Professional Documents

Culture Documents

GZ Aae MST Civ 0003 Rev 3

Uploaded by

Mariam Mousa0 ratings0% found this document useful (0 votes)

27 views97 pagesMST-CIV-0003 - Method Statement for Concrete Work

Original Title

Gz Aae Mst Civ 0003 Rev 3

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMST-CIV-0003 - Method Statement for Concrete Work

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views97 pagesGZ Aae MST Civ 0003 Rev 3

Uploaded by

Mariam MousaMST-CIV-0003 - Method Statement for Concrete Work

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 97

KEOW aan Grand@on

Document Transmittal

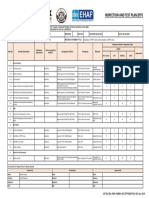

[Transmittal No. OT-0135 Revision:3 Date: 20/10/2019

PROJECTNO. & TITLE Grand Zono-School & Residential

CLIENT Mall of Qatar

‘CONSULTANT EO International Consultant

CONTRACTOR + Al All Engineering WL. Trading & Contracting

Desciine

acter Tait —T Sey 5 Ta rant mage

[B: Sen Ol mer Dicom Geman: ot Oo sey

‘Submit Tyne:

O- Giiner ay vores ay Orem rey D> Scteatn 9)

basen ans) Bnet seer 4s7 1D Peam 059 Oi ones

- ener anne 00) tr eet 0s) out 7

Orin eu 1: rect 0) Ds bem 3)

Name of Sub Contato Super County o Orga

Purpose of

C_riomatoa Drea

[!. SUBJECT DESCRIPTION :-

2. SUBMITTAL DETAILS

WEANSOF DELVERY

sx | 00, REF. No, Rev DATE DESCRIPTION

1 ezaae-nsr.cwo003 3 20-0ct19 | Method Statement for Concrete Works 1 2

Se one mea wna como

?ONTRACTOR: S_

fame: En n Designation: ProiectManacer Signature . Date: 20 October 2018,

fRecerveo ey CONSULTANT ~

ai Signatur: Date:

Review Status Code

B- No Objection

‘No tection Sicomments weoration of] | Reject tobe Reaubmiied

3. CONSULTANT COMMENTS:

8 Sa POT Te TSS Ta es TA

Jonah esau ater het it ber sd pn cmp ah re hansen prone ee eae

[erect song or hg. to of tm ut sh pre oe pont egy napa he

as mamar of sree ase STEM ese ace easton, oat he wah ih ace Toa ee re

ety mamer macau wih Corre

[EO (Consuitane)=

IName : Designation: signature:

[RECEIVED BY CONTRACTOR NAWE SIGNATURE Dares

Form No.

-ADE-F¥-01746-02(4) ating oLegoey of ceence Revision 09

KEOW /Grand@one) Qatar Mat

ek ee

GRAND ZONE - SCHOOL AND RESIDENTIAL

4

Method Statement for Concrete Works

PROJECT NAME

GRAND ZONE-SCHOOL & RESIDENTIAL

CONTRACTOR'S NAME:

AL ALI ENGINEERING W.L.L.

‘CONSULTANT'S NAME:

KEO INTERNATIONAL CONSULTANTS

CLIENT'S NAME:

QATAR MALL

DOCUMENT NO:

GZ-AAE-MST-CIV-0003 Rev 3

Prepared By: | Bilal Sukker Sr.QA/QC Engr.

20 October 2019

Approved By: | Engr. Mohamed Hussein Project Manger

20 October 2019

<=

Reviewed By: | Engr. Mohammad Abdelfattah | QA/OC Manager |} 20 October 2018

0 | 1 August 2019

1] 2September 2019 Second Issue- CRejected

2 | 100ctober 2019 Third Issue-CRejected

3 | 200ctober 2019 Fourth Issue-Issued for Approval

GZ-AAE-MST-ClV-0003 Rev 3

Method Statement for Concrete Works

‘Mcmahon of Aeolus erg th od el poston eo

Review

pproectName + Grand Zone = School & Residential

Jesolo. :G2-AAE-MST-cWv.c8-a003

Document. Ret No: DT 0195

[Prasat Rof. No: G2-AAE-MST.CIV-0009

Document

Comments Sheet (RCS)

RFS: 18-5441-CM00

Doc./Dwg. Reosived Date: 20-Oct-19

KEOW

__Mathod Statement for Concrete Works - T C5 bate 20.0340

[Engineer in charge : Mohamed Afify/ Manshad Manaf Discipline: Civih

Review Response Code: Cc [_ Acne objection B= No Objection Subject to incorporation of all comments as noted C= Rejected, tobe resubmitted

Commented | Review Reference : ihe |KEO Response: Sign{

SN KEO Review Comments . Contractor’

Br | (title (page /clause) i nse Beker Repty ‘ff (OpeniClosed)

the require

ly detalles method

1 MA General wing comments: lozanessr-civ-oons2 | complied (Referto the below eles) Open

nt in the submited method statement is noted|

2. Add material submitals references for ll materials that wil be used

in conjunction wth this method statement

[The material submitas references should be added to the method

tatement. The method siatement shall be resubmited to incorporcte }) conrete mit design ara cer lovane

1 mterial eubr 098. refer lo marked up comments i materials wa be submited for approval once

page (5 of materials to be used in conjunction with Ine designe faze,

his method statoment Rete

|The contractor response is noted. at 7

Jsbervaion of tained foreman o avoid any

>. Add further aiscussion regarding the fabrication of reinforcement

2 Ma Weerel Fite lscassion andor otton 8 ental one taf LAAEMGT-cons.02 [pcre aateston recto ot mora Open

framments shat! be considered and Incorporated into the metho [once bx designs hed ben detete in

statement: [referenced MS and each mix shall the

Storage of reinforcement shal be on suitable structures @ minimum tl mac teste priro be used at te

J 450 mm above the ground surface, |) Compted (Refer to secon 8)

ting and bending ofreinforcament shall bein accordance with 86| Noted and tobe fotoned

[2966. While, soe! bars manufactured according to ASTM standards

hal be fabricated according to CRIs manual of slandard pratcs

vacter to comply.

Review Comments Sheet (RCS)

RFS: 18-5441-CM00

+ Grand Zone - School & Residential

:GZ-AAE-MST-CIV.CS-0003,

[Document. Ref. No.: 0"

[Transmittal Ref. No.: GZ-AAE-MST-CIV-0003

CS Rev.: 3

Doc./Dwg. Rev. 3

‘Doc /Dwg. Received Date: 20-Oct-19

KEOW

JPecument tite: Method Statement for Gonerete Works - - 8 Date: 20-Oct-19

[Engineer in charge: Mohamed Afiy/ Manshad Manaf Discipline: civil

Review Response Code: c A=Noabjecion _B=No Objection Subject Incorporation ofall eommente C=Rejectedtobereubmited |

Commented | Review Reference : | |KEO Response: Sign}

KEO Review Common owg. Refer contra

ons By: {title fpage iclause) Be) te Bo — oy jars reply Off (Open/Closed)

[Submit separate calcutations and shop drawings for the formwork

lystoms.

fhe srictural and shop drawings for the formwor

ystems shal inaividualy,

[Te folowing comments shal be considered and incorporated int he

|rethod statement:

J. The formwork shal! be constructed so that the side forms of

7 Jnembers can be remaved without disturbing tho soft forms a

3 MA Formwork }>. Position chamfer molding strips on edges of permanently exposed|°2-AAE-MST-CI4 2 Done Oper

Jonerete col beams.

striking of the formwork, provide the minimum

formwork as per the referred clause of the projec

[sPectication. However, KEO shall be noted before the removal of

fany formwork.

[The contractor response Is noted. However, as commented earier|

[SE0 shall be noted before the removal of any formwork

Review Comments

ProjectName _: Grand Zone - School & Residential

(CS Ref. No. $GZ-AAE-MST-CIV.CS-0003

(Document. Ref. No DT 0135

[Fransmittal Ref. No.: GZ-AAE-MST-CIV-0003

Document tie: yetnod Statement for Concrete Works

Jnainorin charge : Mohamed aft Marshes

Manaf

[Review Response Code: Cc

A= No objection

Sheet (RCS)

B = No Objection Subject to Incorporation of all comments as noted

KEOW

RFS:

Doc/Dwg. Received Date: 20-Oct-19

C$ Date: 20-Oct-19

Discipline: civil

C= Rejected, tobe resubmitted

Commented

By:

Review Reference :

iis (title page ‘iause)

KEO Review Comments

) Doc./Dwg. Reference:

|KEO Response: Sign}

Contractor's Reply Of (OpeniClosed)

|a. Discharge of the concrete shall be completed within 80 min, or

[before the drum has revolved 300 revolutions, whichever comes fst.

[Refer to QSC 2014 section § part 8.

[Contractor to comply.

[Add steps to be taken in case of concrete stoppage or (other

scenario) resulting to cold joint

[The contractor response is noted. Mearnwhil

to unavoidable reason, place reinforcement

the fist portion an:

|e-The concrete shall not be dropped through a free height greater than|

1.5 m. Refer to QSC 2014 section § part 8.

[Contractor to comply

\8. Add further discussion regarding the concreting in hot weather

Iefering to QCS 2014 section § part 15.

