Professional Documents

Culture Documents

Natural Gas Analyzer Manual For 2310-0012

Uploaded by

UmarFidaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Natural Gas Analyzer Manual For 2310-0012

Uploaded by

UmarFidaCopyright:

Available Formats

Natural Gas Analyzer

1 Valve

Specials and Solutions Group

Rev A Page 1 Saved 04/01/02 3:20 PM

General information

This GC is configured to analyze natural gas according to the ASTM method 1945 and the GPA method 2261. The

analyzer is a one valved system using 1/8 inch packed columns with early back-flush of the C6+ components. A plumbing

diagram is shown below.

.

DATE : 3/18/2002 File

6890 Valve System O/N : ITEM

FLOW INJECTION VALVE COMPARTMENT

BLOCK 2 BLOCK 1 DETECTOR

SOURCE PORT

1/805

Column 2

6 5

7

8 4

OUT

9 3

SAMPLE 10 2

1

IN

Column 1

LOOP

A A

A TCD

PPI

(220)

(102)

6890 Options

102

220

751

805

sa

Fig 1

The columns used in this analyzer are as follows. All are 1/8 inch stainless steel.

Column 1 3 Foot 35% DC200 on PAW 80/100 mesh

Column 2 30 Foot 35% DC200 on PAW 80/100 mesh

The plumbing diagram shows a packed inlet as the flow source for the valves. The pneumatics control module

can also be used as a flow source. Valve 1 is a 10 port valve configured as a gas sampling with sequence reversal and

backflush of the pre-column.

Rev A Page 2 Saved 04/01/02 3:20 PM

Analysis Sequence

The diagrams below show the sequence of the analysis

1. Injection and first minute of the run.

DC200 30 Ft DC200 3Ft TCD

C5-C1,CO2,N2 O2 C6+

Note that the sample is injected onto the short DC200 column.

2. Backflush and reverse flow of the short DC200 ensures that C6 and higher compounds come out early in the

chromatogram as one peak.

C5-C1,CO2,N2 O2 C6+

Installation.

Connect all gases to the GC and power up the GC. If a HP ChemStation is being used - bring up the ChemStation and

load the method NatGas1.M (See floppy disc supplied)

Verify the following conditions

=============================================================================

6890 GC METHOD

=============================================================================

OVEN

Initial temp: 130 'C (On) Maximum temp: 225 'C

Initial time: 14.00 min Equilibration time: 0.25 min

Ramps:

# Rate Final temp Final time

1 0.0(Off)

Post temp: 0 'C

Post time: 0.00 min

Run time: 14.00 min

FRONT INLET (UNKNOWN) BACK INLET ()

Flow: 30.0 mL/min (On)

Gas type: Helium

COLUMN 1 COLUMN 2

Packed Column (not installed)

Model Number: Agilent GPA 2261

30' 30% DC 200 on chrom PAW 80/100

Max temperature: 225 'C

Mode: constant flow

Rev A Page 3 Saved 04/01/02 3:20 PM

Nominal initial flow: 30.0 mL/min

Inlet: Front Inlet

Outlet: Front Detector

Outlet pressure: ambient

FRONT DETECTOR (TCD) BACK DETECTOR (NO DET)

Temperature: 175 'C (On)

Reference flow: 45.0 mL/min (On)

Mode: Constant makeup flow

Makeup flow: 0.0 mL/min (Off)

Makeup Gas Type: Helium

Filament: On

Negative polarity: Off

SIGNAL 1 SIGNAL 2

Data rate: 5 Hz Data rate: 20 Hz

Type: front detector Type: front detector

Save Data: On Save Data: Off

Zero: 0.0 (Off) Zero: 0.0 (Off)

Range: 0 Range: 0

Fast Peaks: Off Fast Peaks: Off

Attenuation: 0 Attenuation: 0

COLUMN COMP 1 COLUMN COMP 2

Derive from front detector Derive from front detector

THERMAL AUX 1

Use: Valve Box Heater

Description:

Initial temp: 75 'C (On)

Initial time: 0.00 min

# Rate Final temp Final time

1 0.0(Off)

VALVES POST RUN

Valve 1 Off Post Time: 0.00 min

Description: gas sampling valve

TIME TABLE

Time Specifier Parameter & Setpoint

0.01 Valve 1: On

1.30 Valve 1: Off

Procedure for a New Setup

This procedure will have to be carried out on a new GC or if new columns are installed or the present columns are re-

conditioned. If new columns are being installed, or present columns need to be conditioned, condition columns as

indicated in the Appendix A

Rev A Page 4 Saved 04/01/02 3:20 PM

Setting the backflush time

The object is to set the backflush time of Valve 1 so that any C6+ compounds are backflushed out

as the first peak. A sample containing hexane or C6+ must be used to set up the valve timing. A

suitable sample is P/N 5080-8756 from Agilent Technologies.

1. Clear the run table of any entries and then enter the following into the run table.

Valve 1 ON Time 0.05

Valve 1 OFF Time 1.20

2. Check that you have the following set up

Oven temp 130°C

Oven time 20 min

Oven rate 0°C/min.

