Professional Documents

Culture Documents

A Case Study of Ground Improvement Using Piers

A Case Study of Ground Improvement Using Piers

Uploaded by

Ashraf Gomah Mohamed ElshamandyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Case Study of Ground Improvement Using Piers

A Case Study of Ground Improvement Using Piers

Uploaded by

Ashraf Gomah Mohamed ElshamandyCopyright:

Available Formats

A Case Study of Ground Improvement Using

Impact™ Piers Method

Alireza Afkhami Aghda, MASc

Troy Issigonis, P.Eng

Horizon Engineering Inc., North Vancouver, BC, Canada

ABSTRACT

This paper presents the case study of ground improvement using Impact Pier™ soil reinforcement at the Chilliwack

General Hospital in southwest British Columbia, Canada. The subject structure is a post-disaster 2-storey emergency

room addition to the existing hospital. Subsurface stratigraphy consists of a “firm to stiff” silty clay to clayey silt which

extends to 1.5 to 3 metres below ground surface, overlying a “very loose to compact” silty sand/ sand that extends to 4.3

to 5.2 metres. Below this depth a “compact to very dense” sandy gravel to gravelly sand was encountered. The ground

water level was observed at 2.7 to 3 metres below ground surface. The loose to compact silty sand was found to be

potentially liquefiable. The subject Impact Pier soil reinforcement method was utilized to improve the properties of the

liquefiable layer at the subject site.

RÉSUMÉ

Ce papier présente l'étude d’un cas d'amélioration du sol en utilisant le renforcement de sol Jetée d'Impact MD à

l'Hôpital général de Chilliwack au sud-ouest de la Columbie-britannique au Canada. La structure en question est une

section d’urgence de deux étages utilisée en cas de désastre ajoutée à l'hôpital existant. La stratigraphie de la sous-

surface se compose d'une couche de glaise limoneuse à limon glaiseux "solide à rigide" qui s'étend de 1,5 à de 3 mètres

sous la surface, au-dessus d’une couche de sable limoneux / sable "très desserré à compact” de 4,3 à 5,2 mètres sous

la surface. Sous cette couche, on retrouve un gravier sablonneux / sable caillouteux “compact à très dense”. Le niveau

de la nappe phréatique est de 2,7 à 3 mètres sous la surface. On a déterminé que le sable limoneux était

potentiellement liquéfiable. Le renforcement de sol Jetée d'Impact MD été utilisé pour améliorer les propriétés de la

couche liquéfiable sur le site en question.

1 INTRODUCTION 1.5 to 3 metres is considered to be potentially

compressible and represents a foundation design

Soil liquefaction has always been a significant issue consideration. The underlying sand/ sand and gravel

during earthquakes when pore pressure may build-up and materials are inferred to be generally compact to dense.

cause loss of shear strength of soil. In this case, lateral However, there are seams of saturated, loose material

displacement and vertical settlements may occur which present within these deposits that represent a seismic

damage buildings, roads and other structures. During the design consideration which can be addressed by

last few decades, many ground improvement methods performing ground improvement in the form of

have been developed to prevent pore pressure build-up densification using either Vibroflotation or rammed

during earthquake, most of them are based on densifying, aggregate pier solutions including Impact Pier™ methods.

reinforcing and draining the potentially liquefiable A reinforcement and densification design has been

materials. Many differing techniques can be used to prepared by Horizon Engineering Inc. that addressed the

accomplish this, including stone columns and Rammed material identified as potentially liquefiable. Deformation

Aggregate Piers. This paper describes a project where analyses for post-liquefaction lateral displacement and

Rammed Aggregate Piers were installed using the ‘Impact vertical settlement were carried out to compare the effect

Pier System’. of densification. This analyses show that by improving the

top 5 metres of soil media and reducing the potential of

liquefaction, post-earthquake deformations decrease

3

2 BACKGROUND significantly to an acceptable range . From a structural

point of view, the building maintains serviceability after the

Chilliwack General Hospital has been in service for many design magnitude earthquake.

years. The subject building is an addition to the existing

hospital and consists of a new 2 storey post-disaster

emergency room and lab building. This project will 3 IMPACT™ PIER METHODOLOGY

modernize and improve the physical environments in the

emergency department and ambulatory care areas. Rammed Aggregate Pier solutions using the Impact Pier

