Professional Documents

Culture Documents

Essential welding procedure qualification record

Uploaded by

mainur mechanical engineerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Essential welding procedure qualification record

Uploaded by

mainur mechanical engineerCopyright:

Available Formats

Page 1 of 2

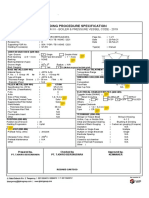

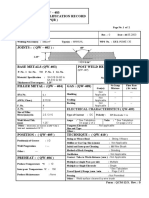

PROCEDURE QUALIFICATION RECORD (PQR)

Project Name : Essential Drag Company Ltd. (EDCL) 3rd Plant PQR No. : BDDE-PQR-CS-001 Rev. 0

Client : Energypac Power Generation Ltd. Pre WPS No. : BDDE-WPS-CS-001 Rev. 0

Contractor : BDDE Project Solution Ltd. Date : 29 January, 2020

Welding Process(es) : GTAW Types : Manual

Code : ASME Sec IX, 2017 Edition

JOINT (QW-402) Weld Sequence

Joint Design : Groove

Backing : Without

Backing Material : N/A

Retainer : N/A

Other : N/A

Groove Design of Test Coupon

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal and process used.)

BASE METALS (QW-403) PWHT (QW-407)

Material Specification : ASTM A106 GR.B Temp. Range (◦C) : N/A

Type/Grade or UNS Number : GR. B or UNS No. K03006 Holding Time (minute) : N/A

P. No. 1 Group No. 1 to P. No. 1 Group No. 1 Heat Rate : N/A

Size of Test Coupon : 60.3mm X 300mm Cool Rate : N/A

Thickness of Test Coupon : 3.91 mm Diameter(mm) : 60.3mm Others : N/A

Certificate No. : 201903196349 Heat No. : 36517

Others : N/A

FILLER METALS(QW-404) GAS (QW-408)

SFA No. : 5.18 Percent Composition

AWS Classification : ER70S-6 (Gases) (Mixture) Flow Rate

F- No :6 Shielding Argon 99.98% 12-15 LPM

A- No :1 Backing N/A N/A N/A

Diameter (mm) : Ø 2.4 mm Others N/A N/A N/A

Trade Name : TGC-50S ELECTRICAL CHARACTERSTICS (QW-409)

Manufacturer : CHOSUN WELDING CO. LTD. Current : DCEN

Electrode Lot/Certificate No. : CS-1911-1166 Polarity : STRAIGHT POLARITY

Deposited Weld Metal : 3.91 mm Heat Input : As mentioned below

Filler Metal Product form : Solid Wire Tungsten Electrode Size and Type : Ø 2.4 mm, 2% THORIATED

Others : N/A Other : N/A

POSITIONS (QW-405) WELDING TECHNIQUE (QW-410)

Groove Position : 6G String/Weave Bed : String and Weave

Welding Progression : UP HILL Method of Cleaning : Chipping, Grinding or Brushing

Fillet Position : N/A Single or Multi Pass/Side : Multiple

Other : N/A Single or Multi Electrodes : Single

PREHEAT TEMP. (QW-406) Method of Back Gouging : N/A

Min. Preheat Temp. (°C) : Ambient Peening : N/A

Max. Interpass Temp. (°C) : 250°C Use of Thermal Process : N/A

Preheat Maintenance : N/A Others : N/A

Others : N/A

Page 2 of 2

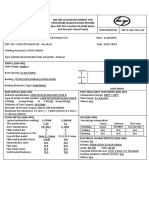

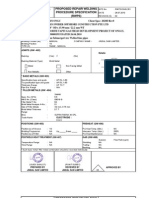

PROCEDURE QUALIFICATION RECORD (PQR)

Project Name : Essential Drag Company Ltd. (EDCL) 3rd Plant PQR No. : BDDE-PQR-CS-001 Rev. 0

Non Destructive Testing

Date Type of Test Result Report No. Remarks

29-Jan-2020 Visual Test Accepted NA

31-Jan-2020 Radiographic Test Accepted BDDE/NCS/PQR/CS/RT-001

Destructive Testing

Tensile Test (QW-150)

Report No. :

Specimen Thickness Ultimate Tensile Ultimate Tensile

Width (mm) Area (mm²) Failure Location Result

No. (mm) load (lbs) Stress (MPa)

T1

T2

Guided Bend Test (QW-160)

Face and Root Bend Test Report No. :

Type Specimen No. Bend Angle (°) Observation Result

Face bend F1

Face bend F2

Root Bend R1

Root Bend R2

Toughness Test (QW-170)

Charpy Impact Test: N/A Report No. : N/A

Dimension Energy Absorved (J)

