iso 2341BARKAT ALINo ratings yet

- QC-F29-Rewinding Form-03Document2 pagesQC-F29-Rewinding Form-03Annabella1234No ratings yet

- Result of The CalibrationDocument1 pageResult of The Calibrationanaban corporationNo ratings yet

- Bis-Dk-Rt-1051 - Ip2022-NaDocument2 pagesBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNo ratings yet

- QAF04 Supplier Quality Plan Rev 00Document1 pageQAF04 Supplier Quality Plan Rev 00Ulhas KavathekarNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Mir 001Document1 pageMir 001MCCIN L&WNo ratings yet

- EX - 12.7MM - PLATE 01 PAUT Report TrainingDocument4 pagesEX - 12.7MM - PLATE 01 PAUT Report Trainingagung akbarNo ratings yet

- Kon D000Document1 pageKon D000MohitNo ratings yet

- Pa3-3125-02-6-Gb Po7779, Inspection ReportDocument3 pagesPa3-3125-02-6-Gb Po7779, Inspection ReportRino SutrisnoNo ratings yet

- KC EntDocument12 pagesKC Entsai associatesNo ratings yet

- Pdi Report AllDocument6 pagesPdi Report AllKailas GadhveNo ratings yet

- Exp.: Date: 2/7/2020: Calculation of Measurement of Uncertainty As Per NABL 141Document1 pageExp.: Date: 2/7/2020: Calculation of Measurement of Uncertainty As Per NABL 141Mechtek LabNo ratings yet

- Inspection Guideline For Soil To Air Interface PipingDocument14 pagesInspection Guideline For Soil To Air Interface PipingBenjapon bt750% (2)

- Inspection and Maintenance of Drill PipeDocument39 pagesInspection and Maintenance of Drill PipeinsaanNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- Sae 1035Document2 pagesSae 1035Maintenance Plant 1 & 2No ratings yet

- Field Guide 2 Russian MANPADS TechnologyDocument2 pagesField Guide 2 Russian MANPADS Technologypp100% (1)

- 0927 KSS Heat-Shrinkable Tubings (SA)Document1 page0927 KSS Heat-Shrinkable Tubings (SA)Nicacio LucenaNo ratings yet

- 25th VFS Air Defenses Guide V2.0Document20 pages25th VFS Air Defenses Guide V2.0eoftebro100% (1)

- Cross Bracing Slotted Strut Channel 41x41x2x2256mm PDFDocument1 pageCross Bracing Slotted Strut Channel 41x41x2x2256mm PDFYaseen PathanNo ratings yet