Professional Documents

Culture Documents

12345

Uploaded by

Anonymous YSJ7TzlCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12345

Uploaded by

Anonymous YSJ7TzlCopyright:

Available Formats

Job Ready Assessment Blueprint

Welding

Welding

Test Code: 4272 / Version: 01

Copyright © 2017 NOCTI. All Rights Reserved.

Welding

General Assessment Information

Blueprint Contents

General Assessment Information Sample Written Items

Written Assessment Information Performance Assessment Information

Specific Competencies Covered in the Test Sample Performance Job

Test Type: The Welding industry-based credential is included in NOCTI’s Job Ready

assessment battery. Job Ready assessments measure technical skills at the

occupational level and include items which gauge factual and theoretical knowledge.

Job Ready assessments typically offer both a written and performance component and

can be used at the secondary and post-secondary levels. Job Ready assessments can

be delivered in an online or paper/pencil format.

Revision Team: The assessment content is based on input from secondary,

post-secondary, and business/industry representatives from the states of Kansas,

Michigan, New York, Oklahoma, Pennsylvania, and Virginia.

CIP

Code

48.0508- Career Cluster 13 - 51-4121.06- Welders, Cutters,

Welding Technology/Welder Manufacturing and Welder Fitters

The Association for Career and Technical Education (ACTE), the leading professional

organization for career and technical educators, commends all students who

participate in career and technical education programs and choose to validate their

educational attainment through rigorous technical assessments. In taking this

assessment you demonstrate to your school, your parents and guardians, your future

employers and yourself that you understand the concepts and knowledge needed to

succeed in the workplace. Good Luck!

(Continued on the following page)

NOCTI Job Ready Assessment Page 2 of 11

Welding

General Assessment Information (continued)

The International Sign Association (ISA) represents manufacturers,

suppliers and users of on-premise signs and sign products from all 50

states and around the globe. The sign and visual communications

industry is a $37.5 billion business that employs more than 200,000

individuals. One of ISA’s long term goals is to showcase and promote the

many exciting and diverse career opportunities that exist within the sign

and visual communications industry and to apprise students of the

abundant employment opportunities that are present to skilled and

qualified candidates. ISA strongly encourages and supports students

that work to enhance their educational achievements by completing

NOCTI assessments.

In the lower division

baccalaureate/associate degree

category, 3 semester hours in Welding

Technology or Mechanical Technology.

NOCTI Job Ready Assessment Page 3 of 11

Welding

Written Assessment

NOCTI written assessments consist of questions to measure an individual’s factual

theoretical knowledge.

Administration Time: 3 hours

Number of Questions: 172

Number of Sessions: This assessment may be administered in one, two, or three sessions.

Areas Covered

12%

10%

15%

7%

12%

11%

9%

12%

12%

NOCTI Job Ready Assessment Page 4 of 11

Welding

Specific Standards and Competencies Included in this Assessment

Safety

• Identify various welding hazards and safe practices

• Display familiarity with industrial and OSHA safety standards

• Demonstrate knowledge of oxyfuel safety procedures

• Demonstrate knowledge of arc welding and cutting safety procedures

• Demonstrate proper and safe use of PPE, hand tools, and power equipment

Physical Characteristics and Mechanical Properties of Metals

• Identify metals by physical characteristics

• Explain the pre-heating and post-heating processes

• Exhibit understanding of distortion control methods

• Identify basic mechanical properties of metals

Weld Fit-Up and Quality

• Identify various joint designs (joint geometry) and welding positions

• Clean and prepare materials for groove and fillet welds

• Identify welding defects and/or discontinuities

• Test welds using various techniques

• Use standard measuring and layout tools

• Describe welding industry codes, standards, and procedures

Welding Symbols and Blueprint Reading

• Interpret weld and welding symbols

• Read and interpret blueprints and sketches

Oxyfuel Cutting (OFC)

• Identify oxyfuel cutting principles

• Identify and maintain oxyfuel equipment

• Assemble and disassemble oxyfuel equipment

• Handle and store compressed gas cylinders

• Cut and form metal with oxyfuel equipment (Continued on the following page)

Please note, due to a shift in OSHA terminology, that any

references to “Material Safety Data Sheets (MSDS)” will be

changed to “Safety Data Sheets (SDS)” during the next

scheduled revision.

