Professional Documents

Culture Documents

Schaeffer2000 PDF

Uploaded by

Dinesh SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schaeffer2000 PDF

Uploaded by

Dinesh SharmaCopyright:

Available Formats

In the Laboratory

Preparation and Analysis of Multiple Hydrates of Simple Salts

Richard W. Schaeffer,* Benny C. Chan, Shireen R. Marshall, Brian Blasiole, Neetha Khan,

Kendra L. Yoder, Melissa E. Trainer, and Claude H. Yoder

Department of Chemistry, Franklin and Marshall College, Lancaster, PA 17604; *R_Schaeffer@fandm.edu

Many salts form more than one hydrate: MnC12ⴢ4H2O The preparation of ionic hydrates can be accomplished

crystallizes from water at room temperature, whereas by four methods:

MnCl2ⴢ2H2O can be obtained by crystallization at 65 °C; 1. slow evaporation of the solvent from a near saturated

CoCl2ⴢ6H2O crystallizes at room temperature, but above solution of the starting hydrate at a temperature within

52 °C, CoCl2ⴢ2H2O forms and above 90 °C, CoCl2ⴢH2O is the stability range of the desired hydrate

stable; CaCl2ⴢ2H2O is available commercially as a desiccant,

2. crystallization within the temperature range of the tar-

but CaCl2ⴢ6H2O is readily formed at room temperature (1).

get hydrate from a saturated solution prepared at

We have developed a laboratory project in which the student

higher temperature (assuming an endothermic heat of

prepares a series of hydrates of simple salts and then deter-

solution)

mines the extent of hydration of the product(s). In conjunction

with previously published articles in this Journal, we believe 3. crystallization within the temperature stability range

this project provides a good introduction to the concepts of from mixed solvents (“knocking the compound out of

solubility, saturation, recrystallization, relative compound solution” by adding a solvent such as 2-propanol to a

stability (e.g., a dihydrate vs tetrahydrate at elevated tempera- nearly saturated aqueous solution)

ture), and simple gravimetric analysis (2, 3). Moreover, the 4. heating a higher hydrate to the temperature range of

project lends itself to many variations. For example, a student the desired lower hydrate

could be given a “starting” hydrated salt and asked to prepare

We have found that the hydrates given in Table 1 are easily

another hydrate within the specified temperature range. Or

prepared by the method indicated. Determination of the

students could be given the formulas of several hydrates stable

water of hydration by heating gently in the Bunsen flame

over different temperature ranges and be asked to “discover”

produced values generally within 1–5% of the theoretical,

a method of preparation. If it is desired to extend the project,

clearly sufficient to determine an integral number of waters

the cation could be determined quantitatively by gravimetric

of hydration. Probably the greatest experimental problem

precipitation of the oxalate, for example, and the anion,

resides in filtration and removal of excess water and simulta-

chloride or sulfate, could be determined by precipitation with

neously protecting the lower hydrates from adsorption of

silver or barium ion, respectively, or by a variety of common

atmospheric water.

volumetric and colorimetric methods (4 ).

Hazards

C AUTION : Some of the compounds used in this exper-

Table 1. Summary of Student Data for Hydrated Salts iment are considered “moderately toxic” (e.g., cobalt chlo-

Hydration (%)

ride LD50, rat, oral = 766 mg/kg) and should be handled

Stability Starting Species Synth

Target Hydrate

Range/°C (CAS No.) Method

with care to avoid ingestion or inhalation of vapors or dust.

Exptl Theor

2-Propanol (CAS 67-63-0) is volatile (0.05 atm at 20 °C)

ZnSO4ⴢ6H2O 39-60 ZnSO4ⴢ7H2O EM 39.0 40.1

and flammable, and should not be ingested (LD50, rat, oral =

(7446-20-0)

5840 mg/kg). We recommend that all reagents be handled

ZnSO4ⴢH2O 6–l00 ZnSO4ⴢ7H2O EM 9.68 10.0

in an appropriate hood. We recommend the use of gloves

(7446-20-0)

and approved safety goggles.

