0% found this document useful (0 votes)

5K views5 pagesVMC Slot Programing

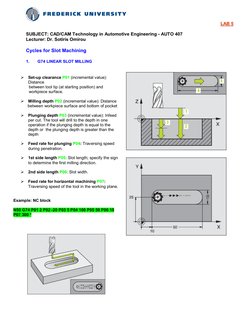

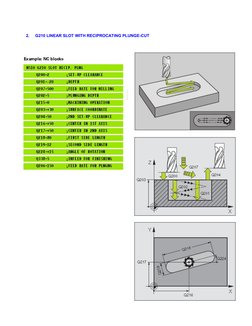

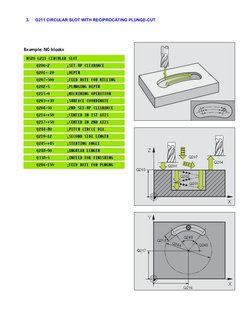

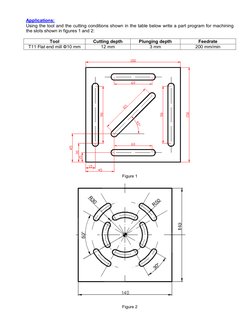

The document discusses different canned cycles for slot milling in CAD/CAM, including linear slot milling using G74 and linear and circular slot milling with reciprocating plunge cuts using G210 and G211. It provides examples of the parameters used for the G74 cycle and assigns a lab to have students write a CNC program to machine linear and circular slots on a part using the appropriate canned cycles and simulation software.

Uploaded by

Mechanical FactsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

5K views5 pagesVMC Slot Programing

The document discusses different canned cycles for slot milling in CAD/CAM, including linear slot milling using G74 and linear and circular slot milling with reciprocating plunge cuts using G210 and G211. It provides examples of the parameters used for the G74 cycle and assigns a lab to have students write a CNC program to machine linear and circular slots on a part using the appropriate canned cycles and simulation software.

Uploaded by

Mechanical FactsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd