Professional Documents

Culture Documents

Typical Framing Guide PDF

Typical Framing Guide PDF

Uploaded by

sahanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical Framing Guide PDF

Typical Framing Guide PDF

Uploaded by

sahanCopyright:

Available Formats

FRAMING GUIDELINES

Cutting, Notching, and Boring Lumber Joists

Joist Size Maximum Maximum Maximum

Hole Notch Depth End Notch

2x4 None None None

2x6 11/2 7/8 13/8

2x8 23/8 11/4 17/8

2x10 3 11/2 23/8

2x12 33/4 17/8 27/8

In joists, never cut holes closer than 2 inches to joist edges, nor make them larger than 1/3 the depth of the joist. Also, don’t make

notches in the middle third of a span, where the bending forces are greatest. They should also not be deeper than 1/6 the depth of

the joist, or 1/4 the depth if the notch is at the end of the joist. Limit the length of notches to 1/3 of the joist’s depth. Use actual,

not nominal, dimensions. (“Field Guide to Common Framing Errors,” 10/91)

Hole-Cutting Rules for Wood I-Joists Min. Distance from Inside Face of

Support to Near Edge of Hole

Distance between hole Do not cut holes larger Depth TJI/Pro 2” 3” 4” 5” 6”

edges must be 2x (min.) than 11/2" in cantilever

length of largest hole; 91/2” 150 1’-0” 1’-6” 3’-0” 5’-0” 6’-6”

applies also to 11/2" holes 250 1’-0” 2’-6” 4’-0” 5’-6” 7’-6”

L 2xL 117/8” 150 1’-0” 1’-0” 1’-0” 2’-0” 3’-0”

250 1’-0” 1’-0” 2’-0” 3’-0” 4’-6”

350 1’-0” 2’-0” 3’-0” 4’-6” 5’-6”

550 1’-0” 1’-6” 3’-0” 4’-6” 6’-0”

14” 250 1’-0” 1’-0” 1’-0” 1’-0” 1’-6”

350 1’-0” 1’-0” 1’-0” 1’-6” 3’-0”

550 1’-0” 1’-0” 1’-0” 2’-6” 4’-0”

11/2" holes can be cut 16” 250 1’-0” 1’-0” 1’-0” 1’-0” 1’-0”

anywhere in the web

(11/2" knockouts Leave 1/8" (min.) of 350 1’-0” 1’-0” 1’-0” 1’-0” 1’-0”

provided 12" o.c.) web at top and Min. distance 550 1’-0” 1’-0” 1’-0” 1’-0” 2’-0”

bottom of hole from table

General Notes:

With wood I-joists and other types of engineered lumber, it’s best *Distances in the charts above are based on uniformly loaded joists using the maxi-

to consult the manufacturer’s literature. The example provided here mum loads shown [in TJM’s] brochure. For other load conditions or hole configura-

is courtesy of Trus Joist MacMillan. (“Repiping With PEX,” 10/99) tions, contact TJM representative.

*For simple span (5-foot minimum) uniformly loaded joists, one maximum-size hole may

be located at the center of the joist span provided no other holes occur in the joist. DO

NOT cut into joist flanges when cutting out web.

Notching and Boring Studs

Never notch in the middle third of

a joist span, and limit the length of

notches to one-third the depth of

the member. The rules for notching

and boring studs differ for bearing

and nonbearing walls. (“Ten

Common Framing Flaws,” 4/95)

OCTOBER JLC 2002

FRAMING GUIDELINES

Cantilevers Rafter Bearing

Bearing wall

Correct:

Rafter heel Incorrect: heel

Joists D bears on plate does not bear Top-bearing

on top plate joist hanger

C It’s best to rest the rafter heel on the plate (left), not on the toe (center). Where this

isn’t possible, you can sometimes support it with a joist hanger (right). The joist

Bearing wall hanger also keeps the rafter from rotating, a job that normally requires ceiling joists

or solid blocking. (“Field Guide to Common Framing Errors,” 10/91)

When a cantilever supports a

bearing wall, the distance it

extends beyond its support (C)

should not exceed the depth of Aligning

the joist (D). (“Field Guide to

Common Framing Errors,” 10/91)

Bearing

Walls

If a bearing wall doesn’t line

D up with the support below, it

should lie no farther away

D than the depth of the joists

(D). If the joists are engi-

neered lumber, the walls and

support must align exactly.

