Professional Documents

Culture Documents

Lampiran 3. WPS of Pile Joint

Uploaded by

Doni Triatmojo0 ratings0% found this document useful (0 votes)

115 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

115 views3 pagesLampiran 3. WPS of Pile Joint

Uploaded by

Doni TriatmojoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

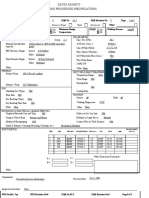

WELDING PROCEDURE SPECIFICATION (WPS)

WPS No.: WPS-H005 PAGE 1 OF 3 DATE 25 Nov 2016

Company Name PT.Pratama Widya

Supporting PQR No. PQR-07 BY(QA DIRECTOR) Date 25 Nov 2016

Welding Process FCAW Type(s)Semi-Auto Manual (Automatic,Manual,Machine,Semi-Auto.)

JOINTS

Joint Design Vee “V"

Backing(Yes) × (NO) Retainers(Yes) (NO) ×

(Refer to both backing and retainers.)

Backing Material(Type) Base metal

[ × ] Metal; [ ] Non-fusing Metal; [ ] Non-metallic; [ ] Other

Sketches,production drawings,weld symbols or written description should show the general arrangement of

The parts to be welded. Where applicable,the root spacing and the details of weld groove may be specified.

BASE METALS

P—No. Group No. 1 to P—No. Group No. 1 or

Specification Type and Grade SS400 to Specification Type and Grade SS400 or

Chem.Analysis and Mech. Prop. to Chem.Analysis and Mech. Prop.

Thickness Range: Base Metal: Groove 3~24mm Fillet not limited

Pipe Dia. Range: Groove Not Limitted Fillet not limited

Other

FILLER METALS Special

SFA No.

AWS No.(Class) AWS A5.1 E7016/JIS Z 3212 D5016

F—No. None

A--No. NA

Size of Filler Metals Φ3.2mm , Φ4mm

WELDING PROCEDURE SPECIFICATION (WPS)

WPS No.: WPS-H005 PAGE 2 OF 3 DATE 25 Nov 2016

Deposited Weld Met.Thickness Range: Groove max 24mm

Fillet not limited

Electrode-Flux (Class) NA

Flux Trade Name NA

Consumable insert NA

Other

POSITIONS POST-WELD HEAT TREATMENT

Position (s) of groove PA

Temperature Range

Weld.Progression: UP X Down NO

Time Range

Position(s) of Fillet PA

GAS

PREHEAT Percent Composition

Preheat Temp. Min. 5 ℃ Gas(es) (Mixture) Flow Rate

Inter pass Temp. Max. 300℃ Shielding None

Preheat Maintenance None Trailing None None None

(Continuous or special heating where applicable shall be recorded) Backing None None None

ELECTRICAL CHARACTERISTICS

Current AC or DC DC Polarity EP

Amps(Range) see below Volts(Range) see below

Tungsten Electrode Size and Type(Pure.Tungsten.2% thoriated.etc.) NA

Mode of Metal Transfer for GMAW (Spray arc, short circuiting arc, etc.) NA

Electrode Wire Feed Speed Range NA

TECHNIQUE

String or Weave Bead String

Orifice or Gas Cup Size NA

WELDING PROCEDURE SPECIFICATION

WPS No.: WPS-H005 PAGE 3 OF 3 DATE 25 Nov 2016

Initial and Inter pass Cleaning(Brushing.Grinding.etc.) Brushing

Method of Back Gouging Carbon arc gouging 、 Brushing

Oscillation NA

Contact Tube To Work Distance NA

Multiple or Single Pass (per side) Multiple

Multiple or Single Electrodes NA

Travel Speed(Range) See below

Peening None

Other

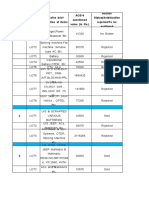

Filler Metal Current Travel Speed

Weld Layers Process Volt. Range Other

Class Dia. Type Polar Amp.Range Range

st

1 layer

1 FCAW E7016 Φ3.2mm DCEP 300-350A 32-34V 8-12cm/min

nd

2 layer

2 FCAW E7016 Φ4mm DCEP 300-350A 32-34V 8-12cm/min

rd

3 layer

2 FCAW E7016 Φ4mm DCEP 300-350A 32-34V 8-12cm/min

PREPARED BY: DATE : APPROVED BY : DATE : ACCEPTED BY AI : DATE :

You might also like

- 420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónDocument7 pages420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónRosa ChNo ratings yet

