Professional Documents

Culture Documents

Ijciet 08 09 069

Uploaded by

Jitender SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijciet 08 09 069

Uploaded by

Jitender SinghCopyright:

Available Formats

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/320125971

A review on the effect of crumb rubber on the

properties of rubbercrete

Article in International Journal of Civil Engineering and Technology · September 2017

CITATIONS READS

0 39

3 authors:

Bashar Mohammed Musa Adamu

Universiti Teknologi PETRONAS Bayero University, Kano

60 PUBLICATIONS 306 CITATIONS 14 PUBLICATIONS 7 CITATIONS

SEE PROFILE SEE PROFILE

Nasir Shafiq

Universiti Teknologi PETRONAS

163 PUBLICATIONS 437 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Durability of Fiber Reinforced Self-Compacting Concrete View project

Artificial Neural Network Prediction Modeling View project

All content following this page was uploaded by Musa Adamu on 30 September 2017.

The user has requested enhancement of the downloaded file.

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 9, September 2017, pp. 599–615, Article ID: IJCIET_08_09_069

Available online at http://http://www.iaeme.com/ijciet/issues.asp?JType=IJCIET&VType=8&IType=9

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication Scopus Indexed

A REVIEW ON THE EFFECT OF CRUMB

RUBBER ON THE PROPERTIES OF

RUBBERCRETE

Bashar S Mohammed*, Musa Adamu, Nasir Shafiq

Depart of Civil and Environmental Engineering,

Universiti Teknologi PETRONAS, 32610, Bandar Seri Iskandar, Perak, Malaysia

ABSTRACT

With rapid increase in the number of vehicles every day, the amount of scrap tire

generated keeps skyrocketing as it is estimated to reach 1.2 billion tonnes annually by

2030. Scrap tires continue to pose serious environmental, health and aesthetic

problems as they are bulky, non-biodegradable, good breeding area for mosquitos

and rodents and also flammable materials. Several attempts have been made for the

proper utilization and management of scrap tires. Due limitation in the recycling of

scrap tires, one of the most viable solution is to used crumb rubber from scrap tire as

partial replacement to fine aggregate in concrete industry. This is rationalized as the

production of concrete hit more than 3.8 billion cubic meters annually, therefore, it

could provide a solution on conservation of natural aggregate and as well as improve

properties of concrete. This paper present a review of the recent researches carried

out on investigating the fresh and hardened properties of rubbercrete. Construction

members and products made of rubbercrete have highlighted as well. In addition,

future application related to rubbercrete advancement has been discussed.

Key words: Waste Tire, Crumb Rubber, Rubbercrete, Sustainability, Recycling

Materials.

Cite this Article: Bashar S Mohammed, Musa Adamu and Nasir Shafiq, A Review on

The Effect of Crumb Rubber On The Properties of Rubbercrete, International Journal

of Civil Engineering and Technology, 8(9), 2017, pp. 599–615.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=9

1. INTRODUCTION

The world population keeps on increasing, with projection of 70% of the population to be

living in the cities by 2050 necessitating the need of automobiles since transportation is

needed more in the cities [1]. With this increase in population, and transportation been one of

the basic necessities in life, thus leading increase in vehicle usage, with China being the

largest automobile producing and marketing country [2, 3]. In the developed countries, it was

estimated that the rate of generation of waste tires stands in the ratio of one passenger tire per

person, with an estimate of 1 billion waste tires generated annually, with an expectation that

the waste tire generation will reach 1.2 billion by 2030, and a total of about 4 billion tires

http://www.iaeme.com/IJCIET/index.asp 599 editor@iaeme.com

A Review on The Effect of Crumb Rubber On The Properties of Rubbercrete

deposited as landfills globally, with more than 50% of the average 1 billion waste tires

produced globally are discarded without any treatment [4-7]. The amount of waste tires

generated in U.S.A escalated to more than 3.8 million tonnes by 2013 with civil engineering

application consuming only about 5% of the waste tire generated [8]. While in 2015 it

escalated to more than 4.1 million tons with civil engineering utilizing about 7% [9]. A tire

can be defined as complex elastomeric formulations composite combined with steel and fiber

codes while a waste tire can simply be defined as a type of solid waste generated from used,

unwanted or discarded tires, irrespective of its size or type and has been removed from its

original usage [10, 11].

1.1. Problems Associate with Waste Tires

Waste tire is a solid waste and its disposal and management poses environmental concern

among several countries [10, 12, 13]. This is mainly due to its non-biodegradable nature as a

result of presence of stabilizers, additives and the cross-linked structure of the elastomeric

polymer material [13]. In other words, disposal of waste tires is very difficult as it requires

large space causing environmental, aesthetic and health related problems to the surrounding

environment, If dumped in the environment, will be stockpiled, causing landfilling problems

with rapidly depleting the available sites for solid waste disposal, and causes so many

environmental and health hazards such as high risk of fire, provides shelter to harmful insects,

rodents and animals such as rats, mosquitoes, snakes, mice etc. [12, 14, 15].

1.2. Possible Solutions to Waste Tire Disposal Problems

Waste tire management continues to pose serious environmental, health and aesthetic

problems and therefore need to be solved. Several attempts have being made for the proper

utilization and management of waste tires. Some of the ways used in waste tire management

include; using waste tire in asphaltic concrete, production of steam through tires incineration,

as fuel for cement kiln, in the production of carbon black, and as an artificial reef in marines

[10]. Waste tires are also used in pyrolysis i.e. production of tire derived fuels due to their

long hydrocarbon chains [16-22]. Majority of the waste tires utilized are used in the pyrolysis

of tire derived fuel, but the use of tires for fuel is economically less advantage compared to

fuel derived from petroleum products, and it involves pollution of environment by releasing

toxic gases to the surrounding environment [23, 24]. They are also used to produce activated

carbon for absorbing pollutant gases from flue gas streams i.e. for pollution control

applications [25-29]. Waste tires are also used for ground rubber applications such as in

flower beds mulch, landfill liners, artificial reefs, breakwaters, embankments, retaining walls,

cover for playground, as asphalt for paving streets and highways, sport surfacing, animal

bedding, as high volume fill for septic systems, fill material for turf grasses, and in concrete as

partial replacement to aggregate etc [9, 10, 30].

Due to the rapid growth and development in the construction industries with higher

demands of concrete which is produced in billions of tonnes annually, emphasis are been laid

on the sustainability of the concrete constituent materials most specifically aggregate which

constituent the highest volume percentage in the concrete to prevent or overcome its possible

shortage which many countries are now facing [7, 10, 13, 31]. In order to manage the

problems associated with waste tire disposal and the possible shortage of aggregate in the

construction industry, incorporating waste tire to partially replace aggregate in concrete seems

to be a possible solution [7, 12].

Waste tires are been used in concrete as partial replacement to fine aggregate or coarse

aggregate. The waste tire is grinded and reduces into smaller particles before replacing

aggregate in concrete, with the steel and thread removed. Mechanical grinding at ambient is

http://www.iaeme.com/IJCIET/index.asp 600 editor@iaeme.com

Bashar S Mohammed, Musa Adamu and Nasir Shafiq

used to produce chipped rubber which is used as coarse aggregate in concrete while crumb

rubber is used as fine aggregate in concrete is produced using cryogenic grinding at low

temperature [7]. For example, waste tire has being used as crumb rubber to partially replace

fine aggregate in concrete [32-40]. Other researchers uses waste tire to partially replace both

fine and coarse aggregate in concrete etc. [41-43]. However few cases exists where waste tires

was used in form of chips to replace coarse aggregate in concrete due to the high reduction in

strength [44, 45]. Waste tires was also used as fine aggregate replacement in concrete for

composite slabs applications, exterior walls, hollow blocks and roller compacted concrete [46-

50].

Different terminologies such as rubbercrete, rubberized concrete and rubcrete were used

to denote concrete containing waste tires as partial replacement of aggregate [24, 42, 51-59].

For this paper rubbercrete will be adapted.

2. CRUMB RUBBER

Crumb rubber is a waste tire in which the size of the whole tire is reduced and grinded into

smaller particle ranging from 4.75 mm to 75μm as shown in figure 2 [10]. It is produced in a

special mill through grinding of the waste tire to granular sizes between 0.425 mm to 4.75

mm, with different sizes produced based on the properties and temperature of the milling

machine generated [31]. It can be used as a partial replacement of fine aggregate in concrete

or mortar [10, 31].

