Professional Documents

Culture Documents

SpinChem Stainless Steel SS316L Chemical Compatibility Chart PDF

SpinChem Stainless Steel SS316L Chemical Compatibility Chart PDF

Uploaded by

Junghietu DorinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SpinChem Stainless Steel SS316L Chemical Compatibility Chart PDF

SpinChem Stainless Steel SS316L Chemical Compatibility Chart PDF

Uploaded by

Junghietu DorinCopyright:

Available Formats

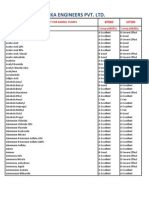

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Acetaldehyde A Allyl Chloride A

Acetamide A Allyl Phenol A

Acetate solvents, crude A Alum Ammonium (ammonium aluminium sulfate) A

Acetate solvents, pure A Alum Chrome (chromium potassium sulfate) A

Acetic acid, 10% A Alum Potassium (potassium aluminium sulfate) A

Acetic acid, 20% A Aluminium Acetate A

Acetic acid, 50% A Aluminium Chloride, 10% B

Acetic acid, 80% B Aluminium Chloride, 20% C

Acetic acid, glacial (anhydrous) A Aluminium Fluoride D

Acetic acid, pure A Aluminium Hydroxide C

Acetic acid, vapours D Aluminium Nitrate A

Acetic Anhydride A Aluminium Potassium Sulfate, 10% A

Acetone A Aluminium Potassium Sulfate, 100% B*

Acetone, 50% water A Aluminium Salts D

Acetonitrile A Aluminium Sulfate, aqueous B*

Acetophenone A Alums A

Acetyl Chloride A Amines A

Acetylene A Ammonia, 10% A

Acrylic Acid A Ammonia anhydrous A*

Acrylonitrile A Ammonia, aqueous A

Adipic Acid, aqueous A *

Ammonia, liquid A*

Alcohol, Amyl A Ammonia, solutions A

Alcohol, Allyl A Ammonium Acetate A

Alcohol, Amyl A Ammonium Bicarbonate A

Alcohol, Benzl B Ammonium Bifluoride B*

Alcohol, Butyl A Ammonium Bromide A

Alcohol, Diacetone A Ammonium Carbonate B

Alcohol, Ethyl A Ammonium Caseinate A

Alcohol, Hexyl A Ammonium Chloride B*

Alcohol, Isobutyl A Ammonium Fluoride D

Alcohol, Isopropyl B Ammonium Hydroxide A

Alcohol, Methyl (methanol, wood alcohol) A Ammonium Metaphosphate A

Alcohol, Octyl A Ammonium Monophosphate A

Alcohol, Propyl A Ammonium Nitrate A

Allkyl Benzene B Ammonium Oxalate A

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Ammonium Persulfate B Beet Sugar Liquors A

Ammonium Phosphate, Dibasic C Benzaldehyde B

Ammonium Phosphate, Monobasic C Benzene B

Ammonium Phosphate, Tribasic B Benzene Sulfonic Acid B

Ammonium Sulfate B Benzoic Acid B

Ammonium Sulfide A Benzol A

Ammonium Sulfite B Benzonitrile D

Ammonium Thiocyanate A Benzyl Chloride B

Ammonium Thiosulfate A Bleach (sodium hydrochlorite, 5.25%) A

Amyl Acetate A Bleach (chlorine, 12.5%) C

Amyl Alcohol A Borax (sodium borate) A

Amyl Chloride B Boric Acid A

Animal Oils A Brake Fluid A

Aniline B Brewery Slop A

Aniline Dyes A Brines, acid B

Aniline Hydrochloride D Bromine D

Antifreeze A Bunker Oils (fuel oils) A

Antimony Trichloride D Butadiene A

Apple Juice A Butane A*

Aqua Regia (80% HCl, 20% HNO3) D Butanol (butyl alcohol) A

Arochlor™ 1248 B Butter A

Argon Gas A Buttermilk A

Aromatic Hydrocarbons C Butyl Acetate (butylacetate) B

Arsenic Acid A *

Butyl Amine A

Arsenic Pentafluoride Gas A Butyl Carbitol A

Arsine Gas A Butyl Cellosolve A

Asphalt, emulsion A Butyl Chloride B

Asphalt, liquid A Butyl Ether A

Barium Carbonate B Butyl Phthalate B*

Barium Chloride A Butylamine A

Barium Hydroxide B Butylene (butadiene) A

Barium Nitrate B Butyric Acid B*

Barium Sulfate B Calcium Bisulfate A

Barium Sulfide B *

Calcium Bisulfide B

Beer A Calcium Bisulfite A

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Calcium Carbonate B Chlorine, dry B

Calcium Chlorate A Chlorine Dioxide D

Calcium Chloride, aqueous, 30% B *

Chlorine Water C

Calcium Fluoride A Chlorine, anhydrous liquid C

Calcium Hydroxide (Lye) B Chlorine, dry B

Calcium Hydroxide, 10% B Chloroacetic Acid B

Calcium Hydroxide, saturated B Chlorobenzene, mono B

Calcium Hypochlorite, 30% C Chloroform, dry A

Calcium Nitrate B *

Chloronapthalene B

Calcium Oxide A Chloropicrin B

Calcium Sulfate B Chlorosulfonic Acid B*

Calgon A Chocolate Syrup A

Cane Juice A Chrome Alum (chromium potassium sulfate) A

Cane Sugar Liquirs A Chromic Acid, 5% A

Caprylic Acid A Chromic Acid, 10% B

Carbolic Acid (phenol) B Chromic Acid, 30% B*

Carbon Bisulfide B Chromic Acid, 50% B*

Carbon Dioxide, dry A Chromic Oxide, aqueous B

Carbon Dioxide, wet A Chromyl Chloride A

Carbon Disulfide (carbon bisulfide) B Cider A

Carbon Monoxide Gas A Citric Acid A*

Carbon Tetrachloride B Citric Oils A

Carbon Tetrachloride Gas, dry B *

Citrus Juices A

Carbon Tetrachlotide Gas, wet A* Clorox® bleach (sodium hypochlorite, 5.23%) C

Carbon Tetraflouride Gas A Cochloroethylene A

Carbonated Water A Cocoa Butter A

Carbonic Acid A Coconut Oil A

Castor Oil A Coffee A

Catsup A Coffee Extracts, hot A

Caustic Potash (sodium hydroxide) A Cooking Oil A

Cellulube A Copper Acetate (blue verdigris) A

Cellusolve (glycol ethers) A Copper Ammonium Acetate A

China Wood Oil (Tung oil) A Copper Carbonate A

Chloric Acid C Copper Chloride D

Chlorinated Glue A Copper Cyanide B

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Copper Fluoborate D Diethyl Carbonate B

Copper Nitrate A *

Diethyl Ether B*

Copper Sulfate, 5% B Diethylamine A

Copper Sulfate, > 5% B Diethylene Glycol A

Copperas (hydrated ferrous sulfate) B Diethylenetriamine B

Corn Oil A Diisobutyl Ketone A

Cottonseed Oil A Diisopropyl Ketone A

Cream A Dimethyl Aniline B*

Cresote Oil (coal tar) A Dimethyl Formamide (DMF) B

Cresols A Dimethyl Hydrazine B

Cresylic Acid A Dimethyl Terephthalate (DMT) B

Crotan Aldehyde A Dimethylamine (DMA) A

Crude Oil, sour (0.5-2.5% sulphur) A Dioctyl Phthalate (DOP) A

Crude Oil, sweet (0.2-0.5% sulphur) A Diphenyl B

Cupric Acid B* Diphenyl Oxide A

Cupric Sulfate, aqueous B Disodium Phosphate A

Cuprous Ammonia Acetate, aqueous B Dowtherms (Diphenyl) A

Cyanic Acid A Dry Cleaning Fluids A

Cyclohexane A Dyes A

Cyclohexanol A Ehtyl Chloride, wet B

Cyclohexanone A *

Ehtylene Chlorohydrin A

Detergent Solution A Epichlorhydrin A

Detergents A Epsom Salts (magnesium sulfate) B

Dextrin B Esters, general A

Dextrose A Ethane A

Diacetone Alcohol A Ethanol A

Diborane A Ethanolamine A

Dibutyl Ether A Ethers A

Dibutyl Phthalate A Ethyl Acetate B

Dibutylamine A Ethyl Acetoacetate A

Dichlorobenzene B Ethyl Acrylate A

Dichloroethane B Ethyl Alcohol A

Dichloroethylene A Ethyl Benzene B

Dichlorohydrin B Ethyl Benzoate B

Diesel Fuels A Ethyl Chloride, dry A

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Ethyl Ether B Freon 14 Tetrafluoromethane A

Ethyl Sulfate D Freon 21 Dichlorofluoromethane A

Ethylene Bromide A Freon 22 Chlorodifluoromethane A

Ethylene Chloride B Freon 23 Trifluoromethane/Fluoro-form CHF A

Ehtylene Chlorohydrin B Freon 31 Chlorofluoromethane A

Ethylene Diamine B Freon 113 TF Trichlorotrifluoroethane A

Ethylene Dichloride (dichlorethane) B Freon 115 Chloropentafluoroethane C A

Ethylene Glycol B Freon 116 Hexafluoroethane C A

Ethylene Oxide B Freon TF (trichlorotrifluoroethane) A

Ethylene Trichloride B Freon, dry A

Fatty Acids A Fruit Juices A

Ferric Chloride D Fuel Oils A

Ferric Hydroxide A Furan Resin A

Ferric Nitrate B Furfural B

Ferric Sulfate A Gallic Acid B

Ferrous Chloride D Gasoline, aviation A

Ferrous Sulfate B Gasoline, high aromatic A

Ferrous Sulfate, saturated B Gasoline, leaded A*

Fertilizer Solutions A Gasoline, refined A

Fish Oils A Gasoline, sour A

Fluoboric Acid B Gasoline, unleaded A*

Fluorine B Gelatin A*

Fluorosilicic Acid D Germane Gas A

Food Fluids and Pastes A Gin A

Formaldehyde, 35% A Glucose A

Formaldehyde, 37% A Glue (PVA, polyvinyl acetate) A*

Formaldehyde, 40% A Glycerine (glycerol) A

Formaldehyde, 50% A Glycolic Acid, < 70% (hydroxyacetic acid) A

Formaldehyde, 100% A Glycols A

Formaldehyde, cold A Gold Monocyanide A

Formaldehyde, hot A Grape Juice A

Formic Acid B Grease A

Freon 11 (trichlorofluoromethane) A Green Liquor Sulfate A

Freon 12 (dichlorodifluoromethane) B Helium Gas A

Freon 13 (chlorotrifluoromethane) A Heptane or n-Heptane A

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Hexane or n-Hexane A Hydroquinone B