(“Field Guide to Common

Framing Errors,” 10/91)

Purlin Design

Splicing Top Plates in Bearing Walls

A properly constructed purlin must be at least the same dimen-

sion as the rafters that it supports. Supporting struts should be

notched into the purlin and installed at an angle not less than Double top plates must be lapped at corners and inter-

45 degrees to transfer the load of the roof to a bearing wall. sections, and splices must be staggered by at least 48

(“Ten Common Framing Flaws,” 4/95) inches. (“Ten Common Framing Flaws,” 4/95)

OCTOBER JLC 2002

FRAMING GUIDELINES

Installing Plywood Sheathing Calculating Snow Loads

When all the panel edges are

supported by solid framing,

1/2-inch plywood sheathing

is stronger against racking

forces when installed hori-

zontally (top sketch). If

there’s no blocking at the 4-

foot mark, the sheathing is

stronger installed vertically,

as long as all edges are sup-

ported (bottom sketch).

(“Frequently Asked Framing

Questions,” 4/98)

Tapered Joist Ends

Overtapering joists to fit 3D When adding up the weight of snow of a

beneath roofs creates inade- max. sloping roof, use the horizontal run of the

quate joist depth at the plate. roof, since the same amount of snow would

A proper cut leaves at least accumulate on a perfectly flat roof. The

half the depth of the joist. D code also allows you to apply a slope reduc-

1/2D min.

(“Field Guide to Common tion factor, to account for snow blowing or

Framing Errors,” 10/91) sliding off a sloping surface. (“Frequently

Asked Framing Questions,” 4/98)

Toe-Nails Are Stronger

Balloon-

Framed

End-nail stud (two 16d Half-Walls

commons required)

Toe-nail stud (four 8d

commons required)

2' minimum

Proper toe-nailed

connection

When adding a shed dormer above balloon-framed half-walls,

When nailing a stud to a plate, a toe-nailed con- don’t build the wall extension directly on top of the balloon wall

nection is typically stronger against lateral forces top plate. Instead, either remove the top plate and carefully splice

than an end-nailed connection. (“Frequently Asked on stud extensions or cut the balloon studs flush and build a new

Framing Questions,” 4/98) full-height stud wall. (“Taking the Sag out of Shed Dormers,” 9/93)

OCTOBER JLC 2002

ROOF FRAMING GUIDELINES

Drop-Ridge Dormers

A. With Structural Ridge Dormer rafter Shed dormer designs sometimes drop the

shed ridge below the main ridge of the

house. With a center bearing wall or struc-

tural ridge (A), this presents no problem; just

Support posts tie in the dormer rafters and add short non-

as required structural rafters above. The drawing shows

Original

rafter three options for tying the dormer rafters to

removed the structural ridge. However, in situations

without a structural ridge (B), special atten-

tion must be given to connecting the dormer

rafters. The author recommends 1/2-inch

carriage bolts at all connections. (“Taking

the Sag out of Shed Dormers,” 9/93)

Structural ridge

Existing

Nonstructural 2 x ridge

B. Without Structural Ridge

Dormer rafter (2) 1/2"

(2) 1/2" carriage

carriage bolts

Dropped bolts

Metal structural Metal

2x4 twist-strip

hanger ridge hanger

hangers

(1) 1/2"

carriage Original

Option 1 Option 2 Option 3 bolt rafter

removed

Ridge Retrofit

Strap Existing

ties ridge

In cases where an existing ridge board

is inadequate for carrying vertical roof

Engineered loads, as in a shed dormer retrofit, you

Reinforcing eaves can use strap ties to suspend a rein-

beam connections forcing beam below the original

ridge. (Practical Engineering, 5/97)

OCTOBER JLC 2002

ROOF FRAMING GUIDELINES

Sizing Structural Ridge Retrofits

Ridge length LVL beam 2x beam*

8' LVL 13/4 x 91/2 (2) 2x10

9' "

10' LVL 1 /4 x 117/8

3 (3) 2x10, (2) 2x12

11' " (2) 2x12

12' " (3) 2x12

13' 3

LVL 1 /4 x 14 Not recommended

14' " "

15' (2) LVL 13/4 x 14 "

16' " "

Note: This table is based on a sample house 24 feet wide (eaves to

eaves), with design snow loads of 30 psf.

