Professional Documents

Culture Documents

Sewage Pump XFP 80C-150E

Uploaded by

Jose CastroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sewage Pump XFP 80C-150E

Uploaded by

Jose CastroCopyright:

Available Formats

ABS submersible sewage pump XFP 80C-150E

Robust, reliable, submersible pumps, with premium efficiency

motors from 1.3 to 11.0 kW. For the pumping of wastewater and

sewage from buildings and sites in private, commercial, industrial

and municipal areas in accordance with EN 12050-1.

Features

* The water-pressure-tight, encapsulated, fully flood-proof motor

and the pump section form a compact, robust, modular con-

struction.

* NEMA Class A temperature rise.

* Premium Efficiency motors in accordance with IEC 60034-30

level IE3 with testing in accordance with IEC60034-2-1.

* Continuously rated motor in submerged and non-submerged

applications.

* Double mechanical seals; SiC-SiC at the medium side, SiC-C at

the motor. All seals are independent of rotation direction and

resistant to temperature shock.

* Anti-wicking cable plug solution.

* High-efficiency hydraulic design with Contrablock (80E) or Con-

trablock Plus (80C, 100C, 100E & 150E) impeller.

* Free solids passage of minimum 75 mm.

* Lubricated-for-life bearings with a calculated life time of min.

50,000 hours.

* Stainless steel shaft. Designed with high safety factor to prevent

fatigue fracture.

* Temperature monitoring by thermal sensors (140 °C) in the sta-

tor windings.

* Seal monitoring by a moisture probe (DI) in the seal chamber Motor

which signals an inspection alert if there is leakage at the shaft Premium Efficiency IE3, three-phase, squirrel-cage motor;

seals. 400 V; 50 Hz; 2-pole (2900 r/min), 4-pole (1450) and 6-pole (980).

* Smooth outer design to reduce rag build-up.

* Stainless steel lifting hoop. Protection type IP 68, with stator insulation Class H.

* DN 80, DN 100 and DN 150 radial slot DIN flange discharge.

* Maximum allowable temperature of the medium for continuous Start-up: 1.3 - 2.9 kW = direct on line (DOL)

operation is 40 °C. 4.0 - 11.0 kW = star-delta (YΔ).

* Maximum submergence depth of 20 m.

* Explosion-proof as standard, in accordance with international Motors with other operating voltages and frequencies are

standards Exd II BT4 and ATEX. also available.

Performance curves Identification Code: e.g. XFP 80C CB1.3 PE22/4-C-50

Hydraulics:

DN: 80 100 150*

XFP ........ Product range

50

8 ............ Discharge outlet DN (cm)

50 Hz

H 45

0 . ...........Hydraulic type

(m) C ............ Volute opening (dia. mm)

40 CB.......... Impeller type

1 ............ Number of impeller vanes

35 3 ............ Impeller size

Motor:

30 PE ......... Premium Efficiency

XFP 80E-CB1 22 .......... Motor power P2 kW x 10

25

4 ............ Number of poles

C ............ Volute opening (dia. mm)

20

50 .......... Frequency

15

XFP 100E-CB1

10

XFP 150E-CB1

5

XFP 80C-CB1

Pump selection

Please use the ABSEL or ACCT program as the only valid selection

Q XFP 100C-CB1

(l/s) tool.

10 20 30 40 50 60 70 80 90 100

* Minimum flow rate Q

Standard and Options

Description Standard Option

Mains voltage 400 V 3~ 230, 500, 230/400, 400/695, 500/866 V

Voltage tolerance ± 10% -

Motor efficiency Premium Eff. IE3 -

Insulation class H -

Temperature monitor Bi-metallic switch Thermistor

Seal monitor DI moisture probe -

Start-up Direct on line (DOL), star-delta (YΔ) -

Approvals Ex -

Mechanical seal (at medium side) SiC-SiC -

Mechanical seal (at motor side) SiC-C -

O-rings NBR -

Cables S1BN8-F EMC

Cable length (m) 10 20, 30, 40, 50

Protective coating 2k Epoxy 120 μm 2k Epoxy 400 μm

Provision for lifting hoist Lifting hoop (150 mm height) -

Cooling Self-cooling -

Installation Wet well Dry well or transportable

Technical Data

XFP Motor Impeller Rated Motor power* Rated Speed Cable Weight

size voltage (kW) current size

(V) P1 P2 (A) (r/min) (kg)