IThe contractor response

Joe considered and incor

| Concrete should not 1@ ambient ar temperature

[exceeds 37 C and rising. Update the method statement.

| The maximum concrete temperature at placement is 30 C.

Concrete Casting

following comments shall

the method statement:

|- Regarcing the mass concrete (any concrete placement with is least

|simension being 1500 mm or greater), the maximum concrete

temperature at placement is 26 C, th

is 70 C during the curing period, ensu

the temperature

ditferental between the geometric canter of each placement and the

!aeometric surface does not exceed 20 C and insulate the concrete,

GZ-AAE-MST-CIV.0008-02 Open

Submited

Review Comments Sheet (RCS) KEOW

PreictName : Grand Zone- School & Residential FS: 1.8447-CMo0

['sRetno. — scz-aaemst-cwv.cs.ctis - - ~c8Rev:3

bocument Ref No: DT 0135 Doe Dw. Res

[Transmittal Ref. No.: GZ-AAE-MST-CIV-0003 Doc.J/Dwg. Received Date: 20-Oct-19

JPecumenttite: Method Statement for Concrete Works — - - ‘€8 Dato: 20-00-19

[Engineer in cherge : Mohamed AVfify/ Manshad Manat Discipline: Civil

|Review Response Code: Cc A=Nocbjedion ___8=No Objection Subject to Incorporation ofalleommentsasnoted C= Rejected, tbe resabmea

Commented | Review Reference : ¥ IKEO Response: Sign|

eee Ngee KEO Review Comments Doc /Dwg. Reference: Contractor's Reply Off (OpentCiosed)

[unt the thermal contol is finished.

'@. Ensure that semples are taken in a shaded area away from|

|vibraton,

[Contractor to comply.

Jb. Determine number of test cubes in accordance with the total

volume of concrete required for each mix and frequency of testing.

IC: Add discussion regarding manner for conducting test for fresh andl

hardened concrete:

Refer to Section 5 Pant 6 of QCS2014 for concrete property

requirements.

|The contractor response is noted. while, the following comments shall

be considered and incorporated into the method statement:

| Slump and temperature tests Carried out at the rate of one|

5 MA | Testing of Concrete JP2-Aae-ust-cranosce Closed

bes at 7 days, 2|

11013 of concrete,

where applicable, test 3 cubes at 28 days and|

[9 cubes at 88 days fore m3 of concrete,

| For S03 and Cl content, test 1 cube at 28 days for every 260 m3 of

concrete

[The contractor response Is noted.

Review Comments Sheet (RCS) KEOW

Project Name: Grand Zone - School & Residential - - RFS: 18-5441-CM00

Ics Ref. No. 1GZ-AAE-MST-CIV.CS-0003,

(Document. Ref.No.: DT 0135

[Transmittal Ref. No.: GZ-AAE-MST-CIV-0003

[Document title: Method Statement for Concrete Works:

[Enalneer in charge: Mohamed Afity/ Manshad Manat

c "Reo obi

n £8 = No Objection Subject to Incorporation of all comments as noted C= Rejected, tobe resubmitted

[Review Response Code:

Reference : Respon

teh peal eee KEO Review Comments Doc JDwg, Reference: Contractor's Reply Rewtceeieost]

sting corer casing performed according to the

cher ind aaa En

o | an Posayesr dining stironsinostetess le wcustevenie: fam ntameetenas coset

Sn eg tn tr

Eve normal sh belated on sta porte

Revved ep cnanee

Pesaran Foie linn om tt

7 MA Elements (Walls & Placing |GZ-AAE-MST-CIV-0003-02 [Done, Refer to 9.5 Closed

Columns)

ing part of the coarse aggregat

le. At the end of each pour, remove cemen

by using sponge, water and wire brush,

[The contractor response is noted.

19 Stoel wire brush,

mall exposed stoe! bars

Review Comments Sheet (RCS) KEO

[Project Name: Grand Zone - School & Residential - RFS: 18.5441-CM00

|CS Ref. No. :GZ-AAE-MST-CIV-CS-0003 CS Rev.: 3.

locum. Re No: DT O135 Doe,Dwg Rev. 3

Transmittal Ref. No.: GZ-AAE-MST-CIV-0003. DocJDwa, Rae ae

Decunent We: Motiod Staten for Concrete Wonks - - :

[Encore charge ? Mohamed Aff Manghod Monet

Review Response Code: Cc ‘A=No objection B= No Objection Subject to incorporation ofall comments as noted (C= Rejected, tobe resubmitted

‘Commented | Review Reference : | IKEO Response: Sign,

oem even en: EO Review Comments Doe Dwg, Reference: Contactors Reply alee

Joins sabe cate on sia por approve hap crowns ony

connor cone

bauer docssonregacng te destin of ome

Covet conzeeton ns here Secnpsern eee

ne conracor responce sree rece at seas

Kenssucon Span sal be kop pope une cena

pr fore point span is casted and released. A) Done

Bf me | PRESETS as tene deamon gia ecg meta, fenscusravamsss sed

ie conta raponce aca ome

Pte conrectr epans ste

Posing sis constuction oma or oundnton ava op

fre opprees Snopes

baa stain no mothoa Salonen, te gourng sequence forthe

Proceaue tr fut iouninion san

9 | MA | “Founaston’ — [etheconmensogaring ne oeseat ene ace apr OAAEMST-OV.0NB02 Open

Jconments ad shlte consders narorecann cee

unetan

Conacr'o comp

Review Comments Sheet (RCS) KEOW

prctName + Grand Zone Schoo! & Reina —

RFS: 18-5441-CMOO

ICS Ref. No. :GZ-AAE-MST-CIV-CS-0003 _

[Document. RefNo: DTO135 _ Doe /Dwg. Rev. : 3 -

Doc /Dw9, Received Date: 20-0c%-19

[Transmittal Ref. No: GZ-AAE-MST-ClV-0003,

[Document tite: Method Statement for Concrete Works _ a C$ Date: 20-Oct-19

[Eraineorin charge +: Mohamed A‘iy/ Manshad Manat Discipline: Civil

Review Response Code: c ‘A= No objection B = No Objection Subject to Incorporation of all comments as nated C= Rejected, to be resubmitted

Commented | Review Reference : | 7 S KEO Response: Sign,

SMe | tte page Rlaneel KEO Review Comments | Bee Ow, Reference: Contractor's Roply GuOmcherah

Inteitent spraying with waters not alowed

Curing and Protection of concrete is prohibited

TOF ma [PimerConoetn fhe wp suac clots and clone sat bo waercued ony, (BEAAEMST-CV.0n822 Open

[Contractor to comply.

[The work procedure was provided for blinding, walls, columns, slabs

land foundation. While, itis noted that

[concrete work such as protection screed (sand cement screed less.

1" MA General ‘screed (over 50 mm thick) |@2-AAE-MST-CNV-000302 Open

ensure that al the concrete

ment.

[he conver eoponse fone

Review Comments Sheet (RCS) KEOW

Jmioct ame: Grand Zone - Schoo & Resident

RFS: 18-5441-CMO0

Ics Ret, No. :GZ-AAE-MST-CIV.CS-0003,

|Document. Rot. No: DT 0135

[Transmittal Ref.No.: GZ-AAE-MST-ClV-0003

[Document tite: Method Statement for Concrete Works

[Engineer in charge : Mohamed Afify/ Manshad Mi

[Review Response Code: Cc

A= No objection 8 = No Objection Subject to Incorporation ofall comments as noted

‘sin | Commented | Reviow Reference :

ty | (ile nage thence KEO Review Comments Doc/Dwg. Reference:

9. Binding, foundations, slab

, walls, retaining wall and slabs considering the

lactual sequence of work

- Approval of concrete mix design, trial mix test results

| Approval of method statement

| Approval of shop drawings

- Inspection of materials (except concrete)

|- Survey and satting out inspection

ction and certification for formwork shoring and scaffolding

Inspection and clearance for embedded lems

9 and sampling of concrete specimen

ing of concrete samples

reports GZ-AAE-MST-CI-000802

's noted. the following comments shall be considered in the

2 MA inspection & Test Plan) T®

ire:

[2 Activity # 4.5: inspection of material -R (review by KEO engineer)

Jb. the activities #2.2, 2.3 and 2.4 are generic. survey, MEP,

Jombedments works to be Incorporated inthe ITP

ITP Moulfed tothe commented Open

smoval and post cor

2. Regarting the slab on grade, add the vito: location

Jand levels (survey work), MEP embedment/box out, pouring concrete

[Project Name

Ics Ref. No.

[Document tte:

+ Grand Zone - Schoo! & Resident

{GZ-AAE-MST-CV-CS-0003

coment. Ret. No DT 0795

[Transmittal Ref. No.: GZ-AAE-MST-CIV-0003

Review Comments Sheet (RCS)

Method Statement for Concrete Works

KEOW

lEncineer in charge : Mohamed Afify Manshad Manat

Review Response Code: C. [_A=no cbjction

Commented | Review Reference : Keo. 2

SN | Ee | (tte ipapetelauso) KEO Review Comments Doc Dwg, Reference: Contractor's Reply eee

[Project Name

Ics Ref. No.

