Professional Documents

Culture Documents

Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.

Uploaded by

Weld Bro SandeepOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.

Uploaded by

Weld Bro SandeepCopyright:

Available Formats

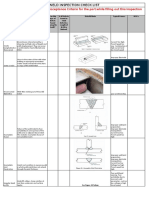

RECORD OF WELDER OR WELDING OPERATOR QUALIFICATION TEST

Date-

Dantal Hyaulics Pvt Ltd.

Welders's name: WQT No.: Stamp No.:

Test description

WPS No: Test coupon Production weld

Specification of base metal(s):

Testing condition and Qualification Limits

Welding Variables(QW-350/361.1/361.2) Actual Values Qualified Range

Welding process(es)

Type;(Manual, Semi-auto/Automatic/Machine)

Backing(Single/double Sided)

Plate / Pipe (Enter diameter if pipe or tube)

Base metal P-or S-Numbers to P- or S-Numbers

Base Metal Thickness (for Weld Overlay)

Filler metal or electrode specification(s)(SFA)

Filler metal F-Number(s)

Consumable insert(GTAW or PAW)

Filler type(Solid/Metal or Flux cored/Powder) (GTAW or PAW)

Deposit thickness for each process

Process 1: 3 layer minimum Yes No

Process 2: 3 layer minimum Yes No

Welding Position

Vertical progression (uphill or downhill)

Inert gas backing(GTAW, PAW, GMAW)

Transfer mode (Spray/Gloubular or Pulse to Short Circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN)

Additional qualification limits for Machine/Automatic welding :

Direct or remote visual control -Yes/No

Automatic arc voltage control(GTAW)- Yes/No

Automatic joint tracking -Yes/No

Single or multiple passes per side -Yes/No

RESULTS:

Visual Examination of Completed weld(QW-302.4) ______________________________________

Bend Test Trans. Root & Face (QW- 462.3(a) Long. Root & Face (QW-462.3(b) Side (QW-462.2)

Pipe Bend Specimen, Corr.-Resistant Overlay (QW-462.5(c) Plate Bend Specimen, Corr. Resistant Overlay (QW-462.5(d)

Macro Test for fusion (QW-462.5(b) Macro Test for fusion (QW-462.5(e)

Type Result Type Result Type Result

Alternative radiographic examination results(QW-191)

Fillet weld-fracture test(QW-180) : Length and percent of defects:__________________________

Macro examination (QW-184) : Fillet size(mm) : ____ x ____ Concavity/convexity(mm.)_____

Other test:

Inspection Agency : ___________________

______________________________________________ ______________________________________________

Laboratry Test No.:

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the requirements

of section IX of ASME Boiler and Pressure Vessel Code/

_________________________

WELDING ENGINEER

(SIGNATURE & DATE)

F 504 HZ R1

You might also like

- WPQ Format Sec IxDocument2 pagesWPQ Format Sec IxParminder SinghNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormAbhinandan BastiNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormTegar OktoberNo ratings yet

- Welders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionDocument8 pagesWelders Performance Qualification Record (WPQ) : Welder Name Identification No. Test DescriptionGerardo Arispe AramayoNo ratings yet

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRvinodNo ratings yet

- DQR Project Quality Control Form for Welder PerformanceDocument1 pageDQR Project Quality Control Form for Welder PerformanceminhnnNo ratings yet

- Qw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document7 pagesQw-484B Format For Welding Operator Performance Qualifications (Wopq) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Gerardo Arispe AramayoNo ratings yet

- Welder Certificate Sample1Document1 pageWelder Certificate Sample1Buddy EkoNo ratings yet

- RSW WOPQ REV. 2010a Interactive FormDocument1 pageRSW WOPQ REV. 2010a Interactive FormcosmicbunnyNo ratings yet

- FO 3310d Welding Performance Qualifications (WPQ) : Registro Calificacion de SoldadoresDocument4 pagesFO 3310d Welding Performance Qualifications (WPQ) : Registro Calificacion de SoldadoresRodolfoNo ratings yet

- SEW Welder Performance QualificationsDocument18 pagesSEW Welder Performance QualificationsmahendraNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- WQT 1236Document1 pageWQT 1236mir31721No ratings yet

- Test Description (Information Only)Document2 pagesTest Description (Information Only)dayalramNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- Welder Performance Qualifications (WPQ)Document1 pageWelder Performance Qualifications (WPQ)tayyabNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSAlesol EquipmentNo ratings yet

- Format For Manufacturer Record of Welding Operator QualificationDocument1 pageFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarNo ratings yet

- FQ 069Document1 pageFQ 069Chava TejaNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSJose Elian Cuellar PinzónNo ratings yet

- FORM QW-484A WELDER PERFORMANCE QUALIFICATIONSDocument1 pageFORM QW-484A WELDER PERFORMANCE QUALIFICATIONSJose Elian Cuellar PinzónNo ratings yet

