0 ratings0% found this document useful (0 votes)

264 views15 pages01 ASME Sec I

Asme sec1

Uploaded by

Jef LoganCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

264 views15 pages01 ASME Sec I

Asme sec1

Uploaded by

Jef LoganCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

‘ASME RPUC-20%7

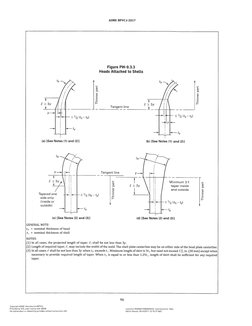

that differ in thickness by mare than one-fourth the thick

ness ofthe thinner section or by more than Yin. (3mm,

whichever isles, When a taper is required on any formed

head thicker than the shell and intended for butt-welded

attachment [see Figure PW-9.3.3, illustrations (e) and

(@)] the length of the skirt as measured from the tangent

line shall meet the requirements in Figure PW.9.33 and

the taper shall be entirely within the skirt. When the ran-

sition Is formed by removing material from the thicker

section, the minimum thickness ofthat section, after the

material is removed, shall not be less than that required

by Part PG. The centerline misaligament between shell

and head shallbe no greater than one-half the difference

botwoen the actual shell and head thickness, as illustrated

in Figure PW-9:33, illustrations (a) through (4).

PW-9.4 Prohibited Welded Joints. Corner joints as

depicted in Figure PW-9.4 are prohibited,

PW-10 HEAT TREATMENT

Vessels and vessel parts shall be preheated and post-

weld heat treated in accordance with the requirements

in PW-38 and PW-39.

PW-11 VOLUMETRIC EXAMINATION OF WELDED

BUTT JOINTS

PW-1L1 Welded butt joints requiring volumetric ex-

amination are specified in Table PW-11. Unless Table

PW-11 restricts volumetric examination to one method,

either the radiographie or the ultrasonic method may be

used. Acceptance of the weld shall he determined by the

method selected for the initial examination of the com:

pleted weld, Ifrepairs are required, the repairs shall be

examined using the same method by which the unaccep-

table Imperfections were detected. Subsequent examina-

tion of the weld following acceptance is beyond the

requirements of this Section and shall be a matter of

agreement between the Manufacturer and the User.

Experience has demonstrated that welded butt joints,

rot requiring volumetric examination hy these rules have

igiven safe and reliable service even ifthey contain imper-

fections that may be disclosed upon further examination,

Any examination and acceptance standards beyond the

requirements of this Section are beyond the scope of this

Code and shall be a matter of agreement between the

Manufacturer and the User.

PW-1L2 Definitions. For use with Table PW-11 and

elsewhere in this Section, the following definitions apply:

butt joint a joint between two members aligned approxi

mately in the same plane,

circumferential butt weld: includes circumferential

welded butt joints in drums, headers, pipes, and tubes,

and welded butt joints attaching formed heads to drums,

shells, and headers.

95

longitudinal bute weld: includes longitudinal and spiral

welded butt joints in drums, shells, headers, pipes, and

tubes; any welded butt joine within a sphere or within a

formed or fat head or tubesheet; and welded butt joints

attaching Insert-nozzles of the type shown in Figure

PW-16., illustrations (q-1) through (q+)

nondestructive examination (NDE): examination methods

used to verify the integrity of materials and welds in a

component without damaging its structure or altering

its mechanical properties. NDE may involve surface, sub-

surface, and volumetric examination,

‘NPS: nominal pipe size

volumetric NDE: a method eapable of detecting imperfec-

tions that may be located anywhere within the examined

volume. For Section I construction, volumetric NDE is lim-

ited to radiographic (RT) and ultrasonic (UT) examination

methods.

PW-1L3 For use with Table PW-11, the size and

thickness of welded butt joints is defined as the larger

and thicker of the two abutting edges after edge

preparation.