CaCl2ⴢ6H2O 55–29 CaCl2ⴢ2H2O TDM 47.6 49.3

(10035-04-8)

Synthesis of Hydrates

CoCl2ⴢ2H2O 49–137 CoCl2ⴢ6H2O DH 21.9 21.7

(7791-13-1) Evaporation Method (EM)

CoCl2ⴢ2H2O 49–137 CoCl2ⴢ6H2O EM 24.3 21.7 A nearly saturated solution of approximately 2 g of the

(7791-13-1)

commercially available ionic hydrates from Table 1 was pre-

MnCl2ⴢ2H2O 5–135 MnCl2ⴢ4H2O EM 22.8 22.3 pared in an 8-in. test tube or 50-mL beaker by adding small

(13446-34-9) amounts of water (usually about 3–5 mL) until the solid dis-

MnCl2ⴢ2H2O 5–135 MnCl2ⴢ4H2O DH 23.2 22.3 solved. A 0.5-mL portion of 2-propanol was added to the

(13446-34-9) solution and the test tube was placed in a water bath or sand

FeCl2ⴢ2H2O 11–155 FeCl2ⴢ4H2O DH 21.3 22.1 bath maintained at a fairly constant temperature (an ordi-

(13478-10-9) nary hot-plate provided sufficient temperature control) within

FeCl2ⴢ2H2O 11–155 FeCl2ⴢ4H2O SAM 22.4 22.1 the stability range of the desired hydrate (see Table 1). The

(13478-10-9) solution was allowed to evaporate until crystals formed. In

JChemEd.chem.wisc.edu • Vol. 77 No. 4 April 2000 • Journal of Chemical Education 509

In the Laboratory

no case was the solution allowed to evaporate to dryness. The Information for the Instructor

rate of evaporation was slowed in some cases by covering the

In this project, a series of inorganic ionic hydrates are

test tube or beaker with Parafilm tape into which several holes

prepared and analyzed for water content. The concepts of

were punched. The crystals were isolated by suction filtration,

hydration, solubility, saturation, crystallization, compound

washed with 2-propanol, and placed in a desiccator overnight.

stability, and simple gravimetric analysis are illustrated and

Temperature Difference Method (TDM) reinforced in a straightforward experiment. We believe the

experiment is probably most suited for the general chemistry

A nearly saturated solution of the commercially available

laboratory, and that the variations possible in the hydrates

hydrate was prepared by placing about 2 g of the starting

prepared and analytical methods employed within the frame-

metal hydrate in an 8-in. test tube or 50-mL beaker, which

work of the procedure described make this a versatile project.

was placed in a water bath or sand bath maintained at a

A glance at Table 1 reveals that not every synthetic method

temperature above the maximum limit for the target hydrate.

was used for each target hydrate. This paper is not meant to be

Distilled water was added dropwise to the test tube until all

an exhaustive report on the preparation of specific hydrates,

the solid was dissolved. One or two additional drops of dis-

but rather a report of an undergraduate-level experiment

tilled water were added and the test tube was again placed

suited to illustrate the topics mentioned. Each of the synthetic

into a water or sand bath maintained at a lower temperature

methods will work with a variety of common hydrates with

within the temperature range for stability of the target hydrate.

the exception of the thermal difference method (TDM),

The target hydrate typically crystallized within 30 min. The

which may not generate product if the target hydrate has a

crystals were isolated by suction filtration, washed with 2-pro-

higher solubility at a lower temperature or has nucleation

panol, and placed in the desiccator overnight.

problems. In one application the instructor could assign a

Solvent Addition Method (SAM) student or small group of students the synthesis and analysis

of a hydrate from Table 1 using all four techniques. Alterna-

A working solution of an ionic hydrate from Table 1 was

tively, multiple hydrates could be assigned using one or more

formed as described in the EM procedure. The test tube or bea-

synthetic approaches. The student would then “discover”

ker containing the working solution was placed into a water or

which approaches seem to work best for each hydrate.