- STD PQR Format PDFDocument2 pagesSTD PQR Format PDFvinothNo ratings yet

- STD PQR Format PDFDocument2 pagesSTD PQR Format PDFvinothNo ratings yet

- FORM QW-484B WELDING OPERATOR QUALIFICATIONSDocument1 pageFORM QW-484B WELDING OPERATOR QUALIFICATIONSKautiilaNo ratings yet

- Welder Qualification ReportDocument17 pagesWelder Qualification ReportAries MarteNo ratings yet

- Suggested Weldin Lr. VijDocument4 pagesSuggested Weldin Lr. Vijmallik017100% (2)

- QW484BDocument1 pageQW484BMohamed Ahmed MaherNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPQ 2Document1 pageWPQ 2FirozNo ratings yet

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- QW484Document1 pageQW484Anonymous 4e7GNjzGWNo ratings yet

- WPS PQRDocument4 pagesWPS PQRGuillermo ZaragozaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Welder Qualification Standard ASMEDocument4 pagesWelder Qualification Standard ASMEammarashraf91No ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- Welder Qualification FormatDocument1 pageWelder Qualification FormatScribdTranslationsNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPQ WELDER PERFORMANCE QUALIFICATIONDocument2 pagesWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- WPQTDocument1 pageWPQTyousab creator2No ratings yet

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument4 pagesQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification RecordDocument1 pageDodsal Pte Ltd Q-Chem Project Doha, Qatar Job No 7979 Welder Qualification Recordravi00098No ratings yet

- WELDER QUALIFICATION RECORDDocument4 pagesWELDER QUALIFICATION RECORDZaidiNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Sample Format: Sensitivity: LNT Construction Internal UseDocument2 pagesSample Format: Sensitivity: LNT Construction Internal UseKarthikNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- Dodsal Pte Ltd Q-Chem Project Doha Qatar Welder QualificationDocument1 pageDodsal Pte Ltd Q-Chem Project Doha Qatar Welder QualificationproxywarNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- What Is Underwater Welding and How It Works?: 6. CraterDocument2 pagesWhat Is Underwater Welding and How It Works?: 6. CraterWeld Bro SandeepNo ratings yet

- UndercutDocument1 pageUndercutWeld Bro SandeepNo ratings yet

- Pir 101870817 BDocument42 pagesPir 101870817 BWeld Bro SandeepNo ratings yet

- Xternal Welding DefectsDocument1 pageXternal Welding DefectsWeld Bro SandeepNo ratings yet

- When The Weld Face Extends Beyond The Weld Toe PDFDocument1 pageWhen The Weld Face Extends Beyond The Weld Toe PDFWeld Bro SandeepNo ratings yet

- Welding DefectsDocument1 pageWelding DefectsWeld Bro SandeepNo ratings yet

- Pir 102035744 BDocument50 pagesPir 102035744 BWeld Bro SandeepNo ratings yet

- Welding Systems and Research Methods Module TimetableDocument1 pageWelding Systems and Research Methods Module TimetableWeld Bro SandeepNo ratings yet

- Rohit Bio DataDocument2 pagesRohit Bio DataWeld Bro SandeepNo ratings yet

- DNV Certifies ESAB's Global Quality Management SystemDocument4 pagesDNV Certifies ESAB's Global Quality Management SystemJuan RubioNo ratings yet

- CV Fabricator & Fitter Pipe Structural Plater JobDocument2 pagesCV Fabricator & Fitter Pipe Structural Plater JobWeld Bro SandeepNo ratings yet

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- Pir 101870816 CDocument51 pagesPir 101870816 CWeld Bro SandeepNo ratings yet

- Pir 101870814 DDocument51 pagesPir 101870814 DWeld Bro SandeepNo ratings yet

- QMDocument1 pageQMWeld Bro SandeepNo ratings yet

- Lasposities Final Rev3 A3 Formaat PDFDocument1 pageLasposities Final Rev3 A3 Formaat PDFWeld Bro SandeepNo ratings yet

- PT Level 1 AnswersDocument4 pagesPT Level 1 AnswersWeld Bro SandeepNo ratings yet

- Spot Weld Mech PropDocument57 pagesSpot Weld Mech PropWeld Bro SandeepNo ratings yet

- Stroy of IndiaDocument2 pagesStroy of IndiaWeld Bro SandeepNo ratings yet

- Letter Detective: An Alphabet Hunt ActivityDocument10 pagesLetter Detective: An Alphabet Hunt ActivityWeld Bro SandeepNo ratings yet

- Hinge DrawingDocument1 pageHinge DrawingWeld Bro SandeepNo ratings yet

- Stroy of IndiaDocument2 pagesStroy of IndiaWeld Bro SandeepNo ratings yet

- Weld Inspection Check List: ChecklistDocument3 pagesWeld Inspection Check List: ChecklistMaheshkumar ManeNo ratings yet