* Fb = 760 psi min. (new grading tables), or 1,000 psi with the old tables

Structural Ridge Connections

Structural ridge beams are a good A.

solution for the loads introduced by

a shed dormer addition. The author

prefers to install them in place of

the nonstructural ridge (A), but they

can also be retrofitted below the

existing ridge (B). The table above

gives the author’s sizing recom-

mendations for LVL and laminated

2x ridge beams. (“Taking the Sag

out of Shed Dormers,” 9/93)

B.

OCTOBER JLC 2002

ROOF FRAMING GUIDELINES

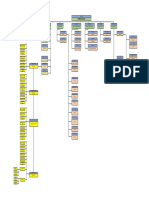

Calculating Load on a King Truss

Assuming a total (dead + live) roof design load of 40 psf:

P = 26' x 16' x 40psf = 13' x 8' x 40psf = 4160 lb. 12

2 2

10

T = 1/2P x Run = 4160 x 12 = 2496 lb.

Rise 2 10

Divide T by bolt capacity to calculate number of bolts (N)

required for joist-rafter connection:

N= T

bolt capacity

To design a rafter-joist king truss to support the end of a structural ridge, the engineer must calculate the tension force, T, that will

be induced in the joist. First, the tributary roof load flowing to the end of the ridge beam is calculated, then this point load, P, is

used to calculate the tension force in the joist. The designer then specifies the bolts needed to carry this tension force at the rafter-

joist connections. (Practical Engineering, 9/97)

Structural Ridge Installation Details

When supporting a structural ridge with a rafter truss, the beam can be sandwiched in place

just like a nonstructural ridge (left), supported by a hanger attached to a gusset plate (mid-

dle), or even hung by straps from an existing ridge board (right). (Practical Engineering, 9/97)

OCTOBER JLC 2002

ROOF FRAMING GUIDELINES

Number of Bolts Required for

King Truss Joist-Rafter Connections

T o use this chart, calculate the point load, P, at the top of the king truss

(always round up), then find the number of bolts required for the roof

pitch. Note that where seven or more 1/2-inch bolts are not recommended,

fewer 1-inch bolts may work. The number of required bolts assumes a single-

shear connection. Reduce bolts by half for double-shear connections. The

chart is based on use of S-P-F 2-by lumber (specific gravity = 0.42). In some,

but not all, cases, fewer bolts would be required if a stronger grade of lumber

were used. Use of lower grades, such as redwood, eastern softwoods, S-P-F

(south), western cedars, western woods, or northern species, would in some

cases require more bolts. When in doubt, the designer should refer to the NDS

tabulated bolt design values, which were used as the basis for this chart.

Point Load (P) on King Truss

Roof Pitch 1000 lb. 2000 lb. 3000 lb. 4000 lb. 5000 lb.

12/12 2 4 5 7* 9*

1 2 3 4 5

10/12 2 4 6 8* 10*

1 2 3 4 5

8/12 3 5 7* 9* 12*

2 3 4 5 6

6/12 3 6 9* 12* 14*

2 3 5 6 7*

4/12 4 8* 12* 16* 20*

2 4 6 8* 10*

3/12 5 11* 16* 21* 26*

3 6 8* 11* 13*

Number of 1/2-inch- *Not recommended

diameter bolts

Number of

1-inch-diameter bolts

Single-Shear Connection Double-Shear Connections

(Practical Engineering, 9/97)

OCTOBER JLC 2002

ROOF FRAMING GUIDELINES

Roof Framing With a Raised Rafter Plate

C.

A.

B.

D.