Hexanol, tertiary A Hydroxyacetic Acid < 70% (glycolic acid) A

Hexyl Alcohol A Hypo (sodium thiosulfate, sodium hyposulfite) A

Honey A Hypochlorites, Sodium D

Hydraulic Oil (petroleum) A Hypochlorous Acid D

Hydraulic Oil (synthetic) A Ink C

Hydrazine A Iodine D

Hydrobromic Acid D Iodine Solution, 10% D

Hydrobromic Acid, 20% D Iodine, in alcohol A

Hydrobromic Acid, 50% D Iodoform A

Hydrobromic Acid, 100% D Isobutyl Acetate B

Hydrobromic Acid, dilute D Isooctane A

Hydrochloric Acid, 20% D Isopropyl Acetate A

Hydrochloric Acid, 37% D Isopropyl Alcohol (isopropanol) A

Hydrochloric Acid, 100% D Isopropyl Ehter A

Hydrochloric Acid, dry gas D Isopropylamine B

Hydrocyanic Acid D Jet Fuel (JP3, JP4, JP5, JP6) A

Hydrofluoric Acid, < 50% D Kerosene A

Hydrofluoric Acid, 50% D Ketchup (tomato sauce) A

Hydrofluoric Acid, 70% D Ketones A

Hydrofluoric Acid, 75% D Lacquers A

Hydrofluoric Acid, 100% C Lacquer Thinners A

Hydrofluosilicic Acid, 20% B Lactic Acid B*

Hydrofluosilicic Acid, 100% D Lard (animal fat) A

Hydrogen Cyanide C Latex A*

Hydrogen Fluoride A Lauric Acid A

Hydrogen Gas A Lead Actate B

Hydrogen Iodine B Lead Chloride B

Hydrogen Peroxide, 10% B Lead Nitrate B

Hydrogen Peroxide, 30% B Lead Sulfamate C

Hydrogen Peroxide, 50% A *

Lead Sulphate A

Hydrogen Peroxide, 100% A *

Ligroin A

Hydrogen Sulfide, aqueous A Lime A

Hydrogen Sulfide, dry A Lime Sulfur (calcium polysulfides) A

Hydrogen Sulfide, wet cold D Linoleic Acid A

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Linseed Oil A Methyl Acrylate A

Lithium Bromide A Methyl Alcohol 10% A

Lithium Chloride A *

Methyl Bromide A

Lithium Hydroxide B Methyl Butyl Ketone A

LPG (liquified petroleum gas) A Methyl Cellosolve B

Lubricants A* Methyl Chloride A

Lubricating Oils A Methyl Ethyl Ketone (MEK) A

Lye (calcium hydroxide) B Methyl Formate A

Lye (potassium hydroxide) A Methyl Isobutyl Carbinol A

Lye (sodium hydroxide) B Methyl Isobutyl Ketone (MIK) B

Machine Oil A Methyl Isopropyl Ketone A

Magnesium Bisulfate A Methyl Methalcrylate B

Magnesium Carbonate B Methyl Sulfuric Acid B

Magnesium Chloride D Methylamine A

Magnesium Hydroxide A Methylene Chloride B

Magnesium Nitrate B Milk A

Magnesium Oxide A Mineral Oil A

Magnesium Sulfate (epsom salts) B Mineral Spirits A

Maleic Acid B Molasses, crude A

Maleic Anhydride A Molasses, edible A

Malic Acid A *

Monochloroacetic Acid A

Manganese Sulfate B *

Monochlorobenzene A

Mash A Monoethanolamine A

Mayonnaise A Morpholine A

Melamine D Motor Oil A*

Mercaptan (methanethiol) A Muriatic Acid (hydrochloric acid) D

Mercuric Chloride, dilute D Mustard A

Mercuric Cyanide C Naphtha A

Mercuric Nitrate A Napthalene A

Mercurous Nitrate A Napthalene Chloride B

Mercury A Napthenic Acid B

Methane A Natural Gas A

Methanol (methyl alcohol, wood alcohol) A Neon Gas A

Methyl Acetate B Nickle Ammonium Sulfate A

Methyl Acetone A Nickle Chloride C

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Nickle Nitrate B* Oil, Fish A