The site is generally underlain with a series of system is a patented technology that uses vertically

interbedded, fluvially deposited clayey silt, sand, sand and forced displacement technology, attempting to densify and

gravel and silt materials (Figure 1). The clayey silt reinforce loose and weak soil below groundwater,

encountered from the surface to a depth of approximately including loose sand, silt, clay, mixed soil layers, and

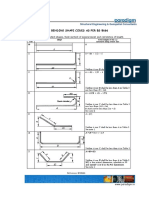

Figure 1. Schematic

S soil profile in the subject site.

uncontrolle ed fill. Vertica

al impact enerrgy combined with 4 TEST SECTIO

ON

downward crowd force effectively

e drivees the steel ca asing

into the soils and also constructs a dense aggre egate The most common n footing in th he subject pro oject is a

column an nd improves the e surrounding soil.

s 1.2m*1.2m footing with

w contact pre essure of 130 kPa which

The un nique installation process dissplaces soil during is deefined as an “F1 Type Fo ooting”. To asssess the

installationn and utilizes vertical

v impact ramming energy to perfoormance of Imp pact Pier syste em, a test program was

construct Rammed

R Aggrregate Pier (RA AP) elements. RAP arrannged in which, 9 piers were installed at a portion of

solutions are intended to provide total and differe ential o of the pierrs was installed at the centre

site; one e of an F1

settlementt control and in ncrease bearin ng support to meet type footing

f location

n. A full scale load

l test was carried

c out

project req quirements. in an effort to assesss the performance with resp pect to soil

1. The e cavity is cre eated to full depth

d by driving a orcement and improved bearing

reinfo b capaccity. Eight

specially designed

d manddrel and tampe er foot using a large surroounding piers were installe ed to provide e ground

static forcee augmented by b dynamic verttical impact energy. improovement with respect to red ducing the po otential for

Tamper fo oot diameters vary

v from 0.3 to

o 0.4 m and de epths liqueffaction. A Locck-Block loade ed platform (1..2m*1.2m)

normally range

r from ab bout 2 to 14 m, depending g on was used to represent the loading conditions similar to

design req quirements. This method elim minates spoils as a all thosee expected at a F1 type footting under Serrviceability

penetrated d soils are displaced laterally. A sacrificiall cap Statee Loading conditions.

c Th

his loaded platform’s

prevents soil

s from enterin ng the tamper footf and mandrrel. settle

ement was mon nitored for 48 hours

h and an immediate

i

2. Afteer driving to de esign depth, thet hollow mandrel settle

ement of 5mm was measure ed. No time dependant

d

serves as a conduit for the placementt of aggregate.. The settle

ement was observed. The 5m mm settlement magnitude

m

aggregate is placed insid de the mandrel and the mand drel is is accceptable. Figure 2 illustrates test section layyout.

lifted, leavving the sacrific

cial cap at the bottom of the pier.

The tamper foot is lifte ed approximately 1 m and then

driven bacck down 0.7 m, forming a 0.3 m thick compa acted

lift. Comp paction is ach hieved through h static force and

dynamic im mpact energy from the ham mmer. The ham mmer

densifies aggregate

a vertiically and the beveled

b tamperr foot

forces ag ggregate latera ally into cavitty sidewalls. It is

envisaged that this resu ults in coupling g with surroun nding

soils and settlement

s con

ntrol. The full displacement piers

also lead to densificatio on increases in soils which h are

densifiable e.

3. Folllowing installation, RAP elementse reinforce

slopes and embankmen nts, support sh hallow foundattions,

floor slabss and tank pad ds. The intent of the elemen nts is

also to attrract stress, resulting reduced settlements.

This meth hod has alread dy been used in Europe and d the

United Sta ates; however, since the subje ect site was the e first

project in Canada utilizing the Impactt Pier methodo ology

for groun nd improveme ent, Horizon Engineering Inc.

designed a test section to evaluate the t performancce of

this metho od prior to proce eed to installation of all piers..

Figurre 2. Test sectio

on layout.

Also five auger holes and five DCPT soundings were

carried out within the extent of this test section to

investigate the effect of installing piers on soil

compactness. The results are presented in Figure 3. As it

implies, DCPT blow counts (N60) after installing piers are

between 20 to 470 percent higher than before, which

represents satisfactory densification. The data indicates

that cleaner sands gain more improvement than silty

sands and fine grained soils.

