Professional Documents

Culture Documents

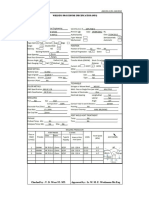

Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Uploaded by

Rizaldy PhoenksOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Uploaded by

Rizaldy PhoenksCopyright:

Available Formats

QW-482 WELDING PROCEDURE SPECIFICATIONS (WPS)

(See QW-200.1 , Section IX, ASME Boiler and Pressure Vessel Code)

Company Name:_____Mechanical Engineering__________By:___ _____M.ABDL GHOZI

Welding Procedure Specification No.: ________1______ Date: ___17 febuari 2020__________Supporting PQR No.

(s)_____1________

Welding process : SMAW Type : MANUAL

JOINTS (QW-402) Details

Joints Design: __V GROOVE_ ____________________

Backing: ____YES_______________________

Baking Material (Type) ______NA__________

Metal xx Nonfusing Metal

Nonmetallic Other

BASE METAL (QW-403)

P-No._____8_________ Group No. _____1________ to P-NO. ____8______ Group No. ____1__________

OR

Specification Type and Grade: SA 240 303______________________________________________________

to Specification Type and Grade: ___SA 240 Gr 304_______________________________________________

OR

Chem. Analysis and Mech. Prop.___________NA________________________________________________

to Chem. Analysis and Mech. Prop. ____________NA____________________________________________

Thickness Range:

Base Metal:10

Groove_______60____________________Fillet______NA_________________________

Other____________NA__________________________________________________________________

FILLER METALS (QW-404)

Spec. No. (SFA) _______5,4______________________________________________________________

AWS No. (Class) _E 308 L-17_______________________________________________________________

F-No. _______________5___________________________________________________________________

A-No. _________________8_________________________________________________________________

Size of Filler Metals _____2,5________________________________________________________________

Weld Metal

Groove _____V-GEROOVE___________________________________________________________

Fillet ____________________________________________________________________________

Electrode-Flux (Class) _______E 308 L-17______________________________________________________

Flux Trade Name ____________ESAB_________________________________________________________

Consumable Insert _______________________________________________________________________

Other _________________________________________________________________________________

WPS No. ________1_________Rev. ___________

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove ________3 G_________________ Temperature Range _____850-1100C_______________

Welding Progression: ____UP: YES________________ Time Range ___________________________________

Positions of Fillet ______NA____________________

PREHEAT (QW-406) Gas (QW-408)

Preheat Temp. Min. __________NA_______________ Percent Composition

Interpass Temp. Max. _________NA______________ Gas(es) Mixture Flow Rate

Preheat Maintenance _________NA______________ Shielding ____NA__ __NA______ ___NA_____

(Continuos of special heating, Where applicable, Should be recorded) Trailling ____NA__ ___NA_____ ____NA__

Backing ____NA_ _____NA____ _NA__

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC _______DC____________________Polarity ____EN(root)Dan EP_________________________

Amps (Ranged) ____45-120_____________________Volts (range) _____22-28_______________________

(Amps and volts range should be recorded for each electrode size, positions and thickness, etc. This information may be listed in a tubular form similar to that

shown below.)

Tungsten Electrode Size and type ____________________NA__________________________________________

Mode of Metal Transfer for SMAW ___________________NA__________________________________________

Electrode Wire Feed Speed Range _________________NA____________________________________________

TECHNIQUE (QW-410)

String or Weave Bead _________Stringer and weaving_______________________________________________

Orifice or Gas Cup Size ___________NA_________________________________________________________

Initial and Interpass Cleaning (Brushing, Grinding, etc.) ___________Grinding__________________________

Method of Back Gousing ___________NA________________________________________________________

Oscillation ______________________NA__________________________________________________________

Contact Tube to Work Distance ______NA________________________________________________________

Multiple or Single Pass (Per side) ___single pass_____________________________________________________

Travel Speed (Range) __________4-10cm/min__________________________________________________

Peening _____________________NA______________________________________________________

Other ______________________NA_____________________________________________________________

Filler Metal Current Other

(e.g.