3. Flush the sample loop with the sample, and press START on the GC. Allow to run for the full 20

minutes. You should get a chromatogram similar to that shown below.

25 uV

Methane

2500

2000

Air

Ethane

1500

Propane

1000

Iso-Butane

Carbon Dioxide

N-Butane

Iso-Pentane

N-Pentane

500

C6 +

0

2.5 5 7.5 10 12.5 15 17.5 20 min

Fig 2.

It is important to check that both pentane peaks are present and that there is no C6 coming out later

in the run.

If the backflush time is set too early you will see that pentane peaks are missing or not all of the

pentane is present. This situation is shown in Fig 3, where a backflush time of 0.70 minutes was

used.

Rev A Page 5 Saved 04/01/02 3:20 PM

If the backflush time is set too late, you will see that the C6 compounds come out later in the run.

The chromatogram shown in Fig 4 shows a peak at 15.1 min when a backflush time for Valve 1 was

set to 1.10 minutes.

25 uV

Methane

4500

4000

3500

3000

2500

2000

Ethane

Air

1500

Propane

C5 and C6

Carbon Dioxide

Iso-Butane

N-Butane

1000

500

0

2 4 6 8 10 12 14 16 min

Fig 3. Backflush too early

25 uV

Methane

2500

2000

Air

Ethane

1500

Propane

1000

Iso-Butane

N-Butane

Iso-Pentane

N-Pentane

500

C6

0

5 10 15 20 25 30 min

Fig 4. Backflush too late

The ideal time is found by increasing the backflush time of Valve 1 in 0.10 increments until the C6

peak starts to appear as shown in Fig 4. When you have found this time, decrement the backflush

Rev A Page 6 Saved 04/01/02 3:20 PM

time in 0.05 decrements until this peak no longer appears. Now set the backflush time to 0.10

minutes earlier. In the example shown in Fig 4, the backflush time was 1.10 minutes. Decrementing

the time to 1.05 minutes resulted in the C6 peak disappearing. Therefore the ideal time will be 1.05 –

0.10 = 0.95 minutes.

Calibration

Connect up a calibration gas to the GC, purge the sample loop with the calibration gas and allow the

pressure in the loop to come down to atmospheric pressure before starting the run. At the end of the

run, calibrate the GC.

Tips on running the analyzer.

Sample introduction

To get reproducible results, do NOT start the GC when sample is flowing through the sample loop.

Always fill the loop and wait for about 15 seconds for the pressure in the sample loop to equilibrate

to atmospheric pressure before starting the run.

To run the GC as an analyzer automatically proceed as follows.

As stated above, it is not recommended to have flow through the sample loop when injecting the

sample into the GC. You will need a way to control the sample gas. One way is to use an external

solenoid valve controlled by the GC. The pressure of the sample to the valve should be in the 5 to

10 psi range (35 to 70 Kilopascals). The valve should be an ON/OFF type of valve. If you wish to

control this directly from the GC it should operate at 24 Volts DC and with a power rating of no more

than 1.8 watts.

Agilent cable P/N G1530-60590

Connect to

EVENT socket

White Black

Sample vent line

6890 GC

Sample in 24 V Solenoid

at 5-10 psi valve 1.8 W

The 6890 has the possibility to control 8 valves. Four of these, Valve 1 to Valve 4 are ‘internal’

valves and are used to control the valves installed on top of your instrument. The other 4 valve

Rev A Page 7 Saved 04/01/02 3:20 PM

controls are available at the rear of the GC through the EVENT socket. Valve 5 and Valve 6 are 24

Volt outputs (1.8 watts ). Valve 7 and Valve 8 are contact closures. As shown on the diagram, the

solenoid valve would be controlled by the Valve 6 command.

To start the GC automatically, one Valve MUST be defined as a “Gas Sampling valve”. This can be

the actual valve that injects the sample. However, when this valve is chosen as the gas sampling

valve, you will not see ANY entries for this valve in the run table. It has been found easier to

configure all valves used in the analysis as “Switching” valves, and to define an unused valve

(dummy) as the gas sampling valve. It will far easier to change times in the timetable, especially if

the injection valve is a 10 port valve with backflush or sequence reversal.

The picture below shows a screen shot of the valve configuration screen where:

V1 is the switching valve used for this analysis

V5 is the “dummy” gas sample valve

V6 is used for the solenoid valve

Rev A Page 8 Saved 04/01/02 3:20 PM

Conditioning the columns.

Due to the high percentage of liquid phase used with these columns, it is advised to condition the

columns disconnected from the detector.

The columns should be heated to 250°C for 12 hours with a flow of 30ml/min of carrier gas.

If the columns are conditioned in this GC, be careful that the valve box containing the valve does not

go above 200°C, other wise permanent damage may be done to the valve.

