Professional Documents

Culture Documents

WPQT

Uploaded by

yousab creator2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPQT

Uploaded by

yousab creator2Copyright:

Available Formats

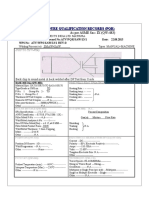

WELDER QUALIFICATION RECORD (WQR) AB-76A 2010-09

tl1a pr(W-1\Jra equipment safety ·aulhorily

Welder'sName: Bi l Smith ABSA F il e N o .: �124 - _1 ______StampNo.- _99

� �1 ____ _

Identifica ti on of WPS followed by welder during welding of test coupon: C S-2 W.P. Reg. # WP-_C _S___

-_ 2 _

Base materia (l s} welded: P-N o.1 to P-No.1 Thickness: 0.280 in. 181 Test Coupon O Prod. Weld

Testing Conditions and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

WeldL'lg Process(es} Used: SMAW SMAW

Type of Welding (i.e., Manual, Semi- Automa tic} Used: manual manual

Base Metal P- or S-Number. To P- o r S-Nurnber: P-No 1 to P- No. 1 P-No.1 to P·No . 1

O Pla te 181 Pipe (enter diameter if pipe ortube) 6inches 2.5 inche s to B inch.es

BaCking,(metal, weld metal, double·welded, etc.); without with wit hout

Filler Metal or E el ctrode Specification(s) (SFA) (inf o only): 51

Filler Metal or Electrode Classificat!on(s) (info only)· #1 - E 6010 #2 • E7018

Filler Metal or Electro de F-Number(s ): F-No,3 F-No. 4 F-No . 3 F-No. 4

Filler Type (solid/metal o r flux cored/p owder) (GTAW or PAW):

C onsumable Ins ert for GTAW o r PAW·

Deposi� Thickness for each process or elec;trode type, etc. (in.}: 0.280 inch 0.560 inch

Process/Electrode #1: SMAW 3 la yers minimum Yes O No 181 Proce ss/E' e l ctrode #2: 3 la.,ers minimum Bl Ye s O No

Weldin g Pos iUon (2G, 6G, SF, etc.): _ 6G-'" __________ a_ -'Il P.__. o_ s_it_ ion_ _____ s_ _

Vert[cal Pr ogress ion (Uphlll or D ownhill): _d_own_hi_ ll

_ ______ __u....,Jph_ _il_l a_n_d_ d_o_v_m_h_il_l__ _

Fuel Gas for OFW or Inert.Gas Backing for .GTAW, PAW. GMAW

Transfer Mode (spray/globular or pul se to short circuit- GMAW): -----------+-----------

GTAW Curr�mt Type/Polar ity (AC. DCEP, DCEN).____ _____ _....._ _________

Results

Vi sua l Examlnati on of Fit-Up: R oot Gc1p: pass Tack Welds: pass ( Length: Number }

Root Pass (Describe Discontinuity if Unacceptable): -===------------------------ -

Completed Weld (Describe defects 1f unacceptable): � �------------------------

a=ss

Bend Test:� Tra nsver se R oot and Face fQW-462.3(a)J D Longitudinal Ro ol and Face {QW-462.3(tl)J D Side [QW-462.2]

O Pipe Bend Specimen. corrosion-resistant overlay fQW-462,5(c}] O Plate Bend-Specimen. corrosion-res1slantoverlay fQW-462.5(d)J

D Macro Test fot Fusion IQW-462.5(lJ)l D Macro Test fot Fusion TOW-462.o(e)]

Type Result Type Result Type Result

face ·oass - no indications face pass - 3/32" indication

root pass - 1 /16" indication Root pass - no indications

(For altematfve qua lificatio n of gr oove welds by volumefric ex amin a tion to QW-191 )

R.T. Results: U, T , Results. -----------------

Fillet Weld - Fracture 'fest (Describe lo.cation, nature and size of any crack or tearing ,of specimen):_____________ _

Length and Per Cent of Defects: inches- ------- - ------------

Macro Test-Fusion : --------------------------------------

Appearance - Fi II et Size (leg.): X inch . Con,vexity: inch. or Concavit y:---- fnch.

Oth er Tes�:-------------- ------------------- -- ----�

Record Information

Film or Specimen s Evaluated by: Company:-----------

Welding superv1 sed by: .,_

T""

on�H'-'=

ud n-------- --------------- --------

...,· s.,,o:.:.:

Mechani·cal te sts c onducted by: TH Testing Laboratory test no.: �� H--11

T � �0 - �i�-�78�----

We certify that the statements in this record are correct and that the test coupons were prepared, welded and te sted in

acco rdance with the req u irements o f Se ction IX ofthe ASME Boiler and Pressure Ve ssel Code.