- Visitor Safety BriefingDocument2 pagesVisitor Safety BriefingDoni TriatmojoNo ratings yet

- Talbott Thunderbolts of The Gods PDFDocument98 pagesTalbott Thunderbolts of The Gods PDFRonald Wederfoort100% (3)

- Brochure Wika CLT - A5 - 280717 PDFDocument19 pagesBrochure Wika CLT - A5 - 280717 PDFHvbryNo ratings yet

- Brosur Kend HardwareDocument48 pagesBrosur Kend Hardwarezullyanto priyo HandokoNo ratings yet

- DD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerDocument7 pagesDD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerMuqorobinNo ratings yet

- Calculation Report For PHC Pile: I. Input Data For Pile's Material I.1. Effective Presstress: ValueDocument3 pagesCalculation Report For PHC Pile: I. Input Data For Pile's Material I.1. Effective Presstress: ValuehuhumaluNo ratings yet

- D2412 PDFDocument6 pagesD2412 PDFDavid SolisNo ratings yet

- Jual Forklift 5 Ton - Bomac FokliftDocument15 pagesJual Forklift 5 Ton - Bomac FokliftBakryRantoeNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- REPUBLIC OF THE PHILIPPINES PROFESSIONAL REGULATION COMMISSION PREBOARD EXAM 1 – Math 1Document10 pagesREPUBLIC OF THE PHILIPPINES PROFESSIONAL REGULATION COMMISSION PREBOARD EXAM 1 – Math 1Joshua Casuga100% (1)

- Unit IV Measurement of Non-Electrical ParametersDocument17 pagesUnit IV Measurement of Non-Electrical ParametersAleesha100% (6)

- Standard Hooks Card-ASTM PDFDocument2 pagesStandard Hooks Card-ASTM PDFIsmael PerezNo ratings yet

- Fiber Carbon (New) - 2018 PDFDocument4 pagesFiber Carbon (New) - 2018 PDFDona Dwi SaputroNo ratings yet

- PolykenDocument7 pagesPolykenJanllo83No ratings yet

- Jis G 3505 LC W RodsDocument1 pageJis G 3505 LC W RodsRamesh DattaNo ratings yet

- Perhitungan Teknis Dan GambarDocument8 pagesPerhitungan Teknis Dan GambarIndraHoedaya100% (1)

- Metode Kerja Umum PDA Test - 2021Document23 pagesMetode Kerja Umum PDA Test - 2021WannNo ratings yet

- HCSDocument4 pagesHCSSeptian Adi SNo ratings yet

- Sika Backing RodDocument2 pagesSika Backing Rodthe pilotNo ratings yet

- Mastertop 100 PDFDocument2 pagesMastertop 100 PDFMohiuddin MuhinNo ratings yet

- Lokfix E75 TDS 8072020Document5 pagesLokfix E75 TDS 8072020KumarRamNo ratings yet

- Aashto/Pci Standard Products: Appendix BDocument2 pagesAashto/Pci Standard Products: Appendix BJavier CaballeroNo ratings yet

- Elephant Moistbloc Gypsum Board Product SpecificationDocument1 pageElephant Moistbloc Gypsum Board Product SpecificationDilon Fernando0% (1)

- U Cân BDE-2007Document49 pagesU Cân BDE-2007Awidhi KresnawanNo ratings yet

- Quick guide to choosing the right flooring gratingDocument32 pagesQuick guide to choosing the right flooring gratingFaris MahmoodNo ratings yet

- Geomembrane HDPE Smooth Black PDFDocument1 pageGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- 8.1 Fis em RebarDocument51 pages8.1 Fis em RebarJeyasingh GopalakrishnanNo ratings yet

- Penetrant Test Report - ContohDocument2 pagesPenetrant Test Report - ContohSmksore PasNo ratings yet

- Summary Test Beton QCDocument4 pagesSummary Test Beton QCRamdan Pramedis SetyaNo ratings yet

- Way Sekampung Regulating DAM Project: TunnelDocument1 pageWay Sekampung Regulating DAM Project: Tunnelardhyr ardhyrNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- Main Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFDocument94 pagesMain Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFMuhammad TrayaNo ratings yet

- Standardized Pile Shoes On Steel Pipe PilesDocument1 pageStandardized Pile Shoes On Steel Pipe PilesnenmilNo ratings yet

- Template Foundation BorepileDocument1 pageTemplate Foundation BorepileMuhammad AmarNo ratings yet