Location Test Temperature Average Result

(mm) Specimen 1 Specimen 2 Specimen 3

WELDING PARAMETERS

Base Metal (mm) Deposited Weld

Welder Name Welder No. Process Position Filler Metal

Dia Thick. Thick (mm)

Al Amin W#002 GTAW 6G 2" 3.91 3.91 ER70S-6

Shamim Hossain W#007 GTAW 6G 2" 3.91 3.91 ER70S-6

Weld Pass Pass Welding Filler Metal Current Type Voltage Travel Speed Heat Input

Ampere (A)

/ Layer No. Process Class Dia (mm) (Polarity) (V) mm/min (KJ/mm)

Root 1 GTAW ER70S-6 2.4 DCEN 89 12 94 0.68

Hot 2 GTAW ER70S-6 2.4 DCEN 88 12 150 0.42

Fill 3 GTAW ER70S-6 2.4 DCEN 90 12 120 0.54

4 GTAW ER70S-6 2.4 DCEN 107 13 115 0.73

Cap

5 GTAW ER70S-6 2.4 DCEN 106 13 110 0.75

We hereby certify that the statement in this record are correct and that the test welds were prepared, welded and tested in accordance with the

requirements of section IX of the ASME Boiler and Pressure Vessel Code 2017 Edition.

Contractor Third Party Inspector Client

BDDE Project Solution Ltd. Bureau Veritas (Bangladesh) Private Ltd. Energypac Power Generation Ltd.

Name: Polak Saha Name: Mohammed Nasir Uddin Name: Khan Mohammad Mehebub Hossain

Sign & Date: Sign & Date: Sign & Date:

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocument3 pagesASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- SWATHI PQR Procedure QualificationDocument10 pagesSWATHI PQR Procedure QualificationMustu AkolawalaNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDocument5 pagesLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- Final PQRDocument130 pagesFinal PQRAhamed Naufal CaNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- PRN004Document2 pagesPRN004beyNo ratings yet

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Glycol Reboiler Still Welding Procedure Specification (PWPSDocument2 pagesGlycol Reboiler Still Welding Procedure Specification (PWPSstdshopNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- Welding Procedure Qualification Records (WPQR) GuideDocument3 pagesWelding Procedure Qualification Records (WPQR) Guideramesh rajaNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiARNo ratings yet

- PQR Welding Procedure for Dissimilar MaterialsDocument3 pagesPQR Welding Procedure for Dissimilar Materialszaki fadlNo ratings yet

- WPS Gtaw) - 47Document2 pagesWPS Gtaw) - 47Dharmendra BhardwajNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- WPS-IOT-005 REV.0 Welding Procedure Specification (IOTPG) - For Proposed OnlyDocument10 pagesWPS-IOT-005 REV.0 Welding Procedure Specification (IOTPG) - For Proposed OnlyUripTobingNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- KSKSKSKS KS D 3576Document18 pagesKSKSKSKS KS D 3576mainur mechanical engineerNo ratings yet

- CV SumonDocument2 pagesCV Sumonmainur mechanical engineerNo ratings yet

- RFQ AgencyDocument23 pagesRFQ Agencymainur mechanical engineerNo ratings yet

- RFI-14, House Connection Survey, Sewer Network (PESSCM - 1-W-1), Block-K, Zone-C (Updated)Document4 pagesRFI-14, House Connection Survey, Sewer Network (PESSCM - 1-W-1), Block-K, Zone-C (Updated)mainur mechanical engineerNo ratings yet

- Elevation Designs For 4 Floors BuildingDocument4 pagesElevation Designs For 4 Floors Buildingmainur mechanical engineerNo ratings yet

- Finance Form Vendor Acknowledgment of Advance PaymentDocument1 pageFinance Form Vendor Acknowledgment of Advance Paymentmainur mechanical engineerNo ratings yet

- Muhammad Nurul Amin - ThesisDocument67 pagesMuhammad Nurul Amin - Thesismainur mechanical engineerNo ratings yet

- Master Grocery List 01Document1 pageMaster Grocery List 01mainur mechanical engineerNo ratings yet

- Master Grocery List for All Your Shopping NeedsDocument1 pageMaster Grocery List for All Your Shopping NeedsJuan VergelNo ratings yet

- Master Grocery List 08Document25 pagesMaster Grocery List 08mainur mechanical engineerNo ratings yet

- FUEL CARD RFQDocument7 pagesFUEL CARD RFQmainur mechanical engineerNo ratings yet

- Basic valve datasheets for inquiryDocument21 pagesBasic valve datasheets for inquirymainur mechanical engineerNo ratings yet

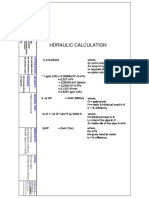

- Hydraulic CalculationDocument1 pageHydraulic Calculationmainur mechanical engineerNo ratings yet

