Professional Documents

Culture Documents

003PQR P1&2 May 17 2018

Uploaded by

Oliver CastroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

003PQR P1&2 May 17 2018

Uploaded by

Oliver CastroCopyright:

Available Formats

QW-112 PROCEDURE QUALIFICATION RECORDS (PQR)

Records Actual Variables Used to Weld Test Coupon

E: ____JTOM CONSTRUCTION __________

Procedure Qualification Record No. JTOM-003-19TR Date:

WPS No. __ JTOM-003-19__________ ____

Welding Process __ GTAW _______________ _______

Type (Automatic, Manual, Machine, or Semi- Automatic) ______MANUAL_____________________________________________

JOINTS (QW-402)

JOINT DESIGN: __BUTT, GROOVE, FILLET________

BACKING ________WITH OR WITHOUT_______

A = 30˚±5

B = 3.05mm

C = 2 to 4mm

D = 1.2mm

Groove Design Test Coupon

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal and process used.

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Specification _____ASTM, 240, A304, A312, tp 316L___ Temperature _______ _N/A____________________________

Type/Grade or UNS Number _____or EQUIVALENT________________ Time _________ N/A____________________________

P-No _8 _ Group No _1 _ to P-No _8 _ Group No _1 _ Other ________ N/A____________________________

Thickness of Test Coupon _____3.05mm______________________

Diameter of Test Coupon _____2” DIA._______________________ GAS (QW-408)

Maximum Pass Thickness ____ <1/2 inch(13mm)_______________

Other ____ NONE___________________________________ Percent Composition

(GAS) (Mixture) Flow Rate

1 2 Shielding _ARGON __99.99%____ _8-22cfh___

Trailing __N/A__ __N/A_____ __ N/A_ ___

SFA 5.9

Backing _ARGON __99.99%____ _8-28cfh___

ER316L Others _NONE_ __N/A_____ __ N/A_ ___

F6

N/A

2.4mm ELECTRICAL CHARACTERISTICS (QW-409)

Current ____ DIRECT CURRENT________________

N/A Polarity ____ _DCSP_________________________

N/A Amps. 80-120_ Volt: 10-28______________________

N/A Tungsten Electrode Size ____2.4mm_ _____________

Mode of Metal Transfer of GMAW, FCAW N/A_______

N/A

Head Input ____ N/A________________________

N/A Other ____ N/A__________________________

3.05mm

NONE TECHNIQUE (QW-410)

FILLER METALS (QW-404) Travel Speed ____ GTAW 50-100mm/sec.______

String or Weave Bead _ String or Weave _______

SFA Specification

Oscillation ____ _____ N/A_______________

AWS Classification Multipass or Single Pass (per side) _ Multiple___

Single or Multiple Electrodes _ Single_______

Filler Metal F No Other ____ NONE______________________

Weld Metal Analysis A-No

Size of Filler Metal

Filler Metal Product Form

JTOM © 2019 All rights reserved.

Supplemental Filler Metal

Electrode Flux Classification

Flux Type

Flux Trade Name

Weld Metal Thickness

Other

POSITION (QW-405)

Position of Groove ____ ____ _ 6G______________________

Weld Progression (Uphill, Downhill) ____ ___UPHILL__________

Other ___________ __________________NONE___________

PREHEAT (QW-406)

Preheat Temperature _____________ 0˚C___________________ BACK WELDING CAN BE DONE ACCESIBLE JOINTS & WHEN

Interpass Temperature ______ _____150˚C___________________ NECESSARY. GRIND TO SOUND METAL PRIOR TO BACK WELDING

QW-483

PQR NO: EAT-002-18

TENSILE TEST

CHARACTER OF FAILURE AND

SPECIMEN NO. WIDTH THICKNESS ULTIMATE TENSILE ULTIMATE UNIT

LOCATION

T1

T2

GUIDED BEND TEST (QW-160)

SPECIMEN NO. BEND ANGLE RESULT LOCATION

ROOTBEND-1 180º

ROOTBEND-2 180º

FACEBEND-1 180º

FACEBEND-1 180º

NOTCH IMPACT VALUES

SPECIMEN SPECIMEN TEST

LOCATI Mils (in. or DROP WEIGHT BREAK (Y/N)

NO. SIZE TEMPERATURE Ft-lv or J % Shear

ON mm)

JTOM © 2019 All rights reserved.

Comments ______________________________________________________________________________________________________

Butt Weld Test (QW-180)

Result-Satisfactory YES NO Penetration into Parent Metal YES NO

Micro Results ___________________________________________________________________________________________________

Other Tests

Type of Test ____________RADIOGRAPHY - ____________

Deposit Analysis _________________________________________________________________________________________________

Other __________________________________________________________________________________________________________

Welder’s Name ____________ ___________________________________

Test Conducted by: __Inwelco Laboratory Services_ Date: __ _ Laboratory Test: __ _

__ _

We, the undersigned, certify that the statement in this record are correct and the test welds were prepared, welded, and tested in

accordance with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code

_ COMPANY JTOM___ ___COMPANY : JTOM___ ___ ___

Welding Inspector Manufacturer/ Contractor Fabrication Head

__Engr. FRED T. PARUNGAO___ ___Engr. OLIVER CASTRO___ ___Engr. JONATHAN TUMNOB___

Test and Conducted by: Prepared by: Approved by:

(Details of record of tests are illustrative only and may be modified to conform to the type and number of tests required by the code.)