Nickle Salt B Oil, Ginger D

Nickle Sulfate B Oil, Lard A

Nitric Acid, 5% A Oil, Lemon A

Nitric Acid, 10% A Oil, Linseed A

Nitric Acid, 20% A Oil, Machine A

Nitric Acid, 30% A Oil, Olive A

Nitric Acid, 50% A Oil, Orange A

Nitric Acid, concentrated A Oil, Palm A

Nitrobenzene B Oil, Peanut A

Nitroethane B Oil, Peppermint A

Nitrogen Gas A Oil, Pine A

Nitrogen Trifluoride Gas A Oil, Rapeseed A

Nitromethane A Oil, Sesame Seed A

Nitropropane B Oil, Silicone A

Nitrous Acid A Oil, Soybean A

Nitrous Acid, 5% A Oil, Sperm (whale) A

Nitrous Acid, 10% A Oil, Tanning A

Nitrous Oxide B Oil, Transformer A

Octane A Oil, Tung (China wood oil) A

Oil Water Mixtures A Oil, Turbine A

Oil, Aniline A Oil, Vegetable A

Oil, Anise A Oils and Fats A

Oil, Bay A Oils, Animal A

Oil, Bone (Dippel’s oil) A Oils, Bunker A

Oil, Castor A Oils, Diesel Fuel (20, 30, 40, 50) A

Oil, Citric A Oils, Fuel Oil (1, 2, 3, 5A, 5B, 6) A

Oil, Clove A Oils, Lubricating A

Oil, Coconut A Oils, Mineral A

Oil, Cod Liver A Oleic Acid A

Oil, Cooking A Oleum, 25% (fuming sulfuric acid) A

Oil, Corn A Olive Oil A

Oil, Cottonseed A Oxalic Acid, 5% A

Oil, Creosote B Oxalic Acid, 10% A

Oil, Crude Oil A Oxalic Acid, 50% D

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Oxalic Acid, cold D Pine Oil A

Oxygen Gas A Pineapple Juice A

Ozone, dry A Plating Solutions, Arsenic A

Ozone, wet A Plating Solutions, Antimony A

Paints and Solvents A Plating Solutions, Brass A

Pam Oil A Plating Solutions, Bronze A

Palmitic Acid A Plating Solutions, Cadmium A

Paraffin A Plating Solutions, Chrome D

Paracymene or p-Cymene A Plating Solutions, Copper D

Paraformaldehyde A Plating Solutions, Gold C

Peanut Oil A Plating Solutions, Indium C

Pectin, liquor A Plating Solutions, Iron C

Pentane A Plating Solutions, Lead C

Peracetic Acid, 40% A Plating solutions, Nickel C

Perchloric Acid C Plating Solutions, Rhodium D

Perchloroethylene, dry A Plating Solutions, Silver A

Perflouropropane Gas A Plating Solutions, Tin C

Petrolatum (Vaseline) A Plating Solutions, Zinc D

Petroleum A Polyethylene Glycol B

Phenol (carbolic acid) B Polyvinyl Acetate (PVA glue) A

Phenol, 10% (carbolic acid) B Potassium Acetate C

Phosgene D Potassium Bicarbonate B

Phosphine Gas A Potassium Bichromate A

Phosphoric Acid (>40%) D Potassium Bisulfate B

Phosphoic Acid, crude B Potassium Bisulfite A

Phosphoric Acid, molten C Potassium Bromate B

Phosphorus A * Potassium Bromide B

Phosphorous Pentaflouride Gas A Potassium Carbonate (potash) A

Phosphorus Oxychloride D Potassium Carbonate, 50% A

Phosphorus Pentoxide A Potassium Chlorate B

Phosphorus Trichloride A * Potassium Chlorate, aqueous 30% B

Photographic Developer A Potassium Chloride A

Phthalic Acid A Potassium Chromate, 30% B

Phthalic Anhydride A Potassium Cyanide A

Picric Acid A Potassium Cyanide, 30% B

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Potassium Dichromate B Resorcinal D

Potassium Diphosphate A Resins and Rosins A

Potassium Ferricyanide B Road Tar A

Potassium Ferrocyanide A Roof Pitch A

Potassium Ferrocyanide, 30% B RP-1 Fuel A

Potassium Fluoride A Rubber Solvents A

Potassium Hydroxide A Rum A

Potassium Hydroxide (Lye, caustic potash) A Rust Inhibitors A

Potassium Hypochlorite B Salad Dressings A

Potassium Iodide A Salad Oil A

Potassium Nitrate B Salicylic Acid B*

Potassium Oxaiate, 20% B Salt Brine (NaCl saturated) A*

Potassium Perchlorate A Salt Solutions A

Potassium Permanganate B Sea Water C

Potassium Persulfate A Sewage A

Potassium Phosphate C Shellac, bleached A

Potassium Sulfate A Shellac, orange A

Potassium Sulfate, 10% A Silane Gas A

Potassium Sulfide B Silicone Oil A

Potassium Sulfite A Silver Bromide D

Potassium Thiosulfate C Silver Chloride D

Propane, gas A Silver Nitrate B

Propane, liquefied A Soap Solutions (stearates) A

Propionaldehyde B Soaps A

Propyl Acetate A Soda Ash (sodium carbonate) A

Propyl Alcohol A Sodium Acetate B

Propylene A Sodium Aluminate A

Propylene Dichloride A Sodium Benzoate D

Propylene Glycol B Sodium Bicarbonate A

Propylene Oxide A Sodium Bisulfate, 10% C

Pydraul A Sodium Bisulfite B

Pyridine A Sodium Borate (Borax) B

Pyrogallic Acid (pyrogallol) B Sodium Bromide C

Pyrrole B Sodium Carbonate (soda ash) A

Quinine A Sodium Chlorate B

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Sodium Chloride B Sodium Sulfite, 10% A