Figure 3. Comparison of average DCPT blows/ft before

and after installing piers at Test section.

5 PIERS INSTALLATION

Pier layout prepared by Horizon Engineering comprises a

triangulation of 440 points within the subject site with main

focus on footing locations.

A specialty contractor (Rapid Impact Piers Ltd.) was

retained to install the Impact piers. During installation,

length of piers and volume of gravel used for each pier

were measured; Average pier diameters were then

calculated. Actual length of each pier depended on the

depth of sandy gravel layer at which point mandrel

installation stopped in practice. Pier installations occurred

during a period of 15 working days.

Using this field data, spatial distribution of length,

average diameter, volume of gravel and date of

installation for each Impact Pier are presented in Figure 4.

As it can be seen, average pier diameter is about 650 mm

to 750 mm with minimum and maximum values of 530

mm and 830 mm. Average diameter of each installed pier

can be considered as an indication of local soil density

before installation; The bigger is the diameter, the less is

the compactness of intact soil.

Shortest piers installed on west side (vicinity of

existing hospital) were 3.05 m and longest piers mostly on

south-east were 4.90 m in length. Figure 4-b shows that

very dense sandy gravel layer is generally deeper on east

and south east of the subject site, resulting in longer

Impact piers to reach this layer. Figure 4: variation of Impact Piers characteristics across

the site.

6 QUALITY CONTROL RESULTS

Eight quality control auger holes and eight DCPT

soundings were carried out after installing about 200 piers

to assess the performance. According to the role of fines

content in liquefaction assessment, sieve analyses tests

were carried out on samples taken from the auger holes

to obtain percent fines and choose an appropriate design

curve for target DCPT blows/ft. Laboratory tests show that

most of the samples taken from 1 m to 3.5 m of depth,

have at least 35 percent of fines content.

Figure 5 compares the DCPT blows/ft (N60) before and

after ground improvement with required DCPT blow

counts/ft according to design specification. Satisfactory

improvement of DCPT blows/ft is observed for most

depths whereas DCPTs are close enough to design

specification curve between 1.5 m and 2.5 m in which soil

consists of silt and silty sand.

Figure 6. Effect of distance from piers, on soil

compactness.

A sensitivity study was also carried out at a triangular grid

of Impact Piers to assess the effect of distance from

installed piers on soil compactness by performing 3 DCPT

soundings with minimum distance of 1.45m, 1.25m and

0.6m from piers, shown as AH09-Q5, AH09-Q5A and

AH09-Q5B on Figure 6 respectively. As it implies,

soundings at 1.45m and 1.25m distances do not clearly

differentiate; while sounding at 0.6m shows higher DCPT

values comparatively to the two other soundings.

7 CONCLUSION

According to this case study, the Impact Pier system is a

fast ground improvement methodology which increases

soil bearing capacity and the ground density. Also,

crushed gravels used as the material for installing piers,

provide good hydraulic conductivity which can reduce the

susceptibility of the soil to liquefaction by preventing pore

pressure build-up. The bottom feed method of placing the

crushed gravel greatly reduces uncertainty regarding the

location of the gravel placement.

Results of this case study show that coarse grained

materials gain better improvement rather than fine grained

soils.

Impact Pier is considered as an effective method for

ground improvement against liquefaction. The vertical

elements can be relied upon to attract stress and reduce

settlement.

8 ACKNOWLEDGMENT

For the purpose of visualization of data in this paper,

Figure 5. Average DCPT blow counts/ft before and after Novo Tech Software Inc. (www.novotechsoftware.com)

ground improvement across the site. has improved their existing VisLog software to add

required features for importing and visualizing Impact

Piers installation data.

Information regarding Rammed Aggregate Pier™

technology including the Impact™ Pier system has been

extracted from websites of Geopier Foundation Company,

Inc. and Rapid Impact Compactors Ltd.

(www.geopier.com , www.rapidimpact.ca).

9 REFERENCES

Horizon Engineering Inc., August 2008. Geotechnical

Report

Horizon Engineering Inc. November 2008. Densification

Design – Post Earthquake Ground Movements.

Horizon Engineering Inc., December 2008. Subgrade

Densification Plan.