JTOM © 2019 All rights reserved.

You might also like

- Digital Transformation in The Insurance IndustryDocument16 pagesDigital Transformation in The Insurance IndustryChafî Red100% (1)

- Sa 479Document12 pagesSa 479negg 348100% (1)

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Document2 pagesCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemNo ratings yet

- AslnDocument2 pagesAslng6vhdytsyzNo ratings yet

- WPS - Pre-Insulated PipesDocument4 pagesWPS - Pre-Insulated Pipesharis bhuttoNo ratings yet

- Suggested Weldin Lr. VijDocument4 pagesSuggested Weldin Lr. Vijmallik017100% (2)

- Sample Format: Sensitivity: LNT Construction Internal UseDocument2 pagesSample Format: Sensitivity: LNT Construction Internal UseKarthikNo ratings yet

- FM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)Document2 pagesFM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)tayyabNo ratings yet

- Uail - Pin Li-Cqa-213-F-01 WPS FormatDocument2 pagesUail - Pin Li-Cqa-213-F-01 WPS FormatKarthikNo ratings yet

- Welder Performance Qualifications (WPQ)Document1 pageWelder Performance Qualifications (WPQ)tayyabNo ratings yet

- Sample: Exhibit 1 Exhibit 1Document1 pageSample: Exhibit 1 Exhibit 1jessy eghNo ratings yet

- PQRDocument2 pagesPQRRavi KumaranNo ratings yet

- Welding Procedure Specification (WPS) : BackingDocument1 pageWelding Procedure Specification (WPS) : BackingtimkemperNo ratings yet

- QW-482 WPS BlankDocument2 pagesQW-482 WPS Blankj29mahonNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document4 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Rizaldy PhoenksNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- 3G Rev-0-D1 - 2 - AL-PQRDocument2 pages3G Rev-0-D1 - 2 - AL-PQRAhmed GomaaNo ratings yet

- 2G Rev-0-D1 - 2 - AL - PQRDocument2 pages2G Rev-0-D1 - 2 - AL - PQRAhmed GomaaNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- Wps Short FormDocument2 pagesWps Short FormsrinivasanNo ratings yet

- JushDocument2 pagesJushg6vhdytsyzNo ratings yet

- L2 WPSDocument1 pageL2 WPSBernardo LeorNo ratings yet

- Joint (QW-402)Document3 pagesJoint (QW-402)MuhammadNajibNo ratings yet

- Form N 2 Sample Welding Procedure SpecificationDocument1 pageForm N 2 Sample Welding Procedure SpecificationViswanath SreepadaNo ratings yet

- WPS TemplateDocument1 pageWPS TemplateMatt De Hoog100% (1)

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- WPS VarillaDocument2 pagesWPS Varillalabingles89No ratings yet

- GTAW SMAW 6 Inch CSDocument1 pageGTAW SMAW 6 Inch CSKentDemeterioNo ratings yet

- Tata Consulting Engineers Limited: P Q T R (PQR)Document2 pagesTata Consulting Engineers Limited: P Q T R (PQR)Rajat KoleyNo ratings yet

- M/S SPML Infra LTDDocument6 pagesM/S SPML Infra LTDyouuuuyNo ratings yet

- Welding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) YesDocument4 pagesWelding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) Yesvarun100% (1)

- Hard Facing OverlayDocument2 pagesHard Facing OverlayAmanSharmaNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- STD PQR Format PDFDocument2 pagesSTD PQR Format PDFvinothNo ratings yet

- STD PQR Format PDFDocument2 pagesSTD PQR Format PDFvinothNo ratings yet

- WPS - Sample - Form D17.1 D17.1M 2010Document1 pageWPS - Sample - Form D17.1 D17.1M 2010Mohammed AzizNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- SGB WPS Al 01Document2 pagesSGB WPS Al 01Ahmed GomaaNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- WPS PQRDocument4 pagesWPS PQRGuillermo ZaragozaNo ratings yet

- Nuclear Power Corporation of India Litd.: Quality Assurance GroupDocument4 pagesNuclear Power Corporation of India Litd.: Quality Assurance GroupviswamanojNo ratings yet

- Power Express Pre-Install Checklist V5.0Document14 pagesPower Express Pre-Install Checklist V5.0Victor Angeles Chauca HuamaniNo ratings yet

- L3 PQRforQualificationDocument1 pageL3 PQRforQualificationBernardo LeorNo ratings yet

- Brazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Document3 pagesBrazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Joyce GordonioNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Form N 3 Sample Procedure Qualification RecordDocument1 pageForm N 3 Sample Procedure Qualification RecordViswanath SreepadaNo ratings yet

- Wps Magi Tig ExempleDocument6 pagesWps Magi Tig ExempleDanem HalasNo ratings yet