NOCTI Job Ready Assessment Page 5 of 11

Welding

Specific Standards and Competencies (continued)

Arc Cutting Process (Carbon Arc and Plasma Arc)

• Identify arc cutting process principles

• Assemble and disassemble arc cutting equipment

• Identify and maintain arc cutting equipment

• Exhibit an understanding of arc cutting consumables

• Demonstrate appropriate use of arc cutting equipment

Shielded Metal Arc Welding (SMAW)

• Explain principles of SMAW

• Set up and maintain SMAW equipment

• Demonstrate selection and application of SMAW consumables

• Perform fillet and groove welds on plate in all positions

Gas Metal Arc Welding (GMAW) and Flux Cored Arc Welding (FCAW)

• Explain principles of GMAW and FCAW

• Set up and maintain GMAW and FCAW equipment

• Demonstrate selection and application of GMAW and FCAW consumables

• Perform fillet and groove welds on plate in all positions

Gas Tungsten Arc Welding (GTAW)

• Explain principles of GTAW

• Set up and maintain GTAW equipment

• Demonstrate selection and application of GTAW consumables

• Perform fillet and groove welds on ferrous and nonferrous metals in all positions

NOCTI Job Ready Assessment Page 6 of 11

Welding

Sample Questions

An SDS (Safety Data Sheet) provides detailed information

A. about matching the base metal metallurgy with the welding filler metal

B. about the operating specifications of welding equipment and machinery

C. regarding appropriate uses of different weld joint geometries

D. regarding possible hazards resulting from the use of a product

A neutral oxygen-acetylene flame has a temperature range of

A. 230 to 280 degrees Fahrenheit

B. 500 to 550 degrees Fahrenheit

C. 3000 to 3500 degrees Fahrenheit

D. 5800 to 6300 degrees Fahrenheit

Oxygen cylinders should be _____ fuel gas cylinders when not in use.

A. stored separately from

B. chained to

C. the same color as

D. at the same pressure as

In the PAC (Plasma Arc Cutting) process, compressed air must be

A. completely dry

B. moist

C. lubricated

D. CO2

Which of the following is a ferrous metal?

A. aluminum

B. copper

C. magnesium

D. mild steel

(Continued on the following page)

NOCTI Job Ready Assessment Page 7 of 11

Welding

Sample Questions (continued)

When welding 3-G certification test weld, the weld must be welded in the _____

position.

A. vertical

B. flat

C. overhead

D. horizontal

Which number is the smallest?

A. 0.250

B. 0.500

C. 0.005

D. 0.050

Which condition would cause an electrode holder to overheat?

A. loose connection

B. excessively long cable

C. insufficient current flow

D. low voltage

The _____ welding process involves a non-consumable electrode.

A. SMAW

B. GMAW

C. GTAW

D. SAW

Argon and helium gases are

A. inert

B. reactive

C. neutral

D. oxidizing

NOCTI Job Ready Assessment Page 8 of 11

Welding

Performance Assessment

NOCTI performance assessments allow individuals to demonstrate their acquired skills by

completing actual jobs using the tools, materials, machines, and equipment related to

the technical area.

Administration Time: 3 hours 18%

23%

Number of Jobs: 6

Areas Covered:

12%

23% Oxyfuel Cutting

Participant will select and set up equipment correctly 20%

and safely, lay out the project according to the provided 15%

diagram, and cut to specified dimensions. 12%

20% SMAW V-Groove, 3G

Participant will select and set up equipment correctly and safely, tack the steel pieces to

the base, and perform three weld passes in a V-groove according to specifications.

12% GMAW, 2F

Participant will select and set up materials correctly and safely, and using tubing, steel,

and welding wire, weld material according to specifications.

15% Aluminum GTAW Tee Joint, 2F

Participant will select and set up equipment correctly and safely, and using aluminum

and filler rod, weld a Tee-joint in the horizontal position according to specifications.

12% Stainless Steel GTAW Lap Joint, 2F

Participant will set up equipment correctly and safely, and using stainless steel and filler

rod, weld a lap joint according to specification.

18% Uphill FCAW, 3F

Participant will set up equipment correctly and safely, and using mild steel and filler

material, weld a root pass and a cap pass according to specifications.

NOCTI Job Ready Assessment Page 9 of 11

Welding

Sample Job

Aluminum GTAW Tee Joint, 2F

Maximum Time: 20 minutes

Participant Activity: The participant will use two pieces of sheet aluminum and filler rod

to weld a Tee-joint in the horizontal position.

