Professional Documents

Culture Documents

PSV

Uploaded by

s33d_2010Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PSV

Uploaded by

s33d_2010Copyright:

Available Formats

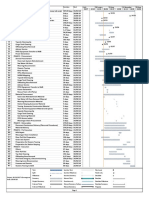

Pressure Safety Valves (PSV)

Course Details

It's paramount for safety that anyone working around PSVs understands how they function,

has the ability to recognise common faults and knows exactly how to rectify these. Score has

provided comprehensive PSV overhaul and test services for all types of relief valve to the

energy industries worldwide for over 30 years. Our team of over 100 field service technicians

are trained in-house and our courses are continually updated based on experiences in the

field, making our training team second to none when it comes to PSV training.

Course Objectives

Following training, attendees will be able to:

o Identify PSV types including conventional, bellows and pilot operated

o Describe function and operation

o State common defects

o Test and certify conventional, bellows and pilot operated PSVs

Course Outlines:

o An overview of PSV types, fail modes and insight into issues

o PSV terminology

o Interpretation of PSV tag information

o The function and operation of various PSV types

o How to recognise common defects and the causes of poor performance

o Guidance on problems found during strip down, component inspection and

reassembly

o PSV calibration

o Pilot operated PSVs

o Maintenance programmes

o PSV overhaul and test procedures (including test specifications )

o Pilot operated PSV overhaul and test procedures

Description, concepts and devices

Set pressure

Overpressure and accumulation

Counter pressure

Reseat pressure and blowdown

Types and parts of a valve

Rupture disks

Calculation and selection of the valve type

Conventional

Balanced

Pilot operated

Discharge area: gas, liquid, steam, biphasic

Discharge using multiple valves

PSV Specification

Size selection

Materials selection

Accessories

Specification of rupture disks, types, concepts and accessories.

Types of disks

Fabrication range

Rupture tolerance

Materials

Accessories

ASME I and API STD 2000 valves

Application of ASME I valves

Application of API STD 2000 valves

Sizing and specification

Safety valves and SIL

Workshop-based training also covers:

o The rectification of common PSV faults/defects

o Pre-test strip down, rebuild, testing and re-certification of direct spring (conventional

and bellows) and pilot operated PSVs

o Pilot operated PSVs

o PSV test verification/witnessing

o Completion of examples of relevant documentation

Practical training is delivered in our custom-built training workshop, resourced with a full

range of specialist equipment including a PSV test cell.

An extensive range of training valves in a variety of conditions is used during workshop

sessions to provide training delegates with experience in realistic working scenarios.

Particular brands of PSV may be sourced for training on request.

o Understand key elements in strip and refurbishment

Who Should Attend

This course has been designed for engineers, operators and mechanical technicians

Course duration:

5 DAYS

You might also like

- Bonanza A36 ChecklistDocument10 pagesBonanza A36 Checklistalbucur100% (4)

- HSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Document5 pagesHSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Saeed JabbariNo ratings yet

- Corrosion Damage in Waste Heat Boilers Major Root Causes and RemediationDocument10 pagesCorrosion Damage in Waste Heat Boilers Major Root Causes and Remediationvaratharajan g rNo ratings yet

- Online Medicine Industry Competitor AnalysisDocument14 pagesOnline Medicine Industry Competitor Analysispawangadiya1210No ratings yet

- Shell Corrosion Under InsulationDocument16 pagesShell Corrosion Under InsulationDavide CongiuNo ratings yet

- Challenges of Welding of Catalyst TubesDocument16 pagesChallenges of Welding of Catalyst TubesTravis SkinnerNo ratings yet

- Asset Mothballing (PRS088a)Document2 pagesAsset Mothballing (PRS088a)john.quintanai5159No ratings yet

- Analyses of Superheater Tube From BoilerDocument8 pagesAnalyses of Superheater Tube From Boilerromi_hamdaniNo ratings yet

