Professional Documents

Culture Documents

Flexural Strength Concrete PDF

Uploaded by

ShazwanShah0 ratings0% found this document useful (0 votes)

19 views2 pagesOriginal Title

Flexural Strength Concrete - NRMCA.com.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views2 pagesFlexural Strength Concrete PDF

Uploaded by

ShazwanShahCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

CIP 16 - Flexural Strength Concrete

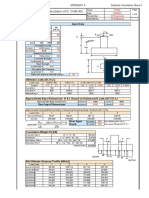

WHAT is Flexural Strength? 1/2 Load 1/2 Load

Flexural strength is one measure of the tensile strength

of concrete. It is a measure of an unreinforced con-

crete beam or slab to resist failure in bending. It is

measured by loading 6 x 6-inch (150 x 150-mm) con-

crete beams with a span length at least three times the

ASTM C 78 - Third-Point Loading - half the load is applied at each third

depth. The flexural strength is expressed as Modulus of the span length. MR is lower than center-point loading. Maximum

of Rupture (MR) in psi (MPa) and is determined by stress is present over the center 1/3 portion of the beam

standard test methods ASTM C 78 (third-point load-

Load

ing) or ASTM C 293 (center-point loading).

Flexural MR is about 10 to 20 percent of compressive

strength depending on the type, size and volume of

coarse aggregate used. However, the best correlation

for specific materials is obtained by laboratory tests

for given materials and mix design. The MR deter- ASTM C 293 - Center-Point Loading - the entire load is applied at the

center span. The MR will be greater than third-point loading. The maxi-

mined by third-point loading is lower than the MR de- mum stress is present only at the center of the beam

termined by center-point loading, sometimes by as much

as 15%.

Never allow the beam surfaces to dry at any time.

WHY Test Flexural Strength? Immerse in saturated limewater for at least 20 hours

Designers of pavements use a theory based on flex- before testing.

ural strength. Therefore, laboratory mix design based Specifications and investigation of apparent low

on flexural strength tests may be required, or a strengths should take into account the higher variabil-

cementitious material content may be selected from ity of flexural strength results. Standard deviation for

past experience to obtain the needed design MR. Some concrete flexural strengths up to 800 psi (5.5 MPa) for

also use MR for field control and acceptance of pave- projects with good control range from about 40 to 80

ments. Very few use flexural testing for structural con- psi (0.3 to 0.6 MPa). Standard deviation values over

crete. Agencies not using flexural strength for field con- 100 psi (0.7 MPa) may indicate testing problems. There

trol generally find the use of compressive strength con- is a high likelihood that testing problems, or moisture

venient and reliable to judge the quality of the concrete differences within a beam caused from premature dry-

as delivered. ing, will cause low strength.

How to Use Flexural Strength? Where a correlation between flexural and compres-

sive strength has been established in the laboratory,

Beam specimens must be properly made in the field. core strengths by ASTM C 42 can be used for com-

Pavement concrete mixtures are stiff (1/2 to 21/2-inch pressive strength to check against the desired value

slump). Consolidate by vibration in accordance with using the ACI 318 criteria of 85 percent of specified

ASTM C 31 and tap sides to release air pockets. For strength for the average of three cores. It is impracti-

higher slump, after rodding, tap the molds to release cal to saw beams from a slab for flexural testing. Saw-

air pockets and spade along the sides to consolidate. ing beams will greatly reduce measured flexural

strength and should not be done. In some instances, NRMCA and the American Concrete Pavement As-

splitting tensile strength of cores by ASTM C 496 is sociation (ACPA) have a policy that compressive

used, but experience is limited on how to apply the data. strength testing is the preferred method of concrete

Another procedure for in-place strength investigation acceptance and that certified technicians should con-

uses compressive strength of cores calibrated by com- duct the testing. ACI Committees 325 and 330 on con-

parison with acceptable placements in proximity to the crete pavement construction and design and the Port-

concrete in question: land Cement Association (PCA) point to the use of

compressive strength tests as more convenient and

Method to Troubleshoot Flexural Strength Using

Compressive Strength of Cores

reliable.