You might also like

- KJ - Gibbs, W.G.Holtz - (1957) - Research On Determining The Density of Sands by Spoon Penetration TestingDocument5 pagesKJ - Gibbs, W.G.Holtz - (1957) - Research On Determining The Density of Sands by Spoon Penetration TestingAnonymous PibYPghNo ratings yet

- Chapitre 2 Techniques de Preparation Du Chantier (Terrassements)Document30 pagesChapitre 2 Techniques de Preparation Du Chantier (Terrassements)Milano100% (2)

- InstallGuide 4.5Document4 pagesInstallGuide 4.5Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Gopal Ranjan-Compressibility and ConsolidationDocument65 pagesGopal Ranjan-Compressibility and ConsolidationEshwar Nukala100% (1)

- EM 1110-1-1904 - Settlement AnalysisDocument205 pagesEM 1110-1-1904 - Settlement AnalysisPDHLibrary100% (1)

- 2000 Increasing Pull-Out Capacity of Granular Pile Anchors in Expansive Soils Using Base GeosyntheticsDocument12 pages2000 Increasing Pull-Out Capacity of Granular Pile Anchors in Expansive Soils Using Base GeosyntheticsS R Kumar Konathala100% (1)

- Finite Element Modelling of Marine ClayDocument14 pagesFinite Element Modelling of Marine ClayOng Tai BoonNo ratings yet

- Compensated Friction-Pile Foundation To Reduce The Seulement of Buildings On The Highly Compressible Volcanic Clay of Mexico CityDocument6 pagesCompensated Friction-Pile Foundation To Reduce The Seulement of Buildings On The Highly Compressible Volcanic Clay of Mexico CityinfoNo ratings yet

- Arslan Et Al 2007Document6 pagesArslan Et Al 2007giridharrajeshNo ratings yet

- Les VRDDocument17 pagesLes VRDSarah TerbahNo ratings yet

- Bâtiment 2Document33 pagesBâtiment 2Abderrahim BoulanouarNo ratings yet

- Geotech 2011137 P 3Document12 pagesGeotech 2011137 P 3Imane EddohaNo ratings yet

- Design of Piled Bridge Abutments On Soft Clays - Stewart1994 - MUST READDocument20 pagesDesign of Piled Bridge Abutments On Soft Clays - Stewart1994 - MUST READThiago GisbertNo ratings yet

- GeoMontreal 2013 - Sam - Bhatt - J - Thomas - PaperDocument5 pagesGeoMontreal 2013 - Sam - Bhatt - J - Thomas - PaperJimmy ThomasNo ratings yet

- Stal9781607500315 1064Document4 pagesStal9781607500315 1064Leonardo TejedorNo ratings yet

- Amélioration Des Sols de Fondation Par Vibroflottation PDFDocument8 pagesAmélioration Des Sols de Fondation Par Vibroflottation PDFZANZANNo ratings yet

- The Effect of Strength Anisotropy On The Behaviour of Embankments On Soft GroundDocument11 pagesThe Effect of Strength Anisotropy On The Behaviour of Embankments On Soft GroundHuy Lê QuangNo ratings yet

- 06 Technical Committee 17 Tc211 06Document5 pages06 Technical Committee 17 Tc211 06ALINo ratings yet

- Heyman - Measurement of The Influence of Lateral Earth PressureDocument5 pagesHeyman - Measurement of The Influence of Lateral Earth PressureMarcelaMarquesNo ratings yet

- TP DRDocument30 pagesTP DRBoris GanmavoNo ratings yet

- Geotech 1996077 P 69Document4 pagesGeotech 1996077 P 69HAMMZANo ratings yet

- Prévention BTP Réistance Des SolsDocument2 pagesPrévention BTP Réistance Des SolsMONTAGNENo ratings yet

- Controle AmeliorationDocument12 pagesControle AmeliorationaymeneNo ratings yet

- 03 Corrige 3Document7 pages03 Corrige 3حمزة شافيNo ratings yet

- PORTANCE DU SOLpdf2 PDFDocument27 pagesPORTANCE DU SOLpdf2 PDFOlga Mugangu100% (1)

- BLPC 191 PP 55-62 CombarieuDocument8 pagesBLPC 191 PP 55-62 CombarieuADJOUTNo ratings yet