Sodium Chlorite A Sodium Tetraborate A

Sodium Chromate B Sodium Thiosulfate B

Sodium Cyanate D Sorghum A

Sodium Cyanide B Sour Crude Oil A

Sodium Ferricyanide A Soy Sauce A

Sodium Ferrocyanide B Soybean Oil A

Sodium Fluoride A Stannic Chloride D

Sodium Hydrogen Sulfite B Stannic Fluoborate A

Sodium Hydrosulfide B Stannic Chloride D

Sodium Hydrosulfite D Stannous Chloride A*

Sodium Hydroxide (Lye, caustic potash) B Starch, aqueous A

Sodium Hydroxide, 20% B *

Stearic Acid A

Sodium Hydroxide, 50% B Stoddard’s Solvent (white spirit, mineral spirits) A

Sodium Hydroxide, 80% B Styrene A

Sodium Hypochlorite, 5.25% C Succinic Acid A

Sodium Hypochlorite, <20% C Succinic Acid Ester A

Sodium Hypochlorite, 100% D Sucrose Solutions A

Sodium Hyposulfate A Sugar Liquids A

Sodium Metaphosphate A Sulfate Liquors B

Sodium Metasilicate, cold A Sulfur A

Sodium Metasilicate, hot A Sulfur Chloride D

Sodium Nitrate B Sulfur Dioxide, dry D

Sodium Perborate B Sulfur Dioxide, wet B

Sodium Peroxide, 10% A Sulfuric Acid, <10% B

Sodium Phosphate, acid A Sulfuric Acid, 10-75% D

Sodium Phosphate, alkaline A Sulfuric Acid, 75-100% D

Sodium Phosphate, Dibasic A Sulfuric Acid, cold concentrated B

Sodium Phosphate, neutral A Sulfuric Acid, hot concentrated C

Sodium Phosphate, Tribasic A Sulfurous Acid B

Sodium Polyphosphate B Sulfuryl Chloride D

Sodium Silicate (water glass) B Sugar Solution A

Sodium Sulfate B Tall Oil (liquid rosin) A

Sodium Sulfide D Tallow A

Sodium Sulfite A Tannic Acid A

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

STAINLESS STEEL (SS316L/EN2348) CHEMICAL COMPATIBILITY CHART

A: Excellent - No effect

B: Good - Minor effect, slight corrosion or decolourization

C: Fair - Moderate effect, not recommended All data based on 22 °C, unless otherwise stated

D: Poor - Severe effect, not recommended Footnote: *Satisfactory to 48 °C

Tannin A Turpentine A

Tanning Liquors A *

Urea B

Tanning Oil A Urea Formaldehyde A

Tar and Tar Oil A Urethane A

Tartaric Acid C Uric Acid B

Tetrachloroethane, anhydrous A Urine A

Tetrachloroethylene A Varnish A

Tetraethyl Lead A Vaseline A

Tetrahydrofuran A Vegetable Juice A

Tetramethylene B Vegetable Oil A

Tetraphosphoric Acid D Vinegar A

Thread Cutting Oils A Vinyl Acetate B

Tin Ammonium Chloride D Vinyl Chloride A

Tin Salts D Water, Deionized (demineralized water) A*

Titanium Dioxide B Water, Distilled A

Titanium Tetrachloride B Water, Fresh A

Toluene (Toluol) A Water, Salt B

Tomato Juice A Water, Sewage A

Transformer Oil A Waxes A

Transmission Fluid Type A B Weed Killers A

Tributyl Phosphate A Whey A

Tricalcium Phosphate B Whiskey A

Trichloroacetic Acid D White Liquor (pulp mill) A

Trichloroacetic Acid, 2N D White Water (paper mill) A

Trichlorobenzene B Wine Vinegar A

Trichloroethane B Wines A

Trichloroethylene B Xenon Gas A

Trichloropropane A Xylene (Xylol), dry B

Tricresylphosphate B Yeast, liquid A

Triethanolamine (triethanol amine) A Zinc Chloride B

Triethylamine A Zinc Hydrosulfite A

Trimethyl Phosphate Gas A Zinc Nitrate A

Trioctyl Phosphate B Zinc Phosphate B

Trisodium Phosphate B Zinc Sulfate B

Tung Oil (China wood oil) A Zinc Sulfate, 30% A

This information should be seen as general guidelines rather than an absolute guarantee. The chemical

compatibility of Stainless Steel 316L will depend on several parameters, such as temperature, concentration,

overall solution composition and other factors concerning the application in which the rotating bed reactor is to

be operated. It is the responsibility of the user to ultimately determine appropriate use.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

You might also like

- GRE Practice Test 4e1153f60b8b56e55598cfc2 Pablobw 1309779242737 Gre - Practice - TestDocument78 pagesGRE Practice Test 4e1153f60b8b56e55598cfc2 Pablobw 1309779242737 Gre - Practice - Testkingsy13100% (3)

- Quarter 2 Module 2 Science 9 Fact Sheet (2Document6 pagesQuarter 2 Module 2 Science 9 Fact Sheet (2Luz Eliza100% (1)

- Silicone Chemical Compatibility Chart PDFDocument7 pagesSilicone Chemical Compatibility Chart PDFTiago SucupiraNo ratings yet

- GENERAL CHEMISTRY - Q1 - Mod7 - Calculating Formula Mass, Empirical Formula and Molecular FormulaDocument21 pagesGENERAL CHEMISTRY - Q1 - Mod7 - Calculating Formula Mass, Empirical Formula and Molecular FormulaArthur Laurel0% (1)

- 316L Stainless Steel Chemical Compatibility ChartDocument12 pages316L Stainless Steel Chemical Compatibility ChartIván López Pavez0% (1)

