Professional Documents

Culture Documents

Abs Submersible Sewage Pump XFP 80C - 151e (GB)

Uploaded by

Ashraf Gomah Mohamed ElshamandyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abs Submersible Sewage Pump XFP 80C - 151e (GB)

Uploaded by

Ashraf Gomah Mohamed ElshamandyCopyright:

Available Formats

ABS submersible sewage pump XFP 80C - 151E

Robust, reliable, submersible pumps, with premium efficiency

motors from 1.3 to 11.0 kW. For pumping of wastewater and

sewage from buildings and sites in private, commercial,

industrial and municipal areas in accordance with EN 12050-1.

Features

□ The water-pressure-tight, encapsulated, fully flood-proof

motor and the pump section form a compact, robust,

modular construction.

□ NEMA Class A temperature rise.

□ Premium Efficiency Motors in accordance with IEC 60034-30

level IE3 with testing in accordance with IEC60034-2-1.

□ Continuously rated motor in submerged and non-submerged

applications.

□ Double mechanical seals; SiC-SiC at the medium side, SiC-C at

the motor. All seals are independent of rotation direction and

resistant to temperature shock.

□ Anti-wicking cable plug solution.

□ High-efficiency hydraulic design with Contrablock (80E & 151E)

or Contrablock Plus (80C, 100C, 100E & 150E) impeller.

□ Free solids passage of 75 mm.

□ Lubricated-for-life bearings with a calculated life time of

min. 50,000 hours.

□ Stainless steel shaft. Designed with high safety factor

to prevent fatigue fracture.

□ Temperature monitoring by thermal sensors (140 °C) in the

stator windings.

□ Seal monitoring by a moisture probe (DI) in the seal chamber Motor

which signals an inspection alert if there is leakage at the Premium Efficiency IE3, three-phase, squirrel-cage motor;

shaft seals. 400 V; 50 Hz; 2-pole (2900 r/min), 4-pole (1450) and 6-pole (980).

□ Smooth outer design to reduce rag build-up.

□ Stainless steel lifting hoop. Protection type IP 68, with stator insulation Class H.

□ DN 80, DN 100 and DN 150 radial slot DIN flange discharge.

□ Maximum allowable temperature of the medium for continuous Start-up: 1.3 - 2.9 kW = direct on line (DOL).

operation is 40 °C. 4.0 - 11.0 kW = star-delta (YΔ).

□ Maximum submergence depth of 20 m.

□ Explosion-proof as standard, in accordance with Motors with other operating voltages and frequencies are

international standards EExd II BT4 and ATEX. also available.

Performance curves Identification Code: e.g. XFP 80C CB1.3 PE22/4-C-50

Hydraulics:

DN: 80 100 150* XFP ........ Product range

50 8 ............ Discharge outlet DN (cm)

H 50 Hz 0 . ...........Hydraulic type

45

(m) C ............ Volute opening (dia. mm)

40 CB.......... Impeller type

1 ............ Number of impeller vanes

35 3 ............ Impeller size

30

Motor:

PE ......... Premium Efficiency

XFP 80E-CB1

25 22 .......... Motor power P2 kW x 10

4 ............ Number of poles

20 C ............ Volute opening (dia. mm)

15 50 .......... Frequency

XFP 100E-CB1

10

XFP 150E-CB1

5 XFP 80C-CB1

XFP 151E-CB2

Q XFP 100C-CB1

(l/s) 10 20 30 40 50 60 70 80 90 100 110 120 130 140

Pump selection

Please use the ABSEL or ACCT program as the only valid

* Minimum flow rate Q selection tool.

Standard and options

Description Standard Option

Mains voltage 400 V 3~ 230, 500, 230/400, 400/695, 500/866 V

Voltage tolerance ± 10% -

Motor efficiency Premium Eff. IE3 -

Insulation class H

Temperature monitor Bi-metallic switch Thermistor

Seal monitor DI moisture probe -

Start-up Direct on line (DOL), star-delta (YΔ) -

Approvals EEx -

Mechanical seal (at medium side) SiC-SiC -

Mechanical seal (at motor side) SiC-C -

O-rings NBR -

Cables H07RN8-F EMC

Cable length (m) 10 20, 30, 40, 50

Protective coating 2k Epoxy 120 µm 2k Epoxy 400 µm

Provision for lifting hoist Lifting hoop (150 mm height) -

Cooling Self-cooling -

Installation Wet well Dry well or transportable

Technical Data

XFP Motor Impeller Rated Motor power* Rated Speed Cable Weight

size voltage (kW) current size

(V) P1 P2 (A) (r/min) (kg)