- Regulamentul UE 305.2011 ENGLEZADocument39 pagesRegulamentul UE 305.2011 ENGLEZAhalexing5957No ratings yet

- Lined Portrait A4 College PDFDocument1 pageLined Portrait A4 College PDFWeld Bro SandeepNo ratings yet

- NDT Methods NotesDocument1 pageNDT Methods NotesWeld Bro SandeepNo ratings yet

- German WordsDocument1 pageGerman WordsWeld Bro SandeepNo ratings yet

- General Familiarity With Other NDT Methods Module 5Document4 pagesGeneral Familiarity With Other NDT Methods Module 5Weld Bro SandeepNo ratings yet

- General Familiarity With Other NDT Methods Module 7Document3 pagesGeneral Familiarity With Other NDT Methods Module 7Weld Bro SandeepNo ratings yet

- FIKE RD Combo With Relief ValvesDocument11 pagesFIKE RD Combo With Relief ValvesAnkit GandhiNo ratings yet

- OrlDocument186 pagesOrlMuli MaroshiNo ratings yet

- Science 8-02.02 - Sensitivity in Living OrganismsDocument9 pagesScience 8-02.02 - Sensitivity in Living OrganismsAnoushia AhmerNo ratings yet

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- Tabcalcs.com general equations sheetDocument2 pagesTabcalcs.com general equations sheetRamadan RashadNo ratings yet

- Erasmus Rotterdam University MCDocument24 pagesErasmus Rotterdam University MCAndreea CroitoruNo ratings yet

- Week 7: Nurses Role in Disaster: Home Mitigation and PreparednessDocument10 pagesWeek 7: Nurses Role in Disaster: Home Mitigation and PreparednessRose Ann LacuarinNo ratings yet

- Genética, Modificaciones y MutacionesDocument12 pagesGenética, Modificaciones y MutacionespokemaniacoplancheNo ratings yet

- Pharmaceutical Ingredients and Excipient - LastpptDocument72 pagesPharmaceutical Ingredients and Excipient - LastpptFANTANo ratings yet

- 2a CTRL DecDocument75 pages2a CTRL Decramanathan balamoorthyNo ratings yet

- Parapsychology QP - WikiDocument371 pagesParapsychology QP - WikiAdamNo ratings yet

- Queer Ecology Critique - Georgetown 2014Document104 pagesQueer Ecology Critique - Georgetown 2014Evan JackNo ratings yet

- Pasture FatteningDocument15 pagesPasture FatteningKartika PurnamasariNo ratings yet

- Unit 4 Early HumansDocument8 pagesUnit 4 Early HumansSepfira ReztikaNo ratings yet

- CD 0400 CH 4 X 100 ML: For in Vitro Diagnostic Use Only. LinearityDocument1 pageCD 0400 CH 4 X 100 ML: For in Vitro Diagnostic Use Only. LinearityNguyễn ThơiNo ratings yet

- MX 201110 enDocument1,203 pagesMX 201110 envajrahastaNo ratings yet

- EE 102 Cabric Final Spring08 o Id15Document10 pagesEE 102 Cabric Final Spring08 o Id15Anonymous TbHpFLKNo ratings yet

- When Ceramic Sociology Meets Material SCDocument10 pagesWhen Ceramic Sociology Meets Material SCJosé Renato TeixeiraNo ratings yet

- Sabp X 002Document18 pagesSabp X 002Hassan MokhtarNo ratings yet

- Mechatronics Test Questions Set - 1Document13 pagesMechatronics Test Questions Set - 1ChippyVijayanNo ratings yet

- Sampling and Field Testing at Wastewater Treatment FacilitiesDocument11 pagesSampling and Field Testing at Wastewater Treatment FacilitiesSundarapandiyan SundaramoorthyNo ratings yet

- Eutelsat 12 West A Satellite FootprintDocument2 pagesEutelsat 12 West A Satellite FootprintSkybrokersNo ratings yet

- 2GIG KEY2 345 Install GuideDocument2 pages2GIG KEY2 345 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- General Biology 1: Go Fast, or Slow Down?Document23 pagesGeneral Biology 1: Go Fast, or Slow Down?Mikhael OiraNo ratings yet

- 09 Exp 11 Buffer SolutionsDocument8 pages09 Exp 11 Buffer SolutionsShainmaugne AdvientoNo ratings yet

- NTPC Training ReportDocument83 pagesNTPC Training ReportAbhishek Mittal100% (2)

- 14-Friedel Crafts Acylation FerroceneDocument10 pages14-Friedel Crafts Acylation FerroceneNguyen Minh Duc100% (1)

- Shock Classification and PathophysiologyDocument40 pagesShock Classification and PathophysiologyErick Anca100% (2)

- F825 - Hotcakes Baby Cardigan FinalDocument2 pagesF825 - Hotcakes Baby Cardigan Finaladina100% (1)

- MetdsgffggDocument263 pagesMetdsgffggVishal Singh GaharwarNo ratings yet