Remarks,

Comments,

Weld Volt Travel Speed Hot Wire

Process Type / Amp

Layer(s) Class Diameter Range Range addition,

Polarity Range Technique,

Torch

Angle,

etc. )

1 Smaw E308L-17 2,4 DCEN

45,70 22-25 4-10CM/MIN

2 Smaw E308L-17 3,2 DCEP

70-120 22-28 4-10CM/MIN

3 Smaw E308L-17 3,2 DCEP

70-120 22-28 4-10CM/MIN

4 Smaw E308L-17 3,2 DCEP

70-120 22-28 4-10CM/MIN

5 Smaw E308L-17 3,2 DCEP

70-120 22-28 4-10CM/MIN

6 Smaw E308L-17 3,2 DCEP

70-120 22-28 4-10CM/MIN

Checked By Approved By

V.D.Waas,ST.MT Ir. W.M.E.WATTIMENA,MS.Eng

For, A-Cast Alloy.

PROCEDURE QUALIFICATION RECORDS (PQR)

(See QW-200.2, Section IX, ASM E Boiler and Pressure Vessel Code)

Company Name: ___Mechanical engineering_______ ______________ ____________

Procedure Qualification Record No. ___________1________________Date: ____________________________

WPS No. 1/WPS/STTL/2020_________________________________________

Welding Process(es) _______________SMAW_______________________________________________________

Type (Manual, Automatic, Semi-Automatic) _____________MANUAL__________________________________

JOINTS(QW420)

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Spec.: ________SA-240__________________ Temperature: __________________________________

Type of Grade: ________340_____________________ Time: _________________________________________

P-No. _________8________to P-No. ________8_______ Other: ________________________________________

Thicknessof Test Coupo n ___10mm_______________

Diameter of Test coupon ___na__________________

Other _____________na________________________

FILLER METALS (QW-404) Gas (QW-408)

SFA Specification ______________A.54_____________ Percent Composition

AWS Classification ________E308L-17_______________ Gas Mixture Flow rate

Filler Metal F-No. _______________5_______________ Shielding ___________ _____________ __________

Weld Metal Analysis A-No. _________8______________ Trailing ___________ _____________ __________

Size of Filler Metal ___________32________________ Backing ___________ _____________ __________

Other __________________na___________________

Weld Metal Thickness ___________na______________

POSITION (QW-405) ELECTRICAL CHARACTERISTICS (QW-409)

Position of Groove ______3G_____________________ Current___DC_______ Polarity ______DCEP_________

Weld Progression ____Uphil______________________ Amps. ____80________Volts _______24_____________

Other _____________na________________________ Tungsten Electrode Size _________na______________

Other ____________________na_________________

PREHEAT (QW-406) TECHNIQUE (QW-410)

Preheat Temperature _na_______________________ Travel Speed ______70mm/min___________________

Interpass temperature ___na____________________ String or Weave Bead __stinger____________________

Other ______________na_______________________ Oscillation ________a_________________________

Multipass or Single Pass (Per Side _Multipass_______

Single or Multiple Electrodes ___Multi Electrode_____

Other ____________na_________________________

PQR No. _____________Rev. ________

Tensile Test (QW-150)

Specimen No. Width Thickness Area Ultimate total Ultimate Unit Type of

mm2 load , N Stress, MPa Failure and

Location

1 19.16 24.91 477.276 232910 488 Weld area

2 19.10 25.15 480.365 235520 190.3 Weld area

Guided – Bend Tests (QW-160)

Type and figure No. QW-462.3 Results

Side Bend Side Bend Side Bend Side Bend

SB-1 SB-2 SB-3 SB-4

Mendril Dia.