[Documont. Ref. N

‘Transmittal Ref. No.:

[Document title:

[Engineer in charge

rand Zone - School & Residential RFS:

-ARE-MST-CIV-C8-0003 csr

DT 0135, Doe JDwg. Rev. :

GZ-AAE-MST-CIV.0003 DocJDwg. Received Dato:

Method St for Concrete Works 8 Date:

+ Mohamed Afify/ Manshad Manaf

Review Comments Sheet (RCS)

-5441-CM00

20-Oct-19

20-Oct-19

KEOW

Review Response Code: Cc [[Aenocbjecion 8 = No Objection Subject to incorporation C= Rejected, tobe res

ont Oneern eete EO Review Comments Doe /Dmg. Reerence: Contractor's Ropiy pe peeieei ses

Include the folowing legislative requiremants andor HSE standards

13 | HSE/JON | Poge3/Section 3 Oz.AnewsT-c1v.00902 [one Refer Sec. 3 Closed

Project Namo

ICS Ret. No.

Document. Ref. No.

‘Transmittal Ref, No.:

Review Comments Sheet (RCS)

+ Grand Zone - Schoo & Residential

{GZ-AAEMST-CIV-68-0003

or oiss

GZ-AAE-MST-CIV-0003

RPS: 18-5441-CM00

cSRev.:3

Doc/Owg. Rev. : 3

Doc/Dwg. Received Date: 20-Oct-19

KEOW

[The contractor resconse noted, amendment made in section 7,

|nstead of 5

JPocument te: Method Statement for Concrete Works ©8 Date: 20-0019

[Engineer in charge: Mohamed Afify/ Manshad Manat Disciptine: civil

Review Response Code: c A=Nocbjecion B= No Objection Subject te incorporation of llcommentsasnoted C= Rejected to beresubminea

= as

Commented | Review Reference : KEO Response: Sign

sn KEO Review Comments Reference: Contractors Reply

By: | (title page /clause) Sera errr Off (OpaniClosed)

14 |HSE oN) Page 47 Section 4 not nude the actual ane-MST-Cv-00007 |Oone,Reerto 47 Closed

‘Secion 3 fire safely plan and QCS Section Section 11

15 | HsEnew fon Ian t and Part 2 shal be Incladed ezansustcv.o0902 _foone, Refer io Sec. 3 Closed

Reference or Response is noted

jesign and toad

Secon? —__talulaon shall be completed prior to steel relforcement work and kindy refer othe approved submit (92

te | Hsena ] —Sedton7, Gzanewsrcivnsos |:Su rhe a Open

ude the safely season including safety

. cy procedures reer scton on

| Heenan General [the contactor response is noted, how ever safely session shal CU-AAEMST-CN-E05-02 [Kd retro secon 6 On

Include bass safety requirements including PPE, vinings ete,

Include the tols, equipments, machineries, pants, et. o be used.

Stoo reinforcement work inclided inthe m

18 |HSE Onn) Page 4, Section 5! shall be included in this secton po GZAAEMST-CV-009°2 [Dane refer to se. 7 Closed

Review Comments Sheet (RCS) KEOW

[Project Name: Grand Zone - School & Residential RFS: 18.5441-CM00

[cs Ref. No. + GZ-AAE-MST-CIV.CS-0003 CS Rov.:2

[Documont. Ref. No: OT 0135

[Transmittal Ref. No: GZ-AAE-MST-CIV-0003,

[Document title:

___ Method Statement for Co

[Engineer in charge: Mohamed Afity/ Manshad M:

Review Response Code: c A=viodbjecion __A=NoOlection Subjecto earuatenofallconmensasneted __C=Reecte tobe esate

Commented | Review Reference : KEO Responso: Sign

KEO Reviow C

cet testes ‘omments /_Pocsows.Reternca: Contractors Reply ae

How about te access contol wile operatives working ontop of steel

bars, form work et? Hazards associted to access legrse shall be

25 shal be provided forthe

19 | Hen IRA s 2 G2-MEMST-CW.00802 |updated Open

pec risk associate ectvly does not covered inrak assosement

Jrsxmaca

20 | sen IRAs 4 GZAAE-MST-CIV-00.02 [Updated as rogues Open

21 | Hsenaw IRA ss GZ-AAE-MST-CWV-00802 Tool and Equipments Updted Open

Review Comments Sheet (RCS) KEOW

Project Name: Grand Zone - Schoo! & Residential RFS: 18-5441-CM00

[CS Ref. No. 1 GZ-AAE-MST-CIV-CS.0003 _

(Document. Ref.No: DT 0135

1. Recalved Date: 20-0c%-19

[Transmittal Ref. No. GZ-AAE-MST-ClV.0003 Doc Dwg, Received Date: 20-0c

became: saiod Satoment or Conese Works at: 20.0040

[Engineer in charge : Mohamed Afify/ Manshad Manaf_ Discipline: Civil

Review Response Code: Cc | A=No objection [B= No Objection Subject to Incorporation of al comments as noted (C=Rejected, tobe resubmitted |

Commented | Review Reforence : c KEO Response: Sign!

eee lee KEO Reviow Comments, Doc /Dwg. Reference: Contractor's Reply Om (Opantioeeds

How the hot work a be controlled? What about the PTW

2 | HseMM HIRAS8 [requirements Liting defined as hazard, whats the control measures | GZ-AAE-MST:CiV.003-02 [Updated as requred Open

or mitigating hazards associated to liting?

[The isk assessment is incomplete and the following items listed]

[below must consider but not limited to:

1. Rebar works

2. Shuttering and de-shuttering

13. De-naling

[4 Material storage / stacking

's. Concreting using placing boom

6. Concrete waste disposal

17. Concrete pump cleaning

8. Possible liting operation forrebars, formwork, et.

Additional

2 Requirements

HSE JON GZ-AAE-MST.C1V.003.2 |Updated as required Open

13. Work at height andor near edges

14, Summer season

15. Use of powor and hand tools

6. Applicaton of curing compound

Tesponse is noted, however most of the|

ned items not been considered in isk assessment and}

Jno control measures provided

Project Namo

Ics Ret. No.

Document. Ref. No.:

[Transmittal Ref. No.:

[Document titte:

[Engineer in charge

+ Grand Zone - School & Resa

{GZ-AAEMST-CIV.CS.0008

T0135

Review Comments Sheet (RCS)

GZ-AAE-MST-CIV-0003,

‘Method Statement for Concrete Works

+ Mohamed Afify/ Manshad Manaf

KEOW

RFS: 18-5441-CMO0

CS Rov. 3

Doc /Dwg. Rev. : 3

Doc./Dwg. Received Date: 20-Oct-19

8 Date: 20-Oct-19

Discipline: civil

Review Response Code: c [_Aenoobietion _8=No Obecon Subject to incorportonfallcommentssroted __€= Rejected tobe rexibmiied

Commented | Review Reference : 5 KEO Response: Sign}

sett tee lle: KEO Review Comments Doc Dwg, Reference: Contractor's Reply eae

lvetnod statement and risk assessment for placing boom erecton|

Adcttonat operation and dismanting is required s

24 | HSE/JON | pettherent |The conescorsapange I tee rowever contactor shall growde| CAAEMST-CWV.00802 |To besbmied spun ieee Open

equed document por commence ask

How AAE wil provide and maintain safe acess and egress going al

Planning and [oworksilsovork as wel as working platorm for the execoton of

25 | HSE/son | Fovtarson [ese actives (e.g. rebar works, shutting, concreting, and’ de] GZ-AAEAMST.CWv.00902 updated (Arua arty in HRA: 3) Open

Preparation shuttering?

Not suficient contol povided in HIRA 3. Refer Point 18

Risk Assessments general. Nevertheless, Contactor io ensure ther

ar no factors coud invoduce adatonal hazards or increase he rks

Close superision and regular safety coverage is sticly requ to

update the risk assesament as work progresses. oo

26 | HSE/JON General Notes Provided HIRA does not co. red and control measures not provided) GZAAE-MST-C1V.003.02 —_|Noted, HRA updated. Op

fa the isk mazerds associated withthe task, Task speci el

ssessment shall be conducted contol measures shall be proved

frigate hazards associated tote tack

Identity hazards associa

HIRA $5 lidenti -h n

a7 | sen | giBASS eon 6z-AAEMST.CW.008.2 [Noted HRA update Ope

Project Namo

Ics Ret. No.

(Document. Ref. No.

‘Transmittal Ref. No.:

[Document title:

[Engineer in charge

t Grand Zone - School & Residential

GZ-AAE-MST-CIV-C8-0003

DT 0135

GZ-AAE-MST-ClV-0003

Method Statement for Concrete Works

+ Mohamed Afify/ Manshad Manat

Review Comments Sheet (RCS)

RFS: 18-5441-CM00

CS Rev.: 3

DocJOwg. Rev.: 2

DocJDwg. Received Date: 20-Oct-19

KEOW

Review Response Code: Cc [Ane objection B-=No Objection Subject to incorporation of all comments as noted (C= Rejected, to be resubmitted

Commented | Review Refarence : KEO Response: Sign-

sm KEO Review Comments Doc dwg. Reference: Contractor's

By: | (title ipage /clauso) Re Off (OpeniCiosed)

HRA se identified as walking around the steel rebar: Provide its

8 HSEIMM | Steet and Rebar Work| yences and control measures to eliminate the consequences GZ-AAE-MST-CN 003-02 Noted, HRA update, Open

JRefer to writen comments atthe submital for added infomators|

21 | HSE/ION | Genera Notes [Re wren comment GZAAEMST-CIv-00802 | Noted Open

nsufcient details together with writen remarks inthe submittal must

reply trough comment sheet and mark all the revised or insrted

28 |HSEWONNM) General Notes {eels for easy ienifcaion czanemst-cw-00002 |notes Open

JAAE shall provide risk assessment specific forthe Kentied task

frovcing adequate contol measures

oth

Corrections or comments made relative to submittals during this review does nat reliev

This review is only in respect of general conformance wit the design intent ofthe project and.

ins, forthe design ofthe projector such parts of the projec he has design responsi

fabrication processes and techniques of construction, coordinating his work with that of other trades, and performing his workin a safo and sate!

all in accordance with the Contract.

for (if design forms part

Contract), for

firming ani

factory mar

Ze the contractor from compliance withthe requitements of his Contract, drawings and specications

neral compliance withthe information given in the Contract documents. The contractor remains responsible, among

lating all quantities and dimensions, selecting

KEOW

rand@one | QATAR MALL

GRAND ZONE - SCHOOL AND RESIDENTIAL

TABLE OF CONTENTS

‘SCOPE AND PURPOSE.

1.1 Purpose.

1.2 Score.

2 DEFINITIONS.

‘3 REFERENCES

4 RESPONSIBILITIES.

4.1 Constauction Manacen:

4.2 Sie EnaineeR:

4.3 Site SuPenvison:

4.4 Sie Foreman:

4.5 QAQC ENGINEER...

4.6 HSE Encinecs

4.7 Quer suavevon:

‘5 MATERIALS,

6 SAFETY REQUIREMENTS AND EMERGENCY PROCEDURES.

6.1 EmeRGENCY Response PLAN

6.2 Means 0F COMMUNICATION...

‘8 STEEL REINFORCEMENT.

8.1 CUTTING aN Benowns

8.2 INSTALLATION OF STEEL REINFORCEMENT...

9 CONCRETE CASTING PROCEDURI

9.4 GENERAL con son 9

‘9.2 TESTING & CONTROL OF FRESH CONCRETE: 2

9.3 Work PROCEDURE FOR BLINDING CONCRETE ssn 12

9.4 Work PROCEDURE FoR SLAB ON GRADE CONCRETE ns B

{9.5 Wok PROCEDURE FOr VERTICAL ELEMENTS (WALLS & COLUMNS) mee}

9.6 Woak PROCEDURE FoR RC ABs: uw

9.7 Work PROCEDURE FOR POST TENSION SLAG: 15

9.8 WoRk PRoceDURE FOR FOUNDATION

10 CURING AND PROTECTION OF CONCRETE

10.1 Mossrune Cun

10.2 Cuniis Compouno.

ALATTACHMENTS. o so

GZ-AAE-MST-CIV- 0003 Rev 3 Page 2 of 17

Method Statement for Concrete Works

‘hs docament she property af AA Engng Co MLL who wl fpr rhs scordng tthe cad peal prowons of ela

KEOW

irand@one | QATAR MALL

ea f aes

GRAND ZONE - SCHOOL AND RESIDENTIAL

HAZARD IDENTIFICATION AND RISK ASSESSWENr.

mm vos

(Cheek Ust—BUNDING...

(Heck ust — FoRdwons vs

(Check ust ~ REINFORCING Steet

(Check ust ~ConcreTE CURING..

‘Sunver Rerorr,

GZ-AAE-MST-CIV- 0003 Rev 3 Page 3 of 17

Method Statement for Concrete Works

‘Ts cocoment the propery of A Engesng Co WIL who wl ssid hts coring othe hl ard pra pein of he aw.

KEOW /Grand@one| Qatar MALL presen ences

Scope and Purpose

1.1 Purpose

‘The purpose for this method statement isto define and document the responsibilities of Key

Project Personnel responsible for

Tequired for properly performing the work in keeping with this Method statement,

. Project

Specification (Mall of Qatar - Grand Zone, School & Residential, Qatar Specification volome

|!) ‘and Code Standards to meet project and quality objectives and maintain good

workmanship practices.

1.2 Scope

This Method Statement, detalls the sequence and activities to be followed for the Concrete

Works during the construction activities for the MALL OF QATAR ~ GRAND ZONE, SCHOOL

RESIDENTIAL, QATAR PROJECT. it defines personnel responsit

related to proper execution of Concrete Works.

2 Definitions

cM ‘Construction Manager

‘Qc ‘Quality Control

L SE Site Engineer

cs Chief Surveyor

HSE Health, Safety and Environment

iP Inspection and Testing Plan

HRA Hazard Identification & Risk Assessment

Consultant KEO. _|

Contractor AIAli Engineering Co.

3 References

Specifications: — QCS 2014 ~ Section 5 - Concrete.

QCS 2014 / Section 1 / Part 10

QCS 2014 / Section 4 / Part 14

QCS 2014 / Section 11 / Part 1.1, 1.5, and 2.3.11

Specifications: Project technical specification — Volume Il — Division 03,

Drawing: Relevant IFT drawing

Approved Project HSE Pian “GZ-AAE-PLN-HSE-0001”

Project Fire safety plan & Emergency plan

GZ-AAE-MST-CIV- 0003 Rev 3

Method Statement for Concrete Works

‘Wisdocamet the papery of 8A Engen Co, WL who slid sighs arnt tec en peel plots

Page 4 of 17

KEOW |Grand@one| QATAR MALL we f ae

GRAND ZONE -SCH004 AND RESIDENTIAL

4 RESPONSIBILITIES

4.1 Construction Manager:

Responsible for overall construction activities ensuring that all quality and safety procedures

are implemented and required approved permits are obtained.

4.2 Site Engineer:

Supervise operations in accordance with the approved Method Statement, shop drawings,

Specifications, material submittals and schedules to achieve the acceptance of the Project

deliverables,

4.3 Site Supervisor:

Supervise closely, the activities designated to them and ensure that al instructions and safety

Procedure are followed and strictly adhered to.

4.4 Site Foreman:

To liaise with Site Engineer and Site Supervisor for the work execution.

4.5 QAQC Engineer:

Gonduct surveillance and inspection duties at various stages to ensure compliance to QA/QC

Plan

Ensure enforcement of safety in accordance with the approved HSE plane.

4.7 Chief surveyor:

To insure regular secure and check the control

with proper monitoring of the executed work at site,

is and maintain all devices calibrated,

5 Materials

> Approved Concrete Mix Design (Ref.: GZ-AAE-MS-ClV-0001)

7 Guring compound (Ref.: GZ-AAE-MS-CIV-0008 or approved equal).

> Bonding Agent (GZ-AAE-MS-CIV-0003 or approved equal).

= Reinforcing steel (Ref.: GZ-AAE-MS-CIV-0011),

> Formwork material (Ref. GZ-AAE-PRQ-STR-0005 or approved equal).

= Polyethylene sheet (GZ-AAE-MS-CIV-0004 or approved equal).

- Water stops (GZ-AAE-MS-ClV-0073).

> High density non-compressible infil (To be submitted).

> Structural Polystyrene fil (To be submitted).

- Spacers

+ Binding wire

= Others,

Each material shall be used under supervision of trained personnel to avoid any incorrect application

or selection of materials at site.

GZ-AAE-MST-CIV- 0003 Rev 3 Page S of 17

Method Statement for Concrete Works

‘Tne document she oper of 6A ngetng WL ho wl slept hs corto the hi end pe pent of ee

KEOW /Grand@one) QATAR MALL crams fee

GRAND ZONE - SCHOOL AND RESIDENTIAL

6 Safety Requirements and Emergency Procedures.

6.1 Emergency Response Plan

AAE shall prepare a comprehensive Emergency Response Plan that will serve as a procedural

and operational document in the event of an emergency incident occurring,

This plan includes provision for emergencies involving, but not limited to Fire Workplace

Incidents leading to fatalities, major injuries or ill health; Natural Disasters; Civil Disturbance,

Terrorism and War, Catastrophic failure of plant and equipment; Environmental Incident (Release

of Hazardous Material Substances)

Periodic drills designed to test the effectiveness of these plans will be carried out in accordance

with a drill schedule, Additional drills will be devised and added to the schedule as main

construction work progresses. Post exercise debriefs and lessons learned will be used to

continually improve response efficiency and effectiveness.

AAE will ensure that adequate resources are made available to allow effectively and timely

Fesponse in the event of an emergency. All personnel will be notified of their role in any given

(foreseeable) emergency situation.

Personnel critical to the effective execution of the emergency response will be suitably trained

and verified as competent. Managers with responsibility for command and control of an

emergency response will be fully competent in the execution of their duties,

Further information is contained in the Emergency Response Plan (AAE - Emergency Response

Plan)

GZ-AAE-MST-CIV- 0003 Rev 3 Page 6 of 17

Method Statement for Concrete Works

‘hs decent the property oF AA neering Co LL who wl safes ght act t the cad penal rovons of the ow.

