Professional Documents

Culture Documents

Wps 1

Uploaded by

Sudhir Kotkar0 ratings0% found this document useful (0 votes)

23 views1 pageOriginal Title

wps1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 pageWps 1

Uploaded by

Sudhir KotkarCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

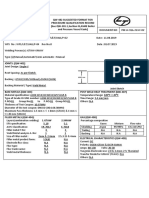

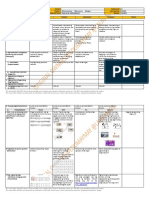

QW-483 ()

PQR No.: TME 356

Tensile Test ( QW-150) – Not Applicable

Specimen No. Width (mm) Thickness (mm) Area (mm2) Ultimate Total Load (N) Ultimate Unit Type of Failure and

Stress, (Mpa) Location

Not Applicable

Guided-Bend Test (QW-160) Test Report No. Q-07512.2 DT. 00/00/0000

Figure No. Type Bending Angle Former Diameter Result

QW-462.2 Transverse side Bend 1 (Bending Angle 180 degree) 4 x t = 40mm Satisfactory (QW-163 Acceptance Criteria)

QW-462.2 Transverse side Bend 2 (Bending Angle 180 degree) 4 x t = 40mm

QW-462.2 Transverse side Bend 3 (Bending Angle 180 degree) 4 x t = 40mm

QW-462.2 Transverse side Bend 4 (Bending Angle 180 degree) 4 x t = 40mm

Toughness test (QW-160) Test Report No. Q-07512 DT.00/00/0000

Specimen No. & Notch Location Specimen Size Test Temperature Impact Values (J)

(mm) Sample 1 Sample 2 Sample 3 Average

Not Applicable

Fillet-Weld test (QW-170)-Not Applicable

Result – Satisfactory: Yes No penetration into Parent Metal: Yes No

Macro – Not Applicable

Vicker Hardness HV-10, REPORT No:Q07512.1 Dtd:00/00/0000

SR. NO. Process Location Result

1 SMAW Weld 000 000 000

2 SMAW Haz 000 000 000

3 SMAW PARENT METAL 000 000 000

OTHER TEST

Types of test

(1)Visual examination : Satisfactory WELDING WITNESS SHOP SHEET Dated.00/00/0000

(2) Dye penetrant Examination : Satisfactory WELDING WITNESS SHOP SHEET Dated.00/00/0000

(3) Chemical Analysis: Refer Annexure – 1;

(4) IGC as per Method ‘’A’’ of ASTM G28: Satisfactory

(5) Metallographic Examination of Weld, HAZ & PARENT METAL : Satisfactory

Welder’s Name: xxx Clock No. ---- Stamp No. W-000

Test conducted by: ABC PVT. LTD. Test report no.: Q-000, Q-000

We certify that the statements in this record are correct and that the test welds were prepared, Welded and tested in accordance

with the Requirement of Section IX of the ASME Boiler and pressure Vessel Code, Edition 2017.

Organization: abc PVT. LTD.

Prepared By: Certified By: Witnessed By:

Engineer (Welding) Head Welding

Page 2 of 3

You might also like

- Structural Notes and Specifications for ConcreteDocument1 pageStructural Notes and Specifications for Concreteroger100% (2)

- Caffeine Natural Coffee BeanDocument1 pageCaffeine Natural Coffee BeanMayang TariNo ratings yet

- Simplex 4100ES 5 Days Customer TrainingDocument1 pageSimplex 4100ES 5 Days Customer TrainingBrahmantyo HadiprasetyoNo ratings yet

- ASME B16.5 Flange Rating CalculatorDocument10 pagesASME B16.5 Flange Rating Calculatorfaizal100% (2)

- Brooks MT 3018Document16 pagesBrooks MT 3018Martin AndradeNo ratings yet

- QW-483 (BACK) PQR No.: Tme 356Document1 pageQW-483 (BACK) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- Tensile test report QW-483Document1 pageTensile test report QW-483Sudhir KotkarNo ratings yet

- QW-483 (Red) PQR No.: Tme 358Document1 pageQW-483 (Red) PQR No.: Tme 358Sudhir KotkarNo ratings yet

- QW-483 (Black) PQR No.: Tme 356Document1 pageQW-483 (Black) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- QW-483 (Green) PQR No.: Tme 356Document1 pageQW-483 (Green) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- KP WPS PQR GTAW FCAWDocument1 pageKP WPS PQR GTAW FCAWwahyuNo ratings yet

- PQR PT Bse WPS 07Document2 pagesPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Smash Enterprises, Pune SME/PQR/51/20-21/GSU SME/WPS/51/20-21Document3 pagesSmash Enterprises, Pune SME/PQR/51/20-21/GSU SME/WPS/51/20-21Meghan GhoneNo ratings yet

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- China Civil Engineering Construction Corperation: Repair Welding Procedure Qualification-Manual Metal ArcDocument1 pageChina Civil Engineering Construction Corperation: Repair Welding Procedure Qualification-Manual Metal ArcMakamu Max Las MokgaoganyiNo ratings yet