- CBDocument4 pagesCBAbdrzk ChkriNo ratings yet

- Chapitre 1-Ouvrages de Soutènement - 2020Document8 pagesChapitre 1-Ouvrages de Soutènement - 2020Háífà MathlouthiNo ratings yet

- Densification Des Sols Par Explosifs Soil Densification The Explosive MethodDocument10 pagesDensification Des Sols Par Explosifs Soil Densification The Explosive MethodAMOUZOUN ChristopheNo ratings yet

- Les Techniques D'améliorations Des SolsDocument35 pagesLes Techniques D'améliorations Des SolsDan EdidiNo ratings yet

- 6-Fondations SuperficiellesDocument26 pages6-Fondations SuperficiellesSerigne Abdoul Aziz MbodjNo ratings yet

- Chapitre II VRDDocument24 pagesChapitre II VRDDominique KouekamNo ratings yet

- Pré Chargement DR HidjebDocument10 pagesPré Chargement DR HidjebAmani BnhNo ratings yet

- Hsieh 1998Document14 pagesHsieh 1998ilobo24100% (1)

- Practical Experience With Piled Raft Design For Tall BuildingsDocument4 pagesPractical Experience With Piled Raft Design For Tall Buildingsmrlee28No ratings yet

- Fondations Superficielles Sur Sol Amélioré Par Inclusions Rigides Verticales-Combarieu, 1990-53.3Document12 pagesFondations Superficielles Sur Sol Amélioré Par Inclusions Rigides Verticales-Combarieu, 1990-53.3Pilo71No ratings yet

- Deep Excavation With Multi Anchored DiapDocument6 pagesDeep Excavation With Multi Anchored DiapLuthfi NNo ratings yet

- Calcul Du Soulevement Dun Pieu Isole FonDocument5 pagesCalcul Du Soulevement Dun Pieu Isole FonSylvain sergentNo ratings yet

- Ges Coor TRVX (Terrassement)Document7 pagesGes Coor TRVX (Terrassement)semara rachidNo ratings yet

- Expose Techniques de Traitements Des SolsDocument20 pagesExpose Techniques de Traitements Des SolsLibasse BANo ratings yet

- Compactage Et Comportement de Sols Fins Humides: Compaction and Behaviour of Wet Fine-Grained SoilsDocument12 pagesCompactage Et Comportement de Sols Fins Humides: Compaction and Behaviour of Wet Fine-Grained SoilsToufik AbbasNo ratings yet

- Fondations Superficielles GFTRDDocument17 pagesFondations Superficielles GFTRDbadaromuald6No ratings yet

- 19th - ICSMGE - Full - Paper - Ground - Improvement - Using - Rigid - Inclusion - For - The - Foundation - of - LNG - Tanks (Hor Et Al, 2017)Document4 pages19th - ICSMGE - Full - Paper - Ground - Improvement - Using - Rigid - Inclusion - For - The - Foundation - of - LNG - Tanks (Hor Et Al, 2017)Boramy HORNo ratings yet

- Réserves RelevéesDocument2 pagesRéserves RelevéesAnonymous IiR8xAa6No ratings yet

- Cours Fondation l3gc - Fada 2021Document229 pagesCours Fondation l3gc - Fada 2021resilience multiservice100% (1)

- Petits Barrages Et Digues Deversantes Jan.95Document81 pagesPetits Barrages Et Digues Deversantes Jan.95Wambié NagaroNo ratings yet

- Essais de La Géotechnique RoutièreDocument142 pagesEssais de La Géotechnique Routièremustapha12 mustapha12No ratings yet

- Adoption de La Techniques de Consolidation Par Collons Ballastées Sous Jacents Aux Fondations D'ouvrages D'artDocument9 pagesAdoption de La Techniques de Consolidation Par Collons Ballastées Sous Jacents Aux Fondations D'ouvrages D'artMohamedAhfourNo ratings yet

- NAAMANE PROJECT-converted - 2 PDFDocument68 pagesNAAMANE PROJECT-converted - 2 PDFYahya FdNo ratings yet

- Chapitre 1 Compactage Du SolDocument3 pagesChapitre 1 Compactage Du Solno pain no gainNo ratings yet

- TerrassementDocument16 pagesTerrassementstoufa73No ratings yet

- TTDocument7 pagesTTAmir HeniNo ratings yet

- Chapitre Iii Les FondationsDocument23 pagesChapitre Iii Les FondationshansdevisdjimelinawaNo ratings yet