2.1. Properties of Crumb Rubber

Crumb rubber is being used in concrete as a partial replacement to fine aggregate to produce

rubbercrete [12]. In comparison to fine aggregate it has lower specific gravity ranging from

0.51 to 1.2, bulk density ranging from 524 kg/m3 to 1273 kg/m3, lower water adsorption,

strength and stiffness [23, 49, 60-62]. Crumb rubber is hydrophobic and non-polar material

which repels water and entraps air into its surface [63]. It also has a different gradation

compared to fine aggregate which falls below the lower limit of the curve in particle size

analysis. Therefore when it partially replaced fine aggregate in rubbercrete, it changes the

grading to a non-continuous aggregate gradation [36]. Partial replacement of fine aggregate

with crumb rubber in rubbercrete is normally done by volume of the materials due to the

lower specific gravity of crumb rubber compared to fine aggregate.

2.2. Processing of Crumb Rubber

Production of Crumb rubber involves the reduction of the whole waste tire into smaller

granules of sizes ranging from 75 µm to 4.75 mm with the steel, fibers dust and any

contaminants removed, leaving only the rubber particles [10]. Therefore processing the waste

tire from the whole to the smaller crumb sizes involves a series of operations. Four methods

are used to grind the rubber to smaller sizes and they include; ambient temperature, cryogenic,

wet, and high-pressure water jet [64]. Similarly, there are also three methods used to reduce

scrap tires to crumb rubber, and they are granular process, cracker mill process and the micro-

mill process. However the most commonly used method in production of crumb rubber are

the cryogenic grinding and the cracker mill process as they produce almost all desirable size

[10].

http://www.iaeme.com/IJCIET/index.asp 601 editor@iaeme.com

A Review on The Effect of Crumb Rubber On The Properties of Rubbercrete

3. PROPERTIES OF RUBBERCRETE

3.1. Fresh Properties of Rubbercrete

Rubbercrete at its fresh state can be cast and molded to any desired shape; therefore fresh

properties of rubbercrete such as workability, density, unit weight, and air content are

important parameters as they may adversely affect the hardened properties of rubbercrete.

3.1.1. Workability

It has been reported that workability of rubbercrete improved with increasing the partial

replacement of crumb rubber percentage to fine aggregate up to 50% [12, 65]. Other

researchers have reported drop in the workability [65, 66]. Similarly, when crumb rubber

replacement percentage increases in dry mix roller compacted rubbercrete, the consistency

improved [49]. This finding was in contrary to another study where consistency was reported

to decrease [37]. However, in another study, it has been concluded that partial replacement of

crumb rubber to fine aggregate has no effect on workability of rubbercrete [14]. The

improvement in the workability is due to the hydrophobic nature of crumb rubber, it would

repels water which results in increasing the water available for the cementitious matrix and

consequently lead to increasing in the flowability of the rubbercrete [37]. On the other hand,

smaller size and surface roughness of crumb rubber particles could adversely effects the

workability. The higher rough surface area of crumb rubber might lead to increase friction

inside the fresh rubbercrete mixture resulting in reduce the flowability [66, 67].

3.1.2 Unit Weight, density and air content

Crumb rubber is non-polar and hydrophobic in nature which entraps air on its surface,

promoting it as an air entraining agent. Therefore, crumb rubber is being used to increase air

content in rubbercrete to improve freeze and thaw resistance [68]. However, higher air content

in rubbercrete leading to reduction in unit weight [63, 69]. Another contributing factor to the

reduction in the unit weight of concrete is the density of crumb rubber is lower that fine sand

by 192% [70, 71]. It has been reported that 1.5% replacement of crumb rubber to fine

aggregate by weight result in increasing in the air content by 26% decreasing the density by

2% [72].

3.2. Hardened Properties

3.2.1 Introduction

Hardened properties of rubbercrete have been investigated and well documented by

researchers. Some of these properties have been improved, while others have shown reduction

as shown in Table 1.

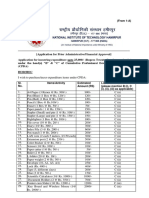

Table 1 Effect of partial replacement of crumb rubber on hardened properties of rubbercrete

Replacement Reduction Increment

Property Reference

Level (%) (%)

Strength Compressive 5 – 30 0.7 – 78.95 [34, 73]

strength

Splitting tensile 5 – 30 5.7 – 66.67 [57, 73]

Strength

Flexural strength 5 – 30 3.8 – 40.74 [74-76]

20 – 30 21.8 – 28.8 [77]

Deformation Static modulus 5 - 30 2 – 52.2 [49, 75]

Dynamic modulus 5 – 30 5.7 – 68.4 [44, 70]

Drying shrinkage 5 – 30 1.7 – 95 [35, 78]

10 42.5 & 69 [70, 79]

http://www.iaeme.com/IJCIET/index.asp 602 editor@iaeme.com

Bashar S Mohammed, Musa Adamu and Nasir Shafiq

Abrasion 5 – 30 0 – 81 [69, 80]

resistance 5 – 25 25 – 34.5 [65]

Impact resistance 5 – 30 71.8 – 198.3 [81, 82]

Damping 5 – 30 27 – 62 [83, 84]

Energy absorption 5 – 30 2.2 – 91 [60, 65]

Brittleness index 5 – 30 37.8 – 63.8 [44]

Peak strain 5 – 30 14 – 251.7 [85, 86]

ultimate strain 5 – 30 62.8 – 183 [85, 86]

peak deflection 5 – 30 3 – 137.5 [85, 86]

Toughness 5 – 30 4 – 193.2 [87, 88]

Fatigue 5 – 30 0.4 – 3.8 [86]

5 – 30 61.4 – 409.7 [85]

Durability Chloride ion 5 – 30 0.8 – 78.3 [14, 67]

penetration 10 – 20 1.37 – 35.85 [14, 24]

Water absorption 10 - 30 2.86 – 95.24 [7, 23]

10 – 30 1.52 – 32.5 [34, 89]

Porosity 10 - 30 21.21 – 1[90, 91]

262.12

Carbonation 5 – 20 5 – 275 [23, 32]

resistance

Corrosion 5 – 20 2.59 – 6.23 [35]

resistance 30 100 [92]

Freeze and thaw 10 – 20 5.24% [68]

resistance

Nonstructural Sound absorption 5 – 30 8.26 – 113.31 [48, 93]

performance Electrical 5 – 30 1.57 – 21.9 [94]

resistivity

Thermal 5 – 30 7.08 – 49.72 [48, 89, 93, 95]

conductivity

3.2.2. Strengths

The reduction in strengths of rubbercrete as shown in table 1 was mainly due to the physical

properties of crumb rubber and its compatibility with fine aggregate. Increased air content in

the fresh rubbercrete mix due to the hydrophobic nature of crumb rubber leads to increased

void content in the hardened rubbercrete thereby allowing stresses concentration across the

pose causing micro cracks formation and consequently reduction in strength [48, 75, 96, 97].

In addition, the entrapped air on the crumb rubber surface increases the interfacial transition

zone (ITZ) thickness, and causes poor bonding with the hardened matrix as the ITZ itself is a

weak porous zone between cement paste and aggregate with the weak bonding causing micro

cracks formation leading to reduced strength and premature failure [6, 52, 98, 99]. In addition

crumb rubber is also non-compactible with sand, having lower specific gravity, strength,

stiffness, and load carrying capacity thus leading to reduced strength when replaced part of

fine aggregate [77, 84]. In addition as crumb rubber changes the aggregate grading in the

rubbercrete mix to a non-continuous with more voids formed due to the inability of the voids

in the aggregate to be filled by the crumb rubber, this leads to a more porous rubbercrete thus

reducing its strength [61]. However, some reported an increase in flexural strength and this is

attributed to the fiber nature of crumb rubber, high ductility and post cracking behavior of

rubbercrete which allows it to resist flexural loads even after failure [34, 100].

In order to reduce the strength loss in rubbercrete several attempts have been made to

either enhancing the bonding between hardened cement paste and crumb rubber or to increase

the chemical reaction in cement to densify the hardened rubbercrete micro structure. For

instance crumb rubber has been pre-coated with limestone and in another case it has been

coated with cement mortar to densify the ITZ and subsequently improving bonding [14, 62,

74, 101, 102]. Others researchers have treated the crumb rubber with sodium hydroxide so as

http://www.iaeme.com/IJCIET/index.asp 603 editor@iaeme.com

A Review on The Effect of Crumb Rubber On The Properties of Rubbercrete

to make its surface rougher to improve bonding [103, 104]. Similarly ultraviolet using water

retention has been applied to crumb rubber to change its surface energy so that to prevent it

from repelling water and entrapping air and consequently improve its bonding [105].