‘The geometric unsharpness Uy is defined by the

equation

Uy = asd

distance from source of radiation to the weld

distance from the source side af the weld tothe flm

source size; the maximum projected dimension of

the radiating source (or effective focal spot) in

the plane perpendicular to the distance D from

the weld

Uy = geometric unsharpness

PW-13 HEAD-TO-FLANGE REQUIREMENTS

Dished heads, other than hemispherical, concave to

pressure to be attached by hutt welding, and flanged

heads or flanged furnace connections to be fillet welded,

shall have a length of flange not less than 1 ia, (25 mm)

for heads or furnace openings not over 24 in. (600 mm)

In external diameter and not less than 1% in. (38 mm)

for heads or furnace openings over 24 in. (600 mm) in

diameter

PW-14 OPENINGS IN OR ADJACENT TO WELDS

‘Any type of opening that meets the requirements for

compensation given in PG-32 through PG-44 may be lo

cated in a welded joint

PW-15 WELDED CONNECTIONS

PW-15.1 Nozzles, other connections, and their com-

pensation may be attached to vessels by arc or gas weld-

Ing. Sufficient weld and compensation shall be provided

ASME BPVCE-2017

figure Pw-9..3

vada Shas

a a

: :

eg Les ign)

Li Steer

idole dst Seen auel

Foote cye

cae ieee le

a heyy 1 taper inside: a

: i tious |E

termi |e | :

‘side only, e = -

cease |} LT esptyaip

rar | |

ae falta

(dibs silo ieee

ae ros

ee isa

ome

em ed sho halo ioc

Eafe eet etreerco Me Ee ER

eee maa ane a areas a ste an airs oni

x

96

ASME pvcL2017

Figure PW-9.4

Prohibited Welded Joint

‘on either side ofthe plane through the center of the open:

ing parallel to the longitudinal axis ofthe vessel, to devel

‘9p the required strength, as prescribed in PG-37, in shear

or tension, whichever Is applicable (see Figure PW-15 for

example calculations, where, if fillet weld has unequal

legs, the value of WL; or WL shall be taken as the length

of the shorter leg).

PW-15.1.1 The stress correction factors in

PW-15.2 shall apply to all welds.

PW-15.1.2 The strength of fillet welds shall be

based on one-half the area subjected to shear, computed

fon the average diameter of the weld

PW-15.1.3 The strength of groove welds shall be

based on one-half the area subjected to shear or tension,

a6 applicable, computed using the minimum weld depth

dimension in the direction under consideration,

PW-15.1.6 The strongth calculations for nozzle at-

tachment welds are not required for the weld configura:

tions shown in Figure PW-16.1, illustrations (a) through

(©), (2) (h), (0), (4-1) through (q-4). (u-1), (v-1}, (WI),

(9, and (2).

PW-15.2 Stress Values for Weld Metal. The allow-

able stress values for groave and fillet welds in percen-

tages of stress values far the vessel material are as

follows:

Ms Peveentog

‘rooveeweld tension 7485

(Groove-weld shear 0%

illeceld shear 23%

NOTE: Thee values are obtinod by combining the following factors

£87498 for combined end and side loading 80% fr shear strength,

and the applicable ointefclency factors

PW-15.3 Compensation plates and sales of nozzles

attached to the outside ofa vessel shall be provided with

atleast one telitale hole [maximum size Yin. (6 mm) pipe

tap] that may be tapped fora preliminary compressed

and soapsids test far tightness of welds that seal of the

inside ofthe vessel. These telltale hols shall e let open

whe the vessel sin service

97

PW-15.4 Figure PW-16.1 illustrates some types offi

sion welded connections which are acceptable

When end faces of nozzle or manhole necks are to re-

main unwelded in the completed vessel, these end faces

shall not be cut by shearing unless at least Yo in

(3 mm) of additional metal is remaved by any method

that will produce a smoath finish,

PW-16 MINIMUM REQUIREMENTS FOR

ATTACHMENT WELDS

PW-16.1 General. Except as permitted in PW-165,

PW-16.6, and PW-167 nozzles and other connections #0

shells, drums, and headers shall he attached by full pene-

tration welds applied from one or both sides, partial pen

tration welds applied from both sides, fillet welds

applied fram beth sides, or fillet and partial penetration

welds on opposite sides. In addition to the strength calcu

lations required in PG-37, the location and minimum size

of attachment welds for nozzles and other connections

shall conform to the requirements in this paragraph,

PW-16.2 Nomenclature. The symbols used in this

paragraph and in Figures PW-16.1 and PW-16.2 are de-

fined as follows

= thickness of vessel shell or head

not less than the smaller of ‘jg in. (6 mm) or

[Link] (inside corner welds may be further

ited by a lesser length of projection of the nozzle

wall beyond the inside face of the vessel wall)