Rev A Page 9 Saved 04/01/02 3:20 PM

You might also like

- QP Investment Portfolio PDFDocument1 pageQP Investment Portfolio PDFUmarFidaNo ratings yet

- Amspec Techtalk - Pona PianoDocument4 pagesAmspec Techtalk - Pona PianoUmarFidaNo ratings yet

- Reformulyzer Operating and Application Manual V 2016 2.5.0 20160511 PDFDocument99 pagesReformulyzer Operating and Application Manual V 2016 2.5.0 20160511 PDFSanthana Kumar Annamalai100% (1)

- SimdistDocument28 pagesSimdistUmarFidaNo ratings yet

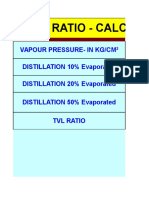

- TVL Ratio CalculationDocument4 pagesTVL Ratio CalculationUmarFidaNo ratings yet

- Astm D 4052-11Document8 pagesAstm D 4052-11UmarFidaNo ratings yet

- RFP 002433Document2 pagesRFP 002433UmarFidaNo ratings yet

- Astm D 4052Document8 pagesAstm D 4052UmarFida0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Plate Tectonics: Eden M Napo Science TeacherDocument27 pagesPlate Tectonics: Eden M Napo Science TeacherMary Rose FajardoNo ratings yet

- Atomic Structure JEE Main and Advanced (Theory)Document19 pagesAtomic Structure JEE Main and Advanced (Theory)Er. Vineet Loomba (IIT Roorkee)No ratings yet

- PPTG101213 Free Fall & Projectile Notes GALLEGODocument74 pagesPPTG101213 Free Fall & Projectile Notes GALLEGORed GallegoNo ratings yet

- Ionic and Covalent BondingDocument51 pagesIonic and Covalent BondingBilly STEVENo ratings yet

- Test Paper 1Document10 pagesTest Paper 1Sanjay Verma100% (1)

- Reshuffl Test 1Document12 pagesReshuffl Test 1PiyushNo ratings yet

- Alaimo2001 - PurificationDocument1 pageAlaimo2001 - PurificationAnna OlszewskaNo ratings yet

- CHE 414 Principles of Plant Design I Part 2Document30 pagesCHE 414 Principles of Plant Design I Part 2ifiokNo ratings yet

- RadioactivityDocument15 pagesRadioactivityBenjamin Teo0% (2)

- Chapter 7Document450 pagesChapter 7Kristen TizzanoNo ratings yet

- Vulkem 350NF - Tremco Epoxy Primer - CVDocument5 pagesVulkem 350NF - Tremco Epoxy Primer - CVAriel Sepúlveda CaroNo ratings yet

- CBSE Class 12 Physics Current ElectricityDocument21 pagesCBSE Class 12 Physics Current ElectricityK_S_Krishna0001No ratings yet

- Multi V S Heat Pump manualDocument24 pagesMulti V S Heat Pump manualHeitor Prudente CorreaNo ratings yet

- Usp GC 621 Dec 2022Document26 pagesUsp GC 621 Dec 2022banapte599706No ratings yet

- 245 Bergander Rev5Document8 pages245 Bergander Rev5mariodalNo ratings yet

- Worksheet Oxidation ReductionDocument7 pagesWorksheet Oxidation ReductionRudi BerlianNo ratings yet

- Preparation and Properties of QuinolineDocument19 pagesPreparation and Properties of QuinolineKundan OjhaNo ratings yet

- Here are the names for the covalent compounds:CO - carbon monoxide CO2 - carbon dioxideDocument67 pagesHere are the names for the covalent compounds:CO - carbon monoxide CO2 - carbon dioxideCacey Daiwey CalixtoNo ratings yet

- Ecosystems ThermodynamicsDocument27 pagesEcosystems Thermodynamicsapi-326805662No ratings yet

- Liquid Soap Making 2Document14 pagesLiquid Soap Making 2Adeyemi100% (2)

- Basic Integration Problems With Answers PDFDocument158 pagesBasic Integration Problems With Answers PDFLily Antonette AgustinNo ratings yet

- Boiling PointDocument10 pagesBoiling PointAshish Malgawa67% (3)

- A Level Environmental Chemistry notes summaryDocument14 pagesA Level Environmental Chemistry notes summarymaxwell Mutare100% (1)

- 2020-General Chemistry 1 Review WorksheetDocument4 pages2020-General Chemistry 1 Review WorksheetNgọc Thảo Vy NguyễnNo ratings yet

- Testing Water QualityDocument13 pagesTesting Water QualitySHIWANG SHARMA100% (4)

- KRM Public School: Chemistry Project FileDocument17 pagesKRM Public School: Chemistry Project FileSHYAM ANo ratings yet

- OSU Biophysics Graduate HandbookDocument62 pagesOSU Biophysics Graduate HandbooksivaNo ratings yet

- Homework AssigmentDocument4 pagesHomework AssigmentIan Pierre0% (1)

- 5977c GC MSD AgilentDocument5 pages5977c GC MSD Agilentashton.selokaNo ratings yet

- CHEM 241 SyllabusDocument2 pagesCHEM 241 SyllabusBob MillerNo ratings yet