Professional Documents

Culture Documents

SGB WPS Al 01

Uploaded by

Ahmed GomaaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SGB WPS Al 01

Uploaded by

Ahmed GomaaCopyright:

Available Formats

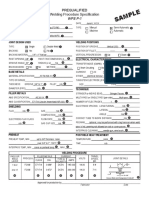

WELDING PROCEDURE SPECIFICATION (WPS)

According to ISO_15614_2

Welding Procedure

SGB-WPS-AL-01

Specification No. _______________ 22-09-2021

Date _________________________ Ahmed Abd EL Baset

Approved _______________________

0

Revisions _____________________ 22-09-2021

Date _________________________ Approved _______________________

Revisions _____________________ Date _________________________ Approved _______________________

Revisions _____________________ Date _________________________ Approved _______________________

Revisions _____________________ Date _________________________ Approved _______________________

SGB-PQR-AL-01

Supporting PQR Numbers ________________ 22-09-2021

_______________ ________________ ________________

Supporting PQR Numbers ________________ _______________ ________________ ________________

_______________________________________________________________________________________________

Joint Filler Metal

Gr.No. 23

_________________ ER4043

Wire No. ____________

Class

Size of electrode _______________________________

1.2 mm

Solid Filler Wire

Type of electrode _______________________________

Other ________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

Shielding Gas

Argon

Shielding gas(es) _______________________________

99.9%

Percent composition_____________________________

15 Lit/Min.

Flow rate______________________________________

Other ________________________________________

_____________________________________________

_____________________________________________

Backing _____________________________________________

N/A

Type ________________________________________ Position

N/A

Permanent ___________________________________ Position All positions for Fillet weld Except PG and J-L045

_______________________________

N/A

Removed ____________________________________ N/A

Welding progression_____________________________

Other _______________________________________ Fillet welds of plate or pipe

Other ________________________________________

____________________________________________ _____________________________________________

____________________________________________ _____________________________________________

____________________________________________ _____________________________________________

____________________________________________ _____________________________________________

Base Metals Preheat

Gr.No. 21

___________ Thickness 1.5 mm to 6_______

________ mm Preheat temperature N/A

____________________________

1100 Al Family, 6061 Al

Alloy and Temper ______________________________ N/A

Interpass temperature ___________________________

Date: 22/09/2021 Doc. No. QA&QC/WPS-01

Page: 1 of 2 Rev.: 00

WELDING PROCEDURE SPECIFICATION (WPS)

According to ISO_15614_2

Cleaning

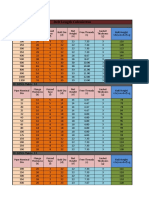

Pass Welding Travel

Grinding & Brushing

Initial cleaning oxide____________________________ No. Process Amps Volts Speed

Solvent

Initial cleaning oil and dirt________________________ 1ST GMAW 120-180 18-22 30 ~ 40 cm/min

Grinding & Brushing

Interpass cleaning _____________________________

____________________________________________

Postweld Heat Treatment

N/A

Original temper ________________________________

N/A

Final temper __________________________________

N/A

Temperature __________________________________

N/A

Time ________________________________________

N/A

Quench ______________________________________

____________________________________________

Process(es)

GMAW

Process _______________ MIG

Type*_______________

Process _______________ Type*_______________

N/A

Electrode (GTAW) _____________________________

____________________________________________

Technique

Weave

Stringer or weave bead _________________________

0.5''

Orifice or gas cup size __________________________

N/A

Oscillation ___________________________________

N/A

Contact tube to work distance ____________________

single or multipass

Single pass or multipass ________________________

per side

Tungsten extension ____________________________

N/A

Grinding

Method of backgouging _________________________

Other _______________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

*Manual, automatic, polarity, pulse, etc.

Sketch of Welding Sequence

Date: 22/09/2021 Doc. No. QA&QC/WPS-01

Page: 2 of 2 Rev.: 00

You might also like

- Hacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)From EverandHacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)No ratings yet

- 2G Rev-0-D1 - 2 - AL - PQRDocument2 pages2G Rev-0-D1 - 2 - AL - PQRAhmed GomaaNo ratings yet

- The Stress-Free Guide to Parenting a Child With ADHD: Effective and Proven Strategies for Alleviating Anxiety and Forming Strong Bonds Without the HassleFrom EverandThe Stress-Free Guide to Parenting a Child With ADHD: Effective and Proven Strategies for Alleviating Anxiety and Forming Strong Bonds Without the HassleNo ratings yet

- 3G Rev-0-D1 - 2 - AL-PQRDocument2 pages3G Rev-0-D1 - 2 - AL-PQRAhmed GomaaNo ratings yet

- B2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormDocument1 pageB2.1 B2.1M 2014 AMD1 Stud Welding WPS PQR or WQR FormtuanNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- JushDocument2 pagesJushg6vhdytsyzNo ratings yet

- Page 20 From API-1104-2016Document1 pagePage 20 From API-1104-2016Riaz AhmadNo ratings yet