Structural Ridge

Connections

The raised rafter plate (A) allows room for insulation above the wall plate, but

the lateral thrust of the roof must be accounted for in the design. When using

a raised rafter plate, Simpson strap ties (B) are the easiest way to resist roof

thrust, according to the author. When an attic floor is in the way, twist straps

will work (C). Extending the attic joists beyond the walls (D) provides a strong

rafter-joist connection, but may require additional hurricane ties to resist wind

uplift. (Practical Engineering, 7/96)

The most effective way to reduce outward roof

thrust is to use a structural ridge beam. Either rest

the rafters on top of a structural ridge (top left) or

use joist hangers attached to the ridge beam (left).

The notch at the bottom of the plumb cut should

be no deeper than one-fourth the rafter width.

(“Common Roof-Framing Errors,” 8/95)

OCTOBER JLC 2002

ROOF FRAMING GUIDELINES

Tension Tie Strapping the

Strap Roof Together

ties

Coil

strap

Ceiling

joist

Ceiling

joist

In the absence of a structural ridge or center bearing wall,

ceiling joists are critical for preventing rafters from spread- Where ceiling joists run perpendicular to

ing. Where the joists are interrupted by a flush-framed the rafters, coil strap makes an excellent

beam, strap ties make an ideal tension connection. rafter tie. (Practical Engineering, 5/97)

(Practical Engineering, 5/97)

Upset Beam

Upset

Strongest Joist Hangers

girder Twist

strap

An “upset” girder is often eas- Double-shear

ier to frame than a flush-framed connector

beam. The joists hang by twist

straps, installed in pairs.

(Practical Engineering, 5/97)

Double-shear

nailing

The Right Angle

Heavy-duty angles like

Heavy-duty

angle

Simpson’s HL or USP’s KHL

are a good solution for

attaching that last deck joist

to the ledger board. Double-shear connectors provide greater

(Practical Engineering, 5/97) strength with fewer nails than ordinary

hangers. The angled nail configuration also

makes it easier to drive the nails in a joist

bay. (Practical Engineering, 5/97)

OCTOBER JLC 2002

You might also like

- The Essential Guide To FramingDocument121 pagesThe Essential Guide To Framingpawkom100% (7)

- Treasured Chest Build A Jewelry BoxDocument9 pagesTreasured Chest Build A Jewelry BoxThanasis KyrgiazoglouNo ratings yet

- 50 Contractor Garage Plans ConstructionDocument90 pages50 Contractor Garage Plans Constructionapsaraso100% (5)

- Detail For Wood Frame House Construction - Illustrated HandbookDocument133 pagesDetail For Wood Frame House Construction - Illustrated HandbookPaulo E. Galdini86% (7)

- Framing Basics PDFDocument130 pagesFraming Basics PDFarhitheo90% (10)

- Carpentry Notes On Basic Roof & Ceiling FramingDocument85 pagesCarpentry Notes On Basic Roof & Ceiling FramingBenessa Rose Quiambao100% (16)

- Residential Structural Design Guide: Second EditionDocument403 pagesResidential Structural Design Guide: Second EditionEgay Lumen100% (9)

- Omega - Installation ManualDocument25 pagesOmega - Installation ManualCreaciones VilberNo ratings yet

- Smith House Case Study AnalysisDocument14 pagesSmith House Case Study AnalysisツsalihahNo ratings yet

- Framing With RoofsDocument5 pagesFraming With Roofsgreenelephant150No ratings yet

- Wood Frame ManualDocument324 pagesWood Frame ManualByron Joshua Casco Duarte100% (1)

- Timber Frame EngeneeringDocument59 pagesTimber Frame Engeneeringde Seta Marina86% (22)

- Complete Book of Framing: An Illustrated Guide for Residential ConstructionFrom EverandComplete Book of Framing: An Illustrated Guide for Residential ConstructionRating: 4 out of 5 stars4/5 (2)

- Building the Timber Frame House: The Revival of a Forgotten CraftFrom EverandBuilding the Timber Frame House: The Revival of a Forgotten CraftRating: 3.5 out of 5 stars3.5/5 (11)

- Build Your Own Garage Manual: More Than 175 PlansFrom EverandBuild Your Own Garage Manual: More Than 175 PlansRating: 4 out of 5 stars4/5 (2)