thickness of lug, hanger, ar bracket, as shown in

Figure PW-16.2

the smaller of Yq in, (19 mm) of the thickness of

either of the weld parts joined by a fille, single

bevel, or single J-weld

thickness of nozzle wall

dimension of partial penetration attachment

welds (fillet, single bevel, or single ), measured

as shown in Figure PW-16.1,

fy + t2 2 1Yatnin measured as shown in Figure PW-16.1,

in,,both ¢y ‘and ¢, shall each be not less than the smaller

OF Ye It. (6 Mien) OF 0.7 yg

Table PW-11

Required Volumetric Examination of Welded Butt Joints

Pressure Part Service Conditions [Note (3

Subject to Furnace Radian Heat

Note Not Subject to Furnace Radiant est [Not

att Weld Type ‘Contains Seam andjer Water Contains Water Contains Steam

‘means ‘Al sves and thicknesses ‘Alsies an thickness ‘A zes ad tikes

CCreumeronsa ween» NPS 30 (ON 280) or > NPS 10 (ON 20) or > NPS 10 (DN 250) or

‘rams end shells > 1Nn (29) eek > :n- 29 mm) Sen. (29 mm hk

thick

CGreumretial wasn» NPS4 (DN 100) or > NPS 10 (ON 260) o > NDS 16 (DN 400) or

‘ines tes, on > Yes (14 mn) tik > e- (28 mm) Sin (43 mm hick

headers thick

‘GENERAL NOTES:

[@) Unless exerted by this table, all ongitudinal and circumferential weldad but Joints are to be volumetrically examined

‘hroughost ther entre length

(6) Volumetrie exarinaton i required when either the size or wall tknes ints exceeded (ie, the dlameter and thickness

liieatons apply independent)

(2. Raiographe examination shall be performed in accordance with P51,

{} Ultrasonic examination shall be carved out in accordance with PW-52,

(6) Personne performing the volumetric examination requtved by this table shall be quolifed and certifi in accordance with

Pwst,

(© Whon any combination of radicgraphi parameters produces a geometric unsharpness exceeding 0.07 in. (1.8 mm) then UT

shall be weed

(e)_ Where the thickness i Below Jin (13 mm) then RT shall be use

(0) Both RT and UT examination are requires for weld in fritc materiale using the electslag process. a grain refining (aus

tenlzng) heat treatment i se the UT examination shall be perform after the est tentment fs completed an austen

Ing heat treatment isnot used, the UT examination shall be done afer an intermediate postweld heat treatment er after the

‘nal poste heat treatment is completed,

(0) Both RT and UT examination are required for welds in any material using the inertia or continuous dive fiction welding

process

0) Foretecarc bolersvolumetee examination ¢ not reguired when the maximum allowable working pressure i £100 psig (700

Pa) and the shell LD. iss 16 i. (40 mm) (Gee PEB-).

(0) For fret boilers, volumetric examination ie not required for

(2), longiudinalweided bt joint in armaces made with the ation oiler metal provided a hend testo sample ofthe

‘weld jin foreach section ofthe furnace meets the requirements of PW-S3

(2). ircumferentia welded butt jolts in furaces (se PFT-14)

(3) bute weld and corner cits meeting the requirements of PET-22.1 through PET-21.3 for waterlegs, furnaces, and

fireboxes

(0). Fer miniature boilers, wohumetrc examination i not required (sce PMD),

(7m) Volumetric examination Is not required for te langiudinl weld in ERW procuct that comply with an acceptable material

specification when used for construction within the linitations of P6-95,

(a) For watertobebotlers, volumetric examination snot required for butt welds and corner joint meeting the requirements of|

PWT-12 and PFT-2,

Notes

(1) Service conditions and pressure part contents areas determined bythe designer.