- F1554 Grade 105 - F1554 Anchor BoltsDocument2 pagesF1554 Grade 105 - F1554 Anchor BoltspandiangvNo ratings yet

- Astm A325-04 STD Specs For Structural Bolts, Steel, Heat TreDocument8 pagesAstm A325-04 STD Specs For Structural Bolts, Steel, Heat TreCharwin Picao100% (1)

- PC Spun PilesDocument2 pagesPC Spun PilesJoglo Solo100% (1)

- Icp Brochure Grade 80Document8 pagesIcp Brochure Grade 80Tee Bun PinNo ratings yet

- Mechanical Testing of Steel Products': Standard Test Methods andDocument46 pagesMechanical Testing of Steel Products': Standard Test Methods andSamuel Peter100% (1)

- Design of elastomeric bearing pad for Type III girderDocument4 pagesDesign of elastomeric bearing pad for Type III girderkenkenmusic100% (1)

- Specifications Casting PDFDocument1 pageSpecifications Casting PDFjahangir_alam44_6764No ratings yet

- Brosur - PT. Jaya Beton IndonesiaDocument8 pagesBrosur - PT. Jaya Beton IndonesiaDita DitaNo ratings yet

- Hooper 1973Document23 pagesHooper 1973Anonymous ImoZI0363No ratings yet

- Learn About PC Sheet Piles Types and SpecificationsDocument1 pageLearn About PC Sheet Piles Types and Specificationsganiardiansyah adam100% (1)

- Low Viscosity Long Life Injection ResinDocument2 pagesLow Viscosity Long Life Injection Resinlim kang hai100% (2)

- Cebex 100 Non-Shrink Grout AdmixtureDocument19 pagesCebex 100 Non-Shrink Grout AdmixturePutu Roby Adhitya Sapanca100% (1)

- ProCeq - Concrete Test HammerDocument80 pagesProCeq - Concrete Test HammerJJUOH85No ratings yet

- Rubber Fender and Products GuideDocument34 pagesRubber Fender and Products GuidesigNo ratings yet

- FerrocementDocument25 pagesFerrocementAnonymous xC6bM4x6U6No ratings yet

- Nitowrap FRC BaruDocument2 pagesNitowrap FRC BaruZax SantanaNo ratings yet

- 004 - Precast Beton CalvaryDocument15 pages004 - Precast Beton CalvaryvzateguhNo ratings yet

- Cement-Treated Base (CTB)Document2 pagesCement-Treated Base (CTB)bunkun100% (1)

- Jotun Malathon TDSDocument5 pagesJotun Malathon TDSBiju_PottayilNo ratings yet

- Brosur Baja Gunung Raja Paksi Welded BeamDocument2 pagesBrosur Baja Gunung Raja Paksi Welded BeamRobbi Shobri RakhmanNo ratings yet

- Kufranja Dam Project Inspection and Test Plan Structural ConcreteDocument2 pagesKufranja Dam Project Inspection and Test Plan Structural ConcretemohNo ratings yet

- Detai Rip Plate: Penerangan Jalan UmumDocument1 pageDetai Rip Plate: Penerangan Jalan UmumGo PeaksNo ratings yet

- MSDS 0008 Concrete Material Safety Data SheetDocument8 pagesMSDS 0008 Concrete Material Safety Data SheetGangsar Lukmanjaya100% (1)

- Anchor 2013 Full EnglishDocument62 pagesAnchor 2013 Full EnglishFhjkda LfljkdNo ratings yet

- Anchor Bolt Details & Hole - AISE PDFDocument1 pageAnchor Bolt Details & Hole - AISE PDFYash PaulNo ratings yet

- PRISM For Earthquake Engineering A Program For Seismic Response Analysis of SDOF SystemDocument13 pagesPRISM For Earthquake Engineering A Program For Seismic Response Analysis of SDOF SystemPrabhat KumarNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- PQR 11 Noram GTDocument6 pagesPQR 11 Noram GTross anthonyNo ratings yet

- Inspection & Test Plan for Survey Instrument StationsDocument2 pagesInspection & Test Plan for Survey Instrument StationsDoni TriatmojoNo ratings yet

- HR HR Tem003 Gen All Site Induction Rev2.0Document20 pagesHR HR Tem003 Gen All Site Induction Rev2.0Doni TriatmojoNo ratings yet