- VRD Cours1Terrasement Master1ArchitectureDocument17 pagesVRD Cours1Terrasement Master1Architectureabdelmjid lamineNo ratings yet

- 4.04.ecran Etanche Rex Modif Ecoul Digue en ChargeDocument10 pages4.04.ecran Etanche Rex Modif Ecoul Digue en ChargeAhmed HLNo ratings yet

- Ii-Fondations SuperficiellesDocument45 pagesIi-Fondations SuperficiellesFadwa El KhouNo ratings yet

- 1 - Gen Et Al 2011 Effectiveness of Partially Penetrating Vertical DrainsDocument15 pages1 - Gen Et Al 2011 Effectiveness of Partially Penetrating Vertical DrainsAnonymous VJHwe0XBNo ratings yet

- Site Characterization For The HZM Immersed TunnelDocument6 pagesSite Characterization For The HZM Immersed TunnelMuhammad Rizaldi NurauliaNo ratings yet

- Technologie de Construction IDocument172 pagesTechnologie de Construction INguyen Hoang Anh50% (2)

- Asma Ben 213Document16 pagesAsma Ben 213AsmaNo ratings yet

- ABS Submersible Sewage Pump XFP 100J To 501U - GBDocument2 pagesABS Submersible Sewage Pump XFP 100J To 501U - GBAshraf Gomah Mohamed ElshamandyNo ratings yet

- Abs Submersible Sewage Pump XFP 80C - 151e (GB)Document2 pagesAbs Submersible Sewage Pump XFP 80C - 151e (GB)Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Group Presentation 2008 (GB)Document23 pagesGroup Presentation 2008 (GB)Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Tapered Beam and Column Elements in Unbraced Framed StructuresDocument15 pagesTapered Beam and Column Elements in Unbraced Framed StructuresAshraf Gomah Mohamed ElshamandyNo ratings yet

- 2014-2015 3rd Year Civil - Seepage Analysis in SoilsDocument30 pages2014-2015 3rd Year Civil - Seepage Analysis in SoilsAshraf Gomah Mohamed ElshamandyNo ratings yet

- BS-EN1992-1-1 - E - 2014 What Is NewDocument1 pageBS-EN1992-1-1 - E - 2014 What Is NewAshraf Gomah Mohamed Elshamandy0% (1)

- FPI Marine BrochureDocument7 pagesFPI Marine BrochureAshraf Gomah Mohamed ElshamandyNo ratings yet

- Thrust Block DesignDocument14 pagesThrust Block DesignAshraf Gomah Mohamed ElshamandyNo ratings yet

- Comparison Between Standards For Seismic Design of Liquid Storage Tanks With Respect To Soil-Foundation-Structure Interaction and Uplift 2012 PDFDocument7 pagesComparison Between Standards For Seismic Design of Liquid Storage Tanks With Respect To Soil-Foundation-Structure Interaction and Uplift 2012 PDFAshraf Gomah Mohamed ElshamandyNo ratings yet

- Bar Bending Shape Codes As Per Bs 8666: Structural Engineering & Geospatial ConsultantsDocument7 pagesBar Bending Shape Codes As Per Bs 8666: Structural Engineering & Geospatial ConsultantsAshraf Gomah Mohamed ElshamandyNo ratings yet

- Bar Bending Shape Codes As Per Bs 8666: Structural Engineering & Geospatial ConsultantsDocument7 pagesBar Bending Shape Codes As Per Bs 8666: Structural Engineering & Geospatial ConsultantsAshraf Gomah Mohamed ElshamandyNo ratings yet

- Evaluating Existing Culverts For Load Capacity Allowing For Soil Structure Interaction 2010Document312 pagesEvaluating Existing Culverts For Load Capacity Allowing For Soil Structure Interaction 2010Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Analysis of The Settlement of Pile Groups 1968Document24 pagesAnalysis of The Settlement of Pile Groups 1968Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Bar Bending Shape Codes As Per Bs 8666: Structural Engineering & Geospatial ConsultantsDocument7 pagesBar Bending Shape Codes As Per Bs 8666: Structural Engineering & Geospatial ConsultantsAshraf Gomah Mohamed ElshamandyNo ratings yet