ACCREDITED ORGANIZATION; 1H Testing AOQPNo.:2552 Expiry Date _12_- 1_ 2_ -__ 3 _1' ____ _ _

Certified by: Tony H udso n Examiner File No. 304 D a te: �0�9- -=0�9-=2- =9�-------

P .O. Card No, (W hen issued}: 11-78 Perfonnance Test ReferenceNo .. _-1_1-7 _ ___ 8_ _ ___ _

Test Coupo n i.0. No.. SMAW- 01-78 Date Co upon is to be retained t o: �11_-=0=2-=-2=9�--- ---

You might also like

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 pageRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNo ratings yet

- Suggested Weldin Lr. VijDocument4 pagesSuggested Weldin Lr. Vijmallik017100% (2)

- Procedure Qualification Records (PQR)Document2 pagesProcedure Qualification Records (PQR)amine algNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- WPS PQRDocument4 pagesWPS PQRGuillermo ZaragozaNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- W15 001S ASME Ahmad TermiziDocument1 pageW15 001S ASME Ahmad TermiziHoJienHauNo ratings yet

- Case Study WPS-PQR (AS-2)Document4 pagesCase Study WPS-PQR (AS-2)Mohamed ElrapatNo ratings yet

- Welder Qualification ReportDocument17 pagesWelder Qualification ReportAries MarteNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- 1.911.032 WPQ Smaw Astm A36Document1 page1.911.032 WPQ Smaw Astm A36Felipe Carrasco sepulvedaNo ratings yet

- SEW Welder Performance QualificationsDocument18 pagesSEW Welder Performance QualificationsmahendraNo ratings yet

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRvinodNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- Sample Format: Sensitivity: LNT Construction Internal UseDocument2 pagesSample Format: Sensitivity: LNT Construction Internal UseKarthikNo ratings yet

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationDocument6 pagesEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasNo ratings yet

- Qualification Soudeur PDFDocument3 pagesQualification Soudeur PDFr_racNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Hard Facing OverlayDocument2 pagesHard Facing OverlayAmanSharmaNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- WPQ 09Document1 pageWPQ 09Budi HahnNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- Wps 225Document29 pagesWps 225Muhammad firdaus rusliNo ratings yet

- PRN004Document2 pagesPRN004beyNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WPS 204 NewDocument6 pagesWPS 204 Newarockiyathass100% (1)

- WPS & PQR of Ravindra KumarDocument4 pagesWPS & PQR of Ravindra Kumartripatipankaj023No ratings yet

- STD PQR Format PDFDocument2 pagesSTD PQR Format PDFvinothNo ratings yet

- STD PQR Format PDFDocument2 pagesSTD PQR Format PDFvinothNo ratings yet

- Welder Performance Qualifications (WPQ)Document1 pageWelder Performance Qualifications (WPQ)tayyabNo ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- XXXXXXX: XXXXXXXXX XXXXXXXXX Welding Procedure Specification WpsDocument3 pagesXXXXXXX: XXXXXXXXX XXXXXXXXX Welding Procedure Specification WpsManivannanMudhaliarNo ratings yet

- 4) WQT Certificate For (SPT-02) (4''x8.56)Document1 page4) WQT Certificate For (SPT-02) (4''x8.56)JithuJohnNo ratings yet

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- AWS Part BDocument32 pagesAWS Part Balefeli260% (2)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- WPS - Pre-Insulated PipesDocument4 pagesWPS - Pre-Insulated Pipesharis bhuttoNo ratings yet

- Welder Certificate Sample1Document1 pageWelder Certificate Sample1Buddy EkoNo ratings yet

- CS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Document2 pagesCS-1 6/1/2015 6/1/2015 R1 Gtaw / Smaw Manual / Manual: Type(s)Nazar Abdul KareemNo ratings yet

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Document23 pagesTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderNo ratings yet

- ASME Boiler and Pressure Vessel Code Welding Procedure SpecificationDocument3 pagesASME Boiler and Pressure Vessel Code Welding Procedure SpecificationArupendranarayan ThakurNo ratings yet

- PQR Asme BlankDocument3 pagesPQR Asme Blankamirul8686No ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Plates ASTM-A240 Gr 304LDocument6 pagesPlates ASTM-A240 Gr 304Labhishek198327No ratings yet

- 5100 PM ChecklistDocument2 pages5100 PM Checklistlogisticacoresa2023No ratings yet

- PQR Group V-Asme (WI74)Document7 pagesPQR Group V-Asme (WI74)Gusrizam DanelNo ratings yet

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- PT Prakarsalanggeng Welder Qualification TestDocument24 pagesPT Prakarsalanggeng Welder Qualification Testmuhammad rizalNo ratings yet

- METALS INSPECTION SERVICES WELDING PROCEDUREDocument6 pagesMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Acer UEIP Terms of UseDocument2 pagesAcer UEIP Terms of UseRayNo ratings yet

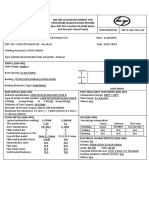

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Aws D14.4 D14.4MDocument134 pagesAws D14.4 D14.4Mgeorgadam198380% (5)