- Liquid Valve Sizing Non-IterativeDocument2 pagesLiquid Valve Sizing Non-Iterativemainur mechanical engineerNo ratings yet

- Instructions For The Use of Allied Valve Control Valve Spec SheetDocument4 pagesInstructions For The Use of Allied Valve Control Valve Spec Sheetmainur mechanical engineerNo ratings yet

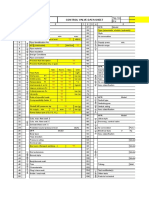

- Control Valve Data Sheet: Tag. NoDocument4 pagesControl Valve Data Sheet: Tag. NoGiftObionochieNo ratings yet

- !!!проработать FPLSHCM - 214 - 1 PDFDocument36 pages!!!проработать FPLSHCM - 214 - 1 PDFSlava75No ratings yet

- Tips - Asme b313 Training SeminarDocument382 pagesTips - Asme b313 Training SeminarMarc Abellán EscuraNo ratings yet

- PNAE G-7-016-89Document7 pagesPNAE G-7-016-89ASME TURKEYNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Safety Data Sheet: 1 Identification of SubstanceDocument4 pagesSafety Data Sheet: 1 Identification of SubstanceProject Sales CorpNo ratings yet

- Unctionally Graded Materials: B.Bharath Kumar (PH.D) Asst - Professor ME DeptDocument30 pagesUnctionally Graded Materials: B.Bharath Kumar (PH.D) Asst - Professor ME Deptbharathkumar0310No ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelSunil Kumar GoudaNo ratings yet

- Types of Electric WeldingDocument7 pagesTypes of Electric WeldingSUKhanNo ratings yet

- Fundamentals of Corrosion MechanismsDocument55 pagesFundamentals of Corrosion Mechanismsfreeuser3No ratings yet

- Syllabus JigsDocument50 pagesSyllabus JigsSang Ka KalaNo ratings yet

- Exhaust Gas After Treatment SystemDocument11 pagesExhaust Gas After Treatment SystemRahul ENo ratings yet

- 9 - 1 H Wood Cabinet Spec Options NelDocument8 pages9 - 1 H Wood Cabinet Spec Options NelinformalitybyusNo ratings yet

- (1xxx Series) Wrought Pure Aluminum, 99.00% or Greater (1100)Document2 pages(1xxx Series) Wrought Pure Aluminum, 99.00% or Greater (1100)Danusa Renata CostaNo ratings yet

- Module 5 Heat Exchanger Design - Part 2Document26 pagesModule 5 Heat Exchanger Design - Part 2Prince immanent BopapeNo ratings yet

- Mold Check ListDocument10 pagesMold Check Listapk11No ratings yet

- BeroCel 102 Tds en 2018Document2 pagesBeroCel 102 Tds en 2018Quoc AnNo ratings yet

- Manual Sierra Horizontal W.F. WellsDocument43 pagesManual Sierra Horizontal W.F. WellsDavidOlivaNo ratings yet

- Multi Spindl Drilling MachineDocument38 pagesMulti Spindl Drilling MachineBoopathi KalaiNo ratings yet

- 1 Ball Mills 1Document106 pages1 Ball Mills 1BharaniChirsabesan100% (3)

- Enhancing The Permeability and PropertieDocument9 pagesEnhancing The Permeability and PropertieAjeeth KumarNo ratings yet

- SS 2006 by Taylor & Francis Group, LLCDocument12 pagesSS 2006 by Taylor & Francis Group, LLCsujit_sekharNo ratings yet

- Solid-Liquid Extraction Process OptimizationDocument9 pagesSolid-Liquid Extraction Process OptimizationPMNo ratings yet

- X3Document23 pagesX3MOHAMEDNo ratings yet

- Rustlick™ B: Rust PreventativeDocument2 pagesRustlick™ B: Rust PreventativeJesús PalomaresNo ratings yet

- Texmaco Limited: Welding Process InstructionDocument15 pagesTexmaco Limited: Welding Process InstructionArvindshuklamechNo ratings yet

- Technical Datasheet Qoc With Jaws: Product InformationDocument1 pageTechnical Datasheet Qoc With Jaws: Product Informationagung wijaya100% (1)

- Form turning - The tool is ground to shape workpieceDocument10 pagesForm turning - The tool is ground to shape workpieceJohn Paul DomingoNo ratings yet

- Providing welding solutions for sugar industry applicationsDocument17 pagesProviding welding solutions for sugar industry applicationsBHARAT KNo ratings yet

- UniBinder 8.2 - 0Document2 pagesUniBinder 8.2 - 0Viqar JawaidNo ratings yet

- The Advantages of Broaching Have Been Stated As UnderDocument3 pagesThe Advantages of Broaching Have Been Stated As UnderNishit ParmarNo ratings yet