sand bath maintained at a temperature within the stability range

Each of the synthetic methods described was tested by

of the target hydrate. After the temperatures equilibrated, 2-pro-

undergraduate students and the results are summarized in

panol was added dropwise until a precipitate formed. (Other

Table 1. Students were very successful in isolating the various

weakly complexing solvents that are miscible with water but less

hydrates by each of the techniques. Moreover, the analysis of

effective than water at solubilizing ionic materials could also be

the water of hydration was successful on the basis of a com-

used to precipitate the hydrate. 2-propanol is a good choice be-

parison of the expected mass percent of water from the “ideal”

cause it is readily available, reasonably safe, and inexpensive.)

formula with the experimental mass percent (see columns 5

The crystals were isolated by suction filtration, washed with 2-

and 6 in Table 1.). The average percent error for the com-

propanol, and placed in the desiccator overnight.

parisons reported was 3.4% (2.3% if one value with an espe-

Direct Heating (DH) cially large error, cobalt(II) chloride via the evaporation

method, is neglected).

Approximately 2 g of the starting hydrate was heated in

The instructor will probably want to include a discussion

an oven for 24 h at a temperature within the stability range

of the nature of hydrated salts (i.e., how is the water incor-

for the hydrate desired. The product hydrate was stored in a

porated into the structure) and the effect of temperature on the

desiccator until analyzed.

extent of hydration. We recommend the excellent discussion

Determination of Water of Hydration by Kauffman and Baxter (5) as a guide.

A 0.5–1.0 g (± l mg) hydrate sample was weighed into a

Literature Cited

porcelain crucible and heated gently with a low Bunsen

burner flame. After approximately 20 min the heat was 1. CRC Handbook of Chemistry and Physics, 75th ed.; Lide, D.

increased until there was no further evidence of the release R., Ed.; CRC: Boca Raton, FL, 1994.

of water. The sample should not be heated so strongly that 2. Silber, H. B. J. Chem. Educ. 1972, 49, 586–589.

decomposition occurs (as evidenced, for example, by an extreme 3. Kielland, J. J. Chem. Educ. 1937, 14, 412–414.

change in color—from blue or green to black in the case of 4. Procedures can be readily found in many laboratory manuals.

iron and copper salts). After cooling in a desiccator the sample See, for example: Day, R. A.; Underwood, A. L. Quantitative

was reweighed and the percent water of hydration was cal- Analysis, 5th ed.; Prentice-Hall: Englewood Cliffs, NJ, 1986.

culated from the difference in weight. 5. Kauffman, G. B.; Baxter, J. F. J. Chem. Educ. 1981, 58, 349–353.

510 Journal of Chemical Education • Vol. 77 No. 4 April 2000 • JChemEd.chem.wisc.edu

You might also like

- Gravimetric Lee AlanDocument2 pagesGravimetric Lee Alankaren capoteNo ratings yet

- Engineering Chemistry Lab ManualDocument57 pagesEngineering Chemistry Lab ManualRemusNo ratings yet

- Banik 1992Document4 pagesBanik 1992Farschad AnsariNo ratings yet

- Alcohol Dehydration (Elimination) : CH H C H C OH CH CH H C H CDocument8 pagesAlcohol Dehydration (Elimination) : CH H C H C OH CH CH H C H CLemontNo ratings yet

- SM 2540 Solids (1997) PDFDocument7 pagesSM 2540 Solids (1997) PDFJames RobinsonNo ratings yet

- Journal of The American Ceramic Society - 2005 - Wu - Effect of PH of Medium On Hydrothermal Synthesis of NanocrystallineDocument7 pagesJournal of The American Ceramic Society - 2005 - Wu - Effect of PH of Medium On Hydrothermal Synthesis of NanocrystallineErhan KaracaNo ratings yet

- General Methods For Proximate and Mineral AnalysisDocument2 pagesGeneral Methods For Proximate and Mineral Analysisf jjNo ratings yet

- Chima Maceda2021Document6 pagesChima Maceda2021Moltimer Folchart CrawNo ratings yet

- GlauberDocument13 pagesGlauberGogo EtahNo ratings yet

- Methods of Sampling and Test (Physical and Chemical) For Water and Waste WaterDocument4 pagesMethods of Sampling and Test (Physical and Chemical) For Water and Waste WatermbvyassNo ratings yet

