Professional Documents

Culture Documents

FMEA

Uploaded by

SamuelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FMEA

Uploaded by

SamuelCopyright:

Available Formats

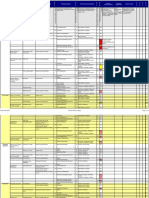

Process / Product

Failure Modes and Effects Analysis

FMEA

(FMEA)

Process or Product

Prepared by: Page ____ of ____

Name:

Responsible: FMEA Date (Orig) ______________ (Rev) _____________

S O D R S O D R

Process Step Key Process Input Potential Failure Mode Potential Failure Effects E Potential Causes C Current Controls E P Actions Recommended Resp. Actions Taken E C E P

V C T N V C T N

How Severe is the

cause or FM occur?

How well can you

detect cause or FM?

How often does

cusotmer?

effect to the

What is the process What is the Key Process In what ways does the Key What is the impact on the Key What causes the Key Input to go What are the existing controls and What are the actions for reducing the Whose What are the completed

step Input? Input go wrong? Output Variables (Customer wrong? procedures (inspection and test) that occurrance of the Cause, or improving Responsible actions taken with the

Requirements) or internal prevent eith the cause or the Failure detection? Should have actions only on for the recalculated RPN? Be

requirements? Mode? Should include an SOP high RPN's or easy fixes. recommende sure to include

number. d action? completion month/year

Secure Xpult on Xpult Loose structure Reduce hitting position accuracy Original rude design Training on operator to manually Stick plastic sheet formed cylindrical holder Samuel 24-Apr-11

table carefully operate Xpult inside the existing soft rubber ball holder to

9 10 8 720 strengthen the structure. Add tight fit pads to 9 2 4 72

secure the Launch angle structure. Add metal

bumpers to secure the stable lever motion.

Adjust launch angle Expected launch angle Get the wrong data Cannot hit the target Careless operator SOP requires operator to double check

indicator indicator 10 1 the data 4 40 0

Determine lever pin Expected lever pin position Get the wrong data Cannot hit the target Careless operator SOP requires operator to double check

position 10 1 the data 4 40 0

Get rubber band on Selected rubber band Unsuitable rubber band is Cannot hit the target Lack of sufficient knowledge on Rely on operator experience Conduct test of variance on different available Samuel 23-Apr-11

selected 10 selecting the right rubber band 10 5 500 rubber bands to determine the best one to be 10 1 2 20

used all the time

Adjust pull back Expected pull back angle Get the wrong data Cannot hit the target Careless operator SOP requires operator to double check

angle 10 1 the data 4 40 0

Actual pull back angle is Reduce hitting position accuracy Operator is suffered from fatigue Operator take rest for every 30 shots Add a reel mechanism with quick release clip, Samuel 24-Apr-11

different from the expected 9 and distraction during manually 8 8 576 so that operator can take time to setup the 9 1 1 9

value setting and holding the lever required angle and wait Xpult to become fully

Actual pull back angle is Reduce hitting position accuracy Original Xpult only has rude Pull Rely on operator experience stable

Stick on printed detial angle marks to enable Samuel 24-Apr-11

different from the reading value 9 back angle marks 9 5 405 precise Pull back angle reading 9 1 2 18

Put ball on ball Selected ball Unsuitable ball is selected Cannot hit the target Lack of sufficient knowledge on Rely on operator experience Conduct test of variance on different available Samuel 23-Apr-11

holder 10 selecting the right ball 10 5 500 balls to determine the best ball to be always 10 1 2 20

used

Release and let go Stable loaded Xpult Rubber band performance is Cannot hit the target Rubber band may become stable Rely on operator experience Use stop watch to allow 10s after setup finish Samuel 24-Apr-11

unstable 10 immediately right after the required 8 5 400 for the rubber band to become stable 10 3 2 60

entension length is adjusted

Rubber band performance Reduce hitting position accuracy Original rubber band hole of Xpult Rely on operator experience Add paper sticker to cover the sharp corners of Samuel 24-Apr-11

degrades 9 has sharp and would hurt the rubber 9 5 405 the rubber band hole to protect the rubber 9 3 2 54

band band

Measure hitting Measurement equipment Ruler could be accidentally Reduce data accuracy hence Careless operator SOP requires operator to double check Use T-ruler to ensure the correct alignment Samuel 24-Apr-11

distance moved during measurement impact the future setup to reduce 9 5 the ruler setup before taking 5 225 and then stick the ruler on the table before 9 1 2 18

hitting position accuracy measurement taking measurement

Page 1

You might also like

- AmefDocument2 pagesAmefAmair Marthz100% (1)