The concrete industry and inspection and testing agen-

Lot 1 Lot 2 Lot 3

cies are much more familiar with traditional cylinder

MR, psi 730 (OK) 688 (?) 731 (OK) compression tests for control and acceptance of con-

Core, psi 4492 4681 4370 crete. Flexure can be used for design purposes, but the

corresponding compressive strength should be used to

Estimate Flexural Strength of Lot 2 = order and accept the concrete. Any time trial batches

730 + 731 are made; both flexural and compressive tests should

4681 x ( ) = 771 psi (OK) be made so that a correlation can be developed for

4492 + 4370 field control.

WHAT are the Problems with Flexure? References:

Flexural tests are extremely sensitive to specimen prepa- 1. How Should Strength be Measured for Concrete Paving? Ri-

ration, handling, and curing procedure. Beams are very chard C. Meininger, NRMCA TIL 420, and Data Summary,

heavy and can be damaged when handled and trans- NRMCA TIL 451, NRMCA, Silver Spring, MD.

ported from the jobsite to the lab. Allowing a beam to 2. Concrete Strength Testing, Peggy Carrasquillo, Chapter 14,

ASTM STP 169C, Significance of Tests and Properties of

dry will yield lower strengths. Beams must be cured in Concrete and Concrete-Making Materials, American Society

a standard manner, and tested while wet. Meeting all for Testing and Mater-ials, West Conshohocken, PA.

these requirements on a jobsite is extremely difficult 3. “Studies of Flexural Strength of Concrete, Part 3, Effects of

often resulting in unreliable and generally low MR val- Variations in Testing Procedures,” Stanton Walker and D. L.

ues. A short period of drying can produce a sharp Bloem, NRMCA Publication No. 75, NRMCA, Silver Spring,

drop in flexural strength. MD.

4. Variation of Laboratory Concrete Flexural Strength Tests, W.

Many state highway agencies have used flexural Charles Greer, Jr., ASTM Cement, Concrete and Aggregates,

strength but are now changing to compressive strength Winter, 1983, American Society for Testing and Materials,

or maturity concepts for job control and quality assur- West Conshohocken, PA.

ance of concrete paving. Cylinder compressive 5. “Concrete Mixture Evaluation and Acceptance for Air Field

strengths are also used for concrete structures. Pavements” Richard C. Meininger and Norm Nelson, NRMCA

Publication 178, September 1991, NRMCA, Silver Spring,

The data point to a need for a review of current test- MD.

ing procedures. They suggest also that, while the flex-

6. Compression vs. Flexural Strength for Quality Control of Pave-

ural strength test is a useful tool in research and in ments, Steve Kosmatka, CTT PL 854, 1985, Portland Cement

laboratory evaluation of concrete ingredients and Association, Skokie, IL.

proportions, it is too sensitive to testing variations

7. Time to Rein in the Flexure Test, Orrin Riley, ACI Concrete

to be usable as a basis for the acceptance or rejec- International, August, 1994, American Concrete Institute,

tion of concrete in the field. (Reference 3) Farmington Hills, MI.

1988, 1989, 1991 AND 2000

You might also like

- Laboratory Experiment 1.3Document6 pagesLaboratory Experiment 1.3Wes FerrerNo ratings yet

- BS 1014-1975 Specification For Pigments For Portland Cement and Portland Cement ProductsDocument15 pagesBS 1014-1975 Specification For Pigments For Portland Cement and Portland Cement ProductsMrcoke SeieNo ratings yet

- Quiz 1 Cost AccountingDocument3 pagesQuiz 1 Cost AccountingAlyssaNo ratings yet

- SHIPPING CONTAINERS ARCHITECTURE Proposal 1Document2 pagesSHIPPING CONTAINERS ARCHITECTURE Proposal 1kartikNo ratings yet

- Structural System in High Rise BuildingDocument7 pagesStructural System in High Rise BuildingjenitaNo ratings yet

- A Guide To Flame Photometer AnalysisDocument17 pagesA Guide To Flame Photometer Analysisarun231187100% (1)

- RefractoriesDocument11 pagesRefractoriesANSH JAINNo ratings yet

- Requisition: FOR Hot Kiln Alignment & Girth Gear InspectionDocument5 pagesRequisition: FOR Hot Kiln Alignment & Girth Gear InspectionAhmad Husni RizalNo ratings yet

- Costs of EqpmentsDocument7 pagesCosts of EqpmentsNishithNo ratings yet

- Curricullum VitaeDocument2 pagesCurricullum Vitaeujang.pantri2001100% (1)

- Flame Photometer TDF-TMFDocument2 pagesFlame Photometer TDF-TMFvtl_murthal6240No ratings yet

- Fluidised Bed SeederDocument11 pagesFluidised Bed SeederAmritanshu ManuNo ratings yet

- Ceramic Phase Equilibrium Diagrams PDFDocument42 pagesCeramic Phase Equilibrium Diagrams PDFPelita Mu'minatus SholihahNo ratings yet

- To Know About The Convenient Level of Small CarDocument35 pagesTo Know About The Convenient Level of Small CarPrannoy RajNo ratings yet

- Process Technology For Efficient and Sustainable Cement ProductionDocument10 pagesProcess Technology For Efficient and Sustainable Cement ProductionAnonymous NxpnI6jCNo ratings yet

- Fineness and StrengthDocument19 pagesFineness and StrengthserkalemtNo ratings yet

- Calcination ProcessDocument82 pagesCalcination ProcessMayur ChhagNo ratings yet

- Flowmaster TheoryDocument68 pagesFlowmaster TheoryCarolina Oliveira MonteiroNo ratings yet

- Engineering Materials: For Further VolumesDocument168 pagesEngineering Materials: For Further VolumesKhalid AbdohNo ratings yet

- Foundation Selection ProcessDocument38 pagesFoundation Selection ProcessGabriel Alexis Malagon Carvajal100% (1)

- Kalina Cycle and Cement IndustryDocument8 pagesKalina Cycle and Cement IndustryEhab SabryNo ratings yet

- Coal Miners SuitDocument4 pagesCoal Miners SuitSudipta BainNo ratings yet

- Friction Torque of A Rotary Shaft Lip SealDocument5 pagesFriction Torque of A Rotary Shaft Lip Sealmans2014No ratings yet

- White CementDocument11 pagesWhite CementLdiabiNo ratings yet

- 15th Euroseminar On Microscopy Applied To Building MaterialsDocument426 pages15th Euroseminar On Microscopy Applied To Building MaterialsAlbertoNo ratings yet

- Cement Manufacturing ProcessDocument11 pagesCement Manufacturing Processashish.khangar9358100% (2)

- IE Welding Simulation With Abaqus 05Document3 pagesIE Welding Simulation With Abaqus 05sajjad_naghdi241100% (1)

- Flame PhotometerDocument5 pagesFlame PhotometerسيليناNo ratings yet

- XRF V1 PDFDocument83 pagesXRF V1 PDFMuhammad Robby Firmansyah100% (1)

- Adaptive Software Development (ASD)Document4 pagesAdaptive Software Development (ASD)Lord KoyoNo ratings yet

- Refractorymaterials 150313053315 Conversion Gate01Document19 pagesRefractorymaterials 150313053315 Conversion Gate01tesfayregs gebretsadikNo ratings yet

- Advanced Heat and MassDocument58 pagesAdvanced Heat and MassJonathan LokeNo ratings yet

- Classification & Properties of Refractories-1Document4 pagesClassification & Properties of Refractories-1pothan33% (3)

- Fluid Mechanics Lectures (1) (University of Baghdad) - Omar F. HasanDocument14 pagesFluid Mechanics Lectures (1) (University of Baghdad) - Omar F. HasanOmar F. HasanNo ratings yet

- Heat Treatment of CastingDocument15 pagesHeat Treatment of CastingjmmshahNo ratings yet

- BV-P2103GB Pneumatic Conveying For The Cement and Gypsum Industries Sept 12Document20 pagesBV-P2103GB Pneumatic Conveying For The Cement and Gypsum Industries Sept 12Kenny RuizNo ratings yet