- 13smi897 PDFDocument18 pages13smi897 PDFtary_nuryanaNo ratings yet

- Theodorou 2007Document4 pagesTheodorou 2007jlmg990201No ratings yet

- Karl Fisher Apparatus and Its Performance VerificationDocument7 pagesKarl Fisher Apparatus and Its Performance VerificationDarlenis RodriguezNo ratings yet

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Liquid HCLDocument8 pagesLiquid HCLLucasNo ratings yet

- Quantitative Determination of WaterDocument23 pagesQuantitative Determination of WaterApurba Sarker Apu100% (1)

- 6 - Simple DistillationDocument6 pages6 - Simple DistillationJade AsparinNo ratings yet

- Determination of Water in Forages & Animal Feeds by Karl Fischer TitrationDocument8 pagesDetermination of Water in Forages & Animal Feeds by Karl Fischer TitrationSV_TokanNo ratings yet

- Castor OilDocument6 pagesCastor OilÖzlem YılmazNo ratings yet

- 921 Water Determination: Method I (Titrimetric)Document4 pages921 Water Determination: Method I (Titrimetric)BossokNo ratings yet

- Experiments To WriteDocument53 pagesExperiments To WriteSUMAIRA ALTAFNo ratings yet

- SM 2540 2011Document7 pagesSM 2540 2011OlgaNo ratings yet

- Titulación de AguaDocument6 pagesTitulación de AguaJuan Carlos RuizNo ratings yet

- 2540Document7 pages2540pollux23No ratings yet

- تكنولوجيا انتاج مياه الشرب Hy 401Document85 pagesتكنولوجيا انتاج مياه الشرب Hy 401kekokebab71No ratings yet

- Manual Amali SKF 3013 A222Document39 pagesManual Amali SKF 3013 A222nadiaNo ratings yet

- Accelerated Stability TestingDocument39 pagesAccelerated Stability Testinguswatun chasanahNo ratings yet

- Maintaining Constant Relative Humidity by Means of Aqueous SolutionsDocument5 pagesMaintaining Constant Relative Humidity by Means of Aqueous SolutionsArunkumar ChandaranNo ratings yet

- Preparing O-Phophoric AcidDocument3 pagesPreparing O-Phophoric AcidsangeetayvermaNo ratings yet

- Process ChemistryDocument16 pagesProcess Chemistrysayani.98banerjeeNo ratings yet

- Determination of Vocs in Ambient Air by Using Gas ChromatographyDocument19 pagesDetermination of Vocs in Ambient Air by Using Gas ChromatographyahosfhaofahfouaNo ratings yet

- Accelerated Stability Testing 1Document39 pagesAccelerated Stability Testing 1Vinaykumar PatelNo ratings yet

- Name Nukhba REG. 18PNL05948 Assignment No.2Document9 pagesName Nukhba REG. 18PNL05948 Assignment No.2Imaan Khan ImaanNo ratings yet

- Temperature Effect On Peak Width and Column Efficiency in Subcritical Water ChromatographyDocument6 pagesTemperature Effect On Peak Width and Column Efficiency in Subcritical Water ChromatographyDANNA SOFIA SANCHEZ CAMACHONo ratings yet

- Mid Semester Solution-2021Document8 pagesMid Semester Solution-2021Bhavik2002No ratings yet

- Ae - NaCl+Sucrose+Water SLEDocument9 pagesAe - NaCl+Sucrose+Water SLEayisha.maharramovaNo ratings yet

- DepyrogenationDocument7 pagesDepyrogenationOscar AyalaNo ratings yet

- Exp 2 Lab ReportDocument9 pagesExp 2 Lab ReportDanish HakimNo ratings yet

- Adsorption of Water From Methanol Solution Using Various AdsorbentDocument12 pagesAdsorption of Water From Methanol Solution Using Various AdsorbentangelNo ratings yet

- Chemistry Investigatory Project - N.SAI ARAVIND - XII-BDocument24 pagesChemistry Investigatory Project - N.SAI ARAVIND - XII-BPreetishNo ratings yet