- PEC corrosion monitoringDocument4 pagesPEC corrosion monitoringmahesh070No ratings yet

- Tosco Final ReportDocument72 pagesTosco Final ReportmyxyptlkNo ratings yet

- Why Do Waste Heat Boilers Fail?: Excessive TemperatureDocument4 pagesWhy Do Waste Heat Boilers Fail?: Excessive TemperatureMaheesha GunathungaNo ratings yet

- RP G103 2007Document82 pagesRP G103 2007Robert SmallwoodNo ratings yet

- Remaining Life Assessment of Engineering ComponentsDocument23 pagesRemaining Life Assessment of Engineering ComponentsIndah PermataNo ratings yet

- Life Extension Methodology For Floating Production InstallationsDocument37 pagesLife Extension Methodology For Floating Production InstallationsDinhQuangDatNo ratings yet

- Asset Integrity Management System (AIMS) Well IntegrityDocument23 pagesAsset Integrity Management System (AIMS) Well IntegrityMohd RezalNo ratings yet

- BP Investigation ReportDocument97 pagesBP Investigation ReportArdi MufrodiNo ratings yet

- Condenser and Heat Exchanger Tube RestorationDocument6 pagesCondenser and Heat Exchanger Tube RestorationspalaniyandiNo ratings yet

- ImpactOfLoadFollowingOnPowerPlantCostAndPerformance FR Rev1 20121010Document49 pagesImpactOfLoadFollowingOnPowerPlantCostAndPerformance FR Rev1 20121010Anonymous knICaxNo ratings yet

- Datasheet Briosil Primer 6-7360P - Eng - 25-08-11Document3 pagesDatasheet Briosil Primer 6-7360P - Eng - 25-08-11SUBODHNo ratings yet

- API RP 530-2009 Data BookDocument120 pagesAPI RP 530-2009 Data Bookscribd_alphaNo ratings yet

- Brunel OGJS Energy OutlookDocument74 pagesBrunel OGJS Energy OutlookSUDHEER NANDINo ratings yet

- Heater Tube Life ManagementDocument19 pagesHeater Tube Life ManagementWeniton Oliveira100% (1)

- Corrosion Guide PDFDocument23 pagesCorrosion Guide PDFredaNo ratings yet

- Decommissioning FPSO detailed chronogramDocument1 pageDecommissioning FPSO detailed chronogramRaphael Bruno100% (2)

- Technical Bulletin 149Document3 pagesTechnical Bulletin 149osperNo ratings yet

- Coked FailureDocument43 pagesCoked FailureMahendra Rathore100% (2)

- Biomass Gasification Smallwood04patelDocument37 pagesBiomass Gasification Smallwood04patelGiovani de MoraisNo ratings yet

- Nace STD TM 0199-99Document8 pagesNace STD TM 0199-99gabriela troncosoNo ratings yet

- Integrity Testing of Aboveground Storage TanksDocument43 pagesIntegrity Testing of Aboveground Storage TanksMakhfud Edy100% (1)

- Replace Gas-Assisted Glycol Pumps with Electric for Efficiency and EmissionsDocument11 pagesReplace Gas-Assisted Glycol Pumps with Electric for Efficiency and EmissionsAmji ShahNo ratings yet

- Galvanic Technique: An Overview ofDocument11 pagesGalvanic Technique: An Overview ofAnnie TahirNo ratings yet

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- Boiler Tube FailureDocument7 pagesBoiler Tube FailureBhupendra GobadeNo ratings yet

- Air Cooler Cleaning TechniqueDocument4 pagesAir Cooler Cleaning Techniquedinakaranpatel100% (1)

- Leak Prevention Repair GuidelinesDocument20 pagesLeak Prevention Repair Guidelinesshank100No ratings yet

- Hot Bolting FPSO BrazilDocument1 pageHot Bolting FPSO BrazilKhan Arshi100% (1)