Furthermore, to densify the hardened rubbercrete microstructure, cement replacement

materials have been used such as silica, ground granulated blast furnace slag, metakoalin and

fly ash [65, 77, 104, 106]. Additionally, crumb rubber has been oxidized using potassium

permanganate (KMnO4) solution before sulphonating it with sodium bisulfite (NaHSO3)

solution so that can have better bonding with hardened cement matrix [107]. Recently nano

silica has been added to rubbercrete to refine the pore system, increase chemical reaction of

cement and densify the ITZ as shown in Figure 3 [52]. While in another study deairing agent

was added to rubbercrete to reduce the air content and consequently improve strength [108].

However in contrary to this it was reported that treating crumb rubber does not significantly

improve strength in rubbercrete compared to normal concrete [109, 110]. It is worthy of note

that treating the crumb rubber would increases the cost of rubbercrete thus offsetting its

advantage. However, using Nano Silica would present an economical solution in mitigating

strength loss in rubbercrete due to its physical and chemical properties and also to its

relatively low cost.

3.2.3 Deformation Properties

3.2.3.1 Static and Dynamic Modulus of Elasticity

The reduction in elastic modulus of rubbercrete is attributed to lower stiffness and elastic

modulus of crumb rubber particles in comparing to the fine aggregate. With the crumb rubber

particles acting like tiny springs in the hardened rubbercrete which having no significant

effect in terms of resisting the applied external loads. This is leading to reduction in strength

which adversely affects the elastic modulus of rubbercrete [14, 60, 66, 111]. In addition

internal factors leading to reduction in elastic modulus of rubbercrete include; weak bonding

between cement paste and crumb rubber particles, higher voids content in the cement paste

together and the thicker and weaker ITZ due to entrapped air by the crumb rubber which

significantly affects the stress-strain behavior. In addition, the lower volumetric proportions of

natural aggregates in rubbercrete lead to reduction in elastic modulus [14, 67]. This is due to

the lower elastic modulus of crumb rubber particles in comparison to that of natural

aggregate. While the reduction in dynamic modulus of elasticity of rubbercrete is mainly

attributed to the higher porosity in the hardened rubbercrete. This is explained by the

reduction in the ultrasonic pulse velocity due to lower density, stiffness and ability of the

crumb rubber particles in absorbing ultrasonic wave [14, 32, 54].

3.2.3.2 Drying Shrinkage and Abrasion Resistance

Drying shrinkage of rubbercrete increases with increasing the crumb rubber content. The

increase in shrinkage of rubbercrete are mainly caused by the following factors: poor bonding

between crumb rubber and cement paste, lower stiffness, lower load carrying capacity of

crumb rubber which leads to reduction in restraint to drying. In addition, higher w/c ratio,

lower strength and modulus of elasticity leading to lower restraint to drying of the rubbercrete

microstructure [15, 23, 35, 112, 113]. While abrasion resistance increases with increasing the

crumb rubber content. This is due to the crumb rubber acting like a brush and preventing the

rubbing and grinding of the rubbercrete surface. Additionally, the fiber-like-shape of crumb is

holding and preserving the cement paste [34, 69, 80].

3.2.3.3 Impact Resistance, Ductility and Energy Absorption

The impact resistance, damping, ductility and energy absorption increase with increasing in

crumb rubber content in rubbercrete. The improvement of impact resistance and damping

http://www.iaeme.com/IJCIET/index.asp 604 editor@iaeme.com

Bashar S Mohammed, Musa Adamu and Nasir Shafiq

ratio of rubbercrete are attributed to the more elastic, higher deformation and lower stiffness

of crumb rubber in comparing to fine aggregate. Therefore, rubbercrete has better ability to

absorb shock, vibration and consequently having higher impact resistance and damping ration

[65, 83]. The energy absorption capacity is measured through different ways such as

brittleness index, peak deflection, ultimate strain, peak strain and peak load. It can also be

measured through the load deflection curve as shown in Figure 4. The improvement in energy

absorption is attributed to the ability of low stiffness crumb rubber to bridge cracks, bend,

twist and compress to allowing the rubbercrete to be relatively more flexible and thus be able

to absorb more energy[65, 67, 86]. In addition, the low stiffness of crumb rubber particles

enables it to decrease internal frictions and recovering extra strain in the rubbercrete matrix

[12, 65]

3.2.3.4 Toughness and Fatigue Performance

Improvement in fatigue performance and toughness of rubbercrete are attributed to the

content of crumb rubber. The fatigue fracture of rubbercrete consists of three phases: 10%

nucleation, 80 % stable and 10% instable phase of the full fatigue life of rubbercrete [86]. The

increase in fatigue is mainly due to the fact that rubber particles suppress the formation of

micro cracks and absorbs more strain energy thereby resisting more cycles of repetitive loads

[85]. While toughness improves due to the higher energy absorption capacity, enhanced strain

energy, and anti-cracking performance of rubbercrete [87, 88].

3.2.4 Durability Performance and Freeze/Thaw Resistance

3.2.4.1 Chloride ion penetration, water absorption, porosity and carbonation resistance

Partially replacing fine aggregate with crumb rubber in rubbercrete adversely affects the

durability of rubbercrete. The increase in chloride penetration of rubbercrete is mainly due to

its high permeability, with poor internal packing and interconnected voids formed by the

crumb rubber due to entrapped air during mixing thus leading to increased porosity and this

favors penetration of chloride ion through permeation, absorption or diffusion [6, 14, 32].

While increase in water absorption is attribute to the high water absorption, thicker and

porous ITZ between crumb rubbers and cement matrix in combination to the higher porosity

in the rubbercrete [33, 92]. With regards to carbonation and corrosion resistance very scares

and limited literatures are available on the subject matter. However, Corrosion resistance and

carbonation resistance have been found to be adversely affected with increasing percentage of

crumb rubber replacement [4, 23, 32, 35, 92]. This due to the well-established fact that

porosity and void ratio of rubbercrete increases with increasing of crumb rubber percentage.

3.2.4.2 Freeze and Thaw Resistance

Freeze and thaw resistance of rubbercrete increases with increasing crumb rubber percentage

[33, 68, 72]. This is due to the increasing in the void ratio inside the rubbercrete. Whereas

these voids provide space to accommodate the increased volume of crystalized water in the

rubbercrete pore system during freezing. Which consequently normalize the internal pressure

hardened rubbercrete during the freeze and thaw cycling.

3.2.5 Nonstructural Performance

3.2.5.1 Sound Absorption and Electrical Resistivity

Both sound absorption and electrical resistivity increases with increasing of crumb rubber

content. However, the increase is sound absorption of rubbercrete is higher for lower sized

crumb rubber compared to larger sizes as shown in Figure 5 [93]. The increase in electrical

resistivity is ascribed to the properties of crumb rubber being a dielectric material and

http://www.iaeme.com/IJCIET/index.asp 605 editor@iaeme.com

A Review on The Effect of Crumb Rubber On The Properties of Rubbercrete

blocking the paths for electric wave to transfer across the rubbercrete, while increase in sound

absorption is due to the ability of the sound to be absorbed by the entrapped air on the crumb

rubber surface [48].

3.2.5.2 Thermal Conductivity

As shown in figure 6, the size of crumb rubber has significant effect on the thermal

conductivity of rubbercrete with lower sizes showing higher values [48, 94, 114]. The

decrease in thermal conductivity is as a result of higher entrapped air in the rubbercrete

mixtures. Whereas both air and crumb rubber have lower thermal conductivity than hardened

cement paste. Hardened cement paste has thermal conductivity of 1.7 Wm/K which is greater

than that of air 0.025 Wm/K and crumb rubber 0.11 Wm/K. This causes the thermal flow to

be opposed by air in the voids and crumb rubber particles [48, 114].

4. CONSTRUCTION AND BUILDING MATERIALS UTILIZING

RUBBERCRETE

Capitalizing on the improved properties of rubbercrete in comparison to normal concrete,

researchers have developed construction building products made of rubbercrete to meet

specific requirements. Some of these products are shown in Table 2.