- Form BPG TepDocument48 pagesForm BPG TepDoni TriatmojoNo ratings yet

- 2.itp Civ 0001Document3 pages2.itp Civ 0001Doni TriatmojoNo ratings yet

- Layout Elevasi +3.5Document1 pageLayout Elevasi +3.5Doni TriatmojoNo ratings yet

- Sequence Inlet Dan Estimasi Volume BetonDocument14 pagesSequence Inlet Dan Estimasi Volume BetonDoni TriatmojoNo ratings yet

- Section A-A: Roof Structural Drawing Will Be Proposed in Another DrawingDocument6 pagesSection A-A: Roof Structural Drawing Will Be Proposed in Another DrawingDoni TriatmojoNo ratings yet

- Hseq Env Pol001 Civ Sea 2914en Environmental Mdi PP JV Rev1.0 (Eng Be)Document1 pageHseq Env Pol001 Civ Sea 2914en Environmental Mdi PP JV Rev1.0 (Eng Be)Doni TriatmojoNo ratings yet

- SY215C9 (Long-Reach Boom) : Dimensions Operation Range Operation RangeDocument1 pageSY215C9 (Long-Reach Boom) : Dimensions Operation Range Operation RangeDoni TriatmojoNo ratings yet

- Lifting Plan Scaffold Abr-SignedDocument7 pagesLifting Plan Scaffold Abr-SignedDoni TriatmojoNo ratings yet

- Stairways & Ladders - A Guide To OSHA RulesDocument15 pagesStairways & Ladders - A Guide To OSHA Ruleseafarmihar2554100% (3)

- Contractor Employer Palembang City Sewerage Project Package A2 Construction of A Domestic Wastewater Treatment Plant & Pump StationDocument1 pageContractor Employer Palembang City Sewerage Project Package A2 Construction of A Domestic Wastewater Treatment Plant & Pump StationDoni TriatmojoNo ratings yet

- Perhitungan Abr StructureDocument4 pagesPerhitungan Abr StructureDoni TriatmojoNo ratings yet

- Contractor Employer Palembang City Sewerage Project Package A2 Construction of A Domestic Wastewater Treatment Plant & Pump StationDocument1 pageContractor Employer Palembang City Sewerage Project Package A2 Construction of A Domestic Wastewater Treatment Plant & Pump StationDoni TriatmojoNo ratings yet

- SWPS Excavation Plan 23-03-21 (Without Exca) - Section A Stage 1Document1 pageSWPS Excavation Plan 23-03-21 (Without Exca) - Section A Stage 1Doni TriatmojoNo ratings yet

- Steel Pile Welding Joint CMSDocument23 pagesSteel Pile Welding Joint CMSDoni TriatmojoNo ratings yet

- Lifting Plan AbrDocument1 pageLifting Plan AbrDoni TriatmojoNo ratings yet

- SWPS Excavation Plan 23-03-21 (Without Exca) - Section B Stage 3Document1 pageSWPS Excavation Plan 23-03-21 (Without Exca) - Section B Stage 3Doni TriatmojoNo ratings yet

- SWPS Excavation Plan 23-03-21 (Without Exca) - Section B Stage 1Document1 pageSWPS Excavation Plan 23-03-21 (Without Exca) - Section B Stage 1Doni TriatmojoNo ratings yet

- SWPS Excavation Plan 23-03-21-LayoutDocument1 pageSWPS Excavation Plan 23-03-21-LayoutDoni TriatmojoNo ratings yet

- Construction Method Statement for Receiving Pile MaterialsDocument26 pagesConstruction Method Statement for Receiving Pile MaterialsDoni TriatmojoNo ratings yet

- HSEQ-QA-CMS0020-CIV-2914 CMS Dynamic Pile Test Rev1Document21 pagesHSEQ-QA-CMS0020-CIV-2914 CMS Dynamic Pile Test Rev1Doni TriatmojoNo ratings yet

- Construction Method Statement Pile WeldingDocument22 pagesConstruction Method Statement Pile WeldingDoni TriatmojoNo ratings yet

- Original Joint ABRDocument1 pageOriginal Joint ABRDoni TriatmojoNo ratings yet

- HSEQ-QA-CMS0022-CIV-2914 CMS Sand FillingDocument24 pagesHSEQ-QA-CMS0022-CIV-2914 CMS Sand FillingDoni TriatmojoNo ratings yet

- SWPS Excavation Plan 23-03-21 (Without Exca) - Section B Stage 4Document1 pageSWPS Excavation Plan 23-03-21 (Without Exca) - Section B Stage 4Doni TriatmojoNo ratings yet

