Professional Documents

Culture Documents

Plate and Pipe Groove and Fillet Welding PDF

Uploaded by

YASH BARDHAN SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plate and Pipe Groove and Fillet Welding PDF

Uploaded by

YASH BARDHAN SinghCopyright:

Available Formats

1/14/2020 Welder’s Test Position (ASME IX QW-461.3-461.7) | Heats School of Welding Technology Inc.

- Tarlac City

Groove Welds in Plate – Test Positions

1G – Flat Position. Plate in horizontal plane with the weld metal deposited from above

2G – Horizontal Position. Plate in a vertical plane with the axis of the weld horizontal

3G – Vertical Position. Plate in a vertical plane with the axis of the weld vertical

4G – Overhead Position. Plate in a horizontal plane with the weld metal deposited from

underneath

Groove Welds in Pipe – Test Positions

1G (rotated) – Flat Position. Pipe with its axis horizontal and rolled during welding so that

the weld metal is deposited from above

2G – Horizontal Position. Pipe with its axis vertical and the axis of the weld in a horizontal

plane. Pipe shall not be rotated during welding

5G – Multiple Position. Pipe with its axis horizontal and with the welding groove in a

vertical plane. Welding shall be done without rotating the pipe

6G – Multiple Position. Pipe with its axis inclined in 45 degrees to horizontal. Welding

shall be done without rotating the pipe.

Fillet Welds in Plate – Test Positions

1F – Flat Position. Plates so placed that the weld is deposited with its axis horizontal and

its throat vertical.

2F – Horizontal. Plates so placed that the weld is deposited with its axis horizontal on the

upper side of the horizontal surface and against vertical surfacde.

3F – Vertical Position. Plates so placed that the weld is deposited with its axis vertical.

4F – Overhead Position. Plates so placed that the weld is deposited with its axis horizontal

on the underside of the horizontal surface and against the vertical surface.

Fillet Welds in Pipe- Test Positions

1F (rotated) – Flat Position – Pipe with its axis incline at 45 degrees to horizontal and

rotated during welding so that weld metal is deposited from above and at the point of

deposition the axis of the weld is horizontal and the throat vertical

2F – Horizontal Position. Pipe with its axis vertical so that the weld is deposited on the

upper side of the horizontal surface against the vertical surface. The axis of the weld will

be horizontal and the pipe is not rotated during welding

2FR – Horizontal Position (Rotated). Pipe with its axis horizontal and the axis of the

deposited weld in the vertical plane. The pipe is rotated during welding.

4F – Overhead Position – Pipe with its axis vertical so that the weld is deposited on the

underside of the horizontal surface against the vertical surface. The axis of the weld will

be horizontal and the pipe is not rotated during welding.

5F – Multiple Position. Pipe with its axis horizontal and the axis of the deposited weld in

the vertical plane. The pipe is not rotated during welding.

https://heatsschoolofweldingtechnology.wordpress.com/2008/12/02/welders-test-position-asme-ix-qw-4613-4617/ 1/1

You might also like

- 11 - WELDING POSITIONS (1) .PPT (Compatibility Mode)Document20 pages11 - WELDING POSITIONS (1) .PPT (Compatibility Mode)Kumawat Prakash75% (4)

- 3f Multi Pass in Vertical PositionDocument11 pages3f Multi Pass in Vertical PositionStephanie SabanganNo ratings yet

- PA / 1G / 1F: This Is The Flat Position, in Which The Welder Has The Piece Right Below The Torch, ThisDocument8 pagesPA / 1G / 1F: This Is The Flat Position, in Which The Welder Has The Piece Right Below The Torch, ThisHitesh MhatreNo ratings yet

- NEW Welding DefectsDocument21 pagesNEW Welding DefectssureshNo ratings yet

- Lesson 3. Welding PositionsDocument2 pagesLesson 3. Welding PositionsElla MaeNo ratings yet

- Pipe Welding: Subject:-Welding Technology (2ME704/2)Document14 pagesPipe Welding: Subject:-Welding Technology (2ME704/2)Saket Jha100% (1)

- Welding Document Print PDFDocument103 pagesWelding Document Print PDFRonneySantosNo ratings yet

- Q2 Smaw 10 Module Welding PositionDocument3 pagesQ2 Smaw 10 Module Welding Positionrhaia saphyr penalosa100% (1)

- Tack Welds.: Weld PositionsDocument8 pagesTack Welds.: Weld PositionsWilly UioNo ratings yet

- Learning Activity Sheets (LAS) For SMAW NC II: Weld Carbon Steel Plates in Flat Position (1G) andDocument4 pagesLearning Activity Sheets (LAS) For SMAW NC II: Weld Carbon Steel Plates in Flat Position (1G) andKler Daradar100% (2)