- Process / Product Failure Modes and Effects Analysis (FMEA) Process / Product Failure Modes and Effects Analysis (FMEA)Document1 pageProcess / Product Failure Modes and Effects Analysis (FMEA) Process / Product Failure Modes and Effects Analysis (FMEA)AbhishekChowdhuryNo ratings yet

- Fmea TemplateDocument1 pageFmea TemplatePaul MendozaNo ratings yet

- Fmea TemplateDocument1 pageFmea TemplateAngeloSkcNo ratings yet

- SSCX Fmea TemplateDocument1 pageSSCX Fmea Templatetami lestariNo ratings yet

- Failure Modes Effects AnalysisDocument1 pageFailure Modes Effects AnalysisAndrei EnacheNo ratings yet

- Failure Modes and Effects Analysis (FMEA) - Risk Assessment MatrixDocument2 pagesFailure Modes and Effects Analysis (FMEA) - Risk Assessment MatrixIoan Mihai ArmăşelNo ratings yet

- Process/Product Potential Failure Modes and Effects Analysis (FMEA)Document8 pagesProcess/Product Potential Failure Modes and Effects Analysis (FMEA)Carlos De Gracia NúñezNo ratings yet

- 4.3.3 Failure Mode and Effect Analysis (FMEA)Document10 pages4.3.3 Failure Mode and Effect Analysis (FMEA)AhmedAhmedNo ratings yet

- FMEA TemplateDocument33 pagesFMEA Templatemani01kandanNo ratings yet

- Basic To FMEADocument11 pagesBasic To FMEAsodagolf0% (1)

- FMEA CP Forms Application ManufacturingDocument15 pagesFMEA CP Forms Application ManufacturingCarlo AlvaradoNo ratings yet

- FMEA HandbookDocument14 pagesFMEA HandbookRakesh Tayenjam100% (2)

- Product Design FMEADocument1 pageProduct Design FMEAsbiasotoNo ratings yet

- Fmea PC ProcessDocument2 pagesFmea PC Processsudeep_singh1No ratings yet

- Item Name: FMEA Team: Prepared By: FMEA Date (Orig) : Revision #Document4 pagesItem Name: FMEA Team: Prepared By: FMEA Date (Orig) : Revision #Alper GmNo ratings yet

- ? What Are The Existing Controls, Ns What Are The Actions ForDocument10 pages? What Are The Existing Controls, Ns What Are The Actions ForPk NimiwalNo ratings yet

- Design and Process FMEA TemplateDocument7 pagesDesign and Process FMEA TemplateRajkumar VijNo ratings yet

- Design and Process FMEA TemplateDocument4 pagesDesign and Process FMEA TemplateAkshay KaranjeNo ratings yet

- Process FMEA TemplateDocument3 pagesProcess FMEA Templateibrahime mohammedNo ratings yet

- Process/Product Failure Modes and Effects Analysis (FMEA) Process/Product Failure Modes and Effects Analysis (FMEA)Document1 pageProcess/Product Failure Modes and Effects Analysis (FMEA) Process/Product Failure Modes and Effects Analysis (FMEA)Abu BindongNo ratings yet

- Intership ExcelDocument8 pagesIntership ExcelanweshaNo ratings yet

- FMEA - Quick Reference Guide: Actions Are Required: (By Priority)Document2 pagesFMEA - Quick Reference Guide: Actions Are Required: (By Priority)Igor PNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document4 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Joshua YbanezNo ratings yet

- Failure Mode Design ProjectDocument12 pagesFailure Mode Design ProjectSaddam AbdullahNo ratings yet

- Design and Process FMEA TemplateDocument4 pagesDesign and Process FMEA TemplateMadhuseptember2022100% (1)

- Design and Process FMEA TemplateDocument4 pagesDesign and Process FMEA TemplateKrunal PandyaNo ratings yet