- MQ SP I 7015 PDFDocument66 pagesMQ SP I 7015 PDFJaseelKanhirathinkalNo ratings yet

- Ipea PRVDocument51 pagesIpea PRVAnonymous qhVGVpNo ratings yet

- Upgrade Your Furnace For Clean FuelsDocument4 pagesUpgrade Your Furnace For Clean Fuelssagar1503No ratings yet

- Pipeline Inspection RecordDocument41 pagesPipeline Inspection RecordJayesh J PillaiNo ratings yet

- Leak Testing & Plugging Procedure For SYN. Loop Waste Heat BoilerDocument3 pagesLeak Testing & Plugging Procedure For SYN. Loop Waste Heat BoilerBESTINNo ratings yet

- 01 Introduction To DunlopDocument33 pages01 Introduction To DunlopFikret YenenNo ratings yet

- Profile Engr. Owais Manzoor (Lead Metallurgist) : International AffiliationDocument6 pagesProfile Engr. Owais Manzoor (Lead Metallurgist) : International AffiliationOwais Manzoor MalikNo ratings yet

- Pressure Relief Device Inspection: Review of NBIC Part 2, Par. 2.5/ Jurisdictional IssuesDocument37 pagesPressure Relief Device Inspection: Review of NBIC Part 2, Par. 2.5/ Jurisdictional IssuesPham LanphuongNo ratings yet

- CUIDocument18 pagesCUIaecf_13No ratings yet

- CRP Sampling Literature PDFDocument8 pagesCRP Sampling Literature PDFgullenariNo ratings yet

- Plant Inspection ReportDocument9 pagesPlant Inspection ReportKevin Keanu Ong100% (1)

- How Corrosion Happens in Oil and Gas IndustryDocument6 pagesHow Corrosion Happens in Oil and Gas Industrysurekha surekhaNo ratings yet

- Subsea Pipelines Pre Commissioning 1687771720Document19 pagesSubsea Pipelines Pre Commissioning 1687771720Doğuhan DenizgezNo ratings yet

- Case Study of The Use of API 581 On HK and HP Material Furnace TubesDocument6 pagesCase Study of The Use of API 581 On HK and HP Material Furnace TubeskbNo ratings yet

- Example Problem RBI PSV - Rev1Document17 pagesExample Problem RBI PSV - Rev1RizkiNo ratings yet

- The Fires and Explosion at BP Oil Grangemouth Refinery LTDDocument48 pagesThe Fires and Explosion at BP Oil Grangemouth Refinery LTDRoo FaNo ratings yet

- Corrosion Monitoring Methods (Chevron)Document65 pagesCorrosion Monitoring Methods (Chevron)Sergey KichenkoNo ratings yet

- Integrity Management With S-RBI: Using The w-IMS ToolDocument28 pagesIntegrity Management With S-RBI: Using The w-IMS ToolHari ShNo ratings yet

- Inspecting Fractionation Towers PDFDocument5 pagesInspecting Fractionation Towers PDFChem.EnggNo ratings yet

- Waterbox InspectionDocument2 pagesWaterbox InspectionFallo SusiloNo ratings yet

- EX-6 Isolating and Overhauling Safeties of Centrifugal Pumps, Reciprocating Pumps, Screw Pumps, Gear Pumps, Vane PumpsDocument1 pageEX-6 Isolating and Overhauling Safeties of Centrifugal Pumps, Reciprocating Pumps, Screw Pumps, Gear Pumps, Vane PumpsAayush AgrawalNo ratings yet

- Request For Quotation (RFQ) For The Provision of Vehicle Hire ServiceDocument6 pagesRequest For Quotation (RFQ) For The Provision of Vehicle Hire ServiceYonas LeulNo ratings yet

- Southern Company/MHI Ltd. Plant Barry CCS DemonstrationDocument23 pagesSouthern Company/MHI Ltd. Plant Barry CCS Demonstrationrecsco2100% (1)

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988From EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNo ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- PDFDocument1 pagePDFs33d_2010No ratings yet

- Basic Vibration Analyst Training & Certification ISO 18436 Category IDocument2 pagesBasic Vibration Analyst Training & Certification ISO 18436 Category Is33d_2010No ratings yet

- Advanced Interpret. of Engineering DRWG Advance Interpretation of Engineering Drawings and Diagrams (Includes P &ID, PFD)Document3 pagesAdvanced Interpret. of Engineering DRWG Advance Interpretation of Engineering Drawings and Diagrams (Includes P &ID, PFD)s33d_2010No ratings yet

- Pipeline System Integrity in HealthcareDocument3 pagesPipeline System Integrity in Healthcares33d_2010No ratings yet

- Water Treatment Technology PDFDocument4 pagesWater Treatment Technology PDFs33d_2010No ratings yet

- Motor Operation & MaintenanceDocument4 pagesMotor Operation & Maintenances33d_2010No ratings yet

- Time ManagementDocument19 pagesTime Managements33d_2010No ratings yet

- Water Treatment Technology PDFDocument4 pagesWater Treatment Technology PDFs33d_2010No ratings yet

- CVDocument5 pagesCVs33d_2010100% (1)

- Advanced Welder Certified - Updated With Daily AgendaDocument4 pagesAdvanced Welder Certified - Updated With Daily Agendas33d_2010No ratings yet

- Pipeline System Integrity in HealthcareDocument3 pagesPipeline System Integrity in Healthcares33d_2010No ratings yet

- Hydralic and Pump CalculationsDocument4 pagesHydralic and Pump Calculationss33d_2010No ratings yet

- TanksDocument5 pagesTankss33d_2010No ratings yet

- Gas Pipeline Accident and Incident Reporting and InteractionsDocument5 pagesGas Pipeline Accident and Incident Reporting and Interactionss33d_2010No ratings yet

- TanksDocument5 pagesTankss33d_2010No ratings yet

- Project Risk Management CourseDocument3 pagesProject Risk Management Courses33d_2010No ratings yet

- TanksDocument5 pagesTankss33d_2010No ratings yet

- Offshore Assest Integrity ManagementDocument4 pagesOffshore Assest Integrity Managements33d_2010No ratings yet

- Pumping Sizing Selection TypesDocument4 pagesPumping Sizing Selection Typess33d_2010No ratings yet

- Well Design Drilling and WorkoverDocument6 pagesWell Design Drilling and Workovers33d_2010100% (1)

- Dry Gas SealDocument5 pagesDry Gas Seals33d_2010No ratings yet

- Fabrication and InstallationDocument6 pagesFabrication and Installations33d_2010No ratings yet

- Piping Stress AnalysisDocument2 pagesPiping Stress Analysiss33d_2010No ratings yet

- PV, EliteDocument2 pagesPV, Elites33d_2010No ratings yet

- Fabrication and InstallationDocument6 pagesFabrication and Installations33d_2010No ratings yet

- PV, EliteDocument2 pagesPV, Elites33d_2010No ratings yet

- Bolted Joint Make UpDocument2 pagesBolted Joint Make Ups33d_2010No ratings yet

- Dry Gas SealDocument5 pagesDry Gas Seals33d_2010No ratings yet

- Maximize Oil Recovery with EOR TrainingDocument3 pagesMaximize Oil Recovery with EOR Trainings33d_2010No ratings yet

- Bolted Joint Make UpDocument2 pagesBolted Joint Make Ups33d_2010No ratings yet

- Finasteride 5mg PDFDocument18 pagesFinasteride 5mg PDFddandan_2No ratings yet

- GCS Guilford County Schools 2020 Staff Manual Omits Obesity From CDC Covid WarningsDocument26 pagesGCS Guilford County Schools 2020 Staff Manual Omits Obesity From CDC Covid WarningscitizenwellsNo ratings yet

