0% found this document useful (0 votes)

534 views2 pagesWelding Procedure Specification WPS Guide

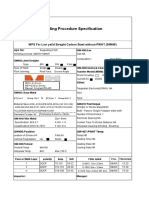

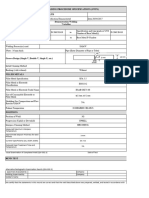

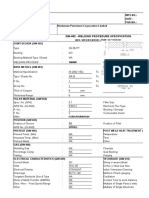

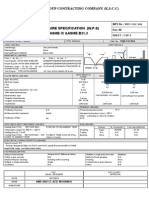

This document outlines a welding procedure specification for butt welding ASTM 36 steel with FCAW using E71T-1C filler metal. The key details are:

1) The WPS is for semi-automatic FCAW butt welding of 3-16mm thick ASTM 36 steel plates in the flat and horizontal positions.

2) E71T-1C filler metal with a 1.2mm diameter will be used with direct current electrode positive polarity at 150-169 amps and 21-23 volts.

3) Multiple passes will be used with a travel speed of 152-170mm/min and a 10-25mm contact tube to work distance. No preheat or

Uploaded by

Mj EdinCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

534 views2 pagesWelding Procedure Specification WPS Guide

This document outlines a welding procedure specification for butt welding ASTM 36 steel with FCAW using E71T-1C filler metal. The key details are:

1) The WPS is for semi-automatic FCAW butt welding of 3-16mm thick ASTM 36 steel plates in the flat and horizontal positions.

2) E71T-1C filler metal with a 1.2mm diameter will be used with direct current electrode positive polarity at 150-169 amps and 21-23 volts.

3) Multiple passes will be used with a travel speed of 152-170mm/min and a 10-25mm contact tube to work distance. No preheat or

Uploaded by

Mj EdinCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd