Professional Documents

Culture Documents

Equotip Conversion Curve

Uploaded by

Sanjay TarteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equotip Conversion Curve

Uploaded by

Sanjay TarteCopyright:

Available Formats

there is no clear physical relationship between the various methods.

Care

must be taken to select the proper conversion table to be used. Please

refer to the online help in the EQUOTIP® 3 indicating device for a list of ac-

ceptable materials for any given material group.

C AU T I O N

Material dependence of conversions

If no conversion into the desired scale is available for the material to be

tested, never select a different material for which the conversion is on

hand! Unpredictable large conversion errors may result. Create a cus-

Conversion deviations for special steel qualities

In particular, conversion deviation can occur with the following steel quali-

ties:

High alloyed steels

In high-speed tool steels, hotwork steels, and ledeburite chromium steels

(group of hight-carbon cold-work steels), the hard materials embedded in

the matrix (ledeburite tunsten carbide e.g. type M7C3 and M6C) cause a

local increase of the E-modulus, resulting in HL-values which are actually

too low. A typical representative of this group is the tool steel for cold work

X210Cr12 (Material No. 1.2080) containing 2.1% C and 12% Cr.

Cold work-hardened steels

Drawn and in part also rolled steels frequently lead to excessive high HL-

values due to the pronounced cold-worked regions near the surface which

simulate higher than actual hardness. Such steels should always be tested

over their entire class-section.

© 2007 Proceq SA Settings 53

Magnetic steels

When testing magnetic materials, the velocity transmitter in the impact body

is influenced by their magnetic field. Therefore, slight deviations of the mea-

sured HL-value may occur.

Surface-hardened steels

Surface-hardended steels and especially case-hardened steels produce HL-

values which are too low when the case-hardening depth is small because

of their soft core.

Tensile strength

For certain steels hardness can be converted to tensile strength according

to DIN EN ISO 18265:2003.

4.7 Setup of plant-internal conversion curves

Proceq provides conversion curves into standard hardness scales for a

series of materials. For special solutions, or when testing materials for which

no generally applicable conversions are available, it is possible for the user

to create own conversion functions if:

– The material cannot be assigned to one of the classes available for the

used impact device.

– The required conversion scale is not available for the impact device

being used or the material class.

– Conversions display systematic deviations.

4.7.1 One point calibration

One point calibration is based on a standard conversion function Hstd(L)

and shifts this vertically so that the conversion of the specified HL-value L1

coincides with the known converted value H1.

H(L) = Hstd(L) - Hstd(L1) + H1

One point calibration is typically used if only one workpiece with known

hardness in the required scale is available or all available reference pieces

have hardness values that are grouped closely together. The workpieces to

be measured are made from the same materials and their hardness differs

only slightly from the reference hardness.

54 Settings © 2007 Proceq SA

Procedure

Assume a reference body with a known hardness H1 in the desired scale.

Measure the hardness with the impact device for which the conversion

should be performed in the corresponding HL scale (see chapter 6). The

mean of at least 10 to 15 HL-values should be formed. The individual

readings should be taken in the same area where the indentations of the

standard scale measurements are located.

Select menu item "Config".

Select submenu item "Customer conversions…".

Select submenu item "One point calibration…".

The "Properties" dialog box opens.

Left-hand column:

Select the impact device for "Original probe".

As "Original material", select a standard material (for which the required

hardness scale is available) that is as similar as possible to the refer-

ence piece.

Select the hardness scale for "Original scale".

Right-hand column:

As "New probe", select the impact device type with which the measure-

ment was performed previously and for which the conversion should be

performed.

"New Material" input field: Enter any name for the material.

© 2007 Proceq SA Settings 55

This name will appear later in the material selection list. The same

material names should be used if conversions for one material into var-

ious scales, e.g. HV, HB and HRC or for various impact device types

are created.

Close the dialog box with the key.

The "One point" dialog box opens. The specified material name is indi-

cated in square brackets.

The selected standard conversion function Hstd(L) is sketched in the

diagram.