(2) A eld will mothe considered subject to radiant hes from the furnace when in a portion ofa pressure part that hes five or mare

rows af tubes between it and the rma,

98

ASME BPVCI.2017

ofthe affected area, and an engineering evaluation for dls-

position shall be performed by the Manufacturer respon:

sible for certifying the boller uni.

PW-44.8.4 Other elements that may be considered

for inclusions in the production examination progeam in

elude the following

(a) validation of chemical composition of the clad, par

ticularly chromium

0) documentation of dimensional characteristics of the

completed component

(@) records of clad areas for each weld consumable

used

(a) bardness testing

(©) examining the clad surface with copper sulfate to

identify bare areas

@) macroscopic and microscopic metallographic

sampling

PW-44.9 Defects confined tothe clad, revealed by the

‘examinations in PW-4.8 or found otherwise, that da not

fencroach on the minimum clad thickness or the minimum

total wall thickness shall be removed locally by mechan-

ical means and the area smoothly blended to the adjacent

contour. Defects that encroach on the minimum clad

thickness or the minimum total wall thickness shall be

‘weld repaired in accordance with the applicable portions

of PW-41. All repaired areas shall subsequently be exam

ined to the requirements of PW-84.8 and subparagraphs

and shown to conform to the acceptance standards in

A270,

INSPECTION AND TESTS

PW-46 GENERAL

PW-46.1 ‘The rules in the following paragraphs apply

specifically to the inspection and testing of power boilers

and power boiler parts that are fabricated by welding and

shall be used in conjunction with the general require

‘ments for inspection and tests in Part PG as well as the

specific requirements for inspection and tests in the ap:

plicable Parts of this Section that pertain to the type of

boiler under consideration,

PW-46.2 Inspection During Fabrication. The Manu-

facturer shall submit the vessel or other pressure part

{or inspection at such stages ofthe work as may be desig

nated by the Inspector

PW-47 CHECK OF WELDING PROCEDURE

PW-47.1 [tis the duty of the Inspector to assure him

self that the welding procedures employed in construc

tion have been qualified under the provisions of Section

IX. The Manufacturer shall submit evidence to the Inspec

tor that those requirements have been met

PW-47.2 ‘The Inspector has the right at any time to

call for and witness the test welding and testing although

itis not mandatory that he witness the test welding and

the testing unless he so desires

PW-48 CHECK OF WELDER AND WELDING

OPERATOR PERFORMANCE

QUALIFICATIONS

PW-48.1 Itisthe duty of the Inspector to assure him:

self thatall welding is done by welders or welding opera:

tors qualified under the provisions of Section IX. The

‘Manufacturer shall make available to the Inspector a cer:

tified copy of the record of performance qualification

tests of each welder and welding operator as evidence

that these requirements have been met.

PW-48.2 The Inspector has the right at any time to

call for and witness the test welding and testing although

it is not mandatory that he witness the test welding and

the testing unless he so desires.

PW-49 CHECK OF HEAT TREATMENT PRACTICE

‘The Inspector shall satisfy himself that all heat treating

operations required by the Code have heen correctly

performed,

PW-50 QUALIFICATION OF NONDESTRUCTIVE

EXAMINATION PERSONNEL

PW-50.1 ‘The Manufacturer shall be responsible for

assuring that nondestructive examination (NDE) person-

nol have been qualified and certified in accordance with

their employer's written practice prior to perforining or

evaluating radiographic or ultrasonic examinations re-

quired by this Section, SNT-TC-14** or CP-189 shall be

used as a guideline for employers to establish their writ-

ten practice. If the techniqutes of computed radiography

(CR), digital radiography (DR), phased array ultrasonic

testing (PAUT), or ultrasonic time-of-flight diffraction

(TOFD) are used, the training, experience, and examina-

ton requirements in Section V, Article 1, Mandatory

Append I shal also be Incluced im the employer's wr

ten practice for each technique as applicable, National or

International Central Certification Programs may be used

to fulfill the examination and demonstration require-

ments of the employer's written practice, Provisions for

training, experience, qualification, and certification of

[NDE personnel shall be described in the Manufacturer's

quality control system (see PG-105.4).