80C-CB1 PE 29/4 2 400 3~ 3.4 3.0 6.4 1450 7G1.5 100

PE 22/4 3, 4 400 3~ 2.5 2.2 4.6 1450 7G1.5 98

PE 13/6 1, 2, 4 400 3~ 1.6 1.3 3.6 980 7G1.5 96

100C-CB1 PE 29/4 2 400 3~ 3.4 3.0 6.4 1450 7G1.5 109

PE 22/4 3, 4 400 3~ 2.5 2.2 4.6 1450 7G1.5 107

PE 13/6 1, 2, 4 400 3~ 1.6 1.3 3.6 980 7G1.5 105

80E-CB1 PE 110/2 1, 2, 3 400 3~ 12.1 11.0 20.1 2900 10G1.5 173

PE 70/2 4 400 3~ 7.7 7.0 13.5 2900 10G1.5 160

2010-06-15 | We reserve the rights to alter specifications due to technical developments.

100E-CB1 PE 90/4 1, 2 400 3~ 10.0 9.0 18.1 1450 10G1.5 189

PE 60/4 3, 4 400 3~ 6.7 6.0 13.6 1450 10G1.5 177

PE 40/4 5 400 3~ 4.4 4.0 8.4 1450 10G1.5 159

150E-CB1 PE 90/4 1, 2, 3 400 3~ 10.0 9.0 18.1 1450 10G1.5 198

PE 60/4 4, 5 400 3~ 6.7 6.0 13.6 1450 10G1.5 186

PE 40/4 6 400 3~ 4.4 4.0 8.4 1450 10G1.5 168

PE 30/6 1, 2, 3, 4 400 3~ 3.5 3.0 6.4 980 10G1.5 168

* P1 = power at mains. P2 = power at motor shaft.

Materials

Description Material

Motor housing Cast iron EN-GJL-250

Volute Cast iron EN-GJL-250

Impeller Cast iron EN-GJL-250

Bottom plate Cast iron EN-GJL-250

Motor shaft Stainless steel 1.4021 (AISI 420)

Lifting hoop Stainless steel 1.4401 (AISI 316)

Fasteners Stainless steel 1.4401 (AISI 316)

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Abs Submersible Sewage Pump XFP 80C - 151e (GB)Document2 pagesAbs Submersible Sewage Pump XFP 80C - 151e (GB)Ashraf Gomah Mohamed ElshamandyNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Catalouge 68Document2 pagesCatalouge 68Mais OmarNo ratings yet

- ABS Submersible Sewage Pump XFP 100J To 501U - GBDocument2 pagesABS Submersible Sewage Pump XFP 100J To 501U - GBAshraf Gomah Mohamed ElshamandyNo ratings yet

- DataBook CDXDocument15 pagesDataBook CDXLê Anh TuấnNo ratings yet

- Item 4 - (P-110) - RASDocument7 pagesItem 4 - (P-110) - RASanse1No ratings yet

- Ex470 490TC (B) 120 (HC) (182) BFDocument2 pagesEx470 490TC (B) 120 (HC) (182) BFcarlos salazarNo ratings yet

- Manual de Operacion DGW310MC 220Document11 pagesManual de Operacion DGW310MC 220Uma A. UcheNo ratings yet

- Incremental Encoder SeriesDocument2 pagesIncremental Encoder SeriesS SaNo ratings yet

- Cat-Ix58 Ix58s Cx58-EDocument2 pagesCat-Ix58 Ix58s Cx58-EDimaco VideoNo ratings yet