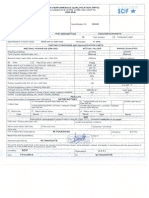

- Basic 5Document21 pagesBasic 5yousab creator2No ratings yet

- Semi Fabric atDocument12 pagesSemi Fabric atirinaNo ratings yet

- Nosotros NoDocument2 pagesNosotros NoAlcindorLeadonNo ratings yet

- Helene Deutsch, A Psychoanalysts Life (Lacanempdf)Document400 pagesHelene Deutsch, A Psychoanalysts Life (Lacanempdf)Carlos AugustoNo ratings yet

- COMPENSATION Class 1 PDFDocument5 pagesCOMPENSATION Class 1 PDFpsicologothNo ratings yet

- Effect of Ethanol Leaf Extract of Chromolaena Odorata On Lipid Profile of Streptozotocin Induced Diabetic Wistar Albino RatsDocument9 pagesEffect of Ethanol Leaf Extract of Chromolaena Odorata On Lipid Profile of Streptozotocin Induced Diabetic Wistar Albino RatsPUBLISHER JOURNALNo ratings yet

- PSYCHOLOGY Lesson 2Document15 pagesPSYCHOLOGY Lesson 2KOSTKANo ratings yet

- Synopsis Format-1Document12 pagesSynopsis Format-1astha SinghNo ratings yet

- How To Make Easy French ToastDocument4 pagesHow To Make Easy French Toastbintang pamungkasNo ratings yet

- C.Systematic ReviewDocument12 pagesC.Systematic ReviewIta ApriliyaniNo ratings yet

- Digital Citizenship vs. Global CitizenshipDocument20 pagesDigital Citizenship vs. Global CitizenshipMacasinag Jamie Anne M.No ratings yet

- CSP Chintu Anna - 1Document12 pagesCSP Chintu Anna - 1sujithNo ratings yet

- Handling Downsizing in The Process Industries - pg11 - 17Document7 pagesHandling Downsizing in The Process Industries - pg11 - 17Soeryanto SlametNo ratings yet

- Journal Pre-Proof: Gait & PostureDocument35 pagesJournal Pre-Proof: Gait & PostureRogerDelaCernaNo ratings yet

- Cozen ResumeDocument3 pagesCozen Resumeapi-534216481No ratings yet

- A Case of Possible Hypersensitivity Reactions To Human InsulinDocument6 pagesA Case of Possible Hypersensitivity Reactions To Human Insulingandik danu pramigaNo ratings yet

- Clinical Psychopharmacology Principles and Practice by S Nassir CompressedDocument600 pagesClinical Psychopharmacology Principles and Practice by S Nassir CompressedCátia Ramos100% (1)

- Gac 311 NotesDocument26 pagesGac 311 NotesZAINABU OLANDONo ratings yet

- Audiometer Impedqnce Audiometer AT235 - USER - MANUALDocument103 pagesAudiometer Impedqnce Audiometer AT235 - USER - MANUALKafina Multi SejahteraNo ratings yet

- Importance of Sustainable Development GoalsDocument2 pagesImportance of Sustainable Development GoalsDyas FerNo ratings yet

- Beers Criteria Journal of Applied Pharmaceutical ScienceDocument8 pagesBeers Criteria Journal of Applied Pharmaceutical Sciencenurul.kusumawardani nurul.kusumawardaniNo ratings yet

- Nursing Standard PrinciplesDocument2 pagesNursing Standard PrinciplesRoscelie KhoNo ratings yet

- Participants List DDO's and Their Staff 25Document3 pagesParticipants List DDO's and Their Staff 25Manoj Digi LoansNo ratings yet

- Can Low-Fat Nutrition Labels Lead To Obesity PDFDocument15 pagesCan Low-Fat Nutrition Labels Lead To Obesity PDFSepti Lidya sariNo ratings yet

- Problem and Its BackgroundDocument7 pagesProblem and Its BackgroundErika Chloe H. YabutNo ratings yet

- Introduction: A New Hierarchy of NeedsDocument5 pagesIntroduction: A New Hierarchy of Needsgun2 block100% (1)

- Ndian Nstitute of Ourism & Ravel Anagement: I T T MDocument69 pagesNdian Nstitute of Ourism & Ravel Anagement: I T T Msilly_chilly100% (4)

- Confounding Variables: Ali Yassin and Bara'a Jardali Presented To Dr. Issam I. ShaaraniDocument12 pagesConfounding Variables: Ali Yassin and Bara'a Jardali Presented To Dr. Issam I. ShaaraniAli GhanemNo ratings yet

- Drug Law Seminar PaperDocument70 pagesDrug Law Seminar PaperBapulNo ratings yet

- 20190923swimming Class ProposalDocument9 pages20190923swimming Class ProposalFit AS50% (2)

- Types of X-Ray Machines ExplainedDocument11 pagesTypes of X-Ray Machines ExplainedMuhammad Abu BakarNo ratings yet

- Oral Surgery Maxill - Anesthesia TechniquesDocument4 pagesOral Surgery Maxill - Anesthesia TechniquesSaif AyedNo ratings yet