80C-CB1 PE29/4 2 400 3~ 3.4 3.0 6.4 1450 7G1.5 94

PE22/4 3, 4 400 3~ 2.5 2.2 4.6 1450 7G1.5 91

PE13/6 1, 2, 4 400 3~ 1.6 1.3 3.6 980 7G1.5 89

100C-CB1 PE29/4 2 400 3~ 3.4 3.0 6.4 1450 7G1.5 98

PE22/4 3, 4 400 3~ 2.5 2.2 4.6 1450 7G1.5 96

PE13/6 1, 2, 4 400 3~ 1.6 1.3 3.6 980 7G1.5 94

80E-CB1 PE110/2 1, 2, 3 400 3~ 12.1 11.0 20.1 2900 10G1.5 166

ABS submersible sewage pump XFP 80C-151E GB 10.2009 ABS reserves the right to alter specifications due to technical developments.

PE70/2 4 400 3~ 7.7 7.0 13.5 2900 10G1.5 153

100E-CB1 PE90/4 1, 2 400 3~ 10.0 9.0 18.1 1450 10G1.5 178

PE60/4 3, 4 400 3~ 6.7 6.0 13.6 1450 10G1.5 167

150E-CB1 PE90/4 1, 2 400 3~ 10.0 9.0 18.1 1450 10G1.5 184

PE60/4 3, 4 400 3~ 6.7 6.0 13.6 1450 10G1.5 171

PE40/4 5 400 3~ 4.4 4.0 8.4 1450 10G1.5 153

151E-CB2 PE90/4 1 400 3~ 10.0 9.0 18.1 1450 10G1.5 188

PE60/4 3 400 3~ 6.7 6.0 13.6 1450 10G1.5 177

PE40/4 5 400 3~ 4.4 4.0 8.4 1450 10G1.5 158

* P1 = power at mains. P2 = power at motor shaft.

Materials Materials

Description Material Description Material

Motor housing Cast iron EN-GJL-250 Motor shaft Stainless steel 1.4021 (AISI 420)

Volute Cast iron EN-GJL-250 Lifting hoop Stainless steel 1.4401 (AISI 316)

Impeller Cast iron EN-GJL-250 Fasteners Stainless steel 1.4401 (AISI 316)

Bottom plate Cast iron EN-GJL-250

ABS Group, Roskildevägen 1, Box 394, SE-201 23 Malmö, Sweden, Tel +46 40 35 04 00, Fax +46 40 30 50 45

www.absgroup.com

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Norsok L-004 Piping Fabrication 2010 PDFDocument30 pagesNorsok L-004 Piping Fabrication 2010 PDFarifin rizal100% (1)

- InstallGuide 4.5Document4 pagesInstallGuide 4.5Ashraf Gomah Mohamed ElshamandyNo ratings yet

- 5 Variable K-MapDocument15 pages5 Variable K-MapBen SewellNo ratings yet

- The Respiratory System - Freebie GuideDocument4 pagesThe Respiratory System - Freebie GuideIndustria Quimica0% (1)

- Sewage Pump XFP 80C-150EDocument2 pagesSewage Pump XFP 80C-150EJose CastroNo ratings yet

- Cat-Ix58 Ix58s Cx58-EDocument2 pagesCat-Ix58 Ix58s Cx58-EDimaco VideoNo ratings yet

- Feedback Encoder For Big Size Motors - Precise Optical Sensing - Very Flat Design - Through Hollow Shaft Up To Ø 30 MM - Robust Die Cast Housing With IP65 ProtectionDocument2 pagesFeedback Encoder For Big Size Motors - Precise Optical Sensing - Very Flat Design - Through Hollow Shaft Up To Ø 30 MM - Robust Die Cast Housing With IP65 ProtectionArmando AristimunoNo ratings yet

- Catalouge 68Document2 pagesCatalouge 68Mais OmarNo ratings yet

- Incremental Encoder SeriesDocument2 pagesIncremental Encoder SeriesS SaNo ratings yet