Table 2 Construction building materials made of rubbercrete

Item Product Specific requirements Reference

Railway

1 Improved fatigue and impact resistance ([115, 116]

slippers/ballast

2 Beams Improved Impact resistance and ductility [117]

3 Composite slab Improved ductility [46]

4 In situ wall panels Improved sound absorption [93]

5 Precast wall panels Improved sound absorption and thermal conductivity [94]

6 Columns Improved seismic resistance [118, 119]

7 Road side barriers Improved impact resistance [120]

Hollow concrete Improved sound absorption, thermal conductivity

8 [48]

blocks and electrical resistivity

9 paving block Improved skid resistance and abrasion resistance [121]

10 Pavement surface Improved sound absorption [122]

Improved toughness, post-failure loads, and

11 Masonry walls [98]

earthquake resistance

Drainage layer in Improved hydraulic conductivity, infiltration rate

12 [123]

green roof and weight reduction

Embankment for

expansive soils in Reduced swelling, increased elastic recovery and

13 [124]

road and railway undrained shear strength

projects

Improved shear strength, axial strain and post-peak

14 Soft clays [125]

strength

5. FUTURE TRENDS

In some developing countries, scrap tires are being used as a low cost supplementary fuel due

to its high calorific value. This is lead to dramatically increase the emission of greenhouse

gases which is the main contributor to the global warming. However, to address this issue,

Kyoto protocol has put in place an enforcement mechanism restriction on production of

greenhouse gases which causes climate changes. Therefore, there will be a serious problem

of scrap tire disposal due to limitation in the landfill availability and also to the associated

multiple environmental and health hazards problems. The current scenario on recycling of

http://www.iaeme.com/IJCIET/index.asp 606 editor@iaeme.com

Bashar S Mohammed, Musa Adamu and Nasir Shafiq

scrap tires is quite narrow for limited applications such as children’s playground, flower beds

mulch, landfill liners, artificial reefs, breakwaters, embankments, retaining walls, sport

surfacing, animal bedding, as high volume fill for septic systems, fill material for turf grasses,

and in concrete as partial replacement to aggregate, there is an urgent need to use recycled

scrap tire in useful mass applications. On the other hand, production of concrete has hit more

than 3.8 billion cubic meters annually. This will lead to depletion in the natural resources

which also will adversely affect the eco-system.

Using crumb rubber from scrap tires as partial replacement to fine aggregate in concrete

results rubbercrete. In comparison with normal concrete, rubbercrete has several improved

properties such as ductility, fatigue performance, impact resistance, thermal conductivity,

acoustic properties, electrical resistivity, etc. However, rubbercrete exhibits lower strengths

and modulus elasticity which discourage personals in the construction industry to practically

accept it. Therefore, attempts have been made to recover the strengths lost by treating and

coating crumb rubber particles. These attempts have failed to provide an acceptable economic

solution. Recently, nano silica has been added to rubbercrete and successfully improves it

strengths without offset cost and other improved properties. Therefore, this will provide

available economical solution to the waste tire management. Although the fresh and hardened

properties of rubbercrete have been thoroughly investigated and well documented by

researchers. However, some aspects require further attention such as: systematic mix design,

fire resistance, behavior in elevated temperatures, carbonation resistance and deformation

properties (shrinkage and creep).

6. CONCULDING REMARKS

This paper reviews the latest works have been conducted to investigate rubbercrete properties

in both fresh and hardened state. The fresh properties include unit weight, air content, and

workability while the hardened properties include compressive, tensile and flexural strengths,

static and dynamic modulus of elasticity, shrinkage, abrasion resistance, impact resistance,

ductility, energy absorption, toughness and fatigue properties. It also covers durability

performances which include chloride Ion Penetration, water absorption, porosity, carbonation

resistance, corrosion resistance, and freeze/thaw resistance. Other physical properties such as

sound absorption, electrical resistivity, and thermal conductivity have been reviewed. The

summary of the remarks derived from this paper are as follows:

Rubbercrete has improved workability and freeze / thaw resistance.

Reduction in the strengths of rubbercrete can be offset economically using nano silica as

cementitious addition.

The lower drying shrinkage of rubbercrete will promote it as good repair mortar and also in

mass concreting application such dams and rigid pavements.

Due to the ability of rubbercrete in absorbing impact loading, members subject to accidental

impact loads can be made of rubbercrete such as crush barrier

The improved fatigue load cycles and toughness of rubbercrete make it suitable for roller

compacted rigid pavement

The rubbercrete can be used in producing of members/products that can be used in improving

life quality of habitants due to its high sound absorption, high electrical resistivity and lower

thermal conductivity.

http://www.iaeme.com/IJCIET/index.asp 607 editor@iaeme.com

A Review on The Effect of Crumb Rubber On The Properties of Rubbercrete

ACKNOWLEDGEMENTS

The authors would like to thank the Ministry of Education (MOE) of Malaysia for granting

the project under code PRGS/1/13/TK03/UTP/02/02.

REFERENCES

[1] S. K. Pathak, V. Sood, Y. Singh, and S. Channiwala, "Real world vehicle emissions: Their

correlation with driving parameters," Transportation Research Part D: Transport and

Environment, vol. 44, pp. 157-176, 2016.

[2] V. K. Gupta, I. Ali, T. A. Saleh, M. Siddiqui, and S. Agarwal, "Chromium removal from

water by activated carbon developed from waste rubber tires," Environmental Science and

Pollution Research, vol. 20, pp. 1261-1268, 2013.

[3] Y. Pan, F. Yang, and C. Li, "Vehicle Usage Measurement and Analysis Based on the

Random Retail Customer," in Proceedings of the FISITA 2012 World Automotive

Congress, 2013, pp. 951-961.

[4] B. S. Thomas, R. C. Gupta, P. Mehra, and S. Kumar, "Performance of high strength

rubberized concrete in aggressive environment," Construction and Building Materials,

vol. 83, pp. 320-326, 2015.

[5] WBCSD, "Managing End-of-Life Tires," World Business Council for Sustainable

Development, Washington DC; USA2008.

[6] B. S. Thomas, R. C. Gupta, and V. J. Panicker, "Recycling of waste tire rubber as

aggregate in concrete: durability-related performance," Journal of Cleaner Production,

vol. 112, pp. 504-513, 2016.

[7] F. Azevedo, F. Pacheco-Torgal, C. Jesus, J. B. de Aguiar, and A. Camões, "Properties and

durability of HPC with tyre rubber wastes," Construction and building materials, vol. 34,

pp. 186-191, 2012.

[8] RMA, "Scrap tire markets in the United States," Rubber Manufacturers Association,

Washington DC, USA2009.

[9] RMA, "Scrap tire markets in the United States," Rubber Manufacturers Association,

Washington DC, USA2016.

[10] R. Siddique, Waste materials and by-products in concrete: Springer Science & Business

Media, 2007.

[11] [OhioEPA, "What Is A Scrap Tire?," D. o. S. a. I. W. Management, Ed., ed. Columbus

Ohio, USA: State of Ohio Environmental Protection Agency, 2007, p. 2.

[12] A. R. Khaloo, M. Dehestani, and P. Rahmatabadi, "Mechanical properties of concrete

containing a high volume of tire–rubber particles," Waste Management, vol. 28, pp. 2472-

2482, 2008.

[13] F. Demir, B. Yesilata, P. Turgut, H. Bulut, and Y. Isiker, "Investigation of the effects of

pH, aging and scrap tire content on the dissolution behaviors of new scrap tire-concrete

mixture structures," Journal of Cleaner Production, vol. 93, pp. 38-46, 2015.

[14] T. Gupta, S. Chaudhary, and R. K. Sharma, "Mechanical and durability properties of

waste rubber fiber concrete with and without silica fume," Journal of Cleaner Production,

vol. 112, pp. 702-711, 2016.

[15] P. Sukontasukkul and K. Tiamlom, "Expansion under water and drying shrinkage of

rubberized concrete mixed with crumb rubber with different size," Construction and

Building Materials, vol. 29, pp. 520-526, 2012.

[16] N. Jantaraksa, P. Prasassarakich, P. Reubroycharoen, and N. Hinchiranan, "Cleaner

alternative liquid fuels derived from the hydrodesulfurization of waste tire pyrolysis oil,"

Energy Conversion and Management, vol. 95, pp. 424-434, 2015.

http://www.iaeme.com/IJCIET/index.asp 608 editor@iaeme.com

Bashar S Mohammed, Musa Adamu and Nasir Shafiq

[17] O. Bičáková and P. Straka, "Co-pyrolysis of waste tire/coal mixtures for smokeless fuel,

maltenes and hydrogen-rich gas production," Energy Conversion and Management, vol.

116, pp. 203-213, 2016.

[18] O. Onay and H. Koca, "Determination of synergetic effect in co-pyrolysis of lignite and

waste tyre," Fuel, vol. 150, pp. 169-174, 2015.

