Professional Documents

Culture Documents

3G Rev-0-D1 - 2 - AL-PQR

Uploaded by

Ahmed GomaaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3G Rev-0-D1 - 2 - AL-PQR

Uploaded by

Ahmed GomaaCopyright:

Available Formats

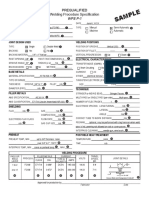

PROCEDURE QUALIFICATION RECORD (PQR)

AWS D1.2 Sixth Edition-2014

BE-PQR-04

Procedure Qualification Record no.______________________________________ 11 October 2020

Date ___________________

BE-WPS-04

WPS no. _____________________________ Process(es) GTAW

1. ___________________ 2. ___________________

Process(es) 1. ___________________ 2. ___________________

_______________________________________________________________________________________________

Design Sketch Welding Sequence Sketch

_______________________________________________________________________________________________

Base metals

Pass Process Travel

M21

Group no. ______________ M21

To _________________ No. No. Amps Volts Speed

1060

Alloy and Temper ________ 1060

To _________________ 1ST GTAW 86 12 15 ~ 20 cm/min

2 mm

Thickness ______________ 2 mm

To _________________

Filler metals

F23

F-number ____________________________________

ER4043

AWS class ___________________________________

2.4 mm

Diameter ____________________________________

Argon

Shielding gas(es) ______________________________

99.9%

Percent composition____________________________

15 Lit/Min.

Flow rate ____________________________________ 3 Phase

Type of welding power source _____________________

2.4mm-2%Thoriate

Tungsten electrode (GTAW) ______________________ _____________________________________________

2.4 mm

Size ________________________________________ Single

Single or multiple electrode _______________________

2%Thoriate

Type ________________________________________ Weave

Stringer or weave bead __________________________

N/A

Backup type __________________________________ AC

Welding current ________________________________

ac or dc

N/A

Alloy ________________________________________ Polarity ______________________________________

AC

Grinding

Backgouging _________________________________ Vertical (3G)

Position of groove ______________________________

_______________________________________________________________________________________________

Cleaning procedure initial Preheat

Grinding & Brushing

Oxide removal method __________________________ N/A

Preheat temperature ____________________________

Solvent

Degreasing agent______________________________ N/A

Interpass temperature ___________________________

Brushing

Cleaning procedure interpass __________________ _____________________________________________

Grinding

Smut removal _________________________________ N/A

Postweld heat treatment ________________________

Solvent

Dye penetrant removal ________________________ N/A

Original temper_________________________________

N/A

Final temper ___________________________________

N/A

Temperature ___________________________________

N/A

Time _________________________________________

N/A

Quench_______________________________________

Date: 11/10/2020 Doc. No. QA&QC/PQR-04

Page: 1 of 2 Rev.: 00

AWS D1.2/D1.2M:2008 ANNEX F

PROCEDURE QUALIFICATION RECORD (PQR)

AWS D1.2 Sixth Edition-2014

GROOVE WELD TEST

Specimen Ultimate Tensile Ultimate Unit Character of Failure

Width Thickness Area

No. Load, lb Stress, psi and Location

GUIDED BEND TEST

Type of Bend Bend Jig Fig. No. Result Type of Bend Bend Jig Fig. No. Results

Face Bend Figure 3.12 Pass

Face Bend Figure 3.12 Pass

Root Bend Figure 3.12 Pass

Root Bend Figure 3.12 Pass

Pass

Visual examination _____________________________ Pass __________________ Fail __________________

N/A

Type and character of failure _________________________________________________________________________

FILLET WELD TEST

Fracture test N/A

__________________________________ N/A

Root fusion ____________________________________

Pass or fail Yes or no

N/A

Macro test: Weld size and contour _________________ N/A

Penetration ____________________________________

Sat. or Unsat. Sat. or Unsat.

HESHAM HUSSEIN AHMED HASSAN ELSHEMY

Welder’s name ________________________________ 2364247136

Clock no. ______________ Stamp no.____________

BAHRA CABLES

Tests conducted by: ______________________________________________________________________ Laboratory

Test number __________________________________ Per:__________________________________________

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in

accordance with the requirements of Clause 4, AWS D1.2/D1.2M, Structural Welding Code—Aluminum.

