Professional Documents

Culture Documents

STD PQR Format PDF

Uploaded by

vinoth0 ratings0% found this document useful (0 votes)

89 views2 pagesOriginal Title

STD PQR FORMAT.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

89 views2 pagesSTD PQR Format PDF

Uploaded by

vinothCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

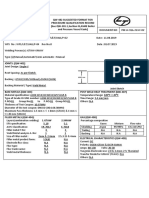

QW - 483

PROCEDURE QUALIFICATION RECORD

(PQR)

Procedure Qualification Record No.: _____________________________ Date : ___________

WPS No.: _______________________________________________________________________________

Welding Process(es): _____________________________________________________________________

Type (Manual, Automatic, Semi-Auto): _____________________________________________________

JOINTS : (QW-402)

Root Gap ---- 3 to 4 mm.

Root Face --- 0 to 1mm.

Included Angle - 70°

BASE METALS (QW-403) POST WELD HEAT TREATMENT(QW-407)

Material Spec.: __________________ Temperature °C: _________________

Type or Grade: __________________ Time: _ .

P.No. _ Gr _ to P.No. _ Gr. . Others: .

Thickness of Test Coupon (mm): _ _

Dia of Test coupon ( mm ): .

Others:

GAS : (QW-408)

% Flow

Gas(es) Composition rate

FILLER METALS : (QW-404) Mixture lit/min

Process Shielding

Weld Metal Analysis A.No. Trailing

Size of Filler Metal mm ∅ Backing

Filler Metal F.No.

SFA Specification

AWS Specification ELECTRICAL CHARACTERSTICS:(QW-409)

Deposited Weld Metal (mm) Current: _______

Pass Thickness(mm) Polarity: ______

Others Amps.: _________ Volts _____

Tungsten Electrode Type & Size ∅ mm:

Others:

POSITION :(QW-405) TECHNIQUE : (QW-410)

Position of Groove: ______ Travel Speed: _____________

Welding Progression: _______________ String or Weave Bead : _____________

Others: Oscillation: _____________

Single pass/Multipass _____________

Single/Multiple Electrode: _____________

PREHEAT :(QW-406) Others:

Preheat Temp. °C: ___________

Interpass Temp. °C: ___________

Others:

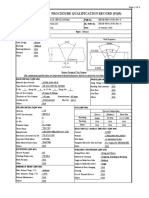

QW 483 PQR No.

TENSILE TEST (QW-150)

Specimen Width Thickness Area Ultimate total load UTS Type of failure and

No. (mm) (mm) (mm²) (kg.) (kg/mm²) location

GUIDED BEND TESTS (QW 160)

Type and Figure No. Results

TOUGHNESS TESTS (QW 170)

Specimen Notch Notch Test Avg. Impact Lateral Exp. Drop Weight

No. location Type Temp. °C Value kg-m % Shear Mils Break No Break

FILLET WELD TEST (QW 180) None

Result : Satisfactory Yes/No.

Macro Results:

Micro:

OTHER TESTS

Type of Test :

Deposit Analysis :

Others:

Welder’s Name : _____________________ T.No.: _____ Stamp No.: _______

Test Conducted by: _____________________. Lab Test No.: ______________________________

We certify that the statements in this record are correct and that the test welds were prepared, welded & tested

in accordance with the requirement of ASME Sect.IX 2001 addenda 2002

Date : Manufacturer :

By :

AUDITED BY :

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- STD PQR Format PDFDocument2 pagesSTD PQR Format PDFvinothNo ratings yet

- Suggested Weldin Lr. VijDocument4 pagesSuggested Weldin Lr. Vijmallik017100% (2)

- Sample Format: Sensitivity: LNT Construction Internal UseDocument2 pagesSample Format: Sensitivity: LNT Construction Internal UseKarthikNo ratings yet

- Tata Consulting Engineers Limited: P Q T R (PQR)Document2 pagesTata Consulting Engineers Limited: P Q T R (PQR)Rajat KoleyNo ratings yet

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 pageRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNo ratings yet

- WPS Format for Welding Procedure SpecificationDocument2 pagesWPS Format for Welding Procedure SpecificationKarthikNo ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- Procedure Qualification Records (PQR)Document2 pagesProcedure Qualification Records (PQR)amine algNo ratings yet