[19] A. Ayanoğlu and R. Yumrutaş, "Production of gasoline and diesel like fuels from waste

tire oil by using catalytic pyrolysis," Energy, vol. 103, pp. 456-468, 2016.

[20] I. Hita, M. Arabiourrutia, M. Olazar, J. Bilbao, J. M. Arandes, and P. C. Sánchez,

"Opportunities and barriers for producing high quality fuels from the pyrolysis of scrap

tires," Renewable and Sustainable Energy Reviews, vol. 56, pp. 745-759, 2016.

[21] W. Li, C. Huang, D. Li, P. Huo, M. Wang, L. Han, et al., "Derived oil production by

catalytic pyrolysis of scrap tires," Chinese Journal of Catalysis, vol. 37, pp. 526-532,

2016.

[22] G.-G. Choi, S.-H. Jung, S.-J. Oh, and J.-S. Kim, "Total utilization of waste tire rubber

through pyrolysis to obtain oils and CO 2 activation of pyrolysis char," Fuel Processing

Technology, vol. 123, pp. 57-64, 2014.

[23] M. Bravo and J. de Brito, "Concrete made with used tyre aggregate: durability-related

performance," Journal of Cleaner Production, vol. 25, pp. 42-50, 2012.

[24] N. Oikonomou and S. Mavridou, "Improvement of chloride ion penetration resistance in

cement mortars modified with rubber from worn automobile tires," Cement and Concrete

Composites, vol. 31, pp. 403-407, 2009.

[25] A. S. Al-Rahbi and P. T. Williams, "Production of activated carbons from waste tyres for

low temperature NOx control," Waste Management, vol. 49, pp. 188-195, 2016.

[26] T. A. Saleh and G. I. Danmaliki, "Influence of acidic and basic treatments of activated

carbon derived from waste rubber tires on adsorptive desulfurization of thiophenes,"

Journal of the Taiwan Institute of Chemical Engineers, 2015.

[27] B. Acevedo, C. Barriocanal, I. Lupul, and G. Gryglewicz, "Properties and performance of

mesoporous activated carbons from scrap tyres, bituminous wastes and coal," Fuel, vol.

151, pp. 83-90, 2015.

[28] L. Li, S. Liu, and T. Zhu, "Application of activated carbon derived from scrap tires for

adsorption of Rhodamine B," Journal of Environmental Sciences, vol. 22, pp. 1273-1280,

2010.

[29] V. K. Gupta, A. Nayak, S. Agarwal, and I. Tyagi, "Potential of activated carbon from

waste rubber tire for the adsorption of phenolics: Effect of pre-treatment conditions,"

Journal of colloid and interface science, vol. 417, pp. 420-430, 2014.

[30] K. Connor, S. Cortesa, S. Issagaliyeva, A. Meunier, O. Bijaisoradat, N. Kongkatigumjorn,

et al., "Developing a sustainable waste tire management strategy for Thailand,"

Worcester, Massachusetts: Worcester Polytechnic Institute, 2013.

[31] B. S. Thomas and R. C. Gupta, "A comprehensive review on the applications of waste tire

rubber in cement concrete," Renewable and Sustainable Energy Reviews, vol. 54, pp.

1323-1333, 2016.

[32] T. Gupta, S. Chaudhary, and R. K. Sharma, "Assessment of mechanical and durability

properties of concrete containing waste rubber tire as fine aggregate," Construction and

Building Materials, vol. 73, pp. 562-574, 2014.

[33] A. M. Rashad, "A comprehensive overview about recycling rubber as fine aggregate

replacement in traditional cementitious materials," International Journal of Sustainable

Built Environment, vol. 5, pp. 46-82, 2016.

[34] B. S. Thomas and R. C. Gupta, "Properties of high strength concrete containing scrap tire

rubber," Journal of Cleaner Production, 2015.

http://www.iaeme.com/IJCIET/index.asp 609 editor@iaeme.com

A Review on The Effect of Crumb Rubber On The Properties of Rubbercrete

[35] W. H. Yung, L. C. Yung, and L. H. Hua, "A study of the durability properties of waste tire

rubber applied to self-compacting concrete," Construction and Building Materials, vol.

41, pp. 665-672, 2013.

[36] A. Moustafa and M. A. ElGawady, "Mechanical properties of high strength concrete with

scrap tire rubber," Construction and Building Materials, vol. 93, pp. 249-256, 2015.

[37] H. Su, J. Yang, T.-C. Ling, G. S. Ghataora, and S. Dirar, "Properties of concrete prepared

with waste tyre rubber particles of uniform and varying sizes," Journal of Cleaner

Production, vol. 91, pp. 288-296, 2015.

[38] N. Azmi, B. Mohammed, and H. Al-Mattarneh, "Engineering Properties of Concrete

Containing Recycled Tyre Rubber," in International Conference on Construction and

Building Technology, 2008, pp. 373-382.

[39] B. S. Mohammed, N. J. Azmi, and M. Abdullahi, "Evaluation of rubbercrete based on

ultrasonic pulse velocity and rebound hammer tests," Construction and Building

Materials, vol. 25, pp. 1388-1397, 2011.

[40] B. Mohammed and N. J. Azmi, "Failure mode and modulus elasticity of concrete

containing recycled tire rubber," The Journal of Solid Waste Technology and

Management, vol. 37, pp. 16-24, 2011.

[41] E. Ganjian, M. Khorami, and A. A. Maghsoudi, "Scrap-tyre-rubber replacement for

aggregate and filler in concrete," Construction and Building Materials, vol. 23, pp. 1828-

1836, 2009.

[42] M. A. Aiello and F. Leuzzi, "Waste tyre rubberized concrete: Properties at fresh and

hardened state," Waste Management, vol. 30, pp. 1696-1704, 2010.

[43] Z. K. Khatib and F. M. Bayomy, "Rubberized Portland cement concrete," Journal of

materials in civil engineering, vol. 11, pp. 206-213, 1999.

[44] L. Zheng, X. S. Huo, and Y. Yuan, "Strength, modulus of elasticity, and brittleness index

of rubberized concrete," Journal of Materials in Civil Engineering, vol. 20, pp. 692-699,

2008.

[45] E. Güneyisi, M. Gesoğlu, and T. Özturan, "Properties of rubberized concretes containing

silica fume," Cement and Concrete Research, vol. 34, pp. 2309-2317, 2004.

[46] B. S. Mohammed, "Structural behavior and m–k value of composite slab utilizing concrete

containing crumb rubber," Construction and Building Materials, vol. 24, pp. 1214-1221,

2010.

[47] B. Yesilata, H. Bulut, and P. Turgut, "Experimental study on thermal behavior of a

building structure using rubberized exterior-walls," Energy and Buildings, vol. 43, pp.

393-399, 2011.

[48] B. S. Mohammed, K. M. A. Hossain, J. T. E. Swee, G. Wong, and M. Abdullahi,

"Properties of crumb rubber hollow concrete block," Journal of Cleaner Production, vol.

23, pp. 57-67, 2012.

[49] A. Meddah, M. Beddar, and A. Bali, "Use of shredded rubber tire aggregates for roller

compacted concrete pavement," Journal of Cleaner Production, vol. 72, pp. 187-192,

2014.

[50] A. Meddah, M. Beddar, and A. Bali, "Experimental study of compaction quality for roller

compacted concrete pavement containing rubber tire wastes," Sustainability, Eco-

efficiency, and Conservation in Transportation Infrastructure Asset Management, p. 273,

2014.

[51] B. S. Mohammed and R. C. H. Loong, "Structural Behavior of Reinforced Rubbercrete

Beams in Shear," in Applied Mechanics and Materials, 2015, pp. 513-517.

[52] B. S. Mohammed, A. B. Awang, S. San Wong, and C. P. Nhavene, "Properties of nano

silica modified rubbercrete," Journal of Cleaner Production, vol. 119, pp. 66-75, 2016.

http://www.iaeme.com/IJCIET/index.asp 610 editor@iaeme.com

Bashar S Mohammed, Musa Adamu and Nasir Shafiq

[53] B. S. Mohammed and N. Azmi, "Strength reduction factors for structural rubbercrete,"

Frontiers of Structural and Civil Engineering, vol. 8, pp. 270-281, 2014.

[54] I. Marie, "Zones of weakness of rubberized concrete behavior using the UPV," Journal of

Cleaner Production, 2016.

[55] S. Sgobba, M. Borsa, M. Molfetta, and G. C. Marano, "Mechanical performance and

medium-term degradation of rubberised concrete," Construction and Building Materials,

vol. 98, pp. 820-831, 2015.