KEOW | Grand@one

QATAR MALL |

GRAND ZONE - SCHOOL AND RESIDENTIAL

6.2 Means of Communication

Cati-Our Prorocot

‘ALAli Engineering Co. -

First Aid / Medical |__|

Department

ACCIDENT/ INCIDENT

Site Engineer /

Site Foreman/Medical

Representative

[>] PROJECT MANAGER.

FIRE /AMBULANCE /

Pouce

CALL: 999.

HOSPITAL,

HSE. OFFICER

|

EMERGENCY Call-Out Protocol

7 Tools, Plant & Equipment

Concrete Pump.

Concrete mixers.

Vibrators.

Trawling machine.

Manual trowels,

Shear line machines (Cutting).

Bending rebar machines.

Coil machines,

Personal Protective Equipment.

GZ-AAE-MST-CIV- 0003 Rev 3

Method Statement for Concrete Work

ks

Page 7 of 17

Tht doament sth ron ef ALANEAgrenng Ca M.LL who wi lege las cog othe ch ange pov ten

KEOW | Grand@one | QATAR MALL

GRAND ZONE - SCHOOL AND RESIDENTIAL

8 Formwork

* Contractor shall ensure that the finished concrete members conform accurately to the

dimensions, lines and elevations shown on the drawings and to the specified tolerances.

+ Formwork shall be of such strength and rigidity as to cary the weight and pressure from the

fresh concrete to be placed on or against it.

* Formwork shail be sufficiently tight to prevent loss of grout during vibration of the concrete and

faces of formwork shall be clean, free from protrusions, adhering grout and other imperfections

or defects. Form surfaces shall be cleaned and repaired before re-use in the construction,

Contractor shall coat forms with form-release agents or form oil. Surplus oil on forms,

reinforcing steel, water stops and construction joints shalll be removed before placing concrete.

* Box-out shall be constructed to be easily removable without damaging concrete and preventing

the loose of grout.

+ Forms of beam sides, walls and columns can be removed after 24 hours of placing concrete.

* The formwork shall be constructed so that the side forms of members can be removed without

disturbing the soffit forms.

* Position chamfer moulding strips on edges of permanently exposed concrete columns and

beams.

* Formwork and props under beam soffts, slabs and other structural elements that support

weight of concrete shall be left in place until concrete achieved a least 70 percent of 28 day

design compressive strength. Forms shall be removed after compressive strength test results

are approved by consultant and according to project specification sec 03 1000 close 3.05 of

division 3. As following:

Vertical formwork to columns, walls and] 24 hours

[large beams

Beam sides 24 hours

Joist or Beam soffts formwork TS days:

Joist, beam or girder soffits for over 6m | 21 days

clear span between structural supports

Props to beams 2i days

Soffit formwork to slab 6 days

Props to slab 15 days

Props to cantilever beam 21 days

8 Steel Reinforcement

8.1 Cutting and Bending

> Prior to start all steel reinforcement, materials shall be segregated as certain in the

storage area conforming project specifications compliance, Storage of reinforcement

Shall be on suitable structures a minimum of 450mm above the ground surface.

> All Cutting/Bending machines should be checked for any deficiencies prior to

commencing the work activities and especially the emergency stop buttons.

> The foreman in charge for the rebar shop illustrates to every charge hand responsible

GZ-AAE-MST-CIV- 0003 Rev 3 Page 8 of 17

Method Statement for Concrete Works

‘Th document the propery of AIA Engen Co WL who wl safeguard ris ccorng tothe ond pa provsonet helm

KEOW |(

pnd @one | QATAR MALL

GRAND ZONE - SCHOOL AND RESIDENTIAL

for a production line the work to done.

Rebar tags showing the quantities, shapes, lengths and diameters will be attached.

The charge hand in his turn should convey the work to be done to his group & constantly

monitor their operations.

The operator in charge of cutting machine starts the operation of cutting the rebar by

instructing the helper to roll the first bar from the production sleeper through the cutting

machine.

The other helper in his turn should adjust the bar to the designated length.

The operator of the cutting machine then manually moves the handle to cut the rebar.

‘The cut rebar is then scrolled on the table to reach the assistant of the bending machine

operator.

‘The operator of the bending machine adjusts the machine parts as per the shape/angle

required and checks the buttons to be set to the correct direction and then starts the

machine until the rebar is bent.

> Fabricated steel reinforcement will be stored in the stockpile area.

» Test results for steel samples to be obtained from approved Third party laboratory and

‘shall be submitted for consultant's review and approval.

vy

v

vovyy

8.2 Installation of steel reinforcement

> Ensure that the reinforcement is clean and free from corrosive pitting, loose rust, loose

mill and oil prior to placing

> All reinforcement shall be securely and accurately fixed in position shown on the

approved drawings to ensure that the reinforcement steel framework as a whole shall

retain its shape.

> Approved binding wire shall be used for tying the bens. The ends of all binding wires

shall be tured internally into the concrete and not allowed to project towards the

surface,

> No part of the reinforcement shall be used to support access ways, working platform or

for conducting of an electric current.

> Reinforcement shall not be straightened or re-bent without approval of the consultant.

> All reinforcement shall be provided with requisite spacers, chairs, ties, bracing,

temporary and permanent supports for reinforcement using approved compatible

materials as per BS 7973.

> Supplementary bans spacers shall be provided to ensure the adequacy of cover and

stability and to fix cast in items and ties bars as required

> The cover block of necessary thickness will be provided. The mortar or concrete used

for making cover block shall be with a high strength,

> Correct concrete cover to the reinforcement shall be maintained with the aid of approved

spacer.

9 Concrete Ca

g Procedure

9.1 GENERAL

> Request for Concrete Pouring shall be submitted to consultant for approval 24 hours in

advance, showing location of work, pouring time and all required items to be inspected

(Formwork, reinforcement, inserts, water stop, ....,etc.) prior to commence concrete

pouring

G2-AAE-MST-CIV- 0003 Rev 3 Page 9 of 17

Method Statement for Concrete Works

“is document she property HAA Enering Ce WILL who wt sfegvard se acon the clan el rove of he ow

KEOW | Grand@one| QATAR MALL =

GRAND ZONE - SCHOOL AND RESIDENTIAL

» Glearance by MEP and surveying parties to be assured prior to commence pouring

concrete.

Access to work to be ready and approve by safety personnel during the work and prior

to inspection.

Concrete batch plant and third party to be checked by QC engineer and there fully

readiness is assured.

Concrete pouring shall be planned considering the weather conditions.

For concreting during hot weather, the hot weather period shall be defined as starting

when the maximum ambient air shade temperature on the Site exceeds 35 C for thron

consecutive days. The end of the hot weather period shall be defined as the period when

the maximum air shade temperature is below 35 C on three consecutive days,

» The contractor shall establish a thermometer on Site that records the ambient air shade

temperature. The thermometer shall be established at a position to provide

representative air temperature for the Site conditions. if requested by the Engineer the

Contractor shall arrange for the calibration of the Site thermometer.

» Concrete Temperature shall at no time during its production or transportation exceed 30°C

‘Conerete production in hot weather to be arranged according to QCS 2014 section 6 part

15.

vy vv

> Upon the arrival of concrete to the casting location the following items shall be checked by

QC engineer! inspector and 3rd party laboratory technician in accordance with ITP for

Concrete Works:

i. Concrete Batching Time.

il, Checking the Discharge time of ready-mix concrete (Max. 90 min. or 300

revolutions)

ii, Concrete Grade

iv. Ambient Temperature (Max.37 C)

V. Concrete Temperature (Max. 30 C)

Vi. Conerete Slump (200 + 40 mm as per Project specification)

vil. Concrete Cubes Samples

> When placing Structural Mass Concrete, do not allow its temperature to exceed 25 C. Do

not allow the concrete to exceed the maximum temperature of 70 C at any time

Guring the curing. Maintain thermal control of each placement until Ensure that the

temperature differential between the geometric center of each placement and the

geometric surface does not exceed 20 C.

» To prevent flash setting ofthe concrete the reinforcement and form work will be sprinkled

by water.

> Concrete surfaces at construction joints shall be treated by any means to remove laitance

and expose the aggregates and an approved bonding adhesive shall be applied to

‘construction joint surface.

> Every effort must be taken to minimize impact between pump boom, placing boom, skip

and the formworks. If any impact occurs in concrete cover, plumb/ alignment of formwork

must be re-checked.

> The concrete shail not be dropped through a free height greater than 1.5 m.

> Concrete vibration shall be executed in a controlled and systematic manner o ensure that

Placed concrete shall be properly compacted to provide uniformity of finished surfaces and

reducing entrapped air sufficiently to attain a concrete density consistent with the intended

Strength and other requirements of concrete mixture.

> The concrete layers should be as level as possible so that vibrator is not used to move the

GZ-ARE-MST-CIV- 0003 Rev 3 Page 10 of 17

Method Statement for Concrete Works

This ocaen th property of ALA Ergin Co. WELL who wl seguir scart the cand pen provors thelam,

KEOW | Grand@one| QATAR MALL

GRAND ZONE - SCHOOL AND RESIDENTIAL |

concrete laterally to prevent segregation. When the placement consists of several layers,

Concrete delivery should be scheduled so that each layer is placed while the preceding one

's plastic to avoid cold joint. ifthe underlying layer has stiffened just beyond the point where:

itcan be penetrated by vibrator, bond can still be obtained by thoroughly and systematically

vibrating the new concrete into contact with the previously placed concrete.