- Module 2 CementDocument20 pagesModule 2 CementKamil ShairNo ratings yet

- Grain Size PDFDocument4 pagesGrain Size PDFSarthak SachdevaNo ratings yet

- ch01 Mekanik BahanDocument78 pagesch01 Mekanik BahanAzman SamerNo ratings yet

- Free Vibration Analysis ofDocument77 pagesFree Vibration Analysis ofvinaycamNo ratings yet

- Document List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FileDocument4 pagesDocument List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FilemkpqNo ratings yet

- Bucket Elevator CatalogDocument34 pagesBucket Elevator CatalogKoray OzturkNo ratings yet

- Fluid Mechanics by RK Bansal Scribde 556 - Google SearchDocument2 pagesFluid Mechanics by RK Bansal Scribde 556 - Google SearchJebDes0% (2)

- Sizing Calculation of Fabric FilterDocument7 pagesSizing Calculation of Fabric FilterNaveed AkramNo ratings yet

- Cement - Introduction and TypesDocument24 pagesCement - Introduction and TypesHarish KumarNo ratings yet

- The Principles of Coal PreparationDocument13 pagesThe Principles of Coal PreparationNdumiso MagaganeNo ratings yet

- How To Use Excel To Create A Bell CurveDocument12 pagesHow To Use Excel To Create A Bell CurvejoeynagaNo ratings yet

- Cast IronDocument29 pagesCast Ironavutu_kunduruNo ratings yet

- On TweelDocument21 pagesOn TweelRaju UpparapellyNo ratings yet

- Unit Conversion SheetDocument1 pageUnit Conversion SheetImran NowsheriNo ratings yet

- Coal Mill InstallationDocument24 pagesCoal Mill InstallationCristian David MurielNo ratings yet

- The Republic of The Union of Myanmar Ministry of ConstructionDocument8 pagesThe Republic of The Union of Myanmar Ministry of ConstructionZEC LIMITEDNo ratings yet

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDocument56 pages1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguNo ratings yet

- Bitumen Test-Part BDocument31 pagesBitumen Test-Part Bபிரபாகரன் முனிசாமிNo ratings yet

- White Card Course MaterialDocument90 pagesWhite Card Course MaterialphanhaibangNo ratings yet

- Mix Design CalculationDocument8 pagesMix Design CalculationEr Digvijay SinghNo ratings yet

- Collective SecurityDocument10 pagesCollective Securitybakex645No ratings yet

- 6177-4 Press and Shrink FitsDocument11 pages6177-4 Press and Shrink FitsRajesh RajwadeNo ratings yet

- Ball MillDocument23 pagesBall MillSajjad Rasool ChaudhryNo ratings yet

- Literature Review Spur GearDocument3 pagesLiterature Review Spur Gearthai avvaiNo ratings yet

- Useful Links For EngineersDocument9 pagesUseful Links For Engineerssanju712100% (6)

- CIP16-Flexural Strenght of ConcreteDocument2 pagesCIP16-Flexural Strenght of Concrete7774R105No ratings yet

- CIP16 - Flexural Strength of ConcreteDocument2 pagesCIP16 - Flexural Strength of ConcretePECMURUGANNo ratings yet

- CIP 16 - Flexural Strength of ConcreteDocument2 pagesCIP 16 - Flexural Strength of ConcreteEkinawa AwanikeNo ratings yet

- Waste Sector ProjectsDocument5 pagesWaste Sector ProjectsMrcoke SeieNo ratings yet

- Bagasse AshDocument6 pagesBagasse AshMrcoke SeieNo ratings yet

- Bagasse AshDocument6 pagesBagasse AshMrcoke SeieNo ratings yet

- Sand EquivalentDocument11 pagesSand EquivalentMrcoke SeieNo ratings yet

- Damp Proof Membrane To PIFA Standard Datasheet 12-08-2011Document3 pagesDamp Proof Membrane To PIFA Standard Datasheet 12-08-2011Mrcoke SeieNo ratings yet