- BS 5266-2Document10 pagesBS 5266-2Anton Husen PurboyoNo ratings yet

- Building A Garden Shed Step By Step Instructions and PlansFrom EverandBuilding A Garden Shed Step By Step Instructions and PlansRating: 2 out of 5 stars2/5 (1)

- Strength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionFrom EverandStrength Of Beams, Floor And Roofs - Including Directions For Designing And Detailing Roof Trusses, With Criticism Of Various Forms Of Timber ConstructionNo ratings yet

- Vacation Homes and Log CabinsFrom EverandVacation Homes and Log CabinsRating: 2.5 out of 5 stars2.5/5 (2)

- Roof Framing: Calculating Lineal and Angular Measurements ForDocument52 pagesRoof Framing: Calculating Lineal and Angular Measurements Foralex100% (1)

- Advanced Framing Construction GuideDocument24 pagesAdvanced Framing Construction GuideCeyanez100% (13)

- Framing Vocabulary Test 2009Document26 pagesFraming Vocabulary Test 2009Randy Stribley100% (1)

- Scott McBride Roof - FramingDocument7 pagesScott McBride Roof - FramingMarius Camy PingaNo ratings yet

- Conventional Wood Frame ConstructionDocument55 pagesConventional Wood Frame Constructioncrysty9986% (7)

- Roof FramingDocument31 pagesRoof Framingpiedrahec100% (1)

- Advanced Framing Construction GuideDocument24 pagesAdvanced Framing Construction GuidePablo Dangelo100% (5)

- Wood Frame House ConstructionDocument241 pagesWood Frame House Constructioneglyph100% (13)

- PostFrameConstructionGuide LowresDocument20 pagesPostFrameConstructionGuide LowresDoug Johns100% (5)

- The Post-Frame Advantage HandbookDocument61 pagesThe Post-Frame Advantage HandbookChuck Achberger100% (1)

- 172-Post Beam Construct2013Document46 pages172-Post Beam Construct2013yourmomsnutz100% (1)

- MinimumStandards - (Ext Wall Framing)Document14 pagesMinimumStandards - (Ext Wall Framing)Samia H. BhuiyanNo ratings yet

- W Wile129Document26 pagesW Wile129pappy186540% (5)

- Structural Design Loads For One - and Two-Family DwellingsDocument47 pagesStructural Design Loads For One - and Two-Family Dwellingsv100% (10)

- Residential Building ConstructionDocument434 pagesResidential Building Constructionvelarajan100% (21)

- Black & Decker The Complete Guide To BathroomsDocument289 pagesBlack & Decker The Complete Guide To Bathroomsasiasi100% (2)

- 13 Ext Walls FramingDocument35 pages13 Ext Walls FramingAnonymous 4SVSd7jN100% (1)

- Framing and Building BasicsDocument19 pagesFraming and Building BasicsDurgaPrasadKrishnaNo ratings yet

- The Complete Guide To DecksDocument322 pagesThe Complete Guide To Decksssshhhki100% (37)

- Wood-Frame House Construction PDFDocument229 pagesWood-Frame House Construction PDFMelendres Benito100% (2)

- Builders Foundation HandbookDocument124 pagesBuilders Foundation Handbookvelarajan100% (11)

- Black & Decker Here's How... DecksDocument98 pagesBlack & Decker Here's How... DecksVic Cumpas100% (3)

- Professional Stairway Building SecretsFrom EverandProfessional Stairway Building SecretsRating: 3.5 out of 5 stars3.5/5 (3)

- 5 Contractor Spec House Plans Blueprints Construction Drawings 1200 Sq Ft to 1800 Sq Ft 3 Bedroom 2 BathFrom Everand5 Contractor Spec House Plans Blueprints Construction Drawings 1200 Sq Ft to 1800 Sq Ft 3 Bedroom 2 BathNo ratings yet

- Carpentry and Framing Inspection Notes: Up to CodeFrom EverandCarpentry and Framing Inspection Notes: Up to CodeRating: 5 out of 5 stars5/5 (1)

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Sheetrock & Shellac: A Thinking Person's Guide to the Art and Science of Home ImprovementFrom EverandSheetrock & Shellac: A Thinking Person's Guide to the Art and Science of Home ImprovementRating: 4.5 out of 5 stars4.5/5 (5)