- Feedback Encoder For Big Size Motors - Precise Optical Sensing - Very Flat Design - Through Hollow Shaft Up To Ø 30 MM - Robust Die Cast Housing With IP65 ProtectionDocument2 pagesFeedback Encoder For Big Size Motors - Precise Optical Sensing - Very Flat Design - Through Hollow Shaft Up To Ø 30 MM - Robust Die Cast Housing With IP65 ProtectionArmando AristimunoNo ratings yet

- Cat-Ck61-E Encoder de Pistón Prensa 1Document2 pagesCat-Ck61-E Encoder de Pistón Prensa 1Ariel SantambrosioNo ratings yet

- 3410565Document3 pages3410565qsifozejcrNo ratings yet

- LISH - Submittal For OutdoorDocument20 pagesLISH - Submittal For OutdoorJimmy AnticonaNo ratings yet

- Series: Incremental EncoderDocument2 pagesSeries: Incremental EncoderbaiadilNo ratings yet

- ABS Submersible Mixed Flow Column Pump AFLX-PE7Document2 pagesABS Submersible Mixed Flow Column Pump AFLX-PE7dansalsaNo ratings yet

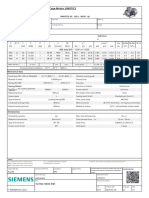

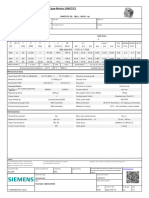

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV2132B Simotics GP - 132 M - Im B3 - 4PSedlynNo ratings yet

- 1LE1503-1DB43-4FK4 Datasheet enDocument1 page1LE1503-1DB43-4FK4 Datasheet enNicolas RossettoNo ratings yet

- DB NF30 en 03 069189 PDFDocument4 pagesDB NF30 en 03 069189 PDFSikapp DisiplinnNo ratings yet

- 1LE1001-0EB42-2FB4 Datasheet enDocument1 page1LE1001-0EB42-2FB4 Datasheet enAde FaisalNo ratings yet

- 1LE1003 1DA43 4AB4 Datasheet enDocument1 page1LE1003 1DA43 4AB4 Datasheet enElio TavaresNo ratings yet

- Catalouge 71Document4 pagesCatalouge 71Mais OmarNo ratings yet

- CSF 110Document46 pagesCSF 110damanchurw210No ratings yet

- TCLT100. Series Optocoupler, Phototransistor Output, SOP-4L, Long Mini-Flat PackageDocument10 pagesTCLT100. Series Optocoupler, Phototransistor Output, SOP-4L, Long Mini-Flat PackageHưng HQNo ratings yet

- Etachrom NC Bomba 1700m011-m012-m013Document16 pagesEtachrom NC Bomba 1700m011-m012-m013Miguel Morales SandovalNo ratings yet

- 1LE1002 1CB23 4AA4 Z B14 Datasheet enDocument1 page1LE1002 1CB23 4AA4 Z B14 Datasheet enzeepython100% (1)

- 90-90-988-TS (BEM-650 Tech Specification)Document9 pages90-90-988-TS (BEM-650 Tech Specification)leoNo ratings yet

- 21.AW .DFMD .100-160.R410A.TM .EN .11.19.rev01Document96 pages21.AW .DFMD .100-160.R410A.TM .EN .11.19.rev01Said El GouziNo ratings yet

- Cat I65 - It65 eDocument2 pagesCat I65 - It65 egustavo gonzalezNo ratings yet

- Finder Relays Series 40 PDFDocument8 pagesFinder Relays Series 40 PDFqwertysasNo ratings yet

- Finder Relays Series 40 PDFDocument8 pagesFinder Relays Series 40 PDFCosmin ConstantinescuNo ratings yet

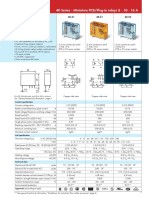

- Features: 40 Series - Miniature PCB/Plug-in Relays 8 - 10 - 16 ADocument16 pagesFeatures: 40 Series - Miniature PCB/Plug-in Relays 8 - 10 - 16 ADante LupuNo ratings yet