Signed _______________________________________

Manufacturer

11 October 2020

Date ________________________________________ By ___________________________________________

Title _________________________________________

Date: 11/10/2020 Doc. No. QA&QC/PQR-04

Page: 2 of 2 Rev.: 00

You might also like

- WELD 2013 SMAW Lesson Plans and MaterialsDocument11 pagesWELD 2013 SMAW Lesson Plans and MaterialsFemi TokunboNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- Hacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)From EverandHacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)No ratings yet

- Welding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) YesDocument4 pagesWelding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) Yesvarun100% (1)

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDocument2 pagesB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- Welding BasicsDocument56 pagesWelding BasicsWONG TSNo ratings yet

- Practice Occupational Health and Safety (Week8)Document37 pagesPractice Occupational Health and Safety (Week8)Steph Phanie G. GomezNo ratings yet

- PQR From D17.1-D17.1M-2010Document1 pagePQR From D17.1-D17.1M-2010Mohammed AzizNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Sample PQRDocument2 pagesSample PQRudaysrp33% (3)

- GRE Chemistry: Inorganic Chemistry Review for GRE Chemistry Subject TestFrom EverandGRE Chemistry: Inorganic Chemistry Review for GRE Chemistry Subject TestNo ratings yet

- RENAULT Fault Codes DTC - Car PDF Manual, Wiring Diagram & Fault Codes DTCDocument19 pagesRENAULT Fault Codes DTC - Car PDF Manual, Wiring Diagram & Fault Codes DTCCristina Stoenescu50% (2)

- 3.0 Welding Imperfections and Material InspectionDocument38 pages3.0 Welding Imperfections and Material Inspectionthanhtung156100% (1)

- Fire Alarm System Inspection and Testing FormDocument4 pagesFire Alarm System Inspection and Testing FormBrahim SemariNo ratings yet

- Lab Manual WeldingDocument83 pagesLab Manual Weldingknizam1971No ratings yet

- Group 8, Welding AssignmentDocument11 pagesGroup 8, Welding AssignmentKavish ChandraNo ratings yet

- Brazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Document3 pagesBrazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Joyce GordonioNo ratings yet

- F4-WPS PQR Stud WeldingDocument1 pageF4-WPS PQR Stud WeldingBernardo LeorNo ratings yet

- Welders CertDocument11 pagesWelders CertAhmed GomaaNo ratings yet

- 200 Top Steam Boiler and Mechanical MCQs and 100 Power Plant MCQsDocument29 pages200 Top Steam Boiler and Mechanical MCQs and 100 Power Plant MCQsJuan Carlos Coca100% (1)

- 200 Top Steam Boiler and Mechanical MCQs and 100 Power Plant MCQsDocument29 pages200 Top Steam Boiler and Mechanical MCQs and 100 Power Plant MCQsJuan Carlos Coca100% (1)

- Boiler Exam Study Guide 1Document10 pagesBoiler Exam Study Guide 1TINHLAING100% (4)

- PQRDocument2 pagesPQRRavi KumaranNo ratings yet

- 2G Rev-0-D1 - 2 - AL - PQRDocument2 pages2G Rev-0-D1 - 2 - AL - PQRAhmed GomaaNo ratings yet

- SGB WPS Al 01Document2 pagesSGB WPS Al 01Ahmed GomaaNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- B2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormDocument1 pageB2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormtuanNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- WPS VarillaDocument2 pagesWPS Varillalabingles89No ratings yet

- AASHTO D1.5 welding procedure specificationDocument1 pageAASHTO D1.5 welding procedure specificationViswanath SreepadaNo ratings yet

- WPS TemplateDocument1 pageWPS TemplateMatt De Hoog100% (1)

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- Form O-5-Welder and Welding Operator Qualification RecordDocument1 pageForm O-5-Welder and Welding Operator Qualification Recordedinson castrilloNo ratings yet

- AWS D1.1 WELDING PROCEDURE ANNEXDocument2 pagesAWS D1.1 WELDING PROCEDURE ANNEXsrinivasanNo ratings yet

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Document2 pagesCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamNo ratings yet