- Ec-2692-220-2 - Void 4SDocument3 pagesEc-2692-220-2 - Void 4SMatheus Fabrício TeixeiraNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- CQ-A6061-(175-0301);(175-0303);(175-0279)Document7 pagesCQ-A6061-(175-0301);(175-0303);(175-0279)Đạt NguyễnNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Magnetic Particle Testing Report SummaryDocument4 pagesMagnetic Particle Testing Report Summarypankaj ranaNo ratings yet

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument4 pagesQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- 1426-EC1942Document3 pages1426-EC1942Deipak HoleNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- S355J2 Plate MTCDocument2 pagesS355J2 Plate MTCHarminder Kumar100% (1)

- Essential welding procedure qualification recordDocument2 pagesEssential welding procedure qualification recordmainur mechanical engineer0% (1)

- Test Report: Measurement Method 1 Resistance Ambient 2 Thermometer Frame 3 Thermocouples BearingDocument1 pageTest Report: Measurement Method 1 Resistance Ambient 2 Thermometer Frame 3 Thermocouples BearingHARDWARE ONENo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- MT 14 465 T1 Report Supplier 1 48.3mm TubeDocument1 pageMT 14 465 T1 Report Supplier 1 48.3mm TubeHaseeb KhanNo ratings yet

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 pageRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- FORM QW-483 (Back) : ASME BPVC - IX-2015Document1 pageFORM QW-483 (Back) : ASME BPVC - IX-2015Anonymous 0rt9KWmNNo ratings yet

- Procedure Qualification Records (PQR)Document2 pagesProcedure Qualification Records (PQR)amine algNo ratings yet

- Kaushik Shah Date: 2011 Form 001 - Format CDocument6 pagesKaushik Shah Date: 2011 Form 001 - Format CsriramNo ratings yet

- WQR V01 PLT 012-ComDocument3 pagesWQR V01 PLT 012-Comhaim timorNo ratings yet

- He Mrut 006Document3 pagesHe Mrut 006Hao TranNo ratings yet

- SAW Test Results NSSW NB-250H & Y-80M Flux WireDocument5 pagesSAW Test Results NSSW NB-250H & Y-80M Flux WireEduard Gonzalo Rojas CervantesNo ratings yet

- SWATHI PQR Procedure QualificationDocument10 pagesSWATHI PQR Procedure QualificationMustu AkolawalaNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormAbhinandan BastiNo ratings yet

- HT Panel Test ReportDocument4 pagesHT Panel Test ReportItx Adi0% (1)

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRvinodNo ratings yet

- Window MTCDocument4 pagesWindow MTCshamshadkadavath1998No ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mobaskaran ayyapparajNo ratings yet

- Electro Qualification Test RecordDocument41 pagesElectro Qualification Test RecordShaikh sohilNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Document23 pagesTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderNo ratings yet

- He Mrut 005Document3 pagesHe Mrut 005Hao TranNo ratings yet

- تقرير اختبارات مواسير الحريقDocument7 pagesتقرير اختبارات مواسير الحريقZeeshanAliNo ratings yet

- Test ReportDocument40 pagesTest ReportMourad BenderradjiNo ratings yet

- 2005-05 - WPS & PQR C5Document6 pages2005-05 - WPS & PQR C5misthahNo ratings yet

- Sandvik 22.8.3.L Welding Wire DatasheetDocument3 pagesSandvik 22.8.3.L Welding Wire DatasheetbhuvandesignNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Quotation: Sr. No. Item Description Quantity Unit Rate AmountDocument1 pageQuotation: Sr. No. Item Description Quantity Unit Rate AmountSudhir KotkarNo ratings yet

- Quotation: Shree EnterprisesDocument1 pageQuotation: Shree EnterprisesSudhir KotkarNo ratings yet

- Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- MS Fabrication Quotation for Shree EnterprisesDocument1 pageMS Fabrication Quotation for Shree EnterprisesSudhir KotkarNo ratings yet

- Quotation: Sr. No. Item Description Quantity Unit Rate AmountDocument1 pageQuotation: Sr. No. Item Description Quantity Unit Rate AmountSudhir KotkarNo ratings yet

- PQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- MS Fabrication Quotation for Shree EnterprisesDocument1 pageMS Fabrication Quotation for Shree EnterprisesSudhir KotkarNo ratings yet

- MS Fabrication Quotation for Shree EnterprisesDocument1 pageMS Fabrication Quotation for Shree EnterprisesSudhir KotkarNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument26 pages1 Input Data: WWW - Hilti.inSudhir KotkarNo ratings yet

- Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- PQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- Prepared By: Certified By: Witnessed byDocument1 pagePrepared By: Certified By: Witnessed bySudhir KotkarNo ratings yet

- Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument26 pages1 Input Data: WWW - Hilti.inSudhir KotkarNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument26 pages1 Input Data: WWW - Hilti.inSudhir KotkarNo ratings yet