NOCTI Job Ready Assessment Page 10 of 11

Welding

Notes

NOCTI Job Ready Assessment Page 11 of 11

You might also like

- 9204400-2223Document16 pages9204400-2223markrosario29makiNo ratings yet

- Report Format ML - 1Document29 pagesReport Format ML - 1Uday ValmikiNo ratings yet

- Competency Based Curriculum for Sheet Metal WorkerDocument45 pagesCompetency Based Curriculum for Sheet Metal WorkerAmit KumarNo ratings yet

- VTU Internship Report on Web DevelopmentDocument21 pagesVTU Internship Report on Web DevelopmentGr RanjereNo ratings yet

- Sample Report 22-23 1Document30 pagesSample Report 22-23 1Ashesh Krishna AdhikariNo ratings yet

- Report Format ML - 2022Document27 pagesReport Format ML - 2022Manasa PJNo ratings yet

- Cepsiab Sample For Web 2021Document37 pagesCepsiab Sample For Web 2021CCENo ratings yet

- A Study On Industrial PaintersDocument40 pagesA Study On Industrial PaintersJabez DhayanNo ratings yet

- report-format-ML 1 1Document29 pagesreport-format-ML 1 1shivammittal200.smNo ratings yet

- Automotive Skills Development Council Qualifications PackDocument38 pagesAutomotive Skills Development Council Qualifications PackPradnya JoshiNo ratings yet

- Mech. Auto Electrical Electronics - CTS2.0 - NSQFDocument48 pagesMech. Auto Electrical Electronics - CTS2.0 - NSQFMr. ZishanNo ratings yet

- OOAD FinalDocument64 pagesOOAD FinalmformyuseNo ratings yet

- Sample Report College Use FSWDDocument30 pagesSample Report College Use FSWDsujangowda462No ratings yet

- Aravindhan PT CV CSWIP TrainerDocument4 pagesAravindhan PT CV CSWIP TrainerGanesan RamamoorthyNo ratings yet

- 3 Perform Industry CalculationsDocument90 pages3 Perform Industry CalculationsRobinson ConcordiaNo ratings yet

- Electrical Installations: Technical DescriptionDocument27 pagesElectrical Installations: Technical DescriptionBacktrxNo ratings yet

- Sample Report College Use UIUXDocument31 pagesSample Report College Use UIUXshubhamgpt2002No ratings yet

- Mechanical Engineering CAD - LKS 2018Document35 pagesMechanical Engineering CAD - LKS 2018rizalNo ratings yet

- Mechanical Engineering Design CADDocument33 pagesMechanical Engineering Design CADمحمد عبداللهNo ratings yet

- Plumber: Sector - PlumbingDocument44 pagesPlumber: Sector - PlumbingAJITH AJITHNo ratings yet

- Level I Mechanics CurricullumDocument93 pagesLevel I Mechanics CurricullummulualemNo ratings yet

- NSQF - Simplified QF SSCQ4401 V3Document13 pagesNSQF - Simplified QF SSCQ4401 V3RadhakrishnanRaghavaNo ratings yet

- MC SSCQ4201 Product Design Engineer-Mechanical v2.0Document23 pagesMC SSCQ4201 Product Design Engineer-Mechanical v2.0ebookddugkyNo ratings yet

- Internship Report AngurajDocument35 pagesInternship Report AngurajRamesh KumarNo ratings yet

- Mechanical Engineering CAD_WSC2021_TD05_EN (1)Document36 pagesMechanical Engineering CAD_WSC2021_TD05_EN (1)udataashutoshNo ratings yet

- MECH ENG 7 YRS QA QC MAT CONT EXPRDocument3 pagesMECH ENG 7 YRS QA QC MAT CONT EXPRAGNEL V VARKEYNo ratings yet

- Akram CV 2022Document3 pagesAkram CV 2022Akram AlhaddadNo ratings yet

- CTS Dental Laboratory Equipment Technician - CTS - NSQF-5Document42 pagesCTS Dental Laboratory Equipment Technician - CTS - NSQF-5Osama Fadel ahmedNo ratings yet

- CTS Welder (Welding and Inspection) - NSQFDocument34 pagesCTS Welder (Welding and Inspection) - NSQFgarden00589No ratings yet

- Akshay B. (BE Mech 4+ Yrs Exp)Document2 pagesAkshay B. (BE Mech 4+ Yrs Exp)VIJAY VAITNo ratings yet

- CTS MECHANIC AUTO ELECTRICAL and ELECTRONICS_NSQFDocument50 pagesCTS MECHANIC AUTO ELECTRICAL and ELECTRONICS_NSQFguptaad2007No ratings yet

