Professional Documents

Culture Documents

Future Semester Course Descriptions

Uploaded by

Lokesh Sangabattula0 ratings0% found this document useful (0 votes)

8 views3 pagesOriginal Title

Future semester course descriptions

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesFuture Semester Course Descriptions

Uploaded by

Lokesh SangabattulaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

List of courses and descriptions of courses that will appear

in the final transcript, but are not in your current transcript

● Course : MM 206-Experimental Techniques in Materials Science

Description: This course is designed to give a basic exposure to the experimental

techniques that are available for the characterization of materials. The goal of the course is

to get students acquainted with basic characterization technique and enable them to quantify

material properties like density, surface area, organic-inorganic content, conductivity,

morphology, porosity etc.. The course starts with the basics of structure of materials- You’ll

revisit lattice structures, point groups, space groups, XRD analysis, fcc-bcc,etc. Further he

will teach about some characterization techniques which are very basic and are used for

characterizing almost everything. These include DTA, TGA, DSC, their working and

applications.

● Course :ME 220-Theory of Machine and Machine Design

Description: Kinematics of linkages, cams and gear trains. Velocity and static force

analysis. Geometry of gear teeth. Spur, helical, worm and bevel gears. Belt and chain drives,

couplings, clutches, and brakes. Design considerations-material selection, allowable stresses

and deflections, fatigue and factor of safety. Design of welded joints. Keys, splines and

cotters. Design of shafts. Bearing selection. Considerations in pressure vessel design. Thin

cylinders.

● Course :EE 209-Electrical/Electronics Lab

Description: This course is an introductory course and one can work hands on with

electronic devices. It also helps familiarize you with the Transformers. Grading during lab

sessions are done based on results in the Electronics lab. In the Electrical lab, which

involves transformer, one has to perform an experiment as demonstrated by the T.As for

different parameters and submit a report.

● Course :MM 220-Computation Lab

Description: Lab concentrates on three languages : Octave, Matlab and Python. The courses

introduces one to each of the language one by one with the help of some solved examples

and further problems to be solved on your own.

● Course :MM 359-Metal Casting and Joining

Description: Casting: Introduction to moulding and casting process. Casting properties of

liquid metals. Casting defects. Patterns. Gating and risering systems.

Solidification: Homogeneous and heterogeneous nucleation. Rate of nucleation.

Solidification of single phase metals and alloys. Constitutional supercooling. Solidification

of multiphase alloys. The structure of ingot. Control of grain structure.

Joining: Principles of fusion and non-fusion methods of joining metallic, ceramic and

composite materials. Arc, plasma, electron-beam and laser welding processes. Adhesive

bonding of metal/polymer and composite systems. Corrosion characteristics of welds.

Automation in welding.

● Course :MM 320-Process Metallurgy Principles

Description: Part-A: Mineral processing Metallurgical accounting and control,

characterization of particles, sizing, fluid dynamics, comminution, liberation, gravity

separation, surfaces and interfaces, froth flotation, Solid-liquid separation.

Part-B: Extraction metallurgy Thermodynamic principles, reaction kinetics, fuel

preparation, copper and zinc smelting. Hydrometallurgy principles and unit operations,

hydrometallurgical flow-sheets (Bayers process). Electrometallurgy principles. Aluminium

production by fused salt electrolysis (Hall-Heroult cell). General methods of refining.

● Course :MM 322-Casting and Joining Lab

Description: Tungsten inert gas welding of mild steel and stainless steel plates.

Determination of weld thermal cycle, cooling rate and macrostructure. Microstructural

characterization of welds Induction melting + Centrifugal casting + ESR. Aluminum casting

+ Metal matrix composite by stir casting. Determination of casting macrostructure.

● Course :MM 323-Manufacturing and Processing Lab

Description: This course deals with some industrial level manufacturing processes at a

small scale in the laboratory. It gives exposure to various processes through which different

materials are synthesized and their characterization. Mostly includes synthesis of glass,

combustion synthesis of materials, polymer processing, dilatometer experiment and powder

compaction etc along with characterization of materials synthesized using techniques like

FTIR, SEM, XRD and DTA etc.

● Course :MM 312-Heat Treatment Laboratory

Description: Determination of critical temperatures, hardenability, effect of cooling rates

quenching media. Studies of tempering phenomena, carburising, heat treatment of special

steels. Group discussions on heat treatment processes like annealing, normalising, hardening

and tempering, special heat treatment processes like austempering, martempering surface

hardening, carburising, carbonitriding, nitriding, cyaniding etc.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ship Stability FormuleDocument12 pagesShip Stability FormuleHaziq Ismail100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Air Control1 Kody I Usterki enDocument2 pagesAir Control1 Kody I Usterki ensebastian92% (12)

- Preheat RequirementsDocument3 pagesPreheat RequirementsVJG369No ratings yet

- Kashmiri Gate IsbtDocument6 pagesKashmiri Gate IsbthuhuhahaheheNo ratings yet

- Research Proposal - Australian National University FRT FellowshipDocument2 pagesResearch Proposal - Australian National University FRT FellowshipLokesh SangabattulaNo ratings yet