- Manual de Operacion DGW310MC 220Document11 pagesManual de Operacion DGW310MC 220Uma A. UcheNo ratings yet

- Item 4 - (P-110) - RASDocument7 pagesItem 4 - (P-110) - RASanse1No ratings yet

- ROTAPULS Incremental Encoder Series C50 Technical SpecificationsDocument2 pagesROTAPULS Incremental Encoder Series C50 Technical SpecificationsbaiadilNo ratings yet

- Catalouge 71Document4 pagesCatalouge 71Mais OmarNo ratings yet

- Optimize submersible sewage pump XFP 100J-501U titleDocument2 pagesOptimize submersible sewage pump XFP 100J-501U titleAshraf Gomah Mohamed ElshamandyNo ratings yet

- Ex470 490TC (B) 120 (HC) (182) BFDocument2 pagesEx470 490TC (B) 120 (HC) (182) BFcarlos salazarNo ratings yet

- ROTAPULS Incremental Encoders GuideDocument2 pagesROTAPULS Incremental Encoders GuideGab SotNo ratings yet

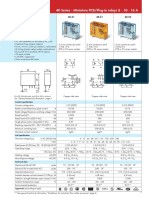

- Finder Relays Series 40 PDFDocument8 pagesFinder Relays Series 40 PDFqwertysasNo ratings yet

- Features: 40 Series - Miniature PCB/Plug-in Relays 8 - 10 - 16 ADocument16 pagesFeatures: 40 Series - Miniature PCB/Plug-in Relays 8 - 10 - 16 ADante LupuNo ratings yet

- Finder Relays Series 40 PDFDocument8 pagesFinder Relays Series 40 PDFCosmin ConstantinescuNo ratings yet

- DataBook_cdxDocument15 pagesDataBook_cdxLê Anh TuấnNo ratings yet

- Cat-Ck61-E Encoder de Pistón Prensa 1Document2 pagesCat-Ck61-E Encoder de Pistón Prensa 1Ariel SantambrosioNo ratings yet

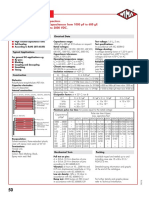

- Wima MKS 4-4147Document13 pagesWima MKS 4-4147Anonymous vKD3FG6RkNo ratings yet

- Cat I65 - It65 eDocument2 pagesCat I65 - It65 egustavo gonzalezNo ratings yet

- CSF 110Document46 pagesCSF 110damanchurw210No ratings yet

- Cat I65 - It65 eDocument2 pagesCat I65 - It65 eMarc Che CollonsNo ratings yet

- ROTACOD Absolute Multi-Turn Encoders GuideDocument3 pagesROTACOD Absolute Multi-Turn Encoders GuideAhmad DagamsehNo ratings yet

- Elevator Encoder Series C82Document2 pagesElevator Encoder Series C82minhasranaNo ratings yet

- LISH - Submittal For OutdoorDocument20 pagesLISH - Submittal For OutdoorJimmy AnticonaNo ratings yet

- Screw Limit Switches XRBA PDFDocument16 pagesScrew Limit Switches XRBA PDFAlphaNo ratings yet

- Three-phase Squirrel-Cage-Motor data sheetDocument1 pageThree-phase Squirrel-Cage-Motor data sheetzeepython100% (1)

- Operating ranges and specifications for MMI 50 centrifugal pumpsDocument8 pagesOperating ranges and specifications for MMI 50 centrifugal pumpsTaimoorNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- Oemer DC Motors QCCDocument21 pagesOemer DC Motors QCCTroformasNo ratings yet

- R410A Duct Inverter Air Conditioner Technical ManualDocument68 pagesR410A Duct Inverter Air Conditioner Technical ManualEdwin JaramilloNo ratings yet

- Efficient submersible pump for wastewater and industrial applicationsDocument2 pagesEfficient submersible pump for wastewater and industrial applicationsdansalsaNo ratings yet

- DC Brushless Fan Specification ApprovalDocument16 pagesDC Brushless Fan Specification ApprovalManuelLentiNo ratings yet

- METALLIZED POLYPROPYLENE MOTOR RUN CAPACITORS SAFETYDocument24 pagesMETALLIZED POLYPROPYLENE MOTOR RUN CAPACITORS SAFETYJesus VerduzcoNo ratings yet

- TCLT100. Series Optocoupler, Phototransistor Output, SOP-4L, Long Mini-Flat PackageDocument10 pagesTCLT100. Series Optocoupler, Phototransistor Output, SOP-4L, Long Mini-Flat PackageHưng HQNo ratings yet

- Manual Potenciometro TocosDocument2 pagesManual Potenciometro TocosLuis Ángel Crisóstomo QuiñonesNo ratings yet

- All-Round Wheeled Encoder For Conveyor Systems Series: (Other Resolutions On Request)Document2 pagesAll-Round Wheeled Encoder For Conveyor Systems Series: (Other Resolutions On Request)RyszardNo ratings yet

- SRC Technical DataDocument6 pagesSRC Technical DataKamel NaitNo ratings yet

- 1LE1001-0EB42-2FB4 Datasheet enDocument1 page1LE1001-0EB42-2FB4 Datasheet enAde FaisalNo ratings yet

- NLCatDocument7 pagesNLCatpaulNo ratings yet

- EAC58EA Sensor VelocidadDocument3 pagesEAC58EA Sensor VelocidadrajalingamNo ratings yet

- GEP65-2 (3-Phase) : Diesel Generating SetDocument6 pagesGEP65-2 (3-Phase) : Diesel Generating SetAbomazen GalalNo ratings yet

- Astec DC-DC Converter - Aa20bDocument6 pagesAstec DC-DC Converter - Aa20bcountry boyNo ratings yet

- Finder 58 Series Relay Interface ModulesDocument12 pagesFinder 58 Series Relay Interface ModulesValerija SilinaNo ratings yet

- 60hz Medium Static Type Concealed Duct Unit Service Manual - Editado NewDocument26 pages60hz Medium Static Type Concealed Duct Unit Service Manual - Editado NewManuel Guardia AraujoNo ratings yet

- Vnso LiteratureDocument5 pagesVnso LiteraturepabloNo ratings yet

- Technical Features and Possible ConfigurationsDocument2 pagesTechnical Features and Possible Configurationsfiti_95No ratings yet

- Smart choice for power distributionDocument11 pagesSmart choice for power distributionrangsa0% (1)

- SW 50 poly RMA solar panel specificationsDocument2 pagesSW 50 poly RMA solar panel specificationsعبدالاله عقيليNo ratings yet

- 3410565Document3 pages3410565qsifozejcrNo ratings yet

- MULTI-V - INDOOR - 36k-48k - Common Exploded - View 2015.11.11 EU and LATDocument8 pagesMULTI-V - INDOOR - 36k-48k - Common Exploded - View 2015.11.11 EU and LATfhelfenstellerNo ratings yet

- E WIMA MKP 4Document11 pagesE WIMA MKP 4kmyisusNo ratings yet

- 1LE1503-1DB43-4FK4_datasheet_enDocument1 page1LE1503-1DB43-4FK4_datasheet_enNicolas RossettoNo ratings yet

- Wima CapacitorDocument11 pagesWima Capacitorchiranjib_kNo ratings yet

- Манометры ТМ (ТВ,ТМВ) Серия10 РОСМАDocument4 pagesМанометры ТМ (ТВ,ТМВ) Серия10 РОСМАSergNo ratings yet

- b41588 A3478 T - Ae4634ffc6Document12 pagesb41588 A3478 T - Ae4634ffc6kerusacba_2011No ratings yet

- Cat C82 e PDFDocument2 pagesCat C82 e PDFSuong TranNo ratings yet

- 8,800TEU Container Carrier LV Transformer SpecificationDocument21 pages8,800TEU Container Carrier LV Transformer SpecificationSerhiiNo ratings yet

- Series Incremental Encoders: Environmental SpecificationsDocument2 pagesSeries Incremental Encoders: Environmental SpecificationsKen LeeNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- EPM-DEM 2.0: Safety InstructionsDocument1 pageEPM-DEM 2.0: Safety InstructionsAshraf Gomah Mohamed ElshamandyNo ratings yet

- Manufacturing Units: We Know How Water WorksDocument12 pagesManufacturing Units: We Know How Water WorksAshraf Gomah Mohamed ElshamandyNo ratings yet