PW-50.2 _ NDE personnel shall be qualified by exam

nation, Qualification of NDE Level Ill personnel certified

prior to the 2004 Edition of Section | may be based on de

monstrated ability, achievement, education, and expert

tence. Such qualification shall he specifically addressed

im the written practice. If the NDE Level Ill personnel

are certified in either the RT or UT methods and uses

the techniques of computed radiography (CR), digital

radiography (DR), phased array ultrasonic testing

28

ar,

ASME BPVC-2017

(PAUT), oF ultrasonic time-of-fight diffraction (TOFD),

then prior to their next recertification period, the require-

ments in Section V, Article 1, Mandatory Appendix Il for

Level Il personnel shall also be met. When NDE person-

nel have heen certified in accordance with a written prac-

tice based on an edition of SNT-TC-1A or CP-189 earlier

‘than that referenced in A-360, their certification shall

be valid until their next scheduled recertification,

PW-50.3 Recertification shall he in accordance with

the employer's written practice based on the edition of

SNT-TC-1A or CP-189 referenced in 4-360. Recertification

may be based on evidence of continued satisfactory per-

formance or by reexamination(s) deemed necessary by

‘the emplayer- In addition, fthe techniques of computed

radiography (CR), digital radiography (DR), phased array

ultrasonic testing (PAUT), or ultrasonic time-of-flight dif-

fraction (TOFD) are used, the training, experience, and ex

amination requirements in Section V, Article 1,

Mandatory Appendix I! shall he met by NDE personnel

prior to recertification

PW-51 RADIOGRAPHIC EXAMINATION

PW-511 When the radiographic examination method

is used for a weld requiring volumetric examination by

PW-11, the weld shall he examined throughout its entire

length by the X-ray or gamma-ray method in accordance

with Section V, Article 2. The requirements of 1-274 are to

be used as a guide but not forthe rejection of radiographs

unless the geometrical unsharpness exceeds 0.07 in.

(1.8 mm)

PW-51.2 A single-weldod circumferential butt joint

‘with backing strip may be radiographed without remav-

ing the backing strip, provided it is not to be removed

subsequently and provided the image ofthe backing strip

‘does not interfere withthe interpretation of the resultant

radiographs,

PW-51.3 Indications shown on the radiographs of

‘welds and characterized as imperfections are unaccepta-

ble under the following conditions, and shall be repaired

as provided in PW-40 and the repair radiographed to

PW-5I:

PW-513.1 Any indication characterized as a crack,

br zone of incomplete fusion or penetration

PW-51.3.2 Any other elongated indication on the

radiograph that has a length greater than

(6) Yai. (6 mm) for ¢ up 10% in. (19 mm)

(0) it for ¢ from Yq in. (19 mmm) to 2% in. (57 mm)

(0% in. (19 mm) for t over 244 in. (57 mm)

where ¢ is the thickness of the weld

PW-5L3.3 Any group of aligned indications that

have an ageregate length greater than ¢ in a length of

12¢, except when the distance between the successive i-

perfections exceeds 62. where L is the length of the long:

fest imperfection in the group,

130

PwW513.4

shown in 4-250,

Rounded indications in excess of those

PW-51.4 A complete set of radiographs for each job

shall be retained by the Manufacturer and kept on file

for a period of at least 5 years. Radiographs may be re:

tained as film, digital images, or files. If film radiographs

are digitized, the digitization shall be in accordance with

Section V, Article 2, Mandatory Appendix i,

PW-52_ ULTRASONIC EXAMINATION

PW-52.1 When the ultrasonic examination method is

uused for a weld requiring volumetric examination by

PW-11, the weld shall be examined throughout its entire

length using the techniques and standards for ultrasonic

examination as defined in Section V, Article 4, Mandatory

Appendix Vil, Ultrasonic Examination Requirements for a

Workmanship Based Acceptance Criteria. As an alterna

tive, Nonmandatory Appendix E may be used for the ul-

trasonic examination of welds requiring volumetric

examination by PW-L1

PW-52.2 The Manufacturer's report, as required by

Section V, Article 4, 7-490, shall be retained by the Man-

tfacturer for a minimum of § yr

PW-52.3 Acceptance-Rejection Standards. Imper-

fections that cause an indication to exceed the evaluation

levels speeified in Section V shall be investigated to the

extent that the ultrasonic examination personnel can de

termine their shape, Identity, and location, and evaluate

them in terms of PW-52.3.1 and PW-52.3.2,

PW-52.3.1 Cracks, lack of fusion, or incomplete

penetration are unacceptable regardless of length,

PW-523.2 Other imperfections are unacceptable if

‘the indication exceeds the reference level and their length

exceeds the fallowing:

(0) in. (6 mm) for € up to Yin, (19 mm)

(0) ‘pe for ¢ from %q in. (19 mm) to 2% in, (57 mm)

(0% in. (19 mm) for t over 2% in. (57 mm)

‘where ¢is the thickness ofthe weld being examined. Ifthe

weld joins two members having different thicknesses at

the weld, ¢ Is the thinner of these two thicknesses.

PW-53 TEST PLATES

PW-53.1 Vessel Test Plates. Cylindrical pressure

parts such as drums and shells and all noncylindrical

pressure parts that are subject to internal pressure and

are fabricated by fusion welding, shall meet the test re

quirements in PW-53.2 through PW-53.9, The following,

are exempt from these requirements:

(a) cylindrical pipe, tubes, and headers subject to inter

nal pressure

(b) all eylindrical pressure parts cons

materials

( all antachment welds

ucted of P-No, 1

ay

a7)

ASME BPVC1-2017

A-100.4.4 _P-No. 5A, Group No. 1 and P-No. $8,

Group No. 1. 40°F (205°C) for material that has either

a specified minimum tensile strength in excess of

60,000 psi (410 MPa) or has both a specified minimum

chromium content above 6.0% and a thickness at the joint

in excess of Yq in. (13 mm); 300°F (150°C) for all ather

materials inthis grouping

A-10¢

(205°C,

5 P-No. 6, Group No. 1, 2, 3. 400°F

1-10.46 P-No. 7, Group No. 2, 2. None.

A-100.4.7P-No. 8, Group No. 1, 2. None.

A-100.4.10 P-No. 10A, Group No. 1. 175°F (80°C).

A-100.4.11 P-No, 101, Group No. 1. 300°F (150°C)

with interpass maintained between 350°F and 40°F

(175°C and 230°C),

A-100.4.12 _P-No. 15E, Group No. 1, 400°F (205°C)

for material that has elther a specified minimum tensile

strength in excess of 60,000 psi (410 MPa) or has bath

a specified minimum chromium content above 6.0% and

a thickness at the joint in excess of a in. (13 mm);

'300°F (150°C) for all other materials in this grouping.

‘A-101 HEATING AND COOLING RATES FOR

POSTWELD HEAT TREATMENT

AAAOLI Heating and evoling rates for weldments and

materials should be established by the Manufacturer.

‘These rates should be sulficient to avoid inducing distor~

tion, residual stresses, cracking, and other detrimental ef

fects into the weldment during postweld heat treatment.

Heating and cooling rates should be established based, in

part, upon successful past practice for specific materials

and thicknesses, by using other Codes and Standards as

a gulde, or by engineering analysis.

A-101.2 For thicknesses of 2 in. or greater, the fllow-

ing rates of heating and cooling should be applied; how:

ever, these rates should not be applied to P-No. 7 and

[Link]. 101 welded base materials:

(a) Above 800°F (425°C), the heating rate should not

exceed 600°F//hr (335°C/h) divided by the thickness in

inches, but in no case should it be more than 600°F/hr

(338°C/h),

(b) Above 800*F (425°C), the cooling rate should not

exceed 600°F/r (335°C/h) divided by the thickness in

inches, but in no case should it be more than 600°F /hr

(335°C/h),

() The rates of heating and cooling need not be less

than 100°F hr (S5°C/b)

From 800*F (425°C) or below, the pressure part should

be cooled in stil air.