- Welding Procedure Specification (WPS) : BackingDocument1 pageWelding Procedure Specification (WPS) : BackingtimkemperNo ratings yet

- L2 WPSDocument1 pageL2 WPSBernardo LeorNo ratings yet

- Sample: Exhibit 1 Exhibit 1Document1 pageSample: Exhibit 1 Exhibit 1jessy eghNo ratings yet

- WPS - Sample - Form D17.1 D17.1M 2010Document1 pageWPS - Sample - Form D17.1 D17.1M 2010Mohammed AzizNo ratings yet

- Form N 3 Sample Procedure Qualification RecordDocument1 pageForm N 3 Sample Procedure Qualification RecordViswanath SreepadaNo ratings yet

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Document2 pagesSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNo ratings yet

- D2000 - 02 - Failure ReportDocument1 pageD2000 - 02 - Failure ReportBartosz OgibowskiNo ratings yet

- AWS D1.1/D1.1M:2010 ANNEX N Magnetic Particle Inspection ReportDocument1 pageAWS D1.1/D1.1M:2010 ANNEX N Magnetic Particle Inspection ReportSathish KumarNo ratings yet

- AWS D1.3/D1.3M:2018 ANNEX B SAMPLE FORM FOR WELDING PROCEDURE QUALIFICATION RECORD (PQRDocument1 pageAWS D1.3/D1.3M:2018 ANNEX B SAMPLE FORM FOR WELDING PROCEDURE QUALIFICATION RECORD (PQRAkihiko TakagiNo ratings yet

- L3 PQRforQualificationDocument1 pageL3 PQRforQualificationBernardo LeorNo ratings yet

- AWS D1.5 PQR TitleDocument1 pageAWS D1.5 PQR TitleNavanitheeshwaran SivasubramaniyamNo ratings yet

- Sample Report of Magnetic-Particle Examination of WeldsDocument1 pageSample Report of Magnetic-Particle Examination of WeldsNavanitheeshwaran SivasubramaniyamNo ratings yet

- WPS - Pre-Insulated PipesDocument4 pagesWPS - Pre-Insulated Pipesharis bhuttoNo ratings yet

- 003PQR P1&2 May 17 2018Document3 pages003PQR P1&2 May 17 2018Oliver CastroNo ratings yet

- Joint (QW-402)Document3 pagesJoint (QW-402)MuhammadNajibNo ratings yet

- Soldering Procedure Qualification Record (SPQR) - Sample FormDocument2 pagesSoldering Procedure Qualification Record (SPQR) - Sample FormBernardo LeorNo ratings yet

- M 3 D1.1 2015 FormDocument1 pageM 3 D1.1 2015 FormĐỗ Văn ChinhNo ratings yet

- Chiller testing and commissioning reportDocument2 pagesChiller testing and commissioning reportagun gunawan100% (1)

- QW-482 WPS BlankDocument2 pagesQW-482 WPS Blankj29mahonNo ratings yet

- Form O-5-Welder and Welding Operator Qualification RecordDocument1 pageForm O-5-Welder and Welding Operator Qualification RecordNavanitheeshwaran SivasubramaniyamNo ratings yet

- Form N3 PDFDocument1 pageForm N3 PDFTavo RojasNo ratings yet

- Solderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MDocument1 pageSolderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MBernardo LeorNo ratings yet

- E07-X02 - 1 Gen. 13.8KV (Without Turbine) Data SheetDocument3 pagesE07-X02 - 1 Gen. 13.8KV (Without Turbine) Data SheetMuhammad IrfanNo ratings yet

- Testing Commisioning Report Ac Split: ProjectDocument2 pagesTesting Commisioning Report Ac Split: Projectagun gunawanNo ratings yet

- Form 7433 Rev PC-3000Document1 pageForm 7433 Rev PC-3000mancangkulNo ratings yet

- FM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)Document2 pagesFM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)tayyabNo ratings yet

- CBIM 2021 Form B-12 - Final Inspection Report For Water SupplyDocument3 pagesCBIM 2021 Form B-12 - Final Inspection Report For Water SupplyMessy Rose Rafales-CamachoNo ratings yet