- CDS-101 C-001 Architectural Room Programme March 2015Document6 pagesCDS-101 C-001 Architectural Room Programme March 2015naveen_86No ratings yet

- Optimize submersible sewage pump XFP 100J-501U titleDocument2 pagesOptimize submersible sewage pump XFP 100J-501U titleAshraf Gomah Mohamed ElshamandyNo ratings yet

- Group Presentation 2008 (GB)Document23 pagesGroup Presentation 2008 (GB)Ashraf Gomah Mohamed ElshamandyNo ratings yet

- 2014-2015 3rd Year Civil - Seepage Analysis in SoilsDocument30 pages2014-2015 3rd Year Civil - Seepage Analysis in SoilsAshraf Gomah Mohamed ElshamandyNo ratings yet

- Hyperstatic Effects PDFDocument13 pagesHyperstatic Effects PDFAnonymous 0tT3SeNo ratings yet

- BS-EN1992-1-1 - E - 2014 What Is NewDocument1 pageBS-EN1992-1-1 - E - 2014 What Is NewAshraf Gomah Mohamed Elshamandy0% (1)

- General Method For Determining Bearing Capacity of Domes With Radial Girders and Circular Elements On Circular Base, With Different Stiffening - 2016Document7 pagesGeneral Method For Determining Bearing Capacity of Domes With Radial Girders and Circular Elements On Circular Base, With Different Stiffening - 2016Ashraf Gomah Mohamed ElshamandyNo ratings yet

- FPI Marine BrochureDocument7 pagesFPI Marine BrochureAshraf Gomah Mohamed ElshamandyNo ratings yet

- 9 Fully Welded Splice 9.1 Description of ConnectionDocument7 pages9 Fully Welded Splice 9.1 Description of ConnectionAshraf Gomah Mohamed ElshamandyNo ratings yet

- Piping Design Layout and Stress AnalysisDocument19 pagesPiping Design Layout and Stress AnalysisSolomon EmavwodiaNo ratings yet

- Mat Foundations Using STAADDocument5 pagesMat Foundations Using STAADSha Mas ShaNo ratings yet

- DIS 3D Isolation Systems PDFDocument1 pageDIS 3D Isolation Systems PDFAshraf Gomah Mohamed ElshamandyNo ratings yet

- Tapered Beam and Column Elements in Unbraced Framed StructuresDocument15 pagesTapered Beam and Column Elements in Unbraced Framed StructuresAshraf Gomah Mohamed ElshamandyNo ratings yet

- Tank Foundation New IdeaDocument9 pagesTank Foundation New IdeaAshraf Gomah Mohamed ElshamandyNo ratings yet

- D9. Pisos AisladoresDocument1 pageD9. Pisos AisladoresJ RCNo ratings yet

- Seismic Isolation in South AmericaDocument8 pagesSeismic Isolation in South AmericaAshraf Gomah Mohamed ElshamandyNo ratings yet

- Novo BPTDocument11 pagesNovo BPTAshraf Gomah Mohamed ElshamandyNo ratings yet

- D9. Pisos AisladoresDocument1 pageD9. Pisos AisladoresJ RCNo ratings yet

- Comparison For Steel TanksDocument19 pagesComparison For Steel TanksAshraf Gomah Mohamed ElshamandyNo ratings yet

- Comparison Between Standards For Seismic Design of Liquid Storage Tanks With Respect To Soil-Foundation-Structure Interaction and Uplift 2012 PDFDocument7 pagesComparison Between Standards For Seismic Design of Liquid Storage Tanks With Respect To Soil-Foundation-Structure Interaction and Uplift 2012 PDFAshraf Gomah Mohamed ElshamandyNo ratings yet

- Mpact of 2015 Earthquakes On A Local Hospital in NepalDocument16 pagesMpact of 2015 Earthquakes On A Local Hospital in NepalAshraf Gomah Mohamed ElshamandyNo ratings yet

- Service Life Assessment of Concrete Structures in The GCC CountriesDocument41 pagesService Life Assessment of Concrete Structures in The GCC CountriesAshraf Gomah Mohamed ElshamandyNo ratings yet

- Comparative Study of Seismic Analysis of Existing Elevated Reinforced Concrete Intze Water Tank Supported On Frame StagingDocument12 pagesComparative Study of Seismic Analysis of Existing Elevated Reinforced Concrete Intze Water Tank Supported On Frame Stagingmailmaverick8167No ratings yet