- Anoop_CVDocument3 pagesAnoop_CVnikhil kannaleNo ratings yet

- Welder CTS2.0 NSQF-3Document40 pagesWelder CTS2.0 NSQF-3Prasanta DasNo ratings yet

- Professional Competency: Resources Used in Defining Competency GuidelinesDocument19 pagesProfessional Competency: Resources Used in Defining Competency GuidelinesRaul Dolo QuinonesNo ratings yet

- Competency Standard - Industrial EngineeringDocument62 pagesCompetency Standard - Industrial EngineeringMonirulbtecNo ratings yet

- Shobhna JainDocument5 pagesShobhna JainakshaypagariyaNo ratings yet

- Technical Description-Web - DevelopmentDocument28 pagesTechnical Description-Web - DevelopmentplaliceNo ratings yet

- Career Objective:: Dhamodharan J Mob: No: 9952424967Document6 pagesCareer Objective:: Dhamodharan J Mob: No: 9952424967Rohit RaiNo ratings yet

- Radiology Technician CTS2.0 NSQF-4Document38 pagesRadiology Technician CTS2.0 NSQF-4vijithebest11No ratings yet

- 2 Interpret Drawings and SketchesDocument93 pages2 Interpret Drawings and SketchesRobinson ConcordiaNo ratings yet

- 01 - Process Control IntroDocument16 pages01 - Process Control IntroqaNo ratings yet

- BD - VV (Mechanical) - CTS2.0 - NSQF-4Document76 pagesBD - VV (Mechanical) - CTS2.0 - NSQF-4NALLAMUTHU SNo ratings yet

- Adi BrochureDocument26 pagesAdi BrochureAbhijith ChandranNo ratings yet

- Chartered Engineer Application Guidance: Ceng MpwiDocument7 pagesChartered Engineer Application Guidance: Ceng MpwiAnonymous SOQFPWBNo ratings yet

- CHNM CTS2.0 NSQF-3Document50 pagesCHNM CTS2.0 NSQF-3Abubeker MehammedNo ratings yet

- 4MT17CS007 Aishwarya K InternshipDocument25 pages4MT17CS007 Aishwarya K InternshipPrakash GNo ratings yet

- Automotive Weld Technician - FLX1.0 - NSQF-4Document50 pagesAutomotive Weld Technician - FLX1.0 - NSQF-4Sharwan KumarNo ratings yet

- Driver Cum Mech (LMV) - CTS2.0 - NSQF-3Document32 pagesDriver Cum Mech (LMV) - CTS2.0 - NSQF-3aartheeveeraaNo ratings yet

- Competency Standard and Assessment Guide For Machine Shop PracticeDocument120 pagesCompetency Standard and Assessment Guide For Machine Shop PracticeSushil Kumar ShresthaNo ratings yet

- YesDocument36 pagesYesVenkatesh .VNo ratings yet

- Government of India launches competency-based curriculum for Artisan Using Advanced Tool NSQF Level 4 programDocument40 pagesGovernment of India launches competency-based curriculum for Artisan Using Advanced Tool NSQF Level 4 programPta NahiNo ratings yet

- Software Assurance Competency ModelDocument44 pagesSoftware Assurance Competency ModelSalih DikenNo ratings yet

- Welder: Craftsmen Training Scheme (CTS) NSQF Level-4Document44 pagesWelder: Craftsmen Training Scheme (CTS) NSQF Level-4Loganathan KNo ratings yet

- Government of India launches new curriculum for Welder (Structural) trainingDocument38 pagesGovernment of India launches new curriculum for Welder (Structural) trainingPta NahiNo ratings yet

- Government of India launches 3D printing technician programDocument46 pagesGovernment of India launches 3D printing technician programparveenrathee123No ratings yet

- CTS MMTM - CTS - NSQF-5Document61 pagesCTS MMTM - CTS - NSQF-5Mr AdibNo ratings yet

- 7 Set-Up Welding Equipment SMAWDocument45 pages7 Set-Up Welding Equipment SMAWRobinson ConcordiaNo ratings yet

- Mechanical Engineering Design - CAD: Technical DescriptionDocument35 pagesMechanical Engineering Design - CAD: Technical DescriptionMuchlis EkoNo ratings yet

- Tube Expander-Tools PDFDocument120 pagesTube Expander-Tools PDFmarceilinus devaluantoNo ratings yet

- Assessment Plan Welder Level 2 Version 3 04-15 - Submited 190416 - Corrections 280317Document14 pagesAssessment Plan Welder Level 2 Version 3 04-15 - Submited 190416 - Corrections 280317Anonymous YSJ7TzlNo ratings yet