- Effect Ranking Criteria: Severity of Effect (Example)Document7 pagesEffect Ranking Criteria: Severity of Effect (Example)Sedhuram SeranNo ratings yet

- Latest FMEA TemplateDocument8 pagesLatest FMEA TemplateBalu HegdeNo ratings yet

- Design Complete ProjectDocument12 pagesDesign Complete ProjectSaddam AbdullahNo ratings yet

- Fmea (Failure Modes and Effects Analysis)Document11 pagesFmea (Failure Modes and Effects Analysis)Oswaldo VallesNo ratings yet

- Failure Modes Effects AnalysisDocument1 pageFailure Modes Effects Analysismarolop siregarNo ratings yet

- FMEA Rev 4Document25 pagesFMEA Rev 4Vale PazNo ratings yet

- Copis & FmeaDocument16 pagesCopis & FmeaEXDE601E100% (2)

- FMEADocument74 pagesFMEAzulfiqarali721No ratings yet

- Design and Process Fmea WorksheetDocument4 pagesDesign and Process Fmea WorksheetEnrico Luis Caube BalisalisaNo ratings yet

- FMEA TrainingDocument30 pagesFMEA Trainingapi-377012184% (19)

- 15 FmeaDocument43 pages15 Fmeaankit7588No ratings yet

- FMEADocument9 pagesFMEADhivakar S K100% (1)

- 04 PmeaDocument42 pages04 PmeapandajayNo ratings yet

- Actividad 4 - AMEFDocument15 pagesActividad 4 - AMEFBrandon VidalNo ratings yet

- AMEF Evidencia 3Document15 pagesAMEF Evidencia 3Brandon VidalNo ratings yet

- AMEF Evidencia 1Document15 pagesAMEF Evidencia 1Brandon VidalNo ratings yet

- Actividad 11 Plan de FalllasDocument15 pagesActividad 11 Plan de FalllasBrandon VidalNo ratings yet

- Process FMEA WorksheetDocument1 pageProcess FMEA WorksheetmohanNo ratings yet

- Formato de PFMEADocument69 pagesFormato de PFMEASadot Lopez PerezNo ratings yet

- 1Document15 pages1Al Mira QomarNo ratings yet

- Potential Failure Mode and Effect Analysis: (Pfmea)Document2 pagesPotential Failure Mode and Effect Analysis: (Pfmea)Mohit KaushikNo ratings yet

- ProcessDocument6 pagesProcessTiến ThànhNo ratings yet

- Failure Mode and Effects Analysis (Process Fmea) : PotentialDocument2 pagesFailure Mode and Effects Analysis (Process Fmea) : Potentialjavier ortizNo ratings yet

- Failure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleDocument1 pageFailure Mode and Effect Analysis (FMEA) : Process: Process Owner: Project ID: Project TitleCarolineNo ratings yet

- PFMEADocument36 pagesPFMEAmohammad touffiqueNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Process/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Document18 pagesProcess/Product Name: Prepared By: Responsible: FMEA Date (Orig.) : (Rev.)Alper GmNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Practical Guide to FMEA : A Proactive Approach to Failure AnalysisFrom EverandPractical Guide to FMEA : A Proactive Approach to Failure AnalysisRating: 5 out of 5 stars5/5 (1)

- Troubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingFrom EverandTroubleshooting and Root Cause Failure Analysis: Equipment Problem SolvingRating: 4.5 out of 5 stars4.5/5 (3)

- Control Plan 110425Document1 pageControl Plan 110425SamuelNo ratings yet

- Fmea IiDocument1 pageFmea IiSamuelNo ratings yet

- CES Venue MapsDocument5 pagesCES Venue MapsSamuelNo ratings yet

- Ces17 Exhibitor ListDocument135 pagesCes17 Exhibitor ListSamuelNo ratings yet

- Stitch2421 1 Kit PDFDocument8 pagesStitch2421 1 Kit PDFJoshua Robertson100% (1)

- 3S Why SandhyavandanDocument49 pages3S Why SandhyavandanvivektonapiNo ratings yet

- 88 Year Old Man Missing in SC - Please ShareDocument1 page88 Year Old Man Missing in SC - Please ShareAmy WoodNo ratings yet