- Austfil 70C-6M BULLETIN EMAIL (1 PDFDocument1 pageAustfil 70C-6M BULLETIN EMAIL (1 PDFAlejandroNo ratings yet

- 2 Terms and Definitions SectionDocument12 pages2 Terms and Definitions SectionJawed AkhterNo ratings yet

- Procedure QualificationDocument68 pagesProcedure QualificationParvee K Nakwal100% (1)

- Asme / Api / Aws GroupDocument35 pagesAsme / Api / Aws GroupDross AlssNo ratings yet

- Weld Test PositionsDocument9 pagesWeld Test PositionssanrexiNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- Welding InspectionDocument43 pagesWelding Inspectionzubairsarwar912No ratings yet

- Welding PositionDocument3 pagesWelding PositionBayu FahribaNo ratings yet

- Welding Positions Welding and NDTDocument6 pagesWelding Positions Welding and NDTALFA ENGINEERINGNo ratings yet

- Remediation Lesson in SMAW NC IIDocument49 pagesRemediation Lesson in SMAW NC IIemmabentonioNo ratings yet

- ETA Engineering. PVT LTD: A Presentation On Welding TechniqueDocument48 pagesETA Engineering. PVT LTD: A Presentation On Welding TechniqueParag NaikNo ratings yet

- F & P NumberDocument17 pagesF & P NumberArfanAliNo ratings yet

- My Ducuments of Welding Positon by Iso and AwsDocument3 pagesMy Ducuments of Welding Positon by Iso and Awslaylayden kaNo ratings yet

- Welding PositionsDocument3 pagesWelding PositionsErhan TolNo ratings yet

- Ice 1.2 Steam Welder Qualifying Test Asme Sect IxDocument28 pagesIce 1.2 Steam Welder Qualifying Test Asme Sect IxThilagavathy SethuramahNo ratings yet

- Grade 11: Automotive ServicingDocument39 pagesGrade 11: Automotive ServicingBe MotivatedNo ratings yet

- Electrode Technical Information: Types of WeldsDocument1 pageElectrode Technical Information: Types of Weldsdev-nullNo ratings yet

- Welding PipeDocument38 pagesWelding PipesafaatNo ratings yet

- Grade 12welding Carbon Steel Pipes Pipe Edge PreparationDocument21 pagesGrade 12welding Carbon Steel Pipes Pipe Edge PreparationVanessa HadJeanxNo ratings yet

- Aws PQR ÇalişmaDocument16 pagesAws PQR Çalişmacan akpınarNo ratings yet

- Teknologi Dan Rekayasa: Oxy-Acetylene WeldingDocument28 pagesTeknologi Dan Rekayasa: Oxy-Acetylene WeldingGigih AstotoNo ratings yet

- LAS No 19 Welding SpecificationsDocument1 pageLAS No 19 Welding SpecificationsRICHARD TIEMPONo ratings yet

- Smaw 12 Module 1 Grade 12Document39 pagesSmaw 12 Module 1 Grade 12HERNAN JAY BUYOK100% (1)

- Positions For Plate and Pipe SpecimensDocument100 pagesPositions For Plate and Pipe Specimensshabbir626No ratings yet

- SMAW 11 ModueDocument39 pagesSMAW 11 ModueFrancis Rico Mutia Rufon100% (8)

- Piro Query Ch. 27.76: Layout For Skew Slab, "27 Conference On Our World in Concrete & Structure"Document1 pagePiro Query Ch. 27.76: Layout For Skew Slab, "27 Conference On Our World in Concrete & Structure"Ankush KumarNo ratings yet

- Smaw Module 2ndQ 1stDocument6 pagesSmaw Module 2ndQ 1stAdoracion Sales HugoNo ratings yet

- ASME & ISO ComparisonDocument5 pagesASME & ISO Comparisonr0m14rNo ratings yet

- Supplemental Information 2Document14 pagesSupplemental Information 2meetvandanapatelNo ratings yet

- Welding TechniquesDocument21 pagesWelding Techniquessharafudheen_sNo ratings yet

- Pipe-To-Pipe: Lignment OF IPEDocument2 pagesPipe-To-Pipe: Lignment OF IPEMunir KadernaniNo ratings yet

- DocumentDocument5 pagesDocumentmohammed siddiqNo ratings yet

- Pipe Welding Information 2Document14 pagesPipe Welding Information 2snilkanthNo ratings yet

- SMAW Pipe Welding TechniquesDocument35 pagesSMAW Pipe Welding Techniquesmiradeel100% (4)

- Class WorkDocument35 pagesClass Worktinu k joyNo ratings yet

- Smaw 12 Module 1 Grade 12 - CompressDocument39 pagesSmaw 12 Module 1 Grade 12 - CompressMichael LogueNo ratings yet