- Guidance Note 4-31-02 of The UK Water Research Centre.Document6 pagesGuidance Note 4-31-02 of The UK Water Research Centre.Mrcoke SeieNo ratings yet

- MsDocument1 pageMsMrcoke SeieNo ratings yet

- Esteem-Brochure-Concise UpdatedDocument20 pagesEsteem-Brochure-Concise UpdatedmonugeniNo ratings yet

- Shear and Diagonal Tension: GeneralDocument10 pagesShear and Diagonal Tension: GeneralRegine Ignacio SobremonteNo ratings yet

- Power and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2017 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Document8 pagesPower and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2017 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Azhar AliNo ratings yet

- GE March 1978 Soil Structure Interaction and Deformation Problems With Large Oil TanksDocument10 pagesGE March 1978 Soil Structure Interaction and Deformation Problems With Large Oil TanksLuis Orlando Ibanez MoraNo ratings yet

- Notes On Pricing Section GDocument8 pagesNotes On Pricing Section GNeminda Dhanushka KumaradasaNo ratings yet

- IPC 08 THDocument80 pagesIPC 08 THNarendra BokreNo ratings yet

- Design of Steel Truss BridgeDocument8 pagesDesign of Steel Truss BridgePrateek Soumya SharmaNo ratings yet

- Pow 16J00114Document2 pagesPow 16J00114amroussyNo ratings yet

- FINA2320 - ABC - 2023 - Tutorial 1Document5 pagesFINA2320 - ABC - 2023 - Tutorial 1Aaron WongNo ratings yet

- Abcm-Case Study: Caterpillar HouseDocument15 pagesAbcm-Case Study: Caterpillar HouseSaransh YadavNo ratings yet

- Installation of T1501 PIPE ProcedureDocument6 pagesInstallation of T1501 PIPE Procedure1339979No ratings yet

- MODUL Spaceframes PDFDocument43 pagesMODUL Spaceframes PDFAthar JantuNo ratings yet

- Kath-Kuni Wall Sectional Detail: Gable RoofDocument4 pagesKath-Kuni Wall Sectional Detail: Gable RoofKomal GuptaNo ratings yet

- Preliminary Beam Size Calculation: Using NSCPDocument10 pagesPreliminary Beam Size Calculation: Using NSCPJoy lauriaNo ratings yet

- 24 Century Construction Sdn. BHD.: Method Statement FormDocument4 pages24 Century Construction Sdn. BHD.: Method Statement FormnaurahimanNo ratings yet

- Slabs Solutions: Easy Light ModularDocument52 pagesSlabs Solutions: Easy Light ModularFrancis Alberto Espinosa PerezNo ratings yet

- Isolated Foundation Calculation (ACI 318M-95)Document6 pagesIsolated Foundation Calculation (ACI 318M-95)Benmark JabayNo ratings yet

- Brutalism in Serbian Architecture: Style or Necessity?: Facta UniversitatisDocument15 pagesBrutalism in Serbian Architecture: Style or Necessity?: Facta UniversitatisVineet ShrivastavaNo ratings yet

- Market Survey SteelsDocument16 pagesMarket Survey SteelsMehul jainNo ratings yet

- New 6.0 M Ret. WallDocument84 pagesNew 6.0 M Ret. WallBharathiNo ratings yet

- MSS SP-69 Pipe Hangers and Supports - Selection and ApplicatDocument18 pagesMSS SP-69 Pipe Hangers and Supports - Selection and Applicatkaiyoom100% (2)

- Tropical ArchitectureDocument5 pagesTropical ArchitectureYen DaNo ratings yet

- Lean EN 2018Document48 pagesLean EN 2018Karan KarnikNo ratings yet

- Warm Humid Climate 1. OrientationDocument4 pagesWarm Humid Climate 1. OrientationmariyaNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 202Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 202Vivek KumarNo ratings yet

- SOW - General - Brick Laying. TowradgiDocument15 pagesSOW - General - Brick Laying. TowradgiJonald DagsaNo ratings yet

- Acceptance Testing of Concrete PipeDocument2 pagesAcceptance Testing of Concrete PipeMagdykamelwilliamNo ratings yet