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- PQRDocument2 pagesPQRRavi KumaranNo ratings yet

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Document2 pagesCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemNo ratings yet

- Hard Facing OverlayDocument2 pagesHard Facing OverlayAmanSharmaNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- QW-483 PQR PROCEDURE QUALIFICATION RECORDDocument6 pagesQW-483 PQR PROCEDURE QUALIFICATION RECORDZam Zam NoorNo ratings yet

- WPS - Pre-Insulated PipesDocument4 pagesWPS - Pre-Insulated Pipesharis bhuttoNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- Welder Performance Qualifications (WPQ)Document1 pageWelder Performance Qualifications (WPQ)tayyabNo ratings yet

- WPS PQRDocument4 pagesWPS PQRGuillermo ZaragozaNo ratings yet

- QW483Document2 pagesQW483Sc TanNo ratings yet

- SWATHI PQR Procedure QualificationDocument10 pagesSWATHI PQR Procedure QualificationMustu AkolawalaNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- PQR ASME SECTION IX WELD PROCEDUREDocument6 pagesPQR ASME SECTION IX WELD PROCEDUREZam Zam NoorNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- WPQ Format Sec IxDocument2 pagesWPQ Format Sec IxParminder SinghNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- 003PQR P1&2 May 17 2018Document3 pages003PQR P1&2 May 17 2018Oliver CastroNo ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRvinodNo ratings yet

- PRN004Document2 pagesPRN004beyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument4 pagesQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- QW484Document1 pageQW484Anonymous 4e7GNjzGWNo ratings yet

- PQR Asme BlankDocument3 pagesPQR Asme Blankamirul8686No ratings yet

- Essential welding procedure qualification recordDocument2 pagesEssential welding procedure qualification recordmainur mechanical engineer0% (1)

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormTegar OktoberNo ratings yet

- WPS Gtaw) - 47Document2 pagesWPS Gtaw) - 47Dharmendra BhardwajNo ratings yet

- Ahp 2X660 (WPS) )Document17 pagesAhp 2X660 (WPS) )Hema NandhNo ratings yet

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationDocument6 pagesEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormAbhinandan BastiNo ratings yet

- AMRITA ENGINEERING WORKS PQRDocument3 pagesAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyNo ratings yet

- Qw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Document3 pagesQw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Zam Zam NoorNo ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Plates ASTM-A240 Gr 304LDocument6 pagesPlates ASTM-A240 Gr 304Labhishek198327No ratings yet

- WPQTDocument1 pageWPQTyousab creator2No ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)surjithkocherilNo ratings yet

- Welder Certificate Sample1Document1 pageWelder Certificate Sample1Buddy EkoNo ratings yet

- SAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Document2 pagesSAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Lovedeep SinghNo ratings yet

- Welding Procedure SpecificationDocument12 pagesWelding Procedure Specificationsanjay sharmaNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Batch Test CertificateDocument1 pageBatch Test CertificatevinothNo ratings yet

- Trailers Division - Management ReviewDocument2 pagesTrailers Division - Management ReviewvinothNo ratings yet

- MTD SOP 17calibrationDocument2 pagesMTD SOP 17calibrationvinothNo ratings yet

- Project Review Meeting MinutesDocument4 pagesProject Review Meeting MinutesvinothNo ratings yet

- MTD SOP 16maintenanceDocument2 pagesMTD SOP 16maintenancevinothNo ratings yet

- MAMMUT TRAILER KPIsDocument3 pagesMAMMUT TRAILER KPIsvinothNo ratings yet

- MTD-QPF-08-05 Estimation of Job Cost Tool R1 - 27-08-06Document1 pageMTD-QPF-08-05 Estimation of Job Cost Tool R1 - 27-08-06vinothNo ratings yet

- Customer satisfaction survey results analysisDocument2 pagesCustomer satisfaction survey results analysisvinothNo ratings yet

- MTD - SOP.18-Masterlog v0Document5 pagesMTD - SOP.18-Masterlog v0vinothNo ratings yet

- MTD-QPF-09-03 MI Manpower Availibility RegisterJuly 2006 - Jan 2007Document5 pagesMTD-QPF-09-03 MI Manpower Availibility RegisterJuly 2006 - Jan 2007vinothNo ratings yet