- The Impact of Social Networking Sites To The Academic Performance of The College Students of Lyceum of The Philippines - LagunaDocument15 pagesThe Impact of Social Networking Sites To The Academic Performance of The College Students of Lyceum of The Philippines - LagunaAasvogel Felodese Carnivora64% (14)

- Unit 4 Transistor Frequency ResponseDocument6 pagesUnit 4 Transistor Frequency ResponseShaina MabborangNo ratings yet

- NCP81205Document1 pageNCP81205Tom TomNo ratings yet

- Rich Gas and Lean GasDocument7 pagesRich Gas and Lean GasManish GautamNo ratings yet

- Proposed 4way D54 Proposed 2way D56: Issue Date DescriptionDocument3 pagesProposed 4way D54 Proposed 2way D56: Issue Date DescriptionADIL BASHIRNo ratings yet

- JHS Integrated Science Preamble, Jan 2012 - FinalDocument15 pagesJHS Integrated Science Preamble, Jan 2012 - Finalfrank adamsNo ratings yet

- Procedures Involved in The Ansys ACP17.2Document10 pagesProcedures Involved in The Ansys ACP17.2Vijayanandh RNo ratings yet

- Family History Timeline Rubric HonorsDocument1 pageFamily History Timeline Rubric Honorsapi-291510568No ratings yet

- General Information Exhibition Guide Lines - 3P 2022Document6 pagesGeneral Information Exhibition Guide Lines - 3P 2022muhammad khanNo ratings yet

- Augmentation of Labour: Nabhan A, Boulvain MDocument8 pagesAugmentation of Labour: Nabhan A, Boulvain MMade SuryaNo ratings yet

- EPA NCP Technical Notebook PDFDocument191 pagesEPA NCP Technical Notebook PDFlavrikNo ratings yet

- Thom22e ch03 FinalDocument44 pagesThom22e ch03 FinalDionisius AlvianNo ratings yet

- Analyse Bacterologique de L EauDocument6 pagesAnalyse Bacterologique de L Eaupeguy diffoNo ratings yet

- 01 C. Toolbar and Message BoxDocument10 pages01 C. Toolbar and Message Boxradu.iacobNo ratings yet

- SmoothWall Express 2.0 Quick-Start GuideDocument6 pagesSmoothWall Express 2.0 Quick-Start Guideinfobits100% (1)

- Munchies BrochureDocument28 pagesMunchies BrochureIbrahim Diaz LazoNo ratings yet

- 7 ApportionmentDocument46 pages7 Apportionmentsass sofNo ratings yet

- Classical Encryption TechniqueDocument18 pagesClassical Encryption TechniquetalebmuhsinNo ratings yet

- Paper Format IJRDTDocument3 pagesPaper Format IJRDTrock starNo ratings yet

- Probecom 11.3M Antenna System Datasheet 2Document2 pagesProbecom 11.3M Antenna System Datasheet 2Hugo MateoNo ratings yet

- SS EN 1991-1-1-2008 (2017) - PreviewDocument16 pagesSS EN 1991-1-1-2008 (2017) - PreviewNg SHun JieNo ratings yet

- Evolution of Strategic HRM As Seen Through Two Founding Books A 30TH Anniversary Perspective On Development of The FieldDocument20 pagesEvolution of Strategic HRM As Seen Through Two Founding Books A 30TH Anniversary Perspective On Development of The FieldJhon Alex ValenciaNo ratings yet

- English Assignment - October 6, 2020 - Group AssignmentDocument3 pagesEnglish Assignment - October 6, 2020 - Group AssignmentDaffa RaihanNo ratings yet

- List of Famous Cities On River Banks in The WorldDocument2 pagesList of Famous Cities On River Banks in The WorldDiptangshu DeNo ratings yet

- Daewoo SJ-210H DSJ-6000LHMDocument44 pagesDaewoo SJ-210H DSJ-6000LHMMarco Antonio100% (5)

- Research Paper Effect of Mobile Banking On Customer-823Document11 pagesResearch Paper Effect of Mobile Banking On Customer-823amittaneja28No ratings yet

- AR Financial StatementsDocument281 pagesAR Financial StatementsISHA AGGARWALNo ratings yet