Fillet Weld Test (QW-180)

Result – Satisfactory : Yes________ No________ Penetration into Parent Metal: Yes ____________ No__________

Other Test

Visual examination of Completed Test: ______________________________________________________________

Radiography Test: _______________________________________________________________________________

Type of test: ___________________________________________________________________________________

Deposit analysis: ________________________________________________________________________________

Other: ________________________________________________________________________________________

Welder’s Name: ________________________________________ Stamp No: _______________________________

Test Conducted By: ______________________________________________________________________________

Laboratory Test report No.: _______________________________________________________________________

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in

accordance with the requirements of section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Checked By Approved By

V.D.Waas,ST.MT Ir. W.M.E.WATTIMENA,MS.Eng

Catatan:

1. Ganti Jenis Huruf ke Times New Roman ukuran 12

2. Tolong lihat kembali WPQR-nya

You might also like

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- QW-482 WPS BlankDocument2 pagesQW-482 WPS Blankj29mahonNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- WPS - Pre-Insulated PipesDocument4 pagesWPS - Pre-Insulated Pipesharis bhuttoNo ratings yet

- FM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)Document2 pagesFM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)tayyabNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- 003PQR P1&2 May 17 2018Document3 pages003PQR P1&2 May 17 2018Oliver CastroNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- WPS PQRDocument4 pagesWPS PQRGuillermo ZaragozaNo ratings yet

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Document2 pagesCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemNo ratings yet

- 01 25284124-8230-26-104-0001 REV.02 Piping List CT1Document1 page01 25284124-8230-26-104-0001 REV.02 Piping List CT1Rajeev KumarNo ratings yet

- Uail - Pin Li-Cqa-213-F-01 WPS FormatDocument2 pagesUail - Pin Li-Cqa-213-F-01 WPS FormatKarthikNo ratings yet

- Wps Borang AdiDocument2 pagesWps Borang AdixernozaqilNo ratings yet

- Wps Borang AdiDocument2 pagesWps Borang AdixernozaqilNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- 01 - 25284124-8230-26-000-0004 - REV.02 - Piping - List - O & U UndergroundDocument2 pages01 - 25284124-8230-26-000-0004 - REV.02 - Piping - List - O & U UndergroundRajeev KumarNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Welder Performance Qualifications (WPQ)Document1 pageWelder Performance Qualifications (WPQ)tayyabNo ratings yet

- 01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InDocument2 pages01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InRajeev KumarNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- Hard Facing OverlayDocument2 pagesHard Facing OverlayAmanSharmaNo ratings yet

- Wps Magi Tig ExempleDocument6 pagesWps Magi Tig ExempleDanem HalasNo ratings yet

- 2 - Focus II C-307 DC Motor Sigma - IngDocument127 pages2 - Focus II C-307 DC Motor Sigma - IngMatias BruschiniNo ratings yet

- PQRDocument2 pagesPQRRavi KumaranNo ratings yet

- Suggested Weldin Lr. VijDocument4 pagesSuggested Weldin Lr. Vijmallik017100% (2)

- PreviewDocument20 pagesPreviewFarhatNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- AslnDocument2 pagesAslng6vhdytsyzNo ratings yet

- WPS - Sample - Form D17.1 D17.1M 2010Document1 pageWPS - Sample - Form D17.1 D17.1M 2010Mohammed AzizNo ratings yet

- Form N 2 Sample Welding Procedure SpecificationDocument1 pageForm N 2 Sample Welding Procedure SpecificationViswanath SreepadaNo ratings yet

- CMP 200 PD Form Rev KDocument2 pagesCMP 200 PD Form Rev KJIM DISIANo ratings yet

- Welding Procedure Specification (WPS) : BackingDocument1 pageWelding Procedure Specification (WPS) : BackingtimkemperNo ratings yet

- Power Express Pre-Install Checklist V5.0Document14 pagesPower Express Pre-Install Checklist V5.0Victor Angeles Chauca HuamaniNo ratings yet