- ABR RC Sequence Rev 1Document11 pagesABR RC Sequence Rev 1Doni TriatmojoNo ratings yet

- 02 Mdi-Pp STQ Xi 2020Document1 page02 Mdi-Pp STQ Xi 2020Doni TriatmojoNo ratings yet

- Physics of Explosions Lab: Trolley Momentum ExperimentDocument6 pagesPhysics of Explosions Lab: Trolley Momentum ExperimentAkili ArmaniNo ratings yet

- Wet Towel Dryer AirflowDocument3 pagesWet Towel Dryer Airflowdendisneha reddy80% (5)

- A Comparison Study of The Electrochemical Polishing of Laser Powder Bed Fusion HR 2 Stainless Steel and Alsi10MgDocument10 pagesA Comparison Study of The Electrochemical Polishing of Laser Powder Bed Fusion HR 2 Stainless Steel and Alsi10Mgsai charanNo ratings yet

- CNC machine preventative checklistDocument4 pagesCNC machine preventative checklistRahel SorriNo ratings yet

- Status of ACE-9 SanctionedDocument7 pagesStatus of ACE-9 SanctionedPuneet NirajNo ratings yet

- Premium Industrial NDT SolutionsDocument16 pagesPremium Industrial NDT SolutionsSiva ShankarNo ratings yet

- Peak Force QNM - Adv Apps Training 2014Document60 pagesPeak Force QNM - Adv Apps Training 2014linhaowen13579No ratings yet

- AHU-B01-04 All Day Dining-Heating PDFDocument1 pageAHU-B01-04 All Day Dining-Heating PDFNgoc Vũ TrầnNo ratings yet

- Reflection of Sound - How Echoes Form and Methods to Calculate Sound SpeedDocument3 pagesReflection of Sound - How Echoes Form and Methods to Calculate Sound SpeedaasrajNo ratings yet

- Laplace Transformation of Periodic FunctionsDocument15 pagesLaplace Transformation of Periodic FunctionsOlin D'souzaNo ratings yet

- Quantum Wells, Wires and Dots ExplainedDocument8 pagesQuantum Wells, Wires and Dots ExplainedShruti AhlawatNo ratings yet

- Bpy2110 Modern Physics Pp1Document2 pagesBpy2110 Modern Physics Pp1klm klmNo ratings yet

- Fluid Mechanics Chapter 3Document42 pagesFluid Mechanics Chapter 3Ricky MakNo ratings yet

- Balloon Powered Race Cars-1Document8 pagesBalloon Powered Race Cars-1Angelica CamilonNo ratings yet

- MARIEL PULBOSA - WS-7 Mole MathtersDocument3 pagesMARIEL PULBOSA - WS-7 Mole MathtersMARIEL PULBOSANo ratings yet

- Chem 3052 Introduction to SpectroscopyDocument22 pagesChem 3052 Introduction to SpectroscopyashenafiNo ratings yet

- S5244 Nicolin Govender PDFDocument23 pagesS5244 Nicolin Govender PDFsubhash thakurNo ratings yet

- Jempson Bridge 1997Document16 pagesJempson Bridge 1997Luis Fernando Zapata LaureanoNo ratings yet

- Phase Difference & Phase RelationshipsDocument24 pagesPhase Difference & Phase RelationshipsGabriel Carl AlpuertoNo ratings yet

- Htpro: Low-Temperature Surface Hardening of Stainless Steel: Christiansen, Thomas Lundin Somers, Marcel A. JDocument3 pagesHtpro: Low-Temperature Surface Hardening of Stainless Steel: Christiansen, Thomas Lundin Somers, Marcel A. Jsabounchimarzieh1995No ratings yet

- Youngs Double SlitDocument4 pagesYoungs Double Slitpmc9q544vwNo ratings yet

- Thermal Denaturation of The Variant of Trypsin InhibitorDocument5 pagesThermal Denaturation of The Variant of Trypsin InhibitorChiara VaccaNo ratings yet

- Blast Pressure Distribution Around Storage TanksDocument10 pagesBlast Pressure Distribution Around Storage TanksNARAYANAN RNo ratings yet

- Shishuvan - STD 7 (2021-22) - IntegersDocument10 pagesShishuvan - STD 7 (2021-22) - IntegersHardik ViraNo ratings yet

- Heat TransferDocument1 pageHeat TransferRisa M. LimNo ratings yet

- Tutorial 2 PDFDocument2 pagesTutorial 2 PDFराधे कृष्णा वर्ल्डNo ratings yet