- MTD-QPF-05-01 Customer Satisfaction Survey ScopeDocument1 pageMTD-QPF-05-01 Customer Satisfaction Survey ScopevinothNo ratings yet

- Mammut Trailer Division: Quality Objectives F 2006-2007 IMPROVED COMMUNICATIONDocument4 pagesMammut Trailer Division: Quality Objectives F 2006-2007 IMPROVED COMMUNICATIONvinothNo ratings yet

- Preventive Action Form for Quality IssuesDocument1 pagePreventive Action Form for Quality IssuesvinothNo ratings yet

- MTD-QPF-07-01a Management Skill Set AssessmentDocument1 pageMTD-QPF-07-01a Management Skill Set AssessmentvinothNo ratings yet

- MTD-QPF-08-08 Drawing Change Request FormDocument1 pageMTD-QPF-08-08 Drawing Change Request FormvinothNo ratings yet

- MTD-QPF-09-01 Annual Recruitment PlanDocument6 pagesMTD-QPF-09-01 Annual Recruitment PlanvinothNo ratings yet

- MTD-QPF-08-07 Master List of DrawingDocument3 pagesMTD-QPF-08-07 Master List of DrawingvinothNo ratings yet

- Welding Traceability ReportDocument1 pageWelding Traceability ReportvinothNo ratings yet

- Non Conformity Report and Corrective, Preventive Action RequestDocument1 pageNon Conformity Report and Corrective, Preventive Action RequestvinothNo ratings yet

- Production Stores Voucher MTD - QF - 12 - 02 Pre Printed BookDocument1 pageProduction Stores Voucher MTD - QF - 12 - 02 Pre Printed BookvinothNo ratings yet

- MTD-QSP-09 Manpower PlanningDocument2 pagesMTD-QSP-09 Manpower PlanningvinothNo ratings yet

- MTD QF 17 01calibrationDocument1 pageMTD QF 17 01calibrationvinothNo ratings yet

- NCR Log Book With GraphDocument3 pagesNCR Log Book With GraphvinothNo ratings yet

- Mounting of Brake System MTD-QF-01-01-dDocument1 pageMounting of Brake System MTD-QF-01-01-dvinothNo ratings yet

- Audit Schedule: Audit No.: - Date Time Department/Section AuditorDocument1 pageAudit Schedule: Audit No.: - Date Time Department/Section AuditorvinothNo ratings yet

- Ocs Engineering & Construction (India) PVT LTD: Quality Assurance DepartmentDocument1 pageOcs Engineering & Construction (India) PVT LTD: Quality Assurance DepartmentvinothNo ratings yet

- MGRP-OTD-R-01 Training Request Form - Doc 2011Document2 pagesMGRP-OTD-R-01 Training Request Form - Doc 2011vinothNo ratings yet

- Non-Conformity Report FormDocument1 pageNon-Conformity Report FormvinothNo ratings yet

- Quality Assembly Plan: If This Is A Paper Copy, It Is Uncontrolled. You Must Verify The On-Line Revision Before UsingDocument2 pagesQuality Assembly Plan: If This Is A Paper Copy, It Is Uncontrolled. You Must Verify The On-Line Revision Before UsingvinothNo ratings yet

- Mammut Group employee training requestDocument3 pagesMammut Group employee training requestvinothNo ratings yet

- ITP For Plumbing & Drainage SystemDocument97 pagesITP For Plumbing & Drainage Systemmagdi badran100% (7)

- Repair Manual Genesis 200 CLS-GBDocument59 pagesRepair Manual Genesis 200 CLS-GBMARCEL1300No ratings yet

- 01 Samss 039Document14 pages01 Samss 039azhar enggNo ratings yet

- 8 Chapter 4 Manufacturing Processes FinalDocument6 pages8 Chapter 4 Manufacturing Processes Finalyogesh vNo ratings yet

- Manual de Servicio dv26Document505 pagesManual de Servicio dv26Servi PadNo ratings yet

- New Fulcrum Canopies - Structural Drawings - PermitDocument6 pagesNew Fulcrum Canopies - Structural Drawings - PermitJorge Alnerto Perez SanchezNo ratings yet