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDocument2 pagesB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- F4-WPS PQR Stud WeldingDocument1 pageF4-WPS PQR Stud WeldingBernardo LeorNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 3 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 3 FillableNavanitheeshwaran SivasubramaniyamNo ratings yet

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Document2 pagesSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamNo ratings yet

- Form N 3 Sample Procedure Qualification RecordDocument1 pageForm N 3 Sample Procedure Qualification RecordViswanath SreepadaNo ratings yet

- WPS Marquez Noroña ProañoDocument7 pagesWPS Marquez Noroña Proañodennis carreraNo ratings yet

- Preventive Maintenance Checklist: Biomedical. EngDocument150 pagesPreventive Maintenance Checklist: Biomedical. EngJuli AgustonoNo ratings yet

- Engine Data SheetDocument2 pagesEngine Data SheetFolk ThiagoNo ratings yet

- Engine Data Sheet PDFDocument2 pagesEngine Data Sheet PDFAly AbdelhamedNo ratings yet

- Engine Data SheetDocument2 pagesEngine Data SheetMohamed MohamedNo ratings yet

- Engine Data Sheet PDFDocument2 pagesEngine Data Sheet PDFabhay dubeyNo ratings yet

- CBIM 2021 Form B-12 - Final Inspection Report For Water SupplyDocument3 pagesCBIM 2021 Form B-12 - Final Inspection Report For Water SupplyMessy Rose Rafales-CamachoNo ratings yet

- Joint (QW-402)Document3 pagesJoint (QW-402)MuhammadNajibNo ratings yet

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Document2 pagesCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemNo ratings yet

- Solderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MDocument1 pageSolderer Performance Qualification (SPQ) - Sample Form: Qualification, AWS B2.3/B2.3MBernardo LeorNo ratings yet

- Soldering Procedure Qualification Record (SPQR) - Sample FormDocument2 pagesSoldering Procedure Qualification Record (SPQR) - Sample FormBernardo LeorNo ratings yet

- WPS VarillaDocument2 pagesWPS Varillalabingles89No ratings yet

- L3 PQRforQualificationDocument1 pageL3 PQRforQualificationBernardo LeorNo ratings yet

- Continental Steel Catalogue PDFDocument175 pagesContinental Steel Catalogue PDFPhong CHee LimNo ratings yet

- Product Handbook Structureal Steel PDFDocument175 pagesProduct Handbook Structureal Steel PDFRanu JanuarNo ratings yet

- Form O-5-Welder and Welding Operator Qualification RecordDocument1 pageForm O-5-Welder and Welding Operator Qualification Recordedinson castrilloNo ratings yet

- Wps Short FormDocument2 pagesWps Short FormsrinivasanNo ratings yet

- WPS TemplateDocument1 pageWPS TemplateMatt De Hoog100% (1)

- Welding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) YesDocument4 pagesWelding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) Yesvarun100% (1)

- Sample: Exhibit 1 Exhibit 1Document1 pageSample: Exhibit 1 Exhibit 1jessy eghNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- Form L-4-Procedure Qualification Record (PQR) WorksheetDocument1 pageForm L-4-Procedure Qualification Record (PQR) WorksheetCemal NergizNo ratings yet

- Form O-5-Welder and Welding Operator Qualification RecordDocument1 pageForm O-5-Welder and Welding Operator Qualification RecordNavanitheeshwaran SivasubramaniyamNo ratings yet

- SBARDocument1 pageSBARJeffrey CollinsNo ratings yet

- WPS - Sample - Form D17.1 D17.1M 2010Document1 pageWPS - Sample - Form D17.1 D17.1M 2010Mohammed AzizNo ratings yet

- Sample PQRDocument2 pagesSample PQRudaysrp33% (3)

- Electrical Wiring Installation FormDocument1 pageElectrical Wiring Installation FormMaya Santiago CandelarioNo ratings yet

- Chemseal - KRS PDFDocument2 pagesChemseal - KRS PDFICPL-RWPNo ratings yet

- Welding Procedure Specification (WPS) : BackingDocument1 pageWelding Procedure Specification (WPS) : BackingtimkemperNo ratings yet

- Heater Check List: Radiant TubesDocument3 pagesHeater Check List: Radiant TubesMastram HatheshNo ratings yet

- Boiler Checklist PDFDocument2 pagesBoiler Checklist PDFSadiq KhattakNo ratings yet

- Plumbing Report TempelateDocument4 pagesPlumbing Report TempelateWjz WjzNo ratings yet

- Form L-5-Welder and Welding Operator Qualification RecordDocument1 pageForm L-5-Welder and Welding Operator Qualification RecordBernardo LeorNo ratings yet

- Uail - Pin Li-Cqa-213-F-01 WPS FormatDocument2 pagesUail - Pin Li-Cqa-213-F-01 WPS FormatKarthikNo ratings yet

- Oxy-Ace & Heating Torch Pre-Use Inspection FormDocument1 pageOxy-Ace & Heating Torch Pre-Use Inspection FormjuvytimbalNo ratings yet