- PWHT of Air Outlet Header DishDocument5 pagesPWHT of Air Outlet Header DishAnonymous YSJ7TzlNo ratings yet

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 pagesCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalNo ratings yet

- © Ncert Not To Be Republished: A I E, A N M MDocument10 pages© Ncert Not To Be Republished: A I E, A N M MbnkjayaNo ratings yet

- Mikron CrazyDrill Crosspilot BrochureDocument8 pagesMikron CrazyDrill Crosspilot BrochureClaudiu IndreNo ratings yet

- Electrical Properties of Lead Solder AlloyDocument9 pagesElectrical Properties of Lead Solder AlloyVedant PrustyNo ratings yet

- ASTM A536 Ductile Iron Castings Tensile RequirementsDocument1 pageASTM A536 Ductile Iron Castings Tensile RequirementsKhin Aung Shwe67% (3)

- STD00017 Issue 18 Corrosion Prevention (26-07-2017)Document28 pagesSTD00017 Issue 18 Corrosion Prevention (26-07-2017)Ace LeeNo ratings yet

- Nickel Al Bronze For SeawaterDocument21 pagesNickel Al Bronze For Seawaterhinsome LeeNo ratings yet

- List of Code & MannualsDocument1 pageList of Code & MannualsRadheshyam GuptaNo ratings yet

- MaterialsDocument3 pagesMaterialsRevanNo ratings yet

- 1.7225 Material 42CrMo4 +QT Steel Chemical Composition, Equivalent, PropertiesDocument7 pages1.7225 Material 42CrMo4 +QT Steel Chemical Composition, Equivalent, PropertiesAdrian D.RazvanNo ratings yet

- Final File-Rahul ChandraDocument18 pagesFinal File-Rahul Chandra8bitdeku69No ratings yet

- ECE5-014 - A4 - Productsheet REXNORD CHAINDocument2 pagesECE5-014 - A4 - Productsheet REXNORD CHAINTRMNo ratings yet

- China Steel SpecificationDocument45 pagesChina Steel SpecificationMohit KohliNo ratings yet

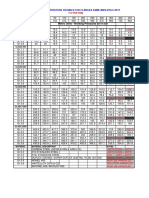

- Pressure/Temperature Ratings For Flanges Asme/Ansi B16.5-2013Document1 pagePressure/Temperature Ratings For Flanges Asme/Ansi B16.5-2013siraphat.bmNo ratings yet

- Ams S 13165Document26 pagesAms S 13165whalenon100% (2)

- BS en 10250-3-2000Document17 pagesBS en 10250-3-2000Mansi BalduwaNo ratings yet

- Ae2253 LPDocument2 pagesAe2253 LPசுஜித் குமார்No ratings yet

- Bill of Materials Cast Iron Double Door Foot ValveDocument1 pageBill of Materials Cast Iron Double Door Foot ValveTanmoy DuttaNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalNo ratings yet

- Lista de Materiales LHMATDocument5 pagesLista de Materiales LHMATfduarteNo ratings yet

- ULMA Advanced Forged Solutions Corporate BrochureDocument8 pagesULMA Advanced Forged Solutions Corporate Brochureaan alfianNo ratings yet

- Extraction of MetalDocument12 pagesExtraction of MetalMonovalent PolyphosphateNo ratings yet

- Astm 183 PDFDocument5 pagesAstm 183 PDFA.YOGAGURUNo ratings yet

- GTU Bachelor Engineering Material Science MetallurgyDocument4 pagesGTU Bachelor Engineering Material Science MetallurgyjanakNo ratings yet

- Mildly Corrosive Solution Applications: Dimensions (Inches)Document2 pagesMildly Corrosive Solution Applications: Dimensions (Inches)Alejandro VegaNo ratings yet

- Hot Corrosion Behavior of GTM SU 718Document16 pagesHot Corrosion Behavior of GTM SU 718Raghav AcharyaNo ratings yet

- En 10083 C50 Steel Plate High Carbon SteelDocument2 pagesEn 10083 C50 Steel Plate High Carbon SteelMatteo BuffoNo ratings yet

- Sour service steel plate requirementsDocument10 pagesSour service steel plate requirementsm5416No ratings yet

- PDFDocument9 pagesPDFvijayachiduNo ratings yet

- Heat TreatingDocument7 pagesHeat TreatingSachinNo ratings yet

- The Effect of Squeeze Pin Dimension and OperationaDocument6 pagesThe Effect of Squeeze Pin Dimension and OperationaLeon GalindoNo ratings yet