In the input field at the top left ("HLD" in this example), enter the mea-

sured hardness L1 in the HL scale of the probe.

The point (L1, Hstd(L1)) is marked in the diagram.

In the box at the top right ("HB" in this example), enter the known hard-

ness H1 in the converted scale.

The new conversion function H(L) now appears in the diagram in black

and the entered point (L1, H(L1)) is drawn in. The original function

Hstd(L) is shown in grey.

In the "Range min" and "Range max" input fields, enter the interval in the

converted scale for which the conversion function should apply.

The limits of the validity range are marked in the diagram by horizontal

lines.

56 Settings © 2007 Proceq SA

NOTE

Validity range

Only relatively small areas are recommended (corresponding to no more

than ±100 HL) for conversion functions generated using one point calibra-

tion.

If necessary, click the "Properties" button or press the key to

change the impact device type or material name. The original conversion

function specification cannot be changed at that time.

Click the "Create" button or press the key to save the created con-

version function.

4.7.2 Two point calibration

Two point calibration uses a standard conversion function Hstd(L) and adds

a straight line so that the resulting conversion function H(L) passes through

two known points (L1, H(L1)) and (L2, H(L2)).

Hstd(L2) - H2 - Hstd(L1) + H1

H(L) = Hstd(L) - Hstd(L1) + H1 + (L - L1)

L2 - L 1

Two point calibration is typically used if at least two workpieces with known

and significantly distinct hardness values in the required scale are available.

The workpieces to be measured are made from the same material and are

neither significantly harder than the hardest reference piece nor significantly

softer than the softest reference piece.

© 2007 Proceq SA Settings 57

Procedure

Two reference objects with known hardness values H1 and H2 in the desired

scale as different as possible from one another are required.

Measure the hardness values with the impact device for which the

conversion should be performed in the corresponding HL scale (see

chapter 6). The means of at least 10 to 15 HL-values should be formed.

The individual readings should be taken in the same area where the

indentations of the standard scale measurements are located.

Select menu item "Config".

Select submenu item "Customer conversions…".

Select submenu item "Two point conversions…".

The "Properties" dialog box opens.

Make settings in the same way as for "One point calibration...".

Close the dialog box with .

The "Two point" dialog box opens. The specified material name is indi-

cated in square brackets.

The selected standard conversion function Hstd(L) is sketched in the

diagram.

In the box at the top left ("HLD" in this example), enter the measured

hardness L1 in HL of the softer of the two reference pieces.

In the box at the top right ("HB" in this example), enter the known hard-

ness H1 in the converted scale.

In the second line, enter the measured HL-hardness L2 and the known

converted hardness H2 of the harder reference workpiece.

58 Settings © 2007 Proceq SA

The diagram now shows the original standard conversion function in

grey and the modified conversion function in black. The interpolation

points are marked.

In the "Range min" and "Range max" input fields, set the interval in the

converted scale for which the conversion function should apply.

The limits of the validity range are marked in the diagram by horizontal

lines.

NOTE

Validity range

We recommend not expanding the validity range to the left and right any

further than half the difference between the reference hardness values.

If necessary, click the "Properties" button or press the key to

change the impact device type and material name. The original conver-

sion function specification cannot be changed at that time.

Click the "Create" button or press the key to save the created con-

version function.

4.7.3 Polynomial specification

An analytical approximation function in the form of a polynomial is available

for converting from the L scale of the used impact device to the required

hardness scale H.

H(L) = A0 + A1L + A2L2 + A3L3 + A4L4 + A5L5

Procedure

Select menu item "Config".

Select submenu item "Customer conversions…".

Select submenu item "Polynomial specification…".

© 2007 Proceq SA Settings 59

The "Create user conversion" dialog box opens:

In the "Enter material name:" input field admit any material name.

Select the impact device in "Select probe type:" for which the conversion

should apply.

Select the conversion scale for "Select hardness scale:".

Close the dialog box with .

The "Polynomial coefficients" dialog box opens:

Enter the known polynomial coefficients in the input fields:

- A0 is the constant coefficient

- A1 linear coefficient

- A2 quadratic coefficient

etc.

If the polynomial is of lower degree than five, the unneeded highest-

order coefficients must be set to zero.

60 Settings © 2007 Proceq SA

Specify a sufficient number of decimal places.

Otherwise, there may be unexpected rounding errors, depending on the

structure of the polynomial. This is important with high-order coefficients

in particular.

By internal rounding the displayed coefficients may differ slightly from the

entered numbers.

NOTE

The input keypad not only makes it possible to enter digits, decimal point

and change of sign ([±]) but also exponents ([E+] and [E-] keys) for scien-

tific notation. "1.75894E-6" is identical to "0.00000175894".

Close the dialog box with .

The "Polynomial" dialog box opens with the specified material name

indicated in square brackets.

The specified polynomial function is sketched in the diagram.

In the "Range min" and "Range max" input fields, enter the limits of the

interval (in HLx!) for which the conversion function should apply.

© 2007 Proceq SA Settings 61

NOTE

Range limits

If you have obtained the polynomial function from numerical fit of meas-

ured values, the range limits should not or only slightly extend the range

covered by your measurements. Extrapolation, in particular with higher-

degree polynomials, can lead to surpises.

If necessary, click the "Properties" button or press the key to

change the material name, impact device type or converted hardness

scale.

If necessary, click the "Coefficients" button or press the key to

check and change the entered polynomial coefficients.

Click the "Create" button or press the key to save the created con-

version function.

4.8 Protocol printouts

4.8.1 Setting printer configuration

Procedure

Connect the printer to either the USB host or the serial port of the indi-

cating device.

Select menu item "Config".

Select submenu item "System settings".

Select submenu item "Printer…".

62 Settings © 2007 Proceq SA

You might also like

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- UWORLD Notes by Subject (Main Division) (Usmle Grassroots)Document80 pagesUWORLD Notes by Subject (Main Division) (Usmle Grassroots)Mital Bhakta83% (18)

- Secret Techniques of IN10SE - The October Man SequenceDocument7 pagesSecret Techniques of IN10SE - The October Man SequenceAnonymous 2gIWpUcA8R33% (3)

- Quantity Take Off ManualDocument61 pagesQuantity Take Off ManualJerrold Quiñola100% (4)

- Finite Element AnalysisDocument219 pagesFinite Element AnalysisRubenNo ratings yet

- Instrumentation ElementsDocument30 pagesInstrumentation ElementsManohar PotnuruNo ratings yet

- Tutorial 38 Coupled Drawdown AnalysisDocument23 pagesTutorial 38 Coupled Drawdown AnalysisImad SoutajiNo ratings yet

- Sacred SpaceDocument440 pagesSacred SpaceAbdiel Cervantes HernandezNo ratings yet

- Green Building ToolsDocument107 pagesGreen Building ToolsVholts Villa VitugNo ratings yet

- SewerCAD QuickStartDocument72 pagesSewerCAD QuickStartMaicol Mena100% (1)

- Blooms Taxonomy and Costas Level of QuestioningDocument6 pagesBlooms Taxonomy and Costas Level of QuestioningChris Tine100% (1)

- QSP 7.1-02. Control of Monitoring and Measuring Resources (Preview)Document4 pagesQSP 7.1-02. Control of Monitoring and Measuring Resources (Preview)Centauri Business Group Inc.100% (1)

- ANSYS Fluent Tutorial Mixing Elbow PDFDocument13 pagesANSYS Fluent Tutorial Mixing Elbow PDFShangkaran RadakrishnanNo ratings yet

- Ansoft TutorialDocument12 pagesAnsoft TutorialNguyenKhanh111No ratings yet

- Linart vs. UgarteDocument1 pageLinart vs. UgarteKristine JoyNo ratings yet

- CAE Pipe Tutorial 2Document88 pagesCAE Pipe Tutorial 2sdrtfg100% (1)

- Column SizingDocument16 pagesColumn SizingSyed Muzamil Ahmed100% (9)

- Tutorial 35 Dynamic Analysis of Machine Foundation PDFDocument18 pagesTutorial 35 Dynamic Analysis of Machine Foundation PDFMarcos MaNo ratings yet

- Caesar II-4 - 4 Oct02Document24 pagesCaesar II-4 - 4 Oct02violinistae2000No ratings yet

- Module#3-Heat ExchangersDocument19 pagesModule#3-Heat ExchangersLa Casa JordanNo ratings yet

- Heat Exchanger DesignDocument12 pagesHeat Exchanger Designshfanse92100% (2)

- Caesar-II 5.2 Version NotesDocument19 pagesCaesar-II 5.2 Version Notesmsvikhas032No ratings yet

- Documents - Pub - SPC 407 Supersonic Amp Hypersonic Fluid Dynamics AnsysDocument41 pagesDocuments - Pub - SPC 407 Supersonic Amp Hypersonic Fluid Dynamics Ansyssun rise1No ratings yet

- Tutorial 3 Heat Exchanger PDFDocument22 pagesTutorial 3 Heat Exchanger PDFBipin GiriNo ratings yet

- 194 Sample ChapterDocument27 pages194 Sample ChapterVikas TiwariNo ratings yet

- Tolerances: ENGR 14.2c: A Dimensioning Technique That Ensures The Interchangeability of PartsDocument52 pagesTolerances: ENGR 14.2c: A Dimensioning Technique That Ensures The Interchangeability of Partsquiquichina17450No ratings yet

- Tutorial Material Data InputDocument6 pagesTutorial Material Data InputJavier TrujillanoNo ratings yet

- Using Coupled Inductors and Inductor CoresDocument6 pagesUsing Coupled Inductors and Inductor Coreskalimbalo100% (1)

- GDT 2Document54 pagesGDT 2Milind JadhavNo ratings yet

- Models - Heat.crossflow Heat ExchangerDocument18 pagesModels - Heat.crossflow Heat ExchangerbabithyNo ratings yet

- 08 Surface HT Volumic VWeld InstructionsDocument10 pages08 Surface HT Volumic VWeld Instructionsjdial9664No ratings yet

- Designing Struts: R-Index of Safety and EconomyDocument1 pageDesigning Struts: R-Index of Safety and EconomyAnton_Young_1962No ratings yet

- 12 Heat LossDocument38 pages12 Heat LossyngterNo ratings yet

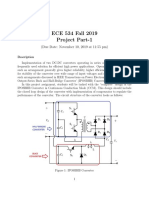

- ECE 534 Project 1 F19Document6 pagesECE 534 Project 1 F19JAY CHHEDANo ratings yet

- Fire Resistance of Reinforced Concrete ColumnDocument23 pagesFire Resistance of Reinforced Concrete Columnspallien spallienkoNo ratings yet

- Manual Durómetros Sadt Hartip-3000Document20 pagesManual Durómetros Sadt Hartip-3000Carlos JavierNo ratings yet

- PSG College OFDocument14 pagesPSG College OFKarthic EaswarNo ratings yet

- Analyse Two Span Slab with Structural ToolkitDocument21 pagesAnalyse Two Span Slab with Structural Toolkitkorosh75No ratings yet

- 3D Tool Wear Lab : Using Archard'S ModelDocument9 pages3D Tool Wear Lab : Using Archard'S ModelMohamedKamalNo ratings yet

- Ansoft Designer Tutorial Quarter WaveDocument10 pagesAnsoft Designer Tutorial Quarter WaveAbdul Kadir Ramos FaisalNo ratings yet

- Ethylene Plus Benzene Design Project Reference (Partial Only)Document11 pagesEthylene Plus Benzene Design Project Reference (Partial Only)YueZhen ChuaNo ratings yet

- Overwrites: Technical NoteDocument3 pagesOverwrites: Technical NoteVivek GosaviNo ratings yet

- What's New EDR V9Document22 pagesWhat's New EDR V9AbdulBasitNo ratings yet

- Caesar Static AnalysisDocument2 pagesCaesar Static Analysisnitesh singhNo ratings yet