- Fire Alarm System Inspection and Testing FormDocument4 pagesFire Alarm System Inspection and Testing FormBrahim SemariNo ratings yet

- Peugeot Xud9 Engine Workshop ManualDocument50 pagesPeugeot Xud9 Engine Workshop ManualKireNo ratings yet

- Identification and SpecificationsDocument8 pagesIdentification and SpecificationsLAZARO GARCIANo ratings yet

- Low Tension Electrical InstallationDocument2 pagesLow Tension Electrical InstallationNicholas TanNo ratings yet

- Injection Mold Design ChecklistDocument4 pagesInjection Mold Design Checklistctansari0% (1)

- Chemaflex 276 HDocument4 pagesChemaflex 276 HghazanfarNo ratings yet

- Welders CertDocument11 pagesWelders CertAhmed GomaaNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- Boiler License Exam GuideDocument45 pagesBoiler License Exam GuideAhmed GomaaNo ratings yet

- Different Types of Welding GaugesDocument10 pagesDifferent Types of Welding GaugesAhmed GomaaNo ratings yet

- Retnaldi Fitriyanto Rico Andhika P Rizkiyan: Find Out MoreDocument15 pagesRetnaldi Fitriyanto Rico Andhika P Rizkiyan: Find Out MoreAlfian Hari GunawanNo ratings yet

- 7.15a - Welding, Brazing, Soldering and BondingDocument22 pages7.15a - Welding, Brazing, Soldering and BondingAslam AwanNo ratings yet

- Welding Consumables Request Card: Client LogoDocument1 pageWelding Consumables Request Card: Client LogoZaidiNo ratings yet

- Toshiba E-STUDIO120 150 Parts ListDocument127 pagesToshiba E-STUDIO120 150 Parts Listkostas_sanNo ratings yet

- 42 M Bow String Girder-10408-5-R PDFDocument1 page42 M Bow String Girder-10408-5-R PDFPhanindra MajetiNo ratings yet

- HOD-P & QC Work BookDocument6 pagesHOD-P & QC Work BookvinodsnNo ratings yet

- Cement Manufacturing ProcessDocument24 pagesCement Manufacturing ProcessVenkata Ramana Murthy VasupilliNo ratings yet

- Juki AMS-210A PGM-1Document52 pagesJuki AMS-210A PGM-1Marco MatosNo ratings yet

- Slag Inclusion - Causes and Remedies PDFDocument1 pageSlag Inclusion - Causes and Remedies PDFkim lawNo ratings yet

- F22 XPDocument49 pagesF22 XPGeorge Kwamina Anaman100% (1)

- Nickel-Cadmium Aircraft Batteries: Model M - 28-1 Battery Replacement PartsDocument4 pagesNickel-Cadmium Aircraft Batteries: Model M - 28-1 Battery Replacement PartsFaisNo ratings yet

- Kemppi Wise, Match Software ManualDocument26 pagesKemppi Wise, Match Software ManualNguyen Minh GiapNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- PLSC0017 Requirements For Welder Qualifications in Accordance With ASME Section IXDocument13 pagesPLSC0017 Requirements For Welder Qualifications in Accordance With ASME Section IXBhavin ParekhNo ratings yet

- Milwaukee DestornilladorDocument1 pageMilwaukee DestornilladorRaúl AbregoNo ratings yet

- ABB Price Book 454Document1 pageABB Price Book 454EliasNo ratings yet

- Lampiran 3. WPS of Pile JointDocument3 pagesLampiran 3. WPS of Pile JointDoni TriatmojoNo ratings yet

- Matching Bolt Nut GradeDocument3 pagesMatching Bolt Nut GradehidexNo ratings yet

- Defects in Gmaw or Mig WeldingDocument13 pagesDefects in Gmaw or Mig WeldingRamesh R100% (1)

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Suzhou First Packing Co.,Ltd Catolog - LindaDocument12 pagesSuzhou First Packing Co.,Ltd Catolog - LindaMuhammad aliNo ratings yet

- Slips & Parts: Cavin TBDocument8 pagesSlips & Parts: Cavin TBmantilla7No ratings yet

- Is 817 For Welding QalificationDocument59 pagesIs 817 For Welding QalificationRathnakrajaNo ratings yet

- WPS - 021Document13 pagesWPS - 021MAT-LIONNo ratings yet

- Acme Screw DataDocument4 pagesAcme Screw DatazbhdzpNo ratings yet

- Nas1003 Thru 1020 Rev. 9Document4 pagesNas1003 Thru 1020 Rev. 9Nathan BossardNo ratings yet

- Cswip 3.1 Part 1Document7 pagesCswip 3.1 Part 1Emad Daghagheleh67% (3)

- Using Welding Inspection ToolsDocument9 pagesUsing Welding Inspection ToolsVinoth RajendraNo ratings yet

- Bolt Length Calculation: IS 6392-Table 11Document3 pagesBolt Length Calculation: IS 6392-Table 11sumit_b123No ratings yet

- Asme-Ix PDFDocument9 pagesAsme-Ix PDFMuhammad ThohirNo ratings yet