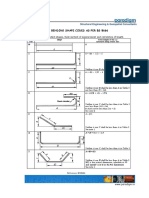

- 3bar Shapes As Per BS8666Document9 pages3bar Shapes As Per BS8666Ashraf Gomah Mohamed ElshamandyNo ratings yet

- Bar Bending Shape Codes per British Standard BS 8666Document7 pagesBar Bending Shape Codes per British Standard BS 8666Ashraf Gomah Mohamed ElshamandyNo ratings yet

- HydrotherapyDocument7 pagesHydrotherapyGialys MoretaNo ratings yet

- Do Not Open This Booklet Until Told To Do So: Question Booklet Series: - Question Booklet No.Document7 pagesDo Not Open This Booklet Until Told To Do So: Question Booklet Series: - Question Booklet No.Rakesh KumawatNo ratings yet

- The Image of The CityDocument17 pagesThe Image of The CityMay Rose ParagasNo ratings yet

- Kapla ResumeDocument35 pagesKapla ResumeAbinashNo ratings yet

- Postmodern EthicsDocument1 pagePostmodern Ethicsgeorge elerickNo ratings yet

- Computations on a waiters bill pad and conversations in the mistDocument3 pagesComputations on a waiters bill pad and conversations in the mistRavishu NagarwalNo ratings yet

- Manual Hoist ProductsDocument40 pagesManual Hoist Productskavin bhagavathyNo ratings yet

- BrosurDocument68 pagesBrosurKiki Xhui7No ratings yet

- SFM Issue Repor 15-4-2023Document3 pagesSFM Issue Repor 15-4-2023Esdras Fransua CisnerosNo ratings yet

- Bio-Sil ULTRA 1050: Medically Pure Platinum-Cured Silicone Tubing With An Ultra-Smooth Inner SurfaceDocument2 pagesBio-Sil ULTRA 1050: Medically Pure Platinum-Cured Silicone Tubing With An Ultra-Smooth Inner SurfaceLari GrossiNo ratings yet

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- Yanmar Mechnical PumpDocument16 pagesYanmar Mechnical Pump송성훈100% (9)

- Engineering StudiesDocument4 pagesEngineering StudiesSamuel PhegelloNo ratings yet

- yudaturana,+Manajer+Jurnal,+dr +nelson+rev+2+ (162-172)Document12 pagesyudaturana,+Manajer+Jurnal,+dr +nelson+rev+2+ (162-172)Fath TiaraNo ratings yet

- Shivag Itim Al ADocument27 pagesShivag Itim Al AKellie RamosNo ratings yet

- Petford & Atherton., 1996Document31 pagesPetford & Atherton., 1996Ivan Hagler Becerra VasquezNo ratings yet

- Proximity Sensing and Warning Technology For Heavy Construction Equipment OperationDocument10 pagesProximity Sensing and Warning Technology For Heavy Construction Equipment OperationAnand ReddyNo ratings yet

- Hearing Aid InformationDocument22 pagesHearing Aid InformationDeepakRodeyNo ratings yet

- 2GIG KEY2 345 Install GuideDocument2 pages2GIG KEY2 345 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Lecture No.3 Part 1 (Fan)Document6 pagesLecture No.3 Part 1 (Fan)Mohsen HassanNo ratings yet

- Wda 201Document72 pagesWda 201MoussaNo ratings yet

- EU Food Label GuidanceDocument99 pagesEU Food Label GuidanceMunteanu CristianNo ratings yet

- Hellstorm NotesDocument57 pagesHellstorm NotesDeni ZenNo ratings yet

- 3 Pipe Mod For Vectra BDocument2 pages3 Pipe Mod For Vectra BEmirhan DöngelNo ratings yet

- My Version of Meatlaof Project DraftDocument3 pagesMy Version of Meatlaof Project DraftCloue Faye I. BasalloNo ratings yet

- Kyocera Fs-6900 Parts ManualDocument28 pagesKyocera Fs-6900 Parts ManualNic CowpeNo ratings yet

- HydrotherapyDocument52 pagesHydrotherapyMpt Sports100% (1)

- OrlDocument186 pagesOrlMuli MaroshiNo ratings yet