- Self-Declaration Form for Business RegistrationDocument2 pagesSelf-Declaration Form for Business RegistrationSudhir KotkarNo ratings yet

- Guide Acting PDFDocument2 pagesGuide Acting PDFSudhir KotkarNo ratings yet

- SelfDeclaration ShopDocument2 pagesSelfDeclaration ShopSudhir KotkarNo ratings yet

- Guide Shop Act PDFDocument2 pagesGuide Shop Act PDFSudhir KotkarNo ratings yet

- Shop Act PDFDocument2 pagesShop Act PDFSudhir KotkarNo ratings yet

- Self Declaration Shop PDFDocument2 pagesSelf Declaration Shop PDFSudhir Kotkar0% (2)

- Name: Sport: Movement PrepDocument24 pagesName: Sport: Movement PrepS HNo ratings yet

- Lab Manual - Skull Bones - English - Student - Fill inDocument6 pagesLab Manual - Skull Bones - English - Student - Fill inthejaskumar2026No ratings yet

- (PP 67-14) Quantifying Cracks in Asphalt Pavement Surfaces From Collected Images Utilizing Automated MethodsDocument7 pages(PP 67-14) Quantifying Cracks in Asphalt Pavement Surfaces From Collected Images Utilizing Automated MethodsAveNo ratings yet

- Joule Gym Marketing Plan for Female-Only Fitness CenterDocument23 pagesJoule Gym Marketing Plan for Female-Only Fitness CenterJeremy BadalNo ratings yet

- Dissertation - December 2022Document71 pagesDissertation - December 2022Musasa TinasheNo ratings yet

- Continuous Renal Replacement TherapyDocument9 pagesContinuous Renal Replacement Therapydoc_next_doorNo ratings yet

- National Coalition For The HomelessDocument7 pagesNational Coalition For The HomelessLee GaylordNo ratings yet

- CardiovascularDocument155 pagesCardiovascularEric VeranoNo ratings yet

- Designing Resistance Training Programmes To Enhance Muscular Fitness A Review of The Acute Programme VariablesDocument12 pagesDesigning Resistance Training Programmes To Enhance Muscular Fitness A Review of The Acute Programme VariablesSheilani MartinsNo ratings yet

- Labrel 104-195Document1,014 pagesLabrel 104-195Maria Seleena HipolitoNo ratings yet

- Product Overview: NCV71208: Octal Solenoid Current Controller With N-FET PredriversDocument1 pageProduct Overview: NCV71208: Octal Solenoid Current Controller With N-FET PredriversDimitar PetrovNo ratings yet

- Project: M/S Cae-Gondia at Nagpur Cable Schedule For Proposed ProjectDocument26 pagesProject: M/S Cae-Gondia at Nagpur Cable Schedule For Proposed ProjectMurali MohanNo ratings yet

- Agco - DBB - f68.f69Document6 pagesAgco - DBB - f68.f69Mohd Khairi Mohd NorzianNo ratings yet

- Curriculum DesignDocument20 pagesCurriculum DesignRose Glaire Alaine TabraNo ratings yet

- CS Risk and Crisis Management FinalDocument62 pagesCS Risk and Crisis Management FinaldangermanNo ratings yet

- Seven Appear in Court On Cocaine, P Charges After North Island Drug Raids - NZ HeraldDocument3 pagesSeven Appear in Court On Cocaine, P Charges After North Island Drug Raids - NZ HeraldVagamundos ArgentinosNo ratings yet

- Animal Names in English and Telugu - 20170912 - 182216545Document17 pagesAnimal Names in English and Telugu - 20170912 - 182216545karimulla goraNo ratings yet

- Warm Vs Cold ShockDocument8 pagesWarm Vs Cold ShockmarleeramirezNo ratings yet

- Bill of Qty. N.C. Sharma, BILSI, BadaunDocument47 pagesBill of Qty. N.C. Sharma, BILSI, BadaunNazim AliNo ratings yet

- 2009 IECC Residential Code Requirements Apr 14 Draft InspectorsDocument4 pages2009 IECC Residential Code Requirements Apr 14 Draft Inspectorsbcap-oceanNo ratings yet

- Low Noise Pseudomorphic HEMT Technical DataDocument4 pagesLow Noise Pseudomorphic HEMT Technical Datahendpraz88No ratings yet

- Fire Prevention and Response Plan for Greenergie PlantDocument8 pagesFire Prevention and Response Plan for Greenergie PlantMelba MangabatNo ratings yet

- 14 People V Manalo (Verba Legis)Document15 pages14 People V Manalo (Verba Legis)zeynNo ratings yet

- DLL - MAPEH 4 - Q4 - W8 - New@edumaymay@lauramos@angieDocument8 pagesDLL - MAPEH 4 - Q4 - W8 - New@edumaymay@lauramos@angieDonna Lyn Domdom PadriqueNo ratings yet

- Chapter III Pharmacokinetics: Durge Raj GhalanDocument64 pagesChapter III Pharmacokinetics: Durge Raj GhalanDurge Raj Ghalan100% (3)