- UntitledDocument2 pagesUntitledGab SotNo ratings yet

- WEG 50076226 Metallized Polypropylene Motor Run Capacitors enDocument24 pagesWEG 50076226 Metallized Polypropylene Motor Run Capacitors enJesus VerduzcoNo ratings yet

- GEP65-2 (3-Phase) : Diesel Generating SetDocument6 pagesGEP65-2 (3-Phase) : Diesel Generating SetAbomazen GalalNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- Fusibles NH FEDERALDocument11 pagesFusibles NH FEDERALantonioNo ratings yet

- 1LE1002-1DB43-4FB4 Datasheet enDocument1 page1LE1002-1DB43-4FB4 Datasheet enshashibagewadiNo ratings yet

- All-Round Wheeled Encoder For Conveyor Systems Series: (Other Resolutions On Request)Document2 pagesAll-Round Wheeled Encoder For Conveyor Systems Series: (Other Resolutions On Request)RyszardNo ratings yet

- Hydac Mobile Filter Systems1Document76 pagesHydac Mobile Filter Systems1bee1406763181No ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1164B Simotics GP - 160 L - Im B3 - 4PDocument3 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1164B Simotics GP - 160 L - Im B3 - 4PMeky Bima TokoNo ratings yet

- 3VM Molded Case Circuit Breakers: General DataDocument1 page3VM Molded Case Circuit Breakers: General DataMarco Antonio Quispe RoqueNo ratings yet

- Optima-R-Fc... BM: VAV Controller, Belimo Modbus ModularDocument43 pagesOptima-R-Fc... BM: VAV Controller, Belimo Modbus ModularpintileirobertNo ratings yet

- BOX BD 1010 M4 059kWDocument4 pagesBOX BD 1010 M4 059kWAiman AliNo ratings yet

- Docs 1055727 DP 5 08 Spec SheetDocument2 pagesDocs 1055727 DP 5 08 Spec SheetkbgwseNo ratings yet

- Dynamic Microphone: Echnical Pecifications EaturesDocument2 pagesDynamic Microphone: Echnical Pecifications Eatureshome studioNo ratings yet

- MMI-50 NT ENG 50HzDocument8 pagesMMI-50 NT ENG 50HzTaimoorNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- Instrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VDocument4 pagesInstrumentation Cable EN 50288-7: Flame Retardant, Sunlight Resistant 90 °C / 500 VShashank SaxenaNo ratings yet

- 1LE1503-1EA23-4AB4 Datasheet enDocument1 page1LE1503-1EA23-4AB4 Datasheet enpatilshailesh123No ratings yet

- DBAFMCV924 Full en Metric LetterDocument6 pagesDBAFMCV924 Full en Metric LetterMechanical2022No ratings yet

- (SM) M (2 3 4 5) OE 14 42HFN1 Q (Multi Outdoor) - EngDocument57 pages(SM) M (2 3 4 5) OE 14 42HFN1 Q (Multi Outdoor) - EngDee RajaNo ratings yet

- 1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enDocument2 pages1LE1503-1DB21-7AB4-Z B02+D22+L22+Y82 Datasheet enMostafaElrakhawyNo ratings yet

- 1LE2421-2BC11-2AA3 DataDocument2 pages1LE2421-2BC11-2AA3 DatatburtickNo ratings yet

- A6 Duct R410A 50Hz Inverter ControlDocument68 pagesA6 Duct R410A 50Hz Inverter ControlEdwin JaramilloNo ratings yet

- 1le1523 1eb43 4FB4Document2 pages1le1523 1eb43 4FB4pmf engineering limitedNo ratings yet

- Gep 400Document6 pagesGep 400Agus Yulfizar0% (1)

- UntitledDocument39 pagesUntitledleejoNo ratings yet

- ABB Medium Voltage Pad Mounted Solution: PVS980-MVP - 2.0 To 4.6 MVADocument4 pagesABB Medium Voltage Pad Mounted Solution: PVS980-MVP - 2.0 To 4.6 MVAJose CastroNo ratings yet