- Page 20 From API-1104-2016Document1 pagePage 20 From API-1104-2016Riaz AhmadNo ratings yet

- SECTION 04 After Sales Service PolicyDocument14 pagesSECTION 04 After Sales Service PolicyRFamDamilyNo ratings yet

- Form L-5-Welder and Welding Operator Qualification RecordDocument1 pageForm L-5-Welder and Welding Operator Qualification RecordBernardo LeorNo ratings yet

- MATV Testing and Commissioning ReportDocument1 pageMATV Testing and Commissioning Reportagun gunawanNo ratings yet

- AWS B2.1/B2.1M:2014-AMD1 performance test recordDocument1 pageAWS B2.1/B2.1M:2014-AMD1 performance test recordNavanitheeshwaran SivasubramaniyamNo ratings yet

- The Stress-Free Guide to Parenting a Child With ADHD: Effective and Proven Strategies for Alleviating Anxiety and Forming Strong Bonds Without the HassleFrom EverandThe Stress-Free Guide to Parenting a Child With ADHD: Effective and Proven Strategies for Alleviating Anxiety and Forming Strong Bonds Without the HassleNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- Different Types of Welding GaugesDocument10 pagesDifferent Types of Welding GaugesAhmed GomaaNo ratings yet

- Boiler License Exam GuideDocument45 pagesBoiler License Exam GuideAhmed GomaaNo ratings yet

- DGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)Document4 pagesDGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Lecture Plan on Joining Processes Featuring Welding TechniquesDocument50 pagesLecture Plan on Joining Processes Featuring Welding TechniquesRajmchzNo ratings yet

- CHW A Magic AireDocument16 pagesCHW A Magic AireMiguel AngelNo ratings yet

- Welder QualificationsDocument1 pageWelder QualificationsmehdiNo ratings yet

- API 577 Reading ChecklistDocument1 pageAPI 577 Reading ChecklistbacabacabacaNo ratings yet

- Product Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Filipe CordeiroNo ratings yet

- Use of Welding in Bridges and Structures Subject To Dynamic Loading - Code of Practice (Document18 pagesUse of Welding in Bridges and Structures Subject To Dynamic Loading - Code of Practice (KrunalNo ratings yet

- Rotex SolarDocument12 pagesRotex Solarcertificat energeticNo ratings yet

- Essential in WeldingDocument3 pagesEssential in WeldingBelle SantosNo ratings yet

- AWS - WZC D19.0-72 Welding Zinc-Coated SteelDocument148 pagesAWS - WZC D19.0-72 Welding Zinc-Coated Steelarnoldbatista55No ratings yet

- Weld Carbon Steel Plate Performing Groove Welding On Carbon Steel PlatesDocument3 pagesWeld Carbon Steel Plate Performing Groove Welding On Carbon Steel PlatesJomar JamonNo ratings yet

- MSIL PS 2 - PVC Socket Weld FailureDocument3 pagesMSIL PS 2 - PVC Socket Weld FailureAjay chaurasiaNo ratings yet

- Islam Aminul CV-1Document2 pagesIslam Aminul CV-1Aminul IslamNo ratings yet

- Scheda Tecnica: IT-SG1 Itb-Sg1Document1 pageScheda Tecnica: IT-SG1 Itb-Sg1ITALFIL S.p.A.No ratings yet

- Weld Procedure Specification (WPS) : Company Name Address Line 1 Address Line 2 Town, County PostcodeDocument1 pageWeld Procedure Specification (WPS) : Company Name Address Line 1 Address Line 2 Town, County PostcodeRicardo SoaresNo ratings yet

- DPR FormatDocument78 pagesDPR FormatMITHUNNo ratings yet

- P Number Soldadores (Welder)Document1 pageP Number Soldadores (Welder)josel213No ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Unit 7 Shielded Gas Arc Welding: ObjectivesDocument29 pagesUnit 7 Shielded Gas Arc Welding: ObjectivesvipulNo ratings yet

- AWS Sustainlibrary PDFDocument3 pagesAWS Sustainlibrary PDFppedringNo ratings yet

- Resume Randy C. QuijanoDocument4 pagesResume Randy C. QuijanoKeneth Samson Del CarmenNo ratings yet