[56] A. T. Noaman, B. A. Bakar, and H. M. Akil, "Experimental investigation on compression

toughness of rubberized steel fibre concrete," Construction and Building Materials, vol.

115, pp. 163-170, 2016.

[57] E. Khalil, M. Abd-Elmohsen, and A. M. Anwar, "Impact Resistance of Rubberized Self-

Compacting Concrete," Water Science, vol. 29, pp. 45-53, 2015.

[58] G. N. Kumar, V. Sandeep, and C. Sudharani, "Using tyres wastes as aggregates in

concrete to form rubcrete–mix for engineering applications," International Journal of

Research in Engineering and Technology, vol. 3, pp. 500-9, 2014.

[59] B. LI, H.-w. TENG, D. HUO, and L.-y. ZHOU, "Mechanical strength of air-entrained

rubcrete," Concrete, vol. 5, p. 032, 2009.

[60] A. O. Atahan and A. Ö. Yücel, "Crumb rubber in concrete: static and dynamic

evaluation," Construction and Building Materials, vol. 36, pp. 617-622, 2012.

[61] H. Liu, X. Wang, Y. Jiao, and T. Sha, "Experimental Investigation of the Mechanical and

Durability Properties of Crumb Rubber Concrete," Materials, vol. 9, p. 172, 2016.

[62] M. Fakhri, "The effect of waste rubber particles and silica fume on the mechanical

properties of Roller Compacted Concrete Pavement," Journal of Cleaner Production, vol.

129, pp. 521-530, 2016.

[63] L. Li, S. Ruan, and L. Zeng, "Mechanical properties and constitutive equations of concrete

containing a low volume of tire rubber particles," Construction and Building Materials,

vol. 70, pp. 291-308, 2014.

[64] M. Sienkiewicz, J. Kucinska-Lipka, H. Janik, and A. Balas, "Progress in used tyres

management in the European Union: a review," Waste Management, vol. 32, pp. 1742-

1751, 2012.

[65] E. Ozbay, M. Lachemi, and U. K. Sevim, "Compressive strength, abrasion resistance and

energy absorption capacity of rubberized concretes with and without slag," Materials and

structures, vol. 44, pp. 1297-1307, 2011.

[66] J. Lv, T. Zhou, Q. Du, and H. Wu, "Effects of rubber particles on mechanical properties of

lightweight aggregate concrete," Construction and Building Materials, vol. 91, pp. 145-

149, 2015.

[67] A. J. Kardos and S. A. Durham, "Strength, durability, and environmental properties of

concrete utilizing recycled tire particles for pavement applications," Construction and

Building Materials, vol. 98, pp. 832-845, 2015.

[68] A. Richardson, K. Coventry, V. Edmondson, and E. Dias, "Crumb rubber used in concrete

to provide freeze–thaw protection (optimal particle size)," Journal of Cleaner Production,

vol. 112, pp. 599-606, 2016.

[69] B. S. Thomas, R. C. Gupta, P. Kalla, and L. Cseteneyi, "Strength, abrasion and permeation

characteristics of cement concrete containing discarded rubber fine aggregates,"

Construction and Building Materials, vol. 59, pp. 204-212, 2014.

[70] T. Uygunoğlu and İ. B. Topçu, "The role of scrap rubber particles on the drying shrinkage

and mechanical properties of self-consolidating mortars," Construction and Building

Materials, vol. 24, pp. 1141-1150, 2010.

http://www.iaeme.com/IJCIET/index.asp 611 editor@iaeme.com

A Review on The Effect of Crumb Rubber On The Properties of Rubbercrete

[71] M. Adamu, B. S. Mohammed, and N. Shafiq, "Effect of Mineral Filler type on Strength of

Roller Compacted Rubbercrete for Pavement Applications," in IOP Conference Series:

Materials Science and Engineering, 2017.

[72] A. E. Richardson, K. A. Coventry, and G. Ward, "Freeze/thaw protection of concrete with

optimum rubber crumb content," Journal of Cleaner Production, vol. 23, pp. 96-103,

2012.

[73] A. Turatsinze, S. Bonnet, and J.-L. Granju, "Potential of rubber aggregates to modify

properties of cement based-mortars: improvement in cracking shrinkage resistance,"

Construction and Building Materials, vol. 21, pp. 176-181, 2007.

[74] O. Onuaguluchi, "Effects of surface pre-coating and silica fume on crumb rubber-cement

matrix interface and cement mortar properties," Journal of Cleaner Production, vol. 104,

pp. 339-345, 2015.

[75] O. Onuaguluchi and D. K. Panesar, "Hardened properties of concrete mixtures containing

pre-coated crumb rubber and silica fume," Journal of Cleaner Production, vol. 82, pp.

125-131, 2014.

[76] Y. Jiang, "Improvement of cracking-resistance and flexural behavior of cement-based

materials by addition of rubber particles," Journal of Wuhan University of Technology-

Mater. Sci. Ed., vol. 23, pp. 579-583, 2008.

[77] A. Yilmaz and N. Degirmenci, "Possibility of using waste tire rubber and fly ash with

Portland cement as construction materials," Waste Management, vol. 29, pp. 1541-1546,

2009.

[78] I. Mohammadi and H. Khabbaz, "Shrinkage performance of Crumb Rubber Concrete

(CRC) prepared by water-soaking treatment method for rigid pavements," Cement and

Concrete Composites, vol. 62, pp. 106-116, 2015.

[79] L. Chunlin, Z. Kunpeng, and C. Depeng, "Possibility of concrete prepared with steel slag

as fine and coarse aggregates: A preliminary study," Procedia Engineering, vol. 24, pp.

412-416, 2011.

[80] M. Gesoğlu, E. Güneyisi, G. Khoshnaw, and S. İpek, "Abrasion and freezing–thawing

resistance of pervious concretes containing waste rubbers," Construction and Building

Materials, vol. 73, pp. 19-24, 2014.

[81] M. M. Al-Tayeb, B. A. Bakar, H. Ismail, and H. M. Akil, "Effect of partial replacement of

sand by fine crumb rubber on impact load behavior of concrete beam: experiment and

nonlinear dynamic analysis," Materials and structures, vol. 46, pp. 1299-1307, 2013.

[82] T. S. Vadivel, R. Thenmozhi, and M. Doddurani, "EXPERIMENTAL BEHAVIOUR OF

WASTE TYRE RUBBER AGGREGATE CONCRETE UNDER IMPACT LOADING*,"

Iranian Journal of Science and Technology. Transactions of Civil Engineering, vol. 38, p.

251, 2014.

[83] C. A. Issa and G. Salem, "Utilization of recycled crumb rubber as fine aggregates in

concrete mix design," Construction and Building Materials, vol. 42, pp. 48-52, 2013.

[84] J. Xue and M. Shinozuka, "Rubberized concrete: A green structural material with

enhanced energy-dissipation capability," Construction and Building Materials, vol. 42,

pp. 196-204, 2013.

[85] F. Liu, W. Zheng, L. Li, W. Feng, and G. Ning, "Mechanical and fatigue performance of

rubber concrete," Construction and Building Materials, vol. 47, pp. 711-719, 2013.

[86] F. Liu, L.-y. Meng, G.-F. Ning, and L.-J. Li, "Fatigue performance of rubber-modified

recycled aggregate concrete (RRAC) for pavement," Construction and Building Materials,

vol. 95, pp. 207-217, 2015.

[87] Y. Guo, J. Zhang, G. Chen, G. Chen, and Z. Xie, "Fracture behaviors of a new steel fiber

reinforced recycled aggregate concrete with crumb rubber," Construction and Building

Materials, vol. 53, pp. 32-39, 2014.

http://www.iaeme.com/IJCIET/index.asp 612 editor@iaeme.com

Bashar S Mohammed, Musa Adamu and Nasir Shafiq

[88] M. M. Reda Taha, A. El-Dieb, M. Abd El-Wahab, and M. Abdel-Hameed, "Mechanical,

fracture, and microstructural investigations of rubber concrete," Journal of materials in

civil engineering, vol. 20, pp. 640-649, 2008.

[89] A. Fadiel, F. Al Rifaie, T. Abu-Lebdeh, and E. Fini, "Use of crumb rubber to improve

thermal efficiency of cement-based materials," Am. J. Eng. Applied Sci, vol. 7, pp. 1-11,

2014.

[90] P. Turgut and B. Yesilata, "Physico-mechanical and thermal performances of newly

developed rubber-added bricks," Energy and Buildings, vol. 40, pp. 679-688, 2008.