- WPS Marquez Noroña ProañoDocument7 pagesWPS Marquez Noroña Proañodennis carreraNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 3 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 3 FillableNavanitheeshwaran SivasubramaniyamNo ratings yet

- B2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormDocument1 pageB2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormtuanNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDocument2 pagesB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- 95-00 JA Stratus CirrusDocument7 pages95-00 JA Stratus CirrusapoogeumtraxNo ratings yet

- Form O-5-Welder and Welding Operator Qualification RecordDocument1 pageForm O-5-Welder and Welding Operator Qualification Recordedinson castrilloNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- E06-X04 - 2 Motors, DC Data SheetDocument3 pagesE06-X04 - 2 Motors, DC Data SheetMuhammad IrfanNo ratings yet

- Chikonhi T - Lecture Presentation (Target Costing)Document15 pagesChikonhi T - Lecture Presentation (Target Costing)stuntNo ratings yet

- 2022 - Module 02 - Chapter 16 - Lean Production - Questions 16-8&16-17&16-19&16-29Document3 pages2022 - Module 02 - Chapter 16 - Lean Production - Questions 16-8&16-17&16-19&16-29krushen galaNo ratings yet

- Total Cost of Ownership in The Services Sector A Case Study PDFDocument12 pagesTotal Cost of Ownership in The Services Sector A Case Study PDFfayyazhussainNo ratings yet

- Suskin & Hall: Responding To The Crisis-Reengineering Court Governance and StructureDocument35 pagesSuskin & Hall: Responding To The Crisis-Reengineering Court Governance and StructureNew England Law ReviewNo ratings yet

- Objectives and Goals of Auditing Vendors and Production DepartmentDocument15 pagesObjectives and Goals of Auditing Vendors and Production DepartmentFfwms SpainNo ratings yet

- Lecture1!1!25337 - Zero Lecture B2B MarketingDocument23 pagesLecture1!1!25337 - Zero Lecture B2B MarketingVijay TushirNo ratings yet

- Competitive Analysis: Professor David H. HsuDocument7 pagesCompetitive Analysis: Professor David H. HsuRidhya MahajanNo ratings yet

- Cores, Chaplets and Chills: AdditivesDocument10 pagesCores, Chaplets and Chills: AdditivesGandi GahanNo ratings yet

- B2BDocument244 pagesB2BJesus ZepedaNo ratings yet

- Product DesignRegal MarineDocument3 pagesProduct DesignRegal MarineSan Hlaing OoNo ratings yet

- Porters Five Forces Model Vodafone JAY PRAJAPATIDocument12 pagesPorters Five Forces Model Vodafone JAY PRAJAPATIJay PrajapatiNo ratings yet

- Evolution of Materials ManagementDocument10 pagesEvolution of Materials Managementvinaycool12344150100% (2)

- Marketing Mms Batch 2023Document40 pagesMarketing Mms Batch 2023Sameer GokhaleNo ratings yet

- OIC R12.1.3 Implementation GuideDocument178 pagesOIC R12.1.3 Implementation GuidedhamodarannNo ratings yet

- Machine Tools Stock ListDocument10 pagesMachine Tools Stock ListElectro Motion UK (Export) LtdNo ratings yet

- Google Adwords Campaign ManagementDocument3 pagesGoogle Adwords Campaign ManagementmaroNo ratings yet

- Case Study Robust LaptopsDocument2 pagesCase Study Robust LaptopsUmar KhattakNo ratings yet

- Demand Flow Technology and TAKTDocument40 pagesDemand Flow Technology and TAKTgokulNo ratings yet

- New Look Annual Report 2021 22Document98 pagesNew Look Annual Report 2021 22Subhrajyoti DuarahNo ratings yet

- Evolution To Global MarketingDocument6 pagesEvolution To Global Marketingmohittiwarimahi100% (2)

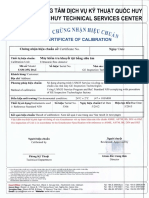

- C/rU G: Trung Tam Dich Vu HUY Quochuy Technical Services CenterDocument4 pagesC/rU G: Trung Tam Dich Vu HUY Quochuy Technical Services CenterPhan PhungNo ratings yet

- Lesson 1 Introduction To Agricultural MarketingDocument3 pagesLesson 1 Introduction To Agricultural MarketingSittie Ainah MacapundagNo ratings yet

- Product and Service DesignDocument60 pagesProduct and Service DesignGlobal internetNo ratings yet

- UoN - ECON1001 Microeconomics For Business Decisions NotesDocument122 pagesUoN - ECON1001 Microeconomics For Business Decisions NotesJia Wei MiaoNo ratings yet

- Supply Chain Resilience Strategy PDFDocument5 pagesSupply Chain Resilience Strategy PDFpraveenaNo ratings yet

- Consumer Usage Behaviour and Clients Satisfaction Among Internet Users in PanaboDocument3 pagesConsumer Usage Behaviour and Clients Satisfaction Among Internet Users in PanaboJenver GaviloNo ratings yet

- Week 6 QuestionsDocument10 pagesWeek 6 QuestionsChandan BcNo ratings yet