- 3827-E10-063 - Modulating Control Valve - EDocument6 pages3827-E10-063 - Modulating Control Valve - EMohamed Elsaid El ShallNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- L2 WPSDocument1 pageL2 WPSBernardo LeorNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- 한벨스크류r22 rc2 tm - engDocument76 pages한벨스크류r22 rc2 tm - enggyeong gyu moonNo ratings yet

- Welding Procedure Specification (WPS) : Joints DesignDocument5 pagesWelding Procedure Specification (WPS) : Joints DesignvirnmontalesNo ratings yet

- CompresorDocument109 pagesCompresorhjmmNo ratings yet

- 2G Rev-0-D1 - 2 - AL - PQRDocument2 pages2G Rev-0-D1 - 2 - AL - PQRAhmed GomaaNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- 01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKDocument2 pages01 25284124-8230-26-000-0006 REV.02 Piping List EXISTING PIPE RACKRajeev KumarNo ratings yet

- Samsung (TDB) DVM S Idu Hidrokit He - HT enDocument32 pagesSamsung (TDB) DVM S Idu Hidrokit He - HT ensloba68No ratings yet

- Sample Format: Sensitivity: LNT Construction Internal UseDocument2 pagesSample Format: Sensitivity: LNT Construction Internal UseKarthikNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Mezz. Anchor Structural Technical Report Rev.01Document10 pagesMezz. Anchor Structural Technical Report Rev.01Mohanad EldarerNo ratings yet

- 3G Rev-0-D1 - 2 - AL-PQRDocument2 pages3G Rev-0-D1 - 2 - AL-PQRAhmed GomaaNo ratings yet

- WPS & PQR of Ravindra KumarDocument4 pagesWPS & PQR of Ravindra Kumartripatipankaj023No ratings yet

- 01 - 25284124-8230-26-000-0010 - REV.01 - Line List - C4 ImportDocument1 page01 - 25284124-8230-26-000-0010 - REV.01 - Line List - C4 ImportRajeev KumarNo ratings yet

- 01 25284124-8230-26-000-0011 REV.01 Piping List HCDSDocument1 page01 25284124-8230-26-000-0011 REV.01 Piping List HCDSRajeev KumarNo ratings yet

- WPS TemplateDocument1 pageWPS TemplateMatt De Hoog100% (1)

- CU Discus CopelandDocument4 pagesCU Discus Copelandahmed sanirNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Joint (QW-402)Document3 pagesJoint (QW-402)MuhammadNajibNo ratings yet

- BaseDocument7 pagesBaseOsamaNo ratings yet

- Placa Base ReporteDocument6 pagesPlaca Base ReporteJose Luis AnayaNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Rizaldy PhoenksNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Bgini KDocument1 pageBgini KRizaldy PhoenksNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- ASME Sec IX Baru FixDocument5 pagesASME Sec IX Baru FixRizaldy PhoenksNo ratings yet

- Auditing Welds Under ASME IX PDFDocument21 pagesAuditing Welds Under ASME IX PDFkbldamNo ratings yet

- Graycor WPS 19 Sample PDFDocument5 pagesGraycor WPS 19 Sample PDFRizaldy PhoenksNo ratings yet

- PLTS Basics - Edit - 12 - Oct19Document31 pagesPLTS Basics - Edit - 12 - Oct19Rizaldy PhoenksNo ratings yet

- Incoloy 800 Round BarDocument6 pagesIncoloy 800 Round BarAshok MehtaNo ratings yet

- Development of High Strength Construction RebarsDocument13 pagesDevelopment of High Strength Construction Rebarsosman recai100% (3)

- Cutting Tool Applications: by George Schneider, Jr. CmfgeDocument9 pagesCutting Tool Applications: by George Schneider, Jr. CmfgeyvanNo ratings yet

- Forging - Case Hardening For 1.5%Ni-Cr-Mo SteelsDocument8 pagesForging - Case Hardening For 1.5%Ni-Cr-Mo SteelsJaison JoseNo ratings yet

- Characteristics Properties and Uses in MetalDocument13 pagesCharacteristics Properties and Uses in MetalIvy DillaNo ratings yet

- HEKO Products and Services: Elements For Bucket ElevatorsDocument36 pagesHEKO Products and Services: Elements For Bucket ElevatorsShariq KhanNo ratings yet

- Steel Alloy Testing OpDocument14 pagesSteel Alloy Testing OpOm PrakashNo ratings yet

- Steel ShotDocument6 pagesSteel ShotExcel Hydro Pneumatics (INDIA) EHPINo ratings yet

- Continuos Steel Reheating Furnaces: Specification, Design and EquipmentDocument68 pagesContinuos Steel Reheating Furnaces: Specification, Design and EquipmentVishal Duggal83% (12)

- 14 Pelleting C-CU Pelletmill V004 PDFDocument4 pages14 Pelleting C-CU Pelletmill V004 PDFEwin Septian GunturNo ratings yet

- 9f Summary SheetsDocument3 pages9f Summary SheetsbanaliaNo ratings yet

- Clean Air enDocument6 pagesClean Air enHyundianto AgNo ratings yet

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDocument1 pageASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaNo ratings yet

- Company ProfileDocument100 pagesCompany ProfileASR MULTIMETALSNo ratings yet

- Engineering Materials Reviewer 3Document23 pagesEngineering Materials Reviewer 3Ronald O.No ratings yet

- Chaitanya IntroductionDocument7 pagesChaitanya Introductionanon_647217551No ratings yet

- Method Statement For Full Flushing ProcessDocument7 pagesMethod Statement For Full Flushing Processgökhan oğuzNo ratings yet

- John S. Page, Conceptual Cost Estimating ManualDocument350 pagesJohn S. Page, Conceptual Cost Estimating ManualIng Hardy Adjunta100% (29)

- FMC PDFDocument20 pagesFMC PDFAnggi SujiwoNo ratings yet

- Lecture - Week 2 - Introduction To SteelDocument49 pagesLecture - Week 2 - Introduction To SteelAhmed MaherNo ratings yet

- Liquid Level Gage Specification Guide PDFDocument30 pagesLiquid Level Gage Specification Guide PDFMark DeMateoNo ratings yet

- Norsok M-601 (Welding and Inspecrtion of Piping)Document24 pagesNorsok M-601 (Welding and Inspecrtion of Piping)John PaulNo ratings yet

- Project On Financial Management: Jaipuria Institute of Management, NoidaDocument24 pagesProject On Financial Management: Jaipuria Institute of Management, NoidaKanak TiwaryNo ratings yet

- Spring Manufacturing ProcessDocument4 pagesSpring Manufacturing ProcessUzma sijratNo ratings yet

- 107 - WELDOX - 700 - UK - Data SheetDocument2 pages107 - WELDOX - 700 - UK - Data SheetLuis AguilarNo ratings yet

- Planilla ComparativaDocument29 pagesPlanilla ComparativaAnthony Luis Zevallos PortilloNo ratings yet

- Nabl Scope TC 7876Document79 pagesNabl Scope TC 7876Kothiyal MukeshNo ratings yet

- Industrial Policy 1956,1991Document12 pagesIndustrial Policy 1956,1991Shri Ram Yadav80% (5)

- Safe Design and Operation of Cryogenic Enclosures: European Industrial Gases Association AisblDocument40 pagesSafe Design and Operation of Cryogenic Enclosures: European Industrial Gases Association AisblKevinNo ratings yet

- Do You Supply Similar Materials?: GB/T 699 Grade 20Document4 pagesDo You Supply Similar Materials?: GB/T 699 Grade 20saputraNo ratings yet