- Plant FoundationDocument23 pagesPlant FoundationGerry TriazNo ratings yet

- Create text annotations in EnSightDocument4 pagesCreate text annotations in EnSightTamin Sanat IranianNo ratings yet

- Steady-State 2D Heat Transfer SimulationDocument6 pagesSteady-State 2D Heat Transfer SimulationAhmed Badr MabroukNo ratings yet

- Fitness For Service AnalysisDocument6 pagesFitness For Service AnalysisGuido KünstlerNo ratings yet

- Aspen+7 3+what's+new PDFDocument5 pagesAspen+7 3+what's+new PDFSrihari KodimelaNo ratings yet

- Check For Errors in The Model: Getting StartedDocument1 pageCheck For Errors in The Model: Getting StartedhalongvanNo ratings yet

- PSIMtipsDocument2 pagesPSIMtipsPorumbescu SergiuNo ratings yet

- Modeling Results Tutorial 2Document96 pagesModeling Results Tutorial 2ibson045001256No ratings yet

- AERODYNAMIC NOISE Worksheet InstructionsDocument6 pagesAERODYNAMIC NOISE Worksheet InstructionsMuhammad Adil KhanNo ratings yet

- 20294-Spur Gears Part 2Document9 pages20294-Spur Gears Part 2YOO SHINNo ratings yet

- Seismic Analysis BenchmarkDocument17 pagesSeismic Analysis Benchmarkarian20202020No ratings yet

- ReadmeDocument98 pagesReadmejuand_121No ratings yet

- Floworks TutorialDocument20 pagesFloworks Tutorialjoseph_shoeNo ratings yet

- Slender Strut (Column) Buckling.: Control, Structure and Syntax of CalculationsDocument11 pagesSlender Strut (Column) Buckling.: Control, Structure and Syntax of CalculationsNageswar RaoNo ratings yet

- Sequential Logic Circuits Using Aldec Active-HDL 8.1 and Xilinx ISE 11Document22 pagesSequential Logic Circuits Using Aldec Active-HDL 8.1 and Xilinx ISE 11Sakthi VelanNo ratings yet

- Morph and transform 3D objects using OmniCAD tools in NXDocument7 pagesMorph and transform 3D objects using OmniCAD tools in NXgustafkusuma_6356813No ratings yet

- Tutorial 2Document7 pagesTutorial 2Jaime HernandezNo ratings yet

- Variance Value Flow CO-PADocument28 pagesVariance Value Flow CO-PAtrinath79No ratings yet

- Wa0014.Document14 pagesWa0014.SANJAY NILAVAN .S.76No ratings yet

- Wireless Probe Hardness Tester HARTIP 2200: Operation ManualDocument21 pagesWireless Probe Hardness Tester HARTIP 2200: Operation ManualindorikiNo ratings yet

- Operating Instructions: Paper Roll Hardness TesterDocument20 pagesOperating Instructions: Paper Roll Hardness TesterSanjay TarteNo ratings yet

- Accurate and Dependable Roll Hardness TestingDocument2 pagesAccurate and Dependable Roll Hardness TestingSanjay TarteNo ratings yet

- Of Paper / Films: Roll Hardness TesterDocument1 pageOf Paper / Films: Roll Hardness TesterSanjay TarteNo ratings yet

- Paper SchmidtDocument1 pagePaper SchmidtSanjay TarteNo ratings yet

- Portable Hardness Testing Leeb - Rockwell - UCI: Astm Din en Iso GB/T JB/TDocument18 pagesPortable Hardness Testing Leeb - Rockwell - UCI: Astm Din en Iso GB/T JB/TstephanyfreireNo ratings yet

- Application Note: Blue Light Industry L.L.CDocument1 pageApplication Note: Blue Light Industry L.L.CSanjay TarteNo ratings yet

- The Use of MuseScore (A Music Transcribing Computer Software) As A Tool in Enhancing The Knowledge and Skills of Non-Music Major Teachers of Tayabas West Central School - IDocument13 pagesThe Use of MuseScore (A Music Transcribing Computer Software) As A Tool in Enhancing The Knowledge and Skills of Non-Music Major Teachers of Tayabas West Central School - IRyan Chester ManzanaresNo ratings yet