- List of Interested Party Transactions To Be Possibly Entered Into by JSC VTB Bank During Its Standard Commercial ActivitiesDocument40 pagesList of Interested Party Transactions To Be Possibly Entered Into by JSC VTB Bank During Its Standard Commercial ActivitiesJose CastroNo ratings yet

- 3 Phase Padmount Transformer Jan 2019Document12 pages3 Phase Padmount Transformer Jan 2019Jose CastroNo ratings yet

- 18 - GEA32687 Spare Parts For Electrical Drives, Motors and Generators FactsheetDocument2 pages18 - GEA32687 Spare Parts For Electrical Drives, Motors and Generators FactsheetJose CastroNo ratings yet

- 3 Phase Pad Mounted Transformer Specification: Littleton Electric Light and Water DepartmentsDocument7 pages3 Phase Pad Mounted Transformer Specification: Littleton Electric Light and Water DepartmentsJose CastroNo ratings yet

- SA Oil and Gas Corporation: 2400E Arizona Biltmore Cir, Phoenix, Arizona 85016 (888) 367-1513Document1 pageSA Oil and Gas Corporation: 2400E Arizona Biltmore Cir, Phoenix, Arizona 85016 (888) 367-1513Jose CastroNo ratings yet

- 18 Petroleum Derivatives Fuels 20180515194521Document4 pages18 Petroleum Derivatives Fuels 20180515194521Jose CastroNo ratings yet

- TDS Biotum PGB 50 70 0618Document2 pagesTDS Biotum PGB 50 70 0618Jose CastroNo ratings yet

- Data Sheet of Viscosity Grade Bitumen Ac 30Document1 pageData Sheet of Viscosity Grade Bitumen Ac 30Jose CastroNo ratings yet

- 2 Ultra Low Sulfur Diesel FuelDocument1 page2 Ultra Low Sulfur Diesel FuelJose CastroNo ratings yet

- Jet Fuel Jpa1 Aviation Kerosene Colonial Grade A1 - Russian Virgin Fuel Oil D6 20180113063743Document2 pagesJet Fuel Jpa1 Aviation Kerosene Colonial Grade A1 - Russian Virgin Fuel Oil D6 20180113063743Jose CastroNo ratings yet

- Wood Utility Pole Design Values in The: Technical BulletinDocument4 pagesWood Utility Pole Design Values in The: Technical BulletinJose CastroNo ratings yet

- Sales & Purchase Agreement: CIF Bulk Bonny Crude OilDocument21 pagesSales & Purchase Agreement: CIF Bulk Bonny Crude OilJose CastroNo ratings yet

- Standard Recovery Diodes: JZZX860D (U) .. SeriesDocument3 pagesStandard Recovery Diodes: JZZX860D (U) .. SeriesJose Castro100% (1)

- Contract Number Kaz010542c0020Document6 pagesContract Number Kaz010542c0020Jose CastroNo ratings yet

- (Dip Test Authorization Letter) : Tomsk/Garbor-Jp54/2Mbl/Spot17Document3 pages(Dip Test Authorization Letter) : Tomsk/Garbor-Jp54/2Mbl/Spot17Jose CastroNo ratings yet

- Beware 03122019-1en PDFDocument14 pagesBeware 03122019-1en PDFJose Castro0% (1)

- Offer Letter: Price ListDocument11 pagesOffer Letter: Price ListJose CastroNo ratings yet

- Fluid Mechanics - Lecture 04Document10 pagesFluid Mechanics - Lecture 04Danny SubramaniamNo ratings yet

- ReportDocument10 pagesReportNeeraj KishoreNo ratings yet

- Hadoop Course Content PDFDocument9 pagesHadoop Course Content PDFNaveen ElancersoftNo ratings yet

- Solved Problems: Single Degree Free VibrationDocument14 pagesSolved Problems: Single Degree Free Vibrationprem adhikariNo ratings yet