- An Introduction To Security Fences R1Document37 pagesAn Introduction To Security Fences R1miguel fuentesNo ratings yet

- GMAW Manual ME 374 LabDocument2 pagesGMAW Manual ME 374 LabAjay KotwalNo ratings yet

- Abr Sinai Onshore Gas Pipeline PDFDocument42 pagesAbr Sinai Onshore Gas Pipeline PDFhamza2085100% (1)

- PQRDocument2 pagesPQRHoangNo ratings yet

- Burns Catalog Online PDFDocument19 pagesBurns Catalog Online PDFjlee_296737No ratings yet

- Dissimilar Metal Welding CrackingDocument10 pagesDissimilar Metal Welding CrackingMohd SyafiqNo ratings yet

- Design Scheme for Temporary Trestle and Boring Platform ConstructionDocument21 pagesDesign Scheme for Temporary Trestle and Boring Platform ConstructionKhandaker Khairul AlamNo ratings yet

- Steel Fabrication Method StatementDocument13 pagesSteel Fabrication Method StatementAfiq JamalNo ratings yet

- Titanium For Subsea and Offshore Industry CatalogueDocument68 pagesTitanium For Subsea and Offshore Industry CatalogueDAVID DINGNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)surjithkocherilNo ratings yet

- Stcs - RCM: Shrinking Tube Control SystemDocument2 pagesStcs - RCM: Shrinking Tube Control SystemAhmed BenmimounNo ratings yet

- Installation: +91 22 2872 8691 WWW - Technonicol.in Info@technonicol - inDocument1 pageInstallation: +91 22 2872 8691 WWW - Technonicol.in Info@technonicol - injaswinder singhNo ratings yet

- B.Tech 3rd Sem Exam Scheme Mechanical EngineeringDocument144 pagesB.Tech 3rd Sem Exam Scheme Mechanical EngineeringPrad UpNo ratings yet

- Welding Hand BookDocument434 pagesWelding Hand BookavmrNo ratings yet

- Field Engineering Limited: Ogabiri Gas Gathering ProjectDocument27 pagesField Engineering Limited: Ogabiri Gas Gathering ProjectAry PutraNo ratings yet

- Hitronic TIG 300A DC Inverter Welding Machine - Goldpeak Tools PH PDFDocument5 pagesHitronic TIG 300A DC Inverter Welding Machine - Goldpeak Tools PH PDFRodney LanagNo ratings yet

- Gfps 9200 Brochure CNC Automated Butt Fusion Machine Line enDocument8 pagesGfps 9200 Brochure CNC Automated Butt Fusion Machine Line enMohammed sabatinNo ratings yet

- Welder performance technique inspection and control certificateDocument1 pageWelder performance technique inspection and control certificatebouchoucha jebaliNo ratings yet

- STR1 T080 8Document1 pageSTR1 T080 8Suntech Testing Limited STLNo ratings yet

- Ferrous Alloys: Revised: October 1980 AuthorDocument36 pagesFerrous Alloys: Revised: October 1980 AuthorsunsirNo ratings yet

- Komatsu Motor Grader Gd655 3c Shop ManualDocument20 pagesKomatsu Motor Grader Gd655 3c Shop Manualwalter100% (19)

- The Effect of Repeated Repair Welding On Mechanical and Corrosion Properties of Stainless Steel 316LDocument12 pagesThe Effect of Repeated Repair Welding On Mechanical and Corrosion Properties of Stainless Steel 316LRami GhorbelNo ratings yet

- Resistance Welding: Introduction and Recent Developments: S. Tripathy & Ajitav SahooDocument6 pagesResistance Welding: Introduction and Recent Developments: S. Tripathy & Ajitav SahooTJPRC PublicationsNo ratings yet

- Wrought Seamless and Welded and Drawn Cobalt Alloy Small Diameter Tubing For Surgical Implants (UNS R30003, UNS R30008, UNS R30035, UNS R30605, and UNS R31537)Document5 pagesWrought Seamless and Welded and Drawn Cobalt Alloy Small Diameter Tubing For Surgical Implants (UNS R30003, UNS R30008, UNS R30035, UNS R30605, and UNS R31537)Ahmad Zubair RasulyNo ratings yet