- Splicing Piles: 4.1 Cast-In-Place PilesDocument1 pageSplicing Piles: 4.1 Cast-In-Place PilesmrmerajNo ratings yet

- Pipe WeldingDocument13 pagesPipe WeldingFord Katim100% (4)

- Upplemental Information 2 WeldDocument16 pagesUpplemental Information 2 WeldMasih BelajarNo ratings yet

- Welding Design, Welding Procedure and Performance QualificationDocument34 pagesWelding Design, Welding Procedure and Performance Qualificationkmas1612100% (3)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- Strenx 700MC D e 2017-04-20Document2 pagesStrenx 700MC D e 2017-04-20Amandeep SinghNo ratings yet

- Relationship Between Microstructure and Ductility of Investment Cast ASTM F-75 Implant AlloyDocument7 pagesRelationship Between Microstructure and Ductility of Investment Cast ASTM F-75 Implant AlloyCatarina Pinto100% (1)

- mcs2019 All PDFDocument204 pagesmcs2019 All PDFRheydel BartolomeNo ratings yet

- Fastener ListDocument9 pagesFastener ListMani Rathinam RajamaniNo ratings yet

- Wps 1Document1 pageWps 1Sudhir KotkarNo ratings yet

- Xie Rehren 2009 Lead Silver Slag China BUMA VIDocument9 pagesXie Rehren 2009 Lead Silver Slag China BUMA VIth_rehrenNo ratings yet

- Cast Wire Rope Clamps-Not For Lifting: 316 Stainless SteelDocument1 pageCast Wire Rope Clamps-Not For Lifting: 316 Stainless SteelKiatchai IttivikulNo ratings yet

- Lincoln ElectrodeDocument52 pagesLincoln ElectrodeSamer BayatiNo ratings yet

- 1 Intergranular Corrosion of Copper Contai Iso CorrDocument8 pages1 Intergranular Corrosion of Copper Contai Iso CorrhamidouhouNo ratings yet

- Is 2507 PDFDocument18 pagesIs 2507 PDFSenthil Kumar Ganesan100% (1)

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDocument2 pagesSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNo ratings yet

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- About Welding Process 13Document1 pageAbout Welding Process 13XerexNo ratings yet

- List of Is /astm / Iso / Jis Standard Required For Steel TestingDocument2 pagesList of Is /astm / Iso / Jis Standard Required For Steel TestingRohit SharmaNo ratings yet

- JIS Standards ListDocument84 pagesJIS Standards ListAhmadreza Aminian36% (11)

- Genesis 2020 PDFDocument154 pagesGenesis 2020 PDFDilon FernandoNo ratings yet

- Stainless Steel PDFDocument110 pagesStainless Steel PDFcidaaalvesNo ratings yet

- Welding Feasibility of Copper and Mild Steel Using TIG WeldingDocument3 pagesWelding Feasibility of Copper and Mild Steel Using TIG WeldingselavilizationNo ratings yet

- Die Casting CalculationDocument4 pagesDie Casting Calculationprabhakarnttf76% (33)

- Infinitigroup: A Better WayDocument52 pagesInfinitigroup: A Better WayMartinus Bagus WicaksonoNo ratings yet

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 pagesA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrNo ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- 005-CEN Unfired Pressure Vessels - CEN TC 54Document2 pages005-CEN Unfired Pressure Vessels - CEN TC 54njkasdncjkdNo ratings yet

- COMPANY PRESENTATION With Sister Concern Jan 2020Document53 pagesCOMPANY PRESENTATION With Sister Concern Jan 2020Mahaveer JainNo ratings yet

- Bollhoff Helicoil Plus Kits and Inserts CatalogueDocument49 pagesBollhoff Helicoil Plus Kits and Inserts CatalogueThor InternationalNo ratings yet

- TDS Manganese Phosphating BCM MP-1501 PDFDocument3 pagesTDS Manganese Phosphating BCM MP-1501 PDFanon_666700113No ratings yet

- Carbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument13 pagesCarbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or Bothalucard375No ratings yet

- PSMA All Members List Region WiseDocument10 pagesPSMA All Members List Region WiseMuhammed Ali100% (1)

- Cast IronDocument27 pagesCast IronSanthoshsharma Devaraju100% (1)

- ALineMetals Linecard042808Document2 pagesALineMetals Linecard042808wangchao821No ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

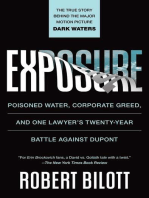

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Did Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksFrom EverandDid Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksNo ratings yet

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Stand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailFrom EverandStand Up That Mountain: The Battle to Save One Small Community in the Wilderness Along the Appalachian TrailRating: 3 out of 5 stars3/5 (3)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Deepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeFrom EverandDeepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeNo ratings yet

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)