- 11th Bio Botany Important Questions For Volume 1 PDFDocument6 pages11th Bio Botany Important Questions For Volume 1 PDFNaren44% (9)

- BMC Analytics For BSM 7.6.04 Reference GuideDocument68 pagesBMC Analytics For BSM 7.6.04 Reference GuideCecilio GutierrezNo ratings yet

- I - Infowatch 16-30 Jun 2023Document141 pagesI - Infowatch 16-30 Jun 2023Suman MondalNo ratings yet

- Peh 12 Reviewer 3RD QuarterDocument12 pagesPeh 12 Reviewer 3RD QuarterRalph Louis RosarioNo ratings yet

- Àmjj JJMJJ JJMJJJJJJJ JJJJJJJ JJ: JJJ JJJ JJJDocument7 pagesÀmjj JJMJJ JJMJJJJJJJ JJJJJJJ JJ: JJJ JJJ JJJDezekiel DriapNo ratings yet

- Physics1ist Year Practical FilDocument27 pagesPhysics1ist Year Practical FilManish GoyalNo ratings yet

- 2013 Red Sox Postseason GuideDocument267 pages2013 Red Sox Postseason Guidejen_rogers295100% (1)

- Module Bar PTX1.6 PDFDocument8 pagesModule Bar PTX1.6 PDFkumelachewbirre22No ratings yet

- Basic Hygiene & Food Safety Training ModuleDocument43 pagesBasic Hygiene & Food Safety Training ModuleRelianceHRNo ratings yet

- BUMBLE D2.2v1 FinalDocument51 pagesBUMBLE D2.2v1 FinalgtdreeeNo ratings yet

- Acr Oss The Line ContactorsDocument2 pagesAcr Oss The Line ContactorshmavisNo ratings yet

- Alessandro Albanese - All Season CollectionDocument29 pagesAlessandro Albanese - All Season CollectionWilliam BourneNo ratings yet

- Linux CommandDocument128 pagesLinux CommandZakNo ratings yet

- Persuasion PyramidDocument1 pagePersuasion PyramidKenzie DoctoleroNo ratings yet

- Spring 2010 Past PaperDocument4 pagesSpring 2010 Past PaperKhizra AliNo ratings yet

- Instant Download Principles of Virology Ebook PDF FREEDocument11 pagesInstant Download Principles of Virology Ebook PDF FREEwalter.penn362100% (51)

- Chapter 1: IntroductionDocument34 pagesChapter 1: IntroductionIntan AifatikaNo ratings yet

- Part Catalogo RMZ250Document67 pagesPart Catalogo RMZ250jesus moralesNo ratings yet

- Automatic Summarization of Youtube Video Transcription Text Using Term Frequency-Inverse Document FrequencyDocument9 pagesAutomatic Summarization of Youtube Video Transcription Text Using Term Frequency-Inverse Document FrequencyKarunya ChavanNo ratings yet

- 4.11 Radiation Protection - AHDocument112 pages4.11 Radiation Protection - AHGina RNo ratings yet

- Dematron 60 70 Parlour Sheet 1.03Document1 pageDematron 60 70 Parlour Sheet 1.03Andrés HurtadoNo ratings yet

- Networker MergedDocument261 pagesNetworker MergedShafee AhmadNo ratings yet

- DEH-1250MPG DEH-1250MP: Owner's Manual Manual de Instrucciones Manual Do ProprietárioDocument80 pagesDEH-1250MPG DEH-1250MP: Owner's Manual Manual de Instrucciones Manual Do ProprietárioMoezz Asif Research Associate-Faculty of Avionics EngineeringNo ratings yet

- How To ApplyDocument129 pagesHow To ApplySasa KasaNo ratings yet

- Practical 9: Enthalpy Change of ReactionDocument4 pagesPractical 9: Enthalpy Change of ReactionJulia QistinaNo ratings yet

- Type Approval Certificate: ABB AB, Control ProductsDocument3 pagesType Approval Certificate: ABB AB, Control ProductsDkalestNo ratings yet