- Class VIII I.I.T.foundation, N.T.S.E.& Science Olympiad Curriculum & Chapter NotesDocument83 pagesClass VIII I.I.T.foundation, N.T.S.E.& Science Olympiad Curriculum & Chapter NotesYo83% (6)

- Valve Material SelectionDocument8 pagesValve Material Selectionerovho100% (1)

- Platinum Group Metals and Compounds: Article No: A21 - 075Document72 pagesPlatinum Group Metals and Compounds: Article No: A21 - 075firda haqiqiNo ratings yet

- Reactor Design Scale UpDocument9 pagesReactor Design Scale UpEntropay UserNo ratings yet

- Ballast Water Treatment by ABSDocument60 pagesBallast Water Treatment by ABSLogovaz100% (1)

- 316L Stainless Steel Chemical Compatibility PDFDocument5 pages316L Stainless Steel Chemical Compatibility PDFsujingthetNo ratings yet

- Bright Acid Copper For Wire and Grounding Rods: E-Brite 202GDocument6 pagesBright Acid Copper For Wire and Grounding Rods: E-Brite 202GUsman ali Cheema100% (1)

- Italy 10 Puglia Basilicata Calabria PDFDocument61 pagesItaly 10 Puglia Basilicata Calabria PDFEntropay UserNo ratings yet

- 316l Stainless Steel Chemical Compatibility From IsmDocument12 pages316l Stainless Steel Chemical Compatibility From IsmAndri YantoNo ratings yet

- 304 Stainless Steel Chemical Compatibility Chart From IsmDocument11 pages304 Stainless Steel Chemical Compatibility Chart From IsmchenNo ratings yet

- 316l Stainless Steel Chemical Compatibility From IsmDocument12 pages316l Stainless Steel Chemical Compatibility From IsmAswindana Ibnu SenaNo ratings yet

- Aluminum Aluminium Chemical Compatiblity Chart From IsmDocument14 pagesAluminum Aluminium Chemical Compatiblity Chart From IsmSanjeev KachharaNo ratings yet

- 304 Stainless Steel Chemical Compatibility ChartDocument8 pages304 Stainless Steel Chemical Compatibility ChartMariana HusainNo ratings yet

- 316L Stainless Steel Chemical Compatibility Chart From ISM - 316l-Stainless-Steel-Chemical-Compatibility-From-IsmDocument1 page316L Stainless Steel Chemical Compatibility Chart From ISM - 316l-Stainless-Steel-Chemical-Compatibility-From-IsmchenNo ratings yet

- 316 Stainless Steel Chemical Compatibility Chart From IsmDocument13 pages316 Stainless Steel Chemical Compatibility Chart From IsmfusilgateNo ratings yet

- 304 Stainless Steel Chemical Compatibility Chart From ISM - 304-Stainless-Steel-Chemical-Compatibility-Chart-From-IsmDocument1 page304 Stainless Steel Chemical Compatibility Chart From ISM - 304-Stainless-Steel-Chemical-Compatibility-Chart-From-IsmchenNo ratings yet

- Ss 316 ChemicalcompatibilitychartDocument17 pagesSs 316 ChemicalcompatibilitychartaurinkokelloNo ratings yet

- Acrylic Pmma Chemical Compatibility Chart From IsmDocument11 pagesAcrylic Pmma Chemical Compatibility Chart From IsmDeidra CadeNo ratings yet

- Thermoset Fiberglass Reinforced Polyester Polycarbonate PVC 302-304 Stainless Steel 316 Stainless Steel Carbon SteelDocument7 pagesThermoset Fiberglass Reinforced Polyester Polycarbonate PVC 302-304 Stainless Steel 316 Stainless Steel Carbon SteelErich ThomasNo ratings yet

- Polysulfone Chemical Compatibility Chart From IsmDocument10 pagesPolysulfone Chemical Compatibility Chart From IsmRezk GhazyNo ratings yet

- HP Chemical Resistance Tech NoteDocument6 pagesHP Chemical Resistance Tech NoteFranco GentiliNo ratings yet

- Chemical Compatibility of PPR Niron PipingDocument9 pagesChemical Compatibility of PPR Niron PipingaurinkokelloNo ratings yet

- Epdm Chemical Compatibility Guide - KelcoDocument10 pagesEpdm Chemical Compatibility Guide - KelcoWei YaoNo ratings yet

- PTFE Chemical Compatibility Chart: Product TF1570 TF1580 TF1590 Teadit 24SH Teadit 24B TF 1510Document11 pagesPTFE Chemical Compatibility Chart: Product TF1570 TF1580 TF1590 Teadit 24SH Teadit 24B TF 1510tomasykNo ratings yet

- PP Chemical ResistanceDocument4 pagesPP Chemical ResistancePoep PeopNo ratings yet

- Neoprene Chemical Compatibility GuideDocument13 pagesNeoprene Chemical Compatibility GuideGilberto YoshidaNo ratings yet

- Chemical Compatibility Reference Chart: Stainless SteelDocument15 pagesChemical Compatibility Reference Chart: Stainless SteelSreesanth SaruvilNo ratings yet

- Chemical Compatibility Reference Chart: Stainless SteelDocument15 pagesChemical Compatibility Reference Chart: Stainless SteelWbeimar Zuluaga ZuluagaNo ratings yet