- Worksheet: CaramelizationDocument3 pagesWorksheet: CaramelizationLoreto T. Porcari JrNo ratings yet

- 3 - Green Synthesis of A Fluorescent Natural Product PDFDocument3 pages3 - Green Synthesis of A Fluorescent Natural Product PDFjavier roo ror100% (1)

- Jove-Protocol-10224Document8 pagesJove-Protocol-10224Natalia CastilloAdroverNo ratings yet

- Drying AgentDocument36 pagesDrying AgentSo MayeNo ratings yet

- Composition and Method For Sweetening HydrocarbonsDocument8 pagesComposition and Method For Sweetening HydrocarbonsIveth RomeroNo ratings yet

- End Sem Solution 29.11.2021Document9 pagesEnd Sem Solution 29.11.2021hp7772858No ratings yet

- Thennal Stability of Surfactants For Reservoir ApplicationDocument14 pagesThennal Stability of Surfactants For Reservoir ApplicationSanjay singhNo ratings yet

- Green Diels Alder ExperimentDocument2 pagesGreen Diels Alder ExperimentchedhedNo ratings yet

- Sintesis de HachDocument2 pagesSintesis de HachJuan Felipe Amaya LunaNo ratings yet

- 2007 - Ronkart - Characterization of The Physical State of Spray-Dried Inulin.2007Document10 pages2007 - Ronkart - Characterization of The Physical State of Spray-Dried Inulin.2007Ramanuzha GunawanNo ratings yet

- Pre Formulation Stability StudiesDocument33 pagesPre Formulation Stability StudiesDinesh Reddy50% (2)

- Determining The Percentage of Water and Formula of An Unknown HydrateDocument2 pagesDetermining The Percentage of Water and Formula of An Unknown HydrateAimee KorantengNo ratings yet

- 8672 2Document9 pages8672 2Imaan Khan ImaanNo ratings yet

- Aguas - Oxígeno DisueltoDocument12 pagesAguas - Oxígeno DisueltoRina Licet Socompi AguilarNo ratings yet

- Determination of Iron With 1,10-PhenanthrolineDocument5 pagesDetermination of Iron With 1,10-PhenanthrolineOmSilence26510% (1)

- Dispersive Liquid-Liquid Microextraction Using The Freezed Floating Organic Drop For Rapid, Fast, and Sensitive Determination of LeadDocument12 pagesDispersive Liquid-Liquid Microextraction Using The Freezed Floating Organic Drop For Rapid, Fast, and Sensitive Determination of LeadrezacvNo ratings yet

- Chemistry Practicals First YearsDocument65 pagesChemistry Practicals First YearsWaleed EmaraNo ratings yet

- IP 6. Protocol - Chemical Principles II LaboratoryDocument5 pagesIP 6. Protocol - Chemical Principles II LaboratoryJavier PratdesabaNo ratings yet

- Air Water LAB 2012Document6 pagesAir Water LAB 2012LESLI RODRIGUEZ BENDEZUNo ratings yet

- File-Mhs PDFDocument5 pagesFile-Mhs PDFCarol SantosNo ratings yet

- EksipienDocument4 pagesEksipienAgung PermataNo ratings yet

- Physiochem Pties & Biol Activity, Chapter 2 - 1Document9 pagesPhysiochem Pties & Biol Activity, Chapter 2 - 1weamNo ratings yet

- Dll-Science 7 - Saturated Unsaturated SolutionsDocument5 pagesDll-Science 7 - Saturated Unsaturated SolutionsART JOSHUA MARA100% (2)

- 6th Class 2nd Term Quick Revision WorksheetDocument4 pages6th Class 2nd Term Quick Revision WorksheetMazhar FarooqNo ratings yet

- Moles&solutionsDocument4 pagesMoles&solutionsestellasr00No ratings yet

- Natrosol 250 MsdsDocument32 pagesNatrosol 250 MsdsArdiany IntanNo ratings yet

- Technical Data Sheet Yipin Yellow Iron Oxide YPC338073Document2 pagesTechnical Data Sheet Yipin Yellow Iron Oxide YPC338073Fabio Arboleda TorresNo ratings yet