- Harshita LoRDocument1 pageHarshita LoRLokesh SangabattulaNo ratings yet

- Device Manufacturing and Processing' and Science and Technology of Thin Films' Wherein HeDocument1 pageDevice Manufacturing and Processing' and Science and Technology of Thin Films' Wherein HeLokesh SangabattulaNo ratings yet

- Apple Cover LetterDocument1 pageApple Cover LetterLokesh SangabattulaNo ratings yet

- Ee209 GroupsDocument1 pageEe209 GroupsLokesh SangabattulaNo ratings yet

- Sangabattula - Lokesh - Motivation Letter - 1998-08-14Document2 pagesSangabattula - Lokesh - Motivation Letter - 1998-08-14Lokesh SangabattulaNo ratings yet

- Lecture 4: Elasticity, Tensor Algebra G E Dieter: 2 T. H. Courtney: 1 Additional Reading: J F Nye: Physical Properties of CrystalsDocument8 pagesLecture 4: Elasticity, Tensor Algebra G E Dieter: 2 T. H. Courtney: 1 Additional Reading: J F Nye: Physical Properties of CrystalsLokesh SangabattulaNo ratings yet

- Problem and Solution On Gear TrainDocument5 pagesProblem and Solution On Gear TrainLokesh SangabattulaNo ratings yet

- Analysis of Tensile Test Data Using MS ExcelDocument22 pagesAnalysis of Tensile Test Data Using MS ExcelLokesh SangabattulaNo ratings yet

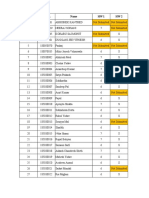

- Air HW1 Marks and Submission Status For HW2Document9 pagesAir HW1 Marks and Submission Status For HW2Lokesh SangabattulaNo ratings yet

- Egm Owners ManualDocument28 pagesEgm Owners Manualmohamed abourayaNo ratings yet

- Reciprocating Compressors For Industrial Refrigeration Series Grasso VDocument56 pagesReciprocating Compressors For Industrial Refrigeration Series Grasso VVadimNo ratings yet

- JW Pump Curve - F3514g-F3524g-F3524gsiDocument1 pageJW Pump Curve - F3514g-F3524g-F3524gsikman548No ratings yet

- CDMA 800 TestDocument10 pagesCDMA 800 TestermellowNo ratings yet

- Pms Color ChartDocument20 pagesPms Color ChartAnaidNo ratings yet

- Overview of CO2 Injection and WAG Sensitivity in SACROC: January 2016Document23 pagesOverview of CO2 Injection and WAG Sensitivity in SACROC: January 2016Jorge Andrés TovarNo ratings yet

- US4027928Document17 pagesUS4027928ShahNo ratings yet

- Komatsu 931 Brochure - EN PDFDocument2 pagesKomatsu 931 Brochure - EN PDFMohammad KasbullahNo ratings yet

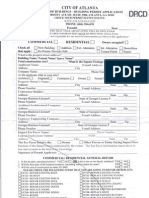

- City of Atlanta Demolition Permit and ProceduresDocument2 pagesCity of Atlanta Demolition Permit and ProceduresgragsdaleNo ratings yet

- MBA ProjectDocument5 pagesMBA ProjectNaushad KhanNo ratings yet

- Module 2: Cost Concepts and Design EconomicsDocument46 pagesModule 2: Cost Concepts and Design EconomicsSyafiq JaafarNo ratings yet

- H-Beam Catalogue JindalDocument4 pagesH-Beam Catalogue JindalVikram DalalNo ratings yet

- 16th National Power Systems ConferenceDocument11 pages16th National Power Systems ConferenceHarish ReddyNo ratings yet

- StormsaverDocument6 pagesStormsaverKanu LiNo ratings yet

- Super Imposed FlowsDocument4 pagesSuper Imposed FlowssuriyaanaNo ratings yet

- 1st AssignmentDocument2 pages1st AssignmentMAI 95No ratings yet

- Technical Data Sheet - RIBLENE - FL 34 F - ITDocument2 pagesTechnical Data Sheet - RIBLENE - FL 34 F - ITEmanuele GizziNo ratings yet

- Nytro® Libra: Property Unit Test Method Specification Limits Typical Data Min Max 1 - FunctionDocument2 pagesNytro® Libra: Property Unit Test Method Specification Limits Typical Data Min Max 1 - FunctionAUFA JAYA PERKASANo ratings yet

- R1-ADseries CorecessDocument314 pagesR1-ADseries Corecesscarrizof100% (1)

- Sheick Portfolio Welcome LetterDocument1 pageSheick Portfolio Welcome Letterapi-231627678No ratings yet

- C-Zone Jun 01Document2 pagesC-Zone Jun 01Razer CicakNo ratings yet

- The Mechanical Properties of Poly (Ether-Ether-Ketone) (PEEK) With Emphasis On The Large Compressive Strain ResponseDocument18 pagesThe Mechanical Properties of Poly (Ether-Ether-Ketone) (PEEK) With Emphasis On The Large Compressive Strain ResponseUriel PeñaNo ratings yet

- The Enigma Group ManualDocument8 pagesThe Enigma Group ManualaicosiNo ratings yet

- Project Coordinator Business Analyst in Charlotte NC Resume Sean BrandonDocument4 pagesProject Coordinator Business Analyst in Charlotte NC Resume Sean BrandonSeanBrandonNo ratings yet