» Stops in concrete, at the end of a period of work, shall be made only at construction joint

locations shown on the drawings and/or positions accepted, Where the positions of

Construction joints are notindicated on the drawings, these may be assumed, for estimating

Purposes, to occur at 5 metre intervals in foundations and retaining walls and at one-third

{0 one-quarter of span in siabs and beams subject toa maximum spacing of approximately

9 metres.

> If ever, a cold joint is formed due to unavoidable reasons, the following procedure is

adopted for treating it:

~ concrete is still controllable, a very minor hardening took place that it can be

removed manually and if vibrators can penetrate the surface without much effort,

fresh concrete can be placed directly against the old surface. The old concrete should

be covered by fresh concrete as quickly as possible and the joint thoroughiy and

systematically vibrated.

~ _ Incase concrete has hardened a bit more but can stil be easily removed by a light

hand pick, the surface will be raked thoroughly and the loose concrete removed

Completely without disturbing the rest of the concrete in depth. rich mortar layer 12

mm in thickness, is placed on the cold joint, fresh concrete is then placed on the

‘mortar layer and the joint is thoroughly and systematically vibrated penetrating the

vibrator deep into the old layer of concrete.

~ _In-case the concrete at the joint has become so stiff that it cannot be remoulded and

‘mortar or slurry does not rise in spite of extensive vibration, after obtaining approval

from the Engineer, the joint is left to harden for at least 12 - 24 hrs. Its then to be

{treated as a regular construction joint, after cutting the concrete to required shape and

preparing the surface.

~ _In.case of cold joint due to unavoidable reason, reinforcement bars willbe placed at

the joint between the first portion and the new pour to serve as connection between

the two portions.

~ Any remedial actions belong to the above shalll be approved by consultant,

» When casting suspended stabs care shail be taken not to allow a built up of concrete in

any particular location, which can cause over loading to false-work than safe capacity,

>» When columns and wall concrete is casted, concrete shall be placed in layers of 300mm-

400mm thickness for correct and proper consolidation of concrete

» When concrete casting around embedded items, care shall be taken to ensure that

consolidation around and undemeath steel plates, bolts, etc. is provided and location of

‘embedded items are not changed.

GZ-AAE-MST-CIV- 0003 Rev 3 Page 11 of 17

Method Statement for Concrete Works

‘Ti documes the prope ofA A Exgaerin Co. W.LL who mses ight acre t the ch ad penal rovons tele

KESW Grand@one| QATAR MALL

germs Bene

GRAND ZONE - SCHOOL AND RESIDENTIAL

9.2 TESTING & CONTROL OF FRESH CONCRETE:

>

>

>

v

vvvy

vvv

>

>

>

Conerste production will be controlled according to the Approved material submittal for

“Ready mix concrete — Mix Design”.

‘Samples for each grade of fresh concrete shall be taken separately. For each day's pour

QC engineer shall obtain at least one composite sample set for each grade of concrete.

Lab Tech shall obtain one composite sample for each day's pour concrete mix less than

110 m3, plus one composite sample for each additional 110 m? or fraction thereof,

minimum one set to be obtained per cast day.

‘Samples for compressive strength composed of 6 cubes 160 mm x 150 mm x 150 mm

shall be taken, 2 Cubes to be tested on 7 days and 2 Cubes to be tested on 28 days and

2 Cubes at 56 days.

For Water Permeabilty & Rapid Chloride Penetration test, 3 specimens at 28 days and 3

‘specimens at 56 days for each 250 m’,

For SOsand Cl contents, 1 cube specimen to be taken for each 250 m2,

Ensure that samples are taken in a shaded area away from vibration.

Concrete unit weight to be checked each 50m, or twice a day as a minimum,

Slump tests shall be carried out in accordance to specifications and conforming to BS EN

12350-2 at the rate of one test per load of concrete delivered to the Site or one test per 10

m3 whichever is the lesser for the first 50 m? of concrete then at a rate of 1 slump test for

every 50 m3 if concrete was consistent during production.

One concrete temperature test shall be performed at the point of placement for each load

to ensure that the concrete temperature doesn't exceed 30 °C at any time.

Concrete samples shall be made and cured in accordance with ASTM 31/C 39.

Deformed or damaged moulds shall not be used for sampling fresh concrete,

Each sample shall have a tag placed on top surfaces indicating the concrete information

below;

* Concrete sample identification number which will start from “1”,

* Concrete delivery ticket number and concrete date.

* Concrete temperature and slump for that set of 6 samples.

‘Samples shall be transported to the final curing water tanks within 48 h.

‘Samples shall be stored in moist condition with free water maintained on their surfaces at

all times at a temperature of 23 + 2°C.

‘Samples for durability test to be taken in accordance with project specification

9.3 Work procedure for blinding concrete

>

>

>

>

>

When excavation of foundation is completed, formation level to be checked and inspected.

When compaction of foundation is completed, contractor shall raise INR to inspect the

‘completed activity in accordance with the ITP.

Request for concrete pouring shall be submitted to consultant for approval, showing

location of work, pouring time and all required data after INR is accepted.

Proper anti termite treatment to be assured prior to start blinding,

Contractor is sole responsible to organize concrete supplier for production, site

Preparations, necessary equipment (including curing materials), precautions for weather

Conditions, lights for night works etc, prior to start of concrete casting,

GZ-AAE-MST-CIV- 0003 Rev 3 Page 12 of 17

Method Statement for Concrete Works

‘hs ocr s the propery of ALA rgnetring Co W.LL wha wl afegurds ret cording tthe cand pen! rvs tea.

Grand@one | QATAR MALL

GRAND ZONE - SCHOOL AND RESIDENTIAL

> Site Engineer will order the concrete to the concrete supplier company. Blinding concrete

will be delivered to site. Required field tests shall be carried out as per ITP for Concrete

Works to ensure that blinding concrete meets the specified requirements.

> Concrete batches which field test results fail shall be rejected,

» Resources as labours and casting tools shall be abundant and enough to carry out the

blinding concrete works and housekeeping after the completion of concrete activities.

> Blinding concrete casting will be performed according to approved shop drawing drawings.

> Concrete surface finishes shall comply with Specification, aligned, smooth and free from

cracks,

> Appropriate curing to be provided as per specification.

9.4 Work procedure for Slab on grade concrete

» When fill is completed, formation level to be checked and inspected,

» When compaction under slab on grade is completed, contractor shall raise INR to inspect

the completed activity in accordance with the ITP.

> Polyethylene sheet Vapor barrier not less than 1000 gauge (250 micron) thick clear lapped

100mm on sides and ends to be laid over approved compacted fil.

> Steel mesh reinforcement to be installed as per shop drawing maintaining lapping and

concrete cover.

> Install joint‘filer strips at slab junctions with vertical surfaces, such as column pedestals,

foundation walls, grade beams, and other locations, as indicated in shop drawings,

> Extend joint-filer strips full width and depth of joint, terminating flush with finished concrete

surface,

> Install joint-iler strips in lengths as long as practicable. Where more than one length is

required, lace or clip sections together.

> Request for concrete pouring shall be submitted to consultant for approval, showing

location of work, pouring time and all required data after INR is accepted.

» Contractor is sole responsible to organize concrete supplier for production, site

preparations, necessary equipment (including curing materials), precautions for weather

Conditions, lights for night works etc. prior to start of concrete casting,

Site Engineer will order the concrete to the concrete supplier company. Concrete will be

delivered to site. Required field tests shall be carried out as per ITP for Concrete Works to

ensure that blinding concrete meets the specified requirements,

Concrete batches which field test results fail shall be rejected,

Resources as labours and casting tools shall be abundant and enough to carry out the

blinding concrete works and housekeeping after the completion of concrete aciivities.

Concrete casting will be performed according to approved shop drawing drawings.

Concrete surface finishes shall comply with Specification, aligned, smooth and free from

cracks.

> Appropriate curing to be provided as per specification — water curing,

v

vv vv

9.5 Work procedure for vertical elements (walls & columns)

> Survey works and setting out for walls and columns (vertical elements) to be performed by

total station, concrete lines to be drawn on the foundation top face by chalk line,

> Working platform will be erected at inner sides of walls and around columns. It has to be

Provided with bracings, handrails and aluminium ladders for climbing.

GZ-AAE-MST-CIV- 0003 Rev 3 Page 13 of 17

Method Statement for Concrete Works

‘ docaments th popety ALAN Engineeing Co, who llegar rights scr tothe cand so provsons th

tg

KEOW | Grand@one | QATAR MALL

GRAND ZONE - SCHOOL AND RESIDENTIAL

> Fix steel reinforcement bars vertically and horizontally as per the approved shop drawings.

> Fix embedded MEP item and raise inspection request for MEP works for clearance.

> Placed External water stops as per approved shop drawing and details, PVC water stop

shall have ribs on either side of the center of the water stop. The water bar used at the

location of expansion joints shall have @ bulb in the center of accommodate the

movements.

Water stops to be fixed and centered at the construction joint location.

Vertical and horizontal joints shall be located on site as per the approved shop drawings.

Raise inspection request for rebar and prior to close shutter.