- Cambridge O Level: English Language 1123/22Document4 pagesCambridge O Level: English Language 1123/22Shania SeneviratneNo ratings yet

- Curriculum DesignDocument20 pagesCurriculum DesignRose Glaire Alaine TabraNo ratings yet

- Preserving Food Drying Fruits and VegetablesDocument12 pagesPreserving Food Drying Fruits and Vegetablespdxpharris100% (1)

- Vrs PresentationDocument24 pagesVrs PresentationshrutipalkarNo ratings yet

- Grade 5. Unit 15Document6 pagesGrade 5. Unit 15Đình ThuậnNo ratings yet

- Edc Power Plant FacilitiesDocument32 pagesEdc Power Plant FacilitiesMichael TayactacNo ratings yet

- Argumentative EssayDocument5 pagesArgumentative Essayapi-538443988No ratings yet

- Section - A: Holiday Homework For Grade XiDocument7 pagesSection - A: Holiday Homework For Grade XiGM Ali KawsarNo ratings yet

- The Life and Works of Dr. Jose P. Rizal: Rizal As A DoctorDocument14 pagesThe Life and Works of Dr. Jose P. Rizal: Rizal As A DoctorPamela MorcillaNo ratings yet

- Codex CRD26Document9 pagesCodex CRD26arely svetlana gaspar badilloNo ratings yet

- Aircraft Instruments and Avionics PDFDocument211 pagesAircraft Instruments and Avionics PDFairbuk doeing88% (8)

- Jear C PB 2018 PDFDocument174 pagesJear C PB 2018 PDFArasu RajendranNo ratings yet

- Complementary Therapies in Clinical Practice: Effect of Aromatherapy On Post-Partum Complications: A Systematic ReviewDocument7 pagesComplementary Therapies in Clinical Practice: Effect of Aromatherapy On Post-Partum Complications: A Systematic ReviewAras PinantiNo ratings yet

- F9Q816Document4 pagesF9Q816Charaf-eddine RamehNo ratings yet

- WP Stratasys TopFiveReasonsDocument7 pagesWP Stratasys TopFiveReasonscititorulturmentatNo ratings yet

- Jurnal Dermatitis AtopikDocument20 pagesJurnal Dermatitis AtopikchintyaNo ratings yet

- Riel Comun Fstguide2Document2 pagesRiel Comun Fstguide2Rosita TejedaNo ratings yet

- Discover the training secrets of legendary bodybuildersDocument129 pagesDiscover the training secrets of legendary bodybuildersfatmir100% (7)

- APC Symmetra PX-2Document8 pagesAPC Symmetra PX-2drastir_777No ratings yet

- Honey & Bee Product Recipes: November 2007Document29 pagesHoney & Bee Product Recipes: November 2007Kyra ThomasNo ratings yet

- Seven Appear in Court On Cocaine, P Charges After North Island Drug Raids - NZ HeraldDocument3 pagesSeven Appear in Court On Cocaine, P Charges After North Island Drug Raids - NZ HeraldVagamundos ArgentinosNo ratings yet

- 0972 June 2021 QP 41 Cie Igcse Physics - Pdfquestion7Document2 pages0972 June 2021 QP 41 Cie Igcse Physics - Pdfquestion7Kareem YouakimNo ratings yet

- Boiler Feedwater ControlDocument14 pagesBoiler Feedwater ControlJonas PeraterNo ratings yet

- Chapter III Pharmacokinetics: Durge Raj GhalanDocument64 pagesChapter III Pharmacokinetics: Durge Raj GhalanDurge Raj Ghalan100% (3)

- Online Pharmacy: Customer ProfilingDocument6 pagesOnline Pharmacy: Customer ProfilingGeorge SebastianNo ratings yet

- Casa de Moda DolcegabbanaDocument4 pagesCasa de Moda Dolcegabbanadianaionelav23No ratings yet