[91] M. Turki, E. Bretagne, M. Rouis, and M. Quéneudec, "Microstructure, physical and

mechanical properties of mortar–rubber aggregates mixtures," Construction and building

materials, vol. 23, pp. 2715-2722, 2009.

[92] O. Karahan, E. Özbay, K. M. Hossain, M. Lachemi, and C. D. Atiş, "Fresh, mechanical,

transport, and durability properties of self-consolidating rubberized concrete," ACI

Materials Journal-American Concrete Institute, vol. 109, p. 413, 2012.

[93] N. Holmes, A. Browne, and C. Montague, "Acoustic properties of concrete panels with

crumb rubber as a fine aggregate replacement," Construction and Building Materials, vol.

73, pp. 195-204, 2014.

[94] P. Sukontasukkul, "Use of crumb rubber to improve thermal and sound properties of pre-

cast concrete panel," Construction and Building Materials, vol. 23, pp. 1084-1092, 2009.

[95] M. R. Hall, K. B. Najim, and C. J. Hopfe, "Transient thermal behaviour of crumb rubber-

modified concrete and implications for thermal response and energy efficiency in

buildings," Applied thermal engineering, vol. 33, pp. 77-85, 2012.

[96] O. Youssf, M. A. ElGawady, J. E. Mills, and X. Ma, "An experimental investigation of

crumb rubber concrete confined by fibre reinforced polymer tubes," Construction and

Building Materials, vol. 53, pp. 522-532, 2014.

[97] Adamu M, Mohammed B.S, and Shafiq N, "Mechanical performance of Roller

Compacted Rubbercrete with different mineral fillers," Jurnal Teknologi, vol. 79, pp. 75 -

88, 2017.

[98] D. M. Sadek and M. M. El-Attar, "Structural behavior of rubberized masonry walls,"

Journal of Cleaner Production, vol. 89, pp. 174-186, 2015.

[99] M. Adamu, B. S. Mohammed, and N. Shafiq, "Nano silica modified roller compacted

rubbercrete – an overview," in Engineering Challenges for Sustainable Future -

Proceedings of the 3rd International Conference on Civil, offshore and Environmental

Engineering, ICCOEE 2016, 2016, pp. 483-488.

[100] Adamu M, Mohammed B S, and S. N, "Flexural performance of nano silica modified

roller compacted rubbercrete," International Journal of Advanced and Applied Sciences,

vol. 4, pp. 6 - 18, 2017.

[101] M. Gesoğlu and E. Güneyisi, "Strength development and chloride penetration in

rubberized concretes with and without silica fume," Materials and Structures, vol. 40, pp.

953-964, 2007.

[102] B. Zhang and G. Li, "The abrasion-resistance investigation of rubberized concrete,"

Journal of Wuhan University of Technology-Mater. Sci. Ed., vol. 27, pp. 1144-1148, 2012.

[103] R. Liu and L. Zhang, "Utilization of waste tire rubber powder in concrete," Composite

Interfaces, vol. 22, pp. 823-835, 2015.

[104] O. Youssf, J. E. Mills, and R. Hassanli, "Assessment of the mechanical performance of

crumb rubber concrete," Construction and Building Materials, vol. 125, pp. 175-183,

2016.

[105] G. Ossola and A. Wojcik, "UV modification of tire rubber for use in cementitious

composites," Cement and Concrete Composites, vol. 52, pp. 34-41, 2014.

http://www.iaeme.com/IJCIET/index.asp 613 editor@iaeme.com

A Review on The Effect of Crumb Rubber On The Properties of Rubbercrete

[106] F. Pelisser, A. Barcelos, D. Santos, M. Peterson, and A. M. Bernardin, "Lightweight

concrete production with low Portland cement consumption," Journal of Cleaner

Production, vol. 23, pp. 68-74, 2012.

[107] L. He, Y. Ma, Q. Liu, and Y. Mu, "Surface modification of crumb rubber and its influence

on the mechanical properties of rubber-cement concrete," Construction and Building

Materials, vol. 120, pp. 403-407, 2016.

[108] K. Kaloush, G. Way, and H. Zhu, "Properties of crumb rubber concrete," Transportation

Research Record: Journal of the Transportation Research Board, pp. 8-14, 2005.

[109] Q. Dong, B. Huang, and X. Shu, "Rubber modified concrete improved by chemically

active coating and silane coupling agent," Construction and Building Materials, vol. 48,

pp. 116-123, 2013.

[110] X. Shu and B. Huang, "Recycling of waste tire rubber in asphalt and Portland cement

concrete: an overview," Construction and Building Materials, vol. 67, pp. 217-224, 2014.

[111] M. Adamu, B. S. Mohammed, and N. Shafiq, "Establishing relationship between modulus

of elasticity and strength of nano silica modified roller compacted rubbercrete "

International Journal of GEOMATE, vol. 13, pp. 103 - 110, 2017.

[112] K. Jingfu, H. Chuncui, and Z. Zhenli, "Strength and shrinkage behaviors of roller-

compacted concrete with rubber additives," Materials and structures, vol. 42, pp. 1117-

1124, 2009.

[113] X. Huang, R. Ranade, W. Ni, and V. C. Li, "On the use of recycled tire rubber to develop

low E-modulus ECC for durable concrete repairs," Construction and Building Materials,

vol. 46, pp. 134-141, 2013.

[114] K. B. Najim and M. R. Hall, "Mechanical and dynamic properties of self-compacting

crumb rubber modified concrete," Construction and building materials, vol. 27, pp. 521-

530, 2012.

[115] A. S. Hameed and A. Shashikala, "Suitability of rubber concrete for railway sleepers,"

Perspectives in Science, 2016.

[116] M. Sol-Sánchez, N. Thom, F. Moreno-Navarro, M. Rubio-Gámez, and G. Airey, "A study

into the use of crumb rubber in railway ballast," Construction and Building Materials, vol.

75, pp. 19-24, 2015.

[117] A. T. Noaman, B. A. Bakar, and H. M. Akil, "The Effect of Combination between Crumb

Rubber and Steel Fiber on Impact Energy of Concrete Beams," Procedia Engineering,

vol. 125, pp. 825-831, 2015.

[118] K. S. Son, I. Hajirasouliha, and K. Pilakoutas, "Strength and deformability of waste tyre

rubber-filled reinforced concrete columns," Construction and building materials, vol. 25,

pp. 218-226, 2011.

[119] O. Youssf, M. A. ElGawady, and J. E. Mills, "Experimental investigation of crumb rubber

concrete columns under seismic loading," in Structures, 2015, pp. 13-27.

[120] M. Elchalakani, "High strength rubberized concrete containing silica fume for the

construction of sustainable road side barriers," in Structures, 2015, pp. 20-38.

[121] F. M. da Silva, L. A. G. Barbosa, R. C. C. Lintz, and A. E. P. Jacintho, "Investigation on

the properties of concrete tactile paving blocks made with recycled tire rubber,"

Construction and Building Materials, vol. 91, pp. 71-79, 2015.

[122] V. Vázquez, J. Luong, M. Bueno, F. Terán, and S. Paje, "Assessment of an action against

environmental noise: Acoustic durability of a pavement surface with crumb rubber,"

Science of The Total Environment, vol. 542, pp. 223-230, 2016.

[123] A. Vila, G. Pérez, C. Solé, A. Fernández, and L. F. Cabeza, "Use of rubber crumbs as

drainage layer in experimental green roofs," Building and Environment, vol. 48, pp. 101-

106, 2012.

http://www.iaeme.com/IJCIET/index.asp 614 editor@iaeme.com

Bashar S Mohammed, Musa Adamu and Nasir Shafiq

[124] Vikram Singh and Abhishek Bawa, Experimental Study on Partial Replacement of

Bitumen with Crumb Rubber, , Volume 8, Issue 7, July 2017, pp. 1164-1170,

International Journal of Civil Engineering and Technology (IJCIET).

[125] Kamlesh Kumar and Ankit, Development of A Bio Shoe System with IOT For Bio-

Medical Applications, International Journal of Civil Engineering and Technology, 8(7),

2017, pp. 438–446.

[126] Mohd. Mohsin Khan, Anurag Sharma and Sandeep Panchal, Use of Crumb Rubber as

Replacement over Aggregate in Concrete. International Journal of Civil Engineering and

Technology, 8(2), 2017, pp. 148–152.

[127] C. H. Signes, J. Garzón-Roca, P. M. Fernández, M. E. G. de la Torre, and R. I. Franco,

"Swelling potential reduction of Spanish argillaceous marlstone Facies Tap soil through

the addition of crumb rubber particles from scrap tyres," Applied Clay Science, vol. 132,

pp. 768-773, 2016.