After obtaining approval for MEP works and reinforcement rebar; close the shutter and

brace it

Fix the outer shutter at already marked lines, plumb it to vertical position then brace it at

the top.

For Water retaining wall tie rods should include water stopper or special water tight ties.

Perform final inspection request for pouring including survey, safety checking, and MEP

items.

Use long rubber hoses clamped to the concrete pump to reduce the height of concrete

falling to avoid segregation occurrence, height shall not be greater than 900 mm,

Use enough number of vibrators to facilitate continuity of concrete placing and Keep two

stands by vibrators.

Placing and compacting of concrete will be in layers 300mm height for walls and 500 for

columns.

Pouring level of columns and walls shall be 25mm above soffit of framing slab. Chip weak

concrete at top of lft before placing reinforcement.

Leave top of concrete surfaces of wall and columns slightly rough be exposing part of the

coarse aggregate using steel wire brush.

At the end of each pour, remove cement from all exposed steel bars by using sponge,

water and wire brush

Start curing immediately after removal of formwork with white impregnate curing

compound, top surface to be water cured for 7 days.

Shutter removal to be arranged not before 24 hours from casting finish time.

Afier shuttering removal inspection check listo be raised for post pouring concrete surface

quality check.

vVovovy v vvvy

VY vvwyvy

9.6 Work procedure for RC Slabs:

> Use approved system for slab as per approved shop drawing for scaffolding system with

necessary bracing.

Erect around slab walking platform width not less than one meter to be used for concrete

finishing and compacting.

Survey check for formwork (levels & coordinates).

Fix steel mesh bottom layer as per approved shop drawing

Fix electrical & mechanical embedded item,

‘Complete steel reinforcement top mesh.

‘Complete MEP embedded items.

Install pouring guides to control surface level.

Raise inspection for MEP clearance, steel, formwork, concrete casting.

vyvvvvy v

GZ-AAE-MST-CIV- 0003 Rev 3 Page 14 of 17

Method Statement for Concrete Works

‘This ocamen se propery oFAAI rng Ce WILL who wi spurs gh acon he han perl provi of ew

KEOW |Grand@one| QATAR MALL sera &

mca

GRAND ZONE - SCHOOL AND RESIDENTIAL

vvvvy

v

Pour concrete at lower part such as drop beam to the level of slab bottom.

Start casting concrete from one end toward the opposite side.

Apply mechanical trawling to the concrete surface using power float.

Start water curing immediately after finishing concrete surface for 7 consecutive days.

Shutter removal to be arranged not before 6 days after finish of conarete casting if concrete

has attained at least 70% of the designed strength (subject to test results) as stated in

‘specification (sec. 3 1000 — close 3,05) and after consultant approval.

Props to be removed alternatively so that no large span to be kept free from props during

shutter removal process. Additional temporary supports if necessary can be added to the

area where the shutter removal is taking place.

Props should be fixed immediately after removal of form work and the props should be

‘enough to carry the load of the slab.

'n case of construction joints, shutter removal to be arranged not less than 6 days for

formwork and 15 days for props after the two sides of construction joint are casted and

attained 70% of the design concrete strength. Additional props can be provided along the

construction joint for more support (if needed).

‘The adjacent span to the construction joint span shalll be kept propped unti the construction

Joint span is casted and released.

‘Structural calculation for the back propping, of the lower slabs or any horizontal element,

shall be submitted along with the structural calculation for the formwork of the RC slab.

‘9.7 Work procedure for Post Tension Slabs:

>

Work procedure for PT concrete will be described in detaile

statement for post-tension concrete works,

@ separate method

9.8 Work procedure for foundation

>

vyv vyv vv

vy

‘Survey works and setting out for foundation to be performed by total station, concrete lines

to be drawn on the screed top face by chalk line,

Fix the outer shutter at already marked lines, plumb it to vertical position then brace it at

the top.

Fix steel reinforcement bars vertically and horizontally as per the approved shop drawings

and steel for columns necks.

Fix embedded MEP item if exist.

Raise inspection request for MEP clearance, embedded items and reinforcement steel.

Perform final inspection request for pouring including survey, safely checking, and MEP

item

Use enough number of vibrators to facilitate continuity of concrete placing as follows,

Keep two stands by vibrators.

Place of concrete to be in sequence shown in the drawing, raft to be divided to eleven

Portions and four major poring strips, special method statement for pouring sequence to be

‘submitted later.

‘Start water curing immediately after finishing concrete surface for 7 days.

‘Shutter removal to be arranged not before 24 to 48 hours from finish of casting concret

as stated in specification (sec. 3 1000 — close 3.05) and after consultant approval.

GZ-AAE-MST-CIV- 0003 Rev 3 Page 15 of 17

Method Statement for Concrete Works

‘is documents the property of AIA Egneting Co, WL howl fgets ight coding the hand perl prov few

KEOW [Grind@one| QATAR MALL

GRAND ZONE - SCHOOL AND RESIDENTIAL

10 Curing and Protection of Concrete

‘* Concrete shall be cured for a minimum period of 7 days in accordance with the requirements

of AC! 308.

* Immediately after placing, the concrete shall be protected from premature drying, any injuries,

effects of rain and dust. All necessary material and equipment shall be available at the point

of conerete placing prior to the concreting operations. Concrete shall not proceed without this

provision.

* Concrete curing shall be done by one or combination of the following methods:

10.1 Moisture Curing

* Concrete surfaces shall be maintained continuously wet for the entire curing period. Burlaps

and other cover of absorbent materials or polyethylene sheet with free of harmful substances

can be used for curing on vertical or horizontal surfaces.

10.2 Curing Compound

* Curing compound shall only be used by the approval of the consultants. The curing compound

shall conform to ASTM C 309,

* Curing compound shall be applied to formed surfaces immediately after the forms are removed

‘and prior to any patching or surface treatment except the cleaning of loose sand, mortar and

debris from the surface.

* Curing compound shall be applied to slab surfaces as soon as the finishing operations are

completed.

* The compound shall be applied in a one coat continuous operation by mechanical spray

equipment at uniform coverage. Two coats may be required due to wind and dust condition or

surface texture and shall only be applied by the approval of the consultants. Concrete surfaces

which have been subjected to rainfall within 3 hours after curing compound has been applied

shall be re-sprayed at the coverage specified for initial application.

GZ-AAE-MST-CIV- 0003 Rev 3 Page 16 of 17

Method Statement for Concrete Works

‘Tis coca te property of AAI Erinening Co, WLLL wh wlsefegad is is accutg tothe ct ge poof he i

KEOW | Grnd@one|) QATAR MALL

appa P snsgpons

GRAND ZONE - SCHOOL AND RESIDENTIAL

11 Attachments

Hazard Identification and Risk Assessment

itp

Check list - Blinding

Check list - Formwork

Check list ~ Reinforcing Stee!

‘Check list ~ Concrete curing

Survey Report

GZ-AAE-MST-ClV- 0003 Rev 3

Method Statement for Concrete Works

Page 17 of 17

‘Th ovement sth property ALA reneing Co, W.LL who wegen ish ecard tthe cand pen proven of een

Grand@one | QATAR MALL

KEOW

| GRAND ZONE - SCHOOL AND RESIDENTIAL

Hazard Identification & Risk Assessment

TNE dosent the propery OLA A Engen Co LL. wh wil feuds ries cong tthe ci nd pena tov the om:

Grand@one KEOW

HAZARD IDENTIFICATION & RISK ASSESSMENT

AE/HSE/FM-001 | Rev 00

(te AKINOLA

29th 0 2019 ‘GRAND ZONE-SCHOOL AND RESIDENTIAL PROJECT HSE SUPERVISOR

‘CONCRETE WORK

1.1 Lack of safety 4 )4 (16 1.1.1 All personnel

awareness may lead to ympetence/awareness level shall

accident hazard. | | be ensured. |

1.1.2 Proof of site induction

training and other required/relevant

Pre shall be ensured,

ladhered.

| | 1.1.5 Tool box talk/STARRT shall

‘be conducted to all Personnel on

1 Preparation activities before

‘commencing the task

Cc Page 1 of 46

am Grand@one KEOW

| HAZARD IDENTIFICATION & RISK ASSESSMENT

‘AE/HSE/FM-001 | Rev 00

Site & documented before start of

work by AAE task supervisor or lead

Person.

2 Pre commencement actives | 2.1 Lack of competence (4/4 (46

| ree metra

E wherever it so

Cc - Page 2 of 46

Grand@one

HAZARD IDENTIFICATION & RISK ASSESSMENT

‘AE/HSE/FM-001 | Rev 00 |

2.2 Unfit/unsuitable 4 ]4 |16

Equipment

Page 3 of 46

‘on windscreen (for all operation

area) and color codes where 1

required.

2.2.2 All Drivers/equipment

Operators shail have a valid Qatar

Operators must have a valid and

approved third party certificate

ation to site.

int and equipment shall

basis and checked filed in

fety office

drivers shall undergo

defensive driver training for all

‘operation area,

2.2.5 Equipment maintenance shall

be a top priority to ensure

suitability to work when required.