- Punching Capacity Nguyen-Minh2012Document12 pagesPunching Capacity Nguyen-Minh2012Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Astm D 5640 - Standard Guide For Selection of Weirs and Flumes For Open-Channel Flow Measurement of WaterDocument7 pagesAstm D 5640 - Standard Guide For Selection of Weirs and Flumes For Open-Channel Flow Measurement of WaterAshraf Gomah Mohamed ElshamandyNo ratings yet

- Engineering GeologyDocument117 pagesEngineering GeologyJoshua Mong'areNo ratings yet

- Price List April 2012 - March 2013Document15 pagesPrice List April 2012 - March 2013Sajjad Amin AminNo ratings yet

- Black Soils of Orissa and Their ManagementDocument3 pagesBlack Soils of Orissa and Their ManagementHanumantha Rao BNo ratings yet

- New Zealand On-Site Stormwater Management Guideline - Water Environment Research FoundationDocument74 pagesNew Zealand On-Site Stormwater Management Guideline - Water Environment Research FoundationFree Rain Garden Manuals100% (1)

- Ajay Stb. Mud Block Ppt2003Document17 pagesAjay Stb. Mud Block Ppt2003ajaykatnauriNo ratings yet

- Fear Robertson Undrainedstrengthofsands CGJ1995Document13 pagesFear Robertson Undrainedstrengthofsands CGJ1995Ten FreireNo ratings yet

- Soil LiquefactionDocument3 pagesSoil Liquefactionniladatika nilaNo ratings yet

- Jharia CoalfieldDocument27 pagesJharia CoalfieldRasmiranjan Jena RajaNo ratings yet

- Geometallurgy of Australian Uranium DepositsDocument65 pagesGeometallurgy of Australian Uranium DepositsENZO ROMÁN MEZANo ratings yet

- Triaxial Test - Set 2Document8 pagesTriaxial Test - Set 2ahm531No ratings yet

- D20sw9-EXCAVATION & FILLINGDocument12 pagesD20sw9-EXCAVATION & FILLINGIlias AsimakisNo ratings yet

- Appendix 1 Calculation of A Chemical Formula From A Mineral AnalysisDocument14 pagesAppendix 1 Calculation of A Chemical Formula From A Mineral Analysisyasin septianNo ratings yet

- 16 11 2021 Yarn Export Price OfferDocument1 page16 11 2021 Yarn Export Price OffercottontradeNo ratings yet

- Construction On Soft Soil1Document80 pagesConstruction On Soft Soil1BluebelgianNo ratings yet

- PI2016 - Geotechnical Characterization of Clearwater Shales For DesignDocument8 pagesPI2016 - Geotechnical Characterization of Clearwater Shales For DesignmauricioNo ratings yet

- Volume Changes Behaviour of Cohesive SoilsDocument13 pagesVolume Changes Behaviour of Cohesive SoilsAlberto AmparánNo ratings yet

- Amrut MittiDocument8 pagesAmrut Mittidonbosskiss100% (2)

- Soil PermeabilityDocument4 pagesSoil PermeabilityKesha623100% (1)

- Yehezkiel Girsang - Karya Tulis IlmiahDocument12 pagesYehezkiel Girsang - Karya Tulis Ilmiahkielo grsgNo ratings yet

- Gonzalo Castro SlidesDocument34 pagesGonzalo Castro SlidesFrancisco Javier Acuña OlateNo ratings yet

- Daivajna VallabhaDocument46 pagesDaivajna VallabhaajaydevmalikNo ratings yet

- Lab 2 CV321 s11184759 FinalDocument18 pagesLab 2 CV321 s11184759 Finalshraddha NadanNo ratings yet

- NZGS - Retaining Walls Part 1 Poster V5Document1 pageNZGS - Retaining Walls Part 1 Poster V5ilamaranNo ratings yet

- CV - Hendro FujionoDocument2 pagesCV - Hendro FujionoRobert ShieldsNo ratings yet

- Hasil Bor DasDocument74 pagesHasil Bor Dasvorda buaymadangNo ratings yet

- Soil ErosionDocument22 pagesSoil Erosiontrudy-annNo ratings yet

- Exploration Work Plan - LimestonDocument12 pagesExploration Work Plan - LimestonAbrahamNo ratings yet

- Edaran Program HATTI MENGAJARDocument1 pageEdaran Program HATTI MENGAJARMuhammad Fayruz RizqiNo ratings yet