[128] J. Yadav and S. Tiwari, "A study on the potential utilization of crumb rubber in cement

treated soft clay," Journal of Building Engineering, 2017.

http://www.iaeme.com/IJCIET/index.asp 615 editor@iaeme.com

View publication stats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Scroll 2019 PDFDocument104 pagesScroll 2019 PDFJitender SinghNo ratings yet

- Design of Well FoundationDocument31 pagesDesign of Well FoundationJitender SinghNo ratings yet

- M - Tech - Civil Engineering (Geotechnical) - Course - STR - and - Syllabus PDFDocument28 pagesM - Tech - Civil Engineering (Geotechnical) - Course - STR - and - Syllabus PDFJitender SinghNo ratings yet

- Certificate For Editorial MemberDocument1 pageCertificate For Editorial MemberJitender SinghNo ratings yet

- Deb 2008Document8 pagesDeb 2008Jitender SinghNo ratings yet

- Analysis of Behavior of Stone Columns and Lime ColumnsDocument24 pagesAnalysis of Behavior of Stone Columns and Lime ColumnsNookendra Pradeep Raju ThotaNo ratings yet

- RMPD2007 Erlingsson CBRDocument17 pagesRMPD2007 Erlingsson CBRJitender SinghNo ratings yet

- Deb 2016Document10 pagesDeb 2016Jitender SinghNo ratings yet

- Form 1-ADocument2 pagesForm 1-AJitender SinghNo ratings yet

- Dec2015 PDFDocument1 pageDec2015 PDFAbhishek AgarwalNo ratings yet

- v1Document9 pagesv1Jitender SinghNo ratings yet

- Assessment of The Load-Deformation Behaviour of Rubber Fibre-Reinforced Cemented Clayey Soil-1Document1 pageAssessment of The Load-Deformation Behaviour of Rubber Fibre-Reinforced Cemented Clayey Soil-1Jitender SinghNo ratings yet

- NIGS00053Document1 pageNIGS00053Jitender SinghNo ratings yet

- JurnalIlmiah ADocument10 pagesJurnalIlmiah AJitender SinghNo ratings yet

- 5 - 10 - 2017 Properties PDFDocument64 pages5 - 10 - 2017 Properties PDFJitender SinghNo ratings yet

- Staad Pro - Portal FrameDocument47 pagesStaad Pro - Portal FrameV.m. Rajan50% (2)

- Receipt PaperDocument1 pageReceipt PaperJitender SinghNo ratings yet

- Experimental Investigation Into Temperature Effect On Hydro-Mechanical Behaviours of BentoniteDocument8 pagesExperimental Investigation Into Temperature Effect On Hydro-Mechanical Behaviours of BentoniteJitender SinghNo ratings yet

- Comments For PHD Work DoneDocument1 pageComments For PHD Work DoneJitender SinghNo ratings yet

- NIT Hamirpur Civil Engineering Class Test on Pavement Materials and DesignDocument2 pagesNIT Hamirpur Civil Engineering Class Test on Pavement Materials and DesignJitender SinghNo ratings yet

- Tuan Noor Hasanah Tuan IsmailDocument84 pagesTuan Noor Hasanah Tuan IsmailJitender SinghNo ratings yet

- QRGFQ Wxwwffi: Fit Hati XalDocument9 pagesQRGFQ Wxwwffi: Fit Hati XalJitender SinghNo ratings yet

- Reviewer Comments IISS D 18 00172 - ReviewerDocument1 pageReviewer Comments IISS D 18 00172 - ReviewerJitender SinghNo ratings yet

- Portal Frame 2Document42 pagesPortal Frame 2abobeedoNo ratings yet

- Finalyearprojectppt 130630232950 Phpapp02Document40 pagesFinalyearprojectppt 130630232950 Phpapp02Jitender SinghNo ratings yet

- Lec10 PDFDocument13 pagesLec10 PDFJitender SinghNo ratings yet

- Art:10.1007/s41062 017 0051 1Document9 pagesArt:10.1007/s41062 017 0051 1Jitender SinghNo ratings yet

- Computational Seismology: An Introduction: Aim of LectureDocument33 pagesComputational Seismology: An Introduction: Aim of LectureDebashis SahaNo ratings yet

- Pavement Design - Civil EngineeringDocument78 pagesPavement Design - Civil Engineeringchittee98100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Psych 1xx3 Quiz AnswersDocument55 pagesPsych 1xx3 Quiz Answerscutinhawayne100% (4)

- Community HelpersDocument3 pagesCommunity Helpersapi-252790280100% (1)

- Red Lion Edict-97 - Manual PDFDocument282 pagesRed Lion Edict-97 - Manual PDFnaminalatrukNo ratings yet

- Satisfaction ExtraDocument2 pagesSatisfaction ExtraFazir AzlanNo ratings yet

- Consumer Behavior PP Chapter 4Document36 pagesConsumer Behavior PP Chapter 4tuongvyvyNo ratings yet

- Daftar Pustaka DaniDocument3 pagesDaftar Pustaka Danidokter linggauNo ratings yet

- Lecture Euler EquationDocument33 pagesLecture Euler EquationYash RajNo ratings yet

- Creating Literacy Instruction For All Students ResourceDocument25 pagesCreating Literacy Instruction For All Students ResourceNicole RickettsNo ratings yet

- Pick Pack Ship Public APIDocument19 pagesPick Pack Ship Public APIgauravpuri198050% (2)

- Is Iso 2692-1992Document24 pagesIs Iso 2692-1992mwasicNo ratings yet

- A Rail-To-Rail Constant Gain Buffered Op-Amp For Real Time Video ApplicationsDocument8 pagesA Rail-To-Rail Constant Gain Buffered Op-Amp For Real Time Video Applicationskvpk_vlsiNo ratings yet

- Rolls-Royce M250 FIRST Network: 2015 Customer Support DirectoryDocument76 pagesRolls-Royce M250 FIRST Network: 2015 Customer Support Directoryale11vigarNo ratings yet

- Senior High School Tracks: Free Powerpoint Templates Free Powerpoint TemplatesDocument11 pagesSenior High School Tracks: Free Powerpoint Templates Free Powerpoint TemplatesGeraldineNo ratings yet

- 06 Dielectrics Capacitance 2018mkDocument41 pages06 Dielectrics Capacitance 2018mkTrần ĐứcAnhNo ratings yet

- BOOK-Deva-Oracle MaterialDocument177 pagesBOOK-Deva-Oracle MaterialPAVANN TNo ratings yet

- Manual PDFDocument9 pagesManual PDFRuth ResuelloNo ratings yet

- Rose Jean AlvarezDocument15 pagesRose Jean AlvarezMika Ela Pantaleon Doria100% (1)

- Greek Myth WebquestDocument9 pagesGreek Myth Webquesthollyhock27No ratings yet

- Format of Synopsis - Project - 1Document5 pagesFormat of Synopsis - Project - 1euforia hubNo ratings yet

- 6 An Indian American Woman in Space 2Document11 pages6 An Indian American Woman in Space 2Manju YadavNo ratings yet

- A Primer On Financial Time Series AnalysisDocument93 pagesA Primer On Financial Time Series AnalysisKM AgritechNo ratings yet

- D41P-6 Kepb002901Document387 pagesD41P-6 Kepb002901LuzioNeto100% (1)

- Hunk 150Document2 pagesHunk 150Brayan Torres04No ratings yet

- 7 - NIBL - G.R. No. L-15380 Wan V Kim - DigestDocument1 page7 - NIBL - G.R. No. L-15380 Wan V Kim - DigestOjie SantillanNo ratings yet

- Health Fitness Guide UK 2018 MayDocument100 pagesHealth Fitness Guide UK 2018 MayMitch Yeoh100% (2)

- 01 The-Mckinsey-Edge-Hattori-En-26154Document5 pages01 The-Mckinsey-Edge-Hattori-En-26154Waqar AhmedNo ratings yet

- Spare Parts List: WarningDocument5 pagesSpare Parts List: WarningÃbdøū Èqúípmeńť MédîcàlNo ratings yet

- DWDM Route Planning A4 WPDocument3 pagesDWDM Route Planning A4 WPChavara MatekweNo ratings yet

- M.Sc. Agriculture (Agronomy)Document23 pagesM.Sc. Agriculture (Agronomy)Abhishek MauryaNo ratings yet

- Raiseyourvoice SFDocument26 pagesRaiseyourvoice SFAttila Engin100% (1)