- Chemical Compatibility ChartDocument16 pagesChemical Compatibility Chartadam_riantoNo ratings yet

- Chemical Compatibility Chart Hypalon: Page 1 of 10 Kelco 15/12/2008Document10 pagesChemical Compatibility Chart Hypalon: Page 1 of 10 Kelco 15/12/2008Jagdish PatelNo ratings yet

- TEFLON and PTFE Chemical ResistanceDocument23 pagesTEFLON and PTFE Chemical ResistanceUniwes ServiceNo ratings yet

- KYNAR (PVDF) Chemical Compatibility & Chemical Resistance ChartDocument11 pagesKYNAR (PVDF) Chemical Compatibility & Chemical Resistance ChartRAMESH SHETTYNo ratings yet

- Chemical Compatibility Reference Chart: PolypropyleneDocument16 pagesChemical Compatibility Reference Chart: PolypropyleneSreesanth SaruvilNo ratings yet

- Sostanza Chemical PP PVDF Aisi 316 Epdm Viton PtfeDocument2 pagesSostanza Chemical PP PVDF Aisi 316 Epdm Viton Ptfescribd1364scribdNo ratings yet

- New Corrosion ChartDocument13 pagesNew Corrosion Charttkcn tvNo ratings yet

- Compatibilidad MaterialesDocument11 pagesCompatibilidad MaterialesestallenodeNo ratings yet

- Chemical Compatibility Reference Chart: Teflon® PTFEDocument17 pagesChemical Compatibility Reference Chart: Teflon® PTFESreesanth SaruvilNo ratings yet

- Chemical Compatibility Reference Chart: Teflon® PTFEDocument17 pagesChemical Compatibility Reference Chart: Teflon® PTFEWbeimar Zuluaga ZuluagaNo ratings yet

- Chemical Resistance For AflasDocument10 pagesChemical Resistance For AflasAlex VarNo ratings yet

- Chemical Resistance GuideDocument20 pagesChemical Resistance GuideDarien EdwardsNo ratings yet

- Chemical Compatibility Reference ChartDocument11 pagesChemical Compatibility Reference ChartSreesanth SaruvilNo ratings yet

- Chemical Compatibility Reference Chart: AluminumDocument16 pagesChemical Compatibility Reference Chart: AluminumSreesanth SaruvilNo ratings yet

- Chemical Resistance Data: Environmental Resistance Table: E-Excellent, G-Good, L-Limited, U-UnsatisfactoryDocument2 pagesChemical Resistance Data: Environmental Resistance Table: E-Excellent, G-Good, L-Limited, U-UnsatisfactoryDipesh ParekhNo ratings yet

- KIJEKA - Pumps Seal CompatibilityDocument14 pagesKIJEKA - Pumps Seal CompatibilitySaurabh DaveNo ratings yet

- Chemical Compatibility Reference Chart: NylonDocument16 pagesChemical Compatibility Reference Chart: NylonSreesanth SaruvilNo ratings yet

- Chemical Resistance List2Document8 pagesChemical Resistance List2Jean Paul Pamo ValdiviaNo ratings yet

- Nylon Chemical Compatibility ChartDocument14 pagesNylon Chemical Compatibility Chartteban09No ratings yet

- Aluminum Chemical Compatibility ChartDocument14 pagesAluminum Chemical Compatibility Chartteban09No ratings yet

- Fluid Compatibility of MetalsDocument357 pagesFluid Compatibility of Metalsdig nameNo ratings yet

- Chemical Compatibility Reference Chart: SteelDocument15 pagesChemical Compatibility Reference Chart: SteelSreesanth SaruvilNo ratings yet

- Chemical Compatibility Reference Chart: PolycarbonateDocument11 pagesChemical Compatibility Reference Chart: PolycarbonateSreesanth Saruvil100% (1)

- Compound Selection and Conversion ChartsDocument6 pagesCompound Selection and Conversion ChartsRolando DoderoNo ratings yet

- Chemical Compatibility Reference Chart: Viton®Document17 pagesChemical Compatibility Reference Chart: Viton®Sreesanth SaruvilNo ratings yet

- Sigma Chemical Resistance ChartDocument7 pagesSigma Chemical Resistance Chartshahbaz1979No ratings yet

- Material Compatibility Guide 3 PDFDocument8 pagesMaterial Compatibility Guide 3 PDFarrancatetasNo ratings yet

- Ame101 LecturenotesDocument5 pagesAme101 Lecturenotesagrocel_bhvNo ratings yet

- Chemical Compatibility Reference Chart: AcetalDocument13 pagesChemical Compatibility Reference Chart: AcetalSreesanth SaruvilNo ratings yet

- Chemical Compatibility GuideDocument12 pagesChemical Compatibility GuideMeuMundoMinecraftNo ratings yet

- Carbon Steel Chemical Compatibility ChartDocument17 pagesCarbon Steel Chemical Compatibility ChartOscar BernalNo ratings yet

- Acetal (Polyoxymethylene) Chemical Compatibility ChartDocument14 pagesAcetal (Polyoxymethylene) Chemical Compatibility Chartteban09No ratings yet

- Beständigkeitsliste - Kunststoffe - Valvecenter UKDocument24 pagesBeständigkeitsliste - Kunststoffe - Valvecenter UKVelibor StokicNo ratings yet