- Type Test Report for AAAC ConductorDocument14 pagesType Test Report for AAAC ConductornigerluvNo ratings yet

- A Literature Review On The Vehicle Routing Problem With Multiple Depepots PDFDocument15 pagesA Literature Review On The Vehicle Routing Problem With Multiple Depepots PDFcarandatruNo ratings yet

- The Brothers KaramazovDocument8 pagesThe Brothers KaramazovAnonymous sao1siUbNo ratings yet

- Truth V.S. OpinionDocument19 pagesTruth V.S. OpinionBek Ah100% (2)

- Getting Started With The NIST Cybersecurity Framework:: A Quick Start GuideDocument3 pagesGetting Started With The NIST Cybersecurity Framework:: A Quick Start GuidejohnNo ratings yet

- Journal of Cleaner Production: Fabíola Negreiros de Oliveira, Adriana Leiras, Paula CerynoDocument15 pagesJournal of Cleaner Production: Fabíola Negreiros de Oliveira, Adriana Leiras, Paula CerynohbNo ratings yet

- Ib Q OnlyDocument1 pageIb Q Onlyapi-529669983No ratings yet

- Reena Mohamad NasirDocument122 pagesReena Mohamad NasirKedai Baju RaniaNo ratings yet

- Emergency Department (Ed) Overcrowding: Evidence-Based Answers To Frequently Asked QuestionsDocument7 pagesEmergency Department (Ed) Overcrowding: Evidence-Based Answers To Frequently Asked QuestionsNurul AidaNo ratings yet

- Activity Guide and Evaluation Rubric - Activity 7 - Creating A WIX PageDocument5 pagesActivity Guide and Evaluation Rubric - Activity 7 - Creating A WIX PageLina VergaraNo ratings yet

- Music in The United KingdomDocument33 pagesMusic in The United KingdomIonut PetreNo ratings yet

- A Comprehensive Guide To The Asia-Pacific Legal Markets - Part ReportDocument18 pagesA Comprehensive Guide To The Asia-Pacific Legal Markets - Part ReportEstherTan0% (1)

- En 14490 After CEN Enquiry (Soil Nailing)Document59 pagesEn 14490 After CEN Enquiry (Soil Nailing)Abraham FIgueroa ARevaloNo ratings yet

- 3 Affect Regulation, Mentalization, and The Development of The Self (Peter Fonagy, Gyorgy Gergely, Elliot L. Jurist Etc.) - 211-259Document49 pages3 Affect Regulation, Mentalization, and The Development of The Self (Peter Fonagy, Gyorgy Gergely, Elliot L. Jurist Etc.) - 211-259Sergio Andres Rico AvendanoNo ratings yet

- Fire Safety Al RaiDocument4 pagesFire Safety Al RairyecunarNo ratings yet

- Work Written: Student - I - Gabriela BocănețDocument14 pagesWork Written: Student - I - Gabriela BocănețEscu NykuNo ratings yet

- Choosing Ayurveda As A Healthcare PractiDocument16 pagesChoosing Ayurveda As A Healthcare PractiAndie PebblesNo ratings yet

- Kumpulan Berenam Pandu Puteri Tunas 2022Document7 pagesKumpulan Berenam Pandu Puteri Tunas 2022Zi YanNo ratings yet

- Book Review of Conceptualising Integration in CLIL and Multilingual EducationDocument5 pagesBook Review of Conceptualising Integration in CLIL and Multilingual EducationAigul AitbaevaNo ratings yet

- Engleza Clasa 1Document4 pagesEngleza Clasa 1Ioana BotarNo ratings yet

- Analysis and Adaptive Control of EDM Sinking Process Using The Ignition Delay Time and Fall TimeDocument4 pagesAnalysis and Adaptive Control of EDM Sinking Process Using The Ignition Delay Time and Fall TimeResearch AssistanceNo ratings yet