- Inv Chem 1Document24 pagesInv Chem 1Animesh kanjilalNo ratings yet

- Lab Activity Aim:: Apparatus and MaterialsDocument2 pagesLab Activity Aim:: Apparatus and MaterialsManushka ThomasNo ratings yet

- Raw Board Battle Round 1Document13 pagesRaw Board Battle Round 1Maridil Joy IsidroNo ratings yet

- 1 s2.0 S135902942030011X MainDocument27 pages1 s2.0 S135902942030011X Mainion1barangaNo ratings yet

- ACTICIDE DСХ 30Document1 pageACTICIDE DСХ 30Fadi MagdyNo ratings yet

- ThesisDocument97 pagesThesisAsra Zafar khanNo ratings yet

- Unit - I: Water TreatmentDocument127 pagesUnit - I: Water TreatmentAnu ShanthanNo ratings yet

- Reactive Extraction of Itaconic Acid Using Quaternary Amine Aliquat 336 in Ethyl Acetate, Toluene, Hexane, and KeroseneDocument9 pagesReactive Extraction of Itaconic Acid Using Quaternary Amine Aliquat 336 in Ethyl Acetate, Toluene, Hexane, and Kerosenebala11ap4598No ratings yet

- Metals and Non MetalsDocument15 pagesMetals and Non Metals2erwr100% (2)

- July 2-6 Concentration of SolutionDocument4 pagesJuly 2-6 Concentration of SolutionLovieAlfonsoNo ratings yet

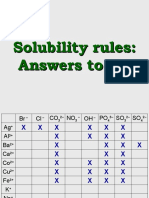

- Solubility Rules: Answers To LabDocument7 pagesSolubility Rules: Answers To LabDeba Jyoti NeogNo ratings yet

- A New Method For The Synthesis of Aliphatic Nitro Compounds1, 2Document5 pagesA New Method For The Synthesis of Aliphatic Nitro Compounds1, 2banjo01No ratings yet

- 5070 w03 QP 3Document8 pages5070 w03 QP 3mstudy123456No ratings yet

- 2118-2517-Methylphenidate 27 mg-28Document400 pages2118-2517-Methylphenidate 27 mg-28Josue Ivan Buendia GarciaNo ratings yet

- Gravimetric Analysis 2Document25 pagesGravimetric Analysis 2Madhuri poulkarNo ratings yet

- Chemical Solutions and Solubility: (Unit Ii Chapter 5 of Your Book)Document31 pagesChemical Solutions and Solubility: (Unit Ii Chapter 5 of Your Book)Camille Ann Faigao FamisanNo ratings yet

- 2018 FY9 FEBasic ScidetailedsolutionsDocument41 pages2018 FY9 FEBasic ScidetailedsolutionskrishNo ratings yet

- Gas Turbine Compressor Washing PDFDocument8 pagesGas Turbine Compressor Washing PDFHANIF AKBARNo ratings yet

- Crystallization PrdasddaoblemsDocument4 pagesCrystallization PrdasddaoblemsJim Laab100% (1)

- Soil Chemistry KeywordsDocument8 pagesSoil Chemistry Keywordssobe64 sNo ratings yet

- Drug Discovery Today - Technologies Volume 9 Issue 2 2012 (Doi 10.1016/j.ddtec.2012.03.006) Stephen R. Byrn Jan-Olav Henck - Optimizing The Physical Form - Opportunities and LDocument6 pagesDrug Discovery Today - Technologies Volume 9 Issue 2 2012 (Doi 10.1016/j.ddtec.2012.03.006) Stephen R. Byrn Jan-Olav Henck - Optimizing The Physical Form - Opportunities and LGotsvnNo ratings yet

- Evaporation: Types of EvaporatorsDocument9 pagesEvaporation: Types of EvaporatorsDr-Khalid Al-ShemmariNo ratings yet

- Work Instruction: Analysis of Finished ProductDocument9 pagesWork Instruction: Analysis of Finished ProductAshish BhardwajNo ratings yet