- CHEMICAL COMPATIBILITY TABLE 2013 Graphical Review Part 3Document6 pagesCHEMICAL COMPATIBILITY TABLE 2013 Graphical Review Part 3RafalNo ratings yet

- Typ 05414 2 enDocument1 pageTyp 05414 2 enEntropay UserNo ratings yet

- Typ 01341 2 enDocument1 pageTyp 01341 2 enEntropay UserNo ratings yet

- Typ 01343 3 enDocument1 pageTyp 01343 3 enEntropay UserNo ratings yet

- Chapter 1 General System DescriptionDocument26 pagesChapter 1 General System DescriptionEntropay UserNo ratings yet

- ListDocument1 pageListEntropay UserNo ratings yet

- ADAMS/Car Templates: About This Guide 3 Using Communicators 5 Template Descriptions 15Document103 pagesADAMS/Car Templates: About This Guide 3 Using Communicators 5 Template Descriptions 15Entropay UserNo ratings yet

- Fgtech Motorbyke Driver List - Nov 2011: Marca Modelli Engine Ecu Type Read Write CHK Write FG TechDocument2 pagesFgtech Motorbyke Driver List - Nov 2011: Marca Modelli Engine Ecu Type Read Write CHK Write FG TechEntropay UserNo ratings yet

- Sigma Vyrobni Program enDocument12 pagesSigma Vyrobni Program enEntropay UserNo ratings yet

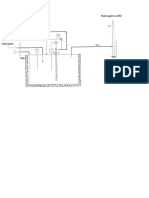

- Recover Crude Oil: Stack Open To ATMDocument1 pageRecover Crude Oil: Stack Open To ATMEntropay UserNo ratings yet

- 00 Rm910eDocument8 pages00 Rm910eemurgarojasNo ratings yet

- 01 IntroductionDocument42 pages01 IntroductionemurgarojasNo ratings yet

- Chemical IndustryDocument18 pagesChemical IndustryTariqul RabbiNo ratings yet

- HTH Pop Up Pool Care GuideDocument12 pagesHTH Pop Up Pool Care GuideKevin J. Thomson IINo ratings yet

- General Chemistry 11th Edition Ebbing Test BankDocument35 pagesGeneral Chemistry 11th Edition Ebbing Test Bankarrowcornet0No ratings yet

- 143Document14 pages143Sandy ManNo ratings yet

- BAR Catalogo Chimico 2016 en - ExportDocument82 pagesBAR Catalogo Chimico 2016 en - ExportdobleNo ratings yet

- M00016896 取扱説明書(英文)Document81 pagesM00016896 取扱説明書(英文)brayan dearmasNo ratings yet

- General Chemistry Lab Safety Yenny HohDocument21 pagesGeneral Chemistry Lab Safety Yenny HohShenghoh5255100% (1)

- T10 QuestionsDocument20 pagesT10 Questionsleafar96100% (4)

- N-2000 Antimicrobial TDSDocument9 pagesN-2000 Antimicrobial TDSRonald Figo Torres EcheNo ratings yet

- Determination of The Stoichiometry of A Redox Reaction: Pre-Lab AssignmentDocument5 pagesDetermination of The Stoichiometry of A Redox Reaction: Pre-Lab AssignmentMarlo B BarreraNo ratings yet

- Edexcel IAL Chemistry Unit 5 October 2021 Question PaperDocument32 pagesEdexcel IAL Chemistry Unit 5 October 2021 Question PaperEffendi Jabid KamalNo ratings yet

- MATERIAL SAFETY DATA SHEET - FrickDocument13 pagesMATERIAL SAFETY DATA SHEET - FricksanNo ratings yet

- Chemistry Notes Very Helpful ISC XIIDocument7 pagesChemistry Notes Very Helpful ISC XIIVishvesh Shrivastav100% (1)

- Aldehydes, Ketones and Carboxylic Acids. Aldehydes and KetonesDocument42 pagesAldehydes, Ketones and Carboxylic Acids. Aldehydes and KetonesVicky VigneshNo ratings yet

- Question Bank of Chapter 1Document4 pagesQuestion Bank of Chapter 1lovika malhotraNo ratings yet

- 0620 s08 QP 1Document24 pages0620 s08 QP 1G M Ali KawsarNo ratings yet

- EXTRACTIVEDocument34 pagesEXTRACTIVEraj mehra100% (1)

- Alfa Laval Gphe Industrial Small Manual enDocument46 pagesAlfa Laval Gphe Industrial Small Manual enjohnPolancotafurNo ratings yet

- Practice Question & Worksheet For Chapter 10: Class-12 Haloalkanes & HaloarenesDocument3 pagesPractice Question & Worksheet For Chapter 10: Class-12 Haloalkanes & Haloarenesxajitib271No ratings yet

- Chemistry 21-23 Paper 6Document103 pagesChemistry 21-23 Paper 6MattMattTv JapanNo ratings yet

- 0620 s03 Ms 1+2+3+5+6 PDFDocument18 pages0620 s03 Ms 1+2+3+5+6 PDFSumaira AliNo ratings yet

- Hydrologic CycleDocument41 pagesHydrologic CyclePatricia Sofia DizonNo ratings yet

- Msds - AdditiveDocument9 pagesMsds - AdditivedanalabNo ratings yet