- 16' x 16' Garage Plans Construction BlueprintsFrom Everand16' x 16' Garage Plans Construction BlueprintsRating: 5 out of 5 stars5/5 (1)

- How to Build a House: A Practical, Common-Sense Guide to Residential ConstructionFrom EverandHow to Build a House: A Practical, Common-Sense Guide to Residential ConstructionRating: 4 out of 5 stars4/5 (5)

- CAT407 Isolated FoundationsDocument9 pagesCAT407 Isolated FoundationsKim Patrick GonzalesNo ratings yet

- TNF Window BoxesDocument4 pagesTNF Window BoxesFaithrul RijalNo ratings yet

- Soft-Storey Behaviour in An Earthquake and Samples of Izmit-DuzceDocument8 pagesSoft-Storey Behaviour in An Earthquake and Samples of Izmit-DuzceH S Vishwanath ShastryNo ratings yet

- Issue 12, 2013 Journal of Civil Engineering and ArchitectureDocument136 pagesIssue 12, 2013 Journal of Civil Engineering and ArchitectureJCEAJournalNo ratings yet

- Building WaterproofingDocument6 pagesBuilding WaterproofingAnirudh Anand100% (2)

- SAOTA 1 Type SingleResidential PDFDocument45 pagesSAOTA 1 Type SingleResidential PDFEdward PeinkeNo ratings yet

- Edgewood Clubhouse FlyerDocument2 pagesEdgewood Clubhouse FlyerinforumdocsNo ratings yet

- Building Regulations - Gurgaon PDFDocument105 pagesBuilding Regulations - Gurgaon PDFShivansh Singh Gautam100% (2)

- Edt - Torre PanamaDocument1 pageEdt - Torre PanamaJorge RamNo ratings yet

- 5 House StylesDocument116 pages5 House StylesAlfred Harvey Elacion100% (3)

- Bookofrandomtables InnsandtavernsDocument59 pagesBookofrandomtables InnsandtavernsSir50% (2)

- ProtaStructure Suite 2018 Whats NewDocument44 pagesProtaStructure Suite 2018 Whats NewHenry100% (1)

- Process Industry Practices Architectural: PIP ARC01016 Building Data SheetDocument12 pagesProcess Industry Practices Architectural: PIP ARC01016 Building Data SheetWNo ratings yet

- The Evolution of Architectural Style in Architect Muzharul Islam's WorkDocument21 pagesThe Evolution of Architectural Style in Architect Muzharul Islam's WorkJafor SadequlNo ratings yet

- In My House I Have Four RoomsDocument2 pagesIn My House I Have Four RoomsAdrianPetrilaNo ratings yet

- May 4 2018Document12 pagesMay 4 2018johnaustin1No ratings yet

- 3-Storey ResidentialDocument4 pages3-Storey ResidentialLesther RobloNo ratings yet

- Sample BOQ 2016Document10 pagesSample BOQ 2016Chameera ManaramNo ratings yet

- SPC-0804.02-90.03 Rev D2 FG Detection and ProtectionDocument16 pagesSPC-0804.02-90.03 Rev D2 FG Detection and ProtectionSofiane MoussaouiNo ratings yet

- Veranda: Architecture DesignDocument14 pagesVeranda: Architecture DesignJethro Martinez MirasolNo ratings yet

- Wall Structures: After The Foundations Have Been Completed The Walls Are Set Out and Construction CommencesDocument16 pagesWall Structures: After The Foundations Have Been Completed The Walls Are Set Out and Construction CommencesMirza Waqar BaigNo ratings yet

- The Golden RatioDocument7 pagesThe Golden RatioManasAroraNo ratings yet

- Right Side Elevation Front Elevation: GL GLDocument1 pageRight Side Elevation Front Elevation: GL GLAnthonio MaraghNo ratings yet

- Design of An Enclosed Football StadiumDocument32 pagesDesign of An Enclosed Football StadiumHani100% (1)

- Mondopave Instal GuideDocument4 pagesMondopave Instal GuideFloorkitNo ratings yet