Grand@one KEOW

HAZARD IDENTIFICATION & RISK ASSESSMENT

‘AE/HSE/FM-001 | Rev 00

3 | Access to workplace 3.1 Unauthorized entry 44 )i6 3.1.4 Fencing/Barricades shallbe 4 914

erected to keep area of activi

well excluded. Operatives shal

| ensure that the barricades are

sufficient to keep off / prevent

| Unauthorized access,

| 3.1.2 Site access points shall

include a boom gate (or similar)

| and security station that is manned

24/7 for the duration of the

Project.

3.1.3 Security signage shall be

erected.

| 3.1.4 Site set up shall be in

accordance with the requirements

set out in KEO HSES 001 ~ General

HSE Requirements for Contractors.

3.1.5 Also on task location,

‘exclusion zone also shall be

marked out to prevent

‘unauthorized entry/exposure to

| risks associated with the task,

C Page 4 of 46

Grand@one KEOW

HAZARD IDENTIFICATION & RISK ASSESSMENT

‘AE/HSE/FM-001 | Rev 00

3.2 Collision with plant a4 /i6 3.2.4 Traffie management shall be 414

and vehicles ine with the

-ements/provisions in

ur(AAE) site Traffic management

| plan/KEO HSES 001 - General HSE

Requirements for Contractors,

HSES 017 ~ Mobile Plant and

Vehicles & HSES 022 ~

Management of Site Traffic

3.2.2 A site logistics/Traffc

management plan shall be

prepared. This shall detail the site

boundary, pedestrian and vehicle

access, site roads, parking; lay

down areas and temporary

structures

3.2.3 Traffic management signage

| and lighting shall be installed as

| necessary.

3.2.4 Traffic management

arrangements for labor drop oft /

collection shall be implemented.

Labor shall not be put at risk from

moving vehicles and machinery

| and delivery concrete trucks.

3.2.5 Traffic Marshalls or ‘Flag’

| men shall control heavy trat

routes and crossing points.

Page 5 of 4

Grand@one KEOW

j

HAZARD IDENTIFICATION & RISK ASSESSMENT

‘AE/HSE/FM-001 | Rev 00

separate pedestrians from

traffic. Pedestrian routes si

clearly marked and illuminated

where necessary. Signage should

be in a language understood by

the majority of the labour.

| 3.2.7 Banks man shall be assign to

‘moving equipment to ensure

| and safe movement around on

Site speed limit of 20Km/H

be enforced,

3.2.9 Speed breakers such as

hump shall be introduced on the

road.

3.2.10 Site security shall be

empowered to monitor and advice

drivers as required.

Page 6 of 46 -

Grand@one KEOW |

HAZARD IDENTIFICATION & RISK ASSESSMENT |

3.3 Slip trip and falls [e335 3.3.1 All Access must be ensured 5/1 | 5

are fee of obstructions, They must

be maintained, dry and clear of

and material storage.

| 3.3.2 A high level of personal

awareness is required from all

employees while transiting around

site both during day and night

| Sine

3.3.3 Where possible workers shall

| adhere to designated pedestrian

walkways.

3.3.4 Adequate cable or hose

management.

3.3.5 All personal are to maintain 2

high degree of vigilance wile

moving around site. All work areas

are required to be kept free os far

as is reasonably practicable from

9 cable; timbers; stones etc

3.3.6 Temporary access shall be

provided over the steel rebar to

fe easy access and

transiting around work location,

| 3.3.8 Waste cleared away as soon

| as it’s generated. Also continuous

housekeeping before, during and

after the task has been completed.

3.3.9 Adequate safe work area

management must be maintained.

Page 7 of 46 =

Grand@one

HAZARD IDENTIFICATION & RISK ASSESSMENT

[4

Material delivery -

Preparation/ Loading and

Offloading of materials

4.1 -Injury to persons.

-Damage to vehicles.

-Damage to equipment.

-Damage to property.

“Injury o Fatality

‘AE/HSE/FM-001 | Rev 00 |

Page 8 of 46

4.1.1 Eyes on path.

4.1.2 Eyes on task.

4.1.3 No personnel are permitted

to be in line of fire of loading

operation. 4.1.4 Only loading of

materials will take place within the

designated or controlled area.

4.1.5 Loading and unloading area

to be barricaded, or

4.1.6 Where barricading are not

task at hand with adequate

supervision.

| 4.1.8 All eyes must be on task

diring loading and offenaing

indside of equipment and

ives must be kept away

from line of fire. Barricades must

be provided to provide

zone as required dui .

4.1.10 No personnel are permitted

to be in line of fire of loading

operat

4.1.11 Only loading of materials

will take place within the

Grand@one KEOW

HAZARD IDENTIFICATION & RISK ASSESSMENT

‘AE/HSE/FM-001 | Rev 00 |

designated or controlled area.

4.1.12 Loading and unloading area

to be barricaded, or

4.1.13 Where barricading are not

Used at a loading area, a fiagmen

will be used to control all

movement activities at the area.

5 = Injury 4/4 "46 (high) "5.1.1 Only trained, competent, 4 -<1~—4

= Fatality | licensed, authorized and skilled

| materials onto vehicle ~ Damage to equipment ork

= Damage to materials 5.1.2 Statutory inspection and

| routine maintenance on forklift

5.1.3 Well maintained forklift only

| to be used.

5.1.4 Eyes on path.

5.1.5 Eyes on task,

5.1.6 Forklift operator to be aware

where applicable to wear: |

Hard hat; Safety boots;

5; Gloves; Reflector

Page 9 of 46

Grand@one

KEOW |

HAZARD IDENTIFICATION & RISK ASSESSMENT

6

Work at Height: Using

Scaffold as w.

ion) at

height and for form work or

false wall work

Vehicles on site

E/HSE/FM-001 | Rev 00 |

Page 10 of 46

La

6.1.1 Scaffolding is inspected ail

during construction and once

complete by an individual with a

scaffolding license

6.1.2Maximum weight of

scaffolding is agreed upon prior to

set-up of scaffold

6.1.2Scaffolding to be secured to

Prevent unauthorized access

6.1.3-Scaffolding is inspected for

defects or damage prior to use

6.1.4-Scaffolding is inspected after

repairs have been made

6.1.5-Scaffolding is inspected

every thirty days |

6.1.6-Scaffolding to be erected and

dismantied by a contractor with a

6.1.7-Agree weight/strength

specification of scaffolding with

scaffolding contractors before

‘engaging them to erect scaffolding

on site

6.1.8-Maintain awareness of total

weight on scaffold, including |

‘employees i}

6.1.9-Under no circumstances are

employees to alter scaffolding

erected by contractors

(0-No employees to work at

in adverse weather

Grand@one KEOW

HAZARD IDENTIFICATION & RISK ASSESSMENT

‘AE/HSE/FM-001 | Rev 00 |

| 6.1.11-Weather protection to be

taken into account when selecting

6.1,12-Employees to use the

correct manual handling

techniques at all times

6.1.13-Scaffold construction area

to be isolated and cleared of all

persons

6.1.14-Trucks are to be escorted

to the area where the scaffolding is

to be constructed

6.1.15-Truck driver made aware,

prior to driving into construction

area, where materials are to be

placed and where the scaffold is to

be erected

6.1.16-Use Personal Protective

Equipment (PPE) such as

| appropriate gloves, head

protection and safety footwear

6.1.17-Employees have completed

Work Safely at Heights Training

| Course

6.1.18-An emergency rescue plan

has been established

| 6.1.19-Manual handling training

| for all employees.

6.1.20Use fall arrest equipment

(harness) attached at all times to

the scaffold when working

‘Page 11 of 46 =

Grand@one KEOW

HAZARD IDENTIFICATION & RISK ASSESSMENT

AE/HSE/FM-001 | Rev 00 | ——|

] 44 716 ail4

7.1.1, Unload rebar from trailers as

close as possible to work area,

7.1. 2. Use proper lifting devices

whenever possible.

7.1.3. Use horses where possible

to reduce repetitive bending,

7.1.4, Use proper lifting

techniques.

Do not overextend.

Reposition yourself if

needed. Do not carry more

| than you can handle.

7.1.8, Get help with heavy and/or

7 | Rebar fixing/Installations Strains

when working in teams.

10, Take regular breaks to

relieve fatigue from constant

lifting.

| 7.1.11, Observe careful hand

placement. Watch out for ends of

tie wire and sharp edges on rebar.

7.1.12, The use of heavy duty

gloves is required.

7.1.13. Use careful hand

placement to prevent pinch points,

7.1.14. Keep fingers out from In-

| between bundles or pieces of

rebar.

7.1.15. Get help with heavy and/or

| awkward bars.

__ Pate 12 oF 46 - a

Grand@one

KEOW

HAZARD IDENTIFICATION & RISK ASSESSMENT

‘AE/HSE/FM-001 | Rev 00 |

7.1.16. Clean work area as needed i

during the day. Pick-up tie wire,

dunnage and excess material as

work progresses.

7.1.17. Keep walk area and paths

of travel unobstructed.

7.1.18. Watch where you are

walking.

7.1.19. Use careful foot placement

while walking on rebar mats and at |

decks.

7.1.20. At excavations, stay back

from edge unless entering or

exiting. 7.1.21. Make sure that

guardrail is around perimeter

and/or use fall protection.

7.1. 22.Make sure that all floor

openings and holes are covered or

protected.

7.1. 23.Must wear a personal fall

arrest system (PFAS) if working