264

ROUNDED INDICATION CHARTS

A-250 ACCEPTANCE STANDARD FOR

RADIOGRAPHICALLY DETERMINED

ROUNDED INDICATIONS IN WELDS

A-250.1 Applicability of These Standards. These

standards are applicable to ferritic, austenitic, and non

Ferrous materials,

42502 Terminology.

A-250.2.1 Rounded Indications. Indications with a

maximum length of three times the width or less on the

radiograph are defined as rounded indications. These

dications may be circular elliptical, conical, or regular in

shape and may have tals. When evaluating the size of an

indication, the tail shall be included. The indication may

be from any imperfection in the weld, such as porosity,

slag, or tungsten

A-250.2.2 Aligned Indications. A sequence of four

‘or more rounded indications shall be considered to be

aligned when they touch a line parallel to the length of

the weld drawn through the center of the twa outer

rounded indications.

A-250.2.3 Thickness t. ¢ is the thickness of the

weld, excluding any allowable reinforcement. For a butt

weld joining two parts having different thicknesses at

the weld, ris the thinner ofthese two thicknesses. IF fall

penetration weld includes a fillet weld, the thickness of

the fillet weld throat shall be included in ¢

‘A-2503 Acceptance Criteria

A-250.3.1 Image Density. Density within the i

age of the indication may vary and is not a criterion for

acceptance or rejection.

A-250.3.2 Relevant Indications (See Table

£-250.3.2for Examples) Ony those rounded indications

which exceed the following dimensions shall be eons

fred relevant:

(6) ot for ¢ tess han My in, (3 mm)

(6) “fea in. (0.4 mm) for ¢ Ye in. to Ys in. (6 mm),

inchusive

“o “Yao in. (0.8 mm) for ¢ Yin. (6 mm) to 2 in. (50 mm),

(6) froin (16 mm) for € greater than 2 in, (50 mm)

4-2503.3__ Maximum Size of Rounded Indication

(See Table A-250.32 for Examples). The maximum per-

missible size of any indication shall be Yt, oF Yaa It

(4 min), whichever is smaller: except that an isolated in

dication separated from an adjacent indication by 1 in.

(25mm) or more may be Yt, or 4 in. (6 m7), whichever

isless. Fre greater than 2 in. (50 mm) the maximum per-

imssible size ofan slated indication shal be Increased to

Yin. (10 mm)

A-250.3.4 Aligned Rounded Indications. Aligned

rounded indications are acceptable when the summation

of the diameters ofthe indications is es than ¢ na length

ASME BPVCL-2017

of 12¢ (see Figure A-250.3.4-1). The length of groups of

aligned rounded indications and the spacing between

the groups shall meet the requirements of Figure

A-2503.4-2,

A-250.3.5 Spacing. The distance between adjacent

rounded indications is not a factor in determining accep-

tance or rejection, except as required for isolated i

tons or groups of aligned indications,

A-250.3.6 Rounded Indication Charts. The

rounded indications characterized as imperfections shall

not exceed that shown in the charts.

‘The charts in Figures A-250,3.6-1 through A-25033.6-6

illustrate various types of assorted, randomly dispersed,

and clustered rounded indications for different weld

thicknesses greater than Yin (3 mm). These charts re-

present the maximum acceptable concentration limits

{for rounded indications.

‘The chart for each thickness range represents full-scale

6 in, (150 mm) radiographs, and shall not be enlarged or

reduced, The distributions shown are not necessarily the

patterns that may appear on the radiograph, but are ty

cal of the concentration and size of indications permitted.

A-250.3.7 Weld Thickness t Less Than % in.

(3mm). For ¢ less than Yin. (3 mm), the maximum num

ber of rounded indications shall not exceed 12 in a 6 i.

(150 mm) length of weld, A proportionally fewer number

of indications shall be permitted in welds less than 6 in.

(250 mm) in length,

A-250.3.8 Clustered indications. The iustrations

for clustered indications show up to four times as many

indications in a local area, as that shown in the illustra-

tions for random indications, The length of an acceptable

luster shall not exceed the lesser of 1 in, (25 min) ar 2

Where more than one cluster is present, the sum of the

lengths ofthe clusters shall not exceed 1 in. (25 mm) in

26 In, (150 mm) length of wold

Table A-250.3.2

‘Maximum Permissible Size of Rounded

Indication

(Examples Only)

US Gastomary Units

‘Thelness tin, Random nated

es than he “he

% cost amie

he naz ‘nse

x nea foes

he 0078 oxo

% 097 os

he 108 ease

x oxas 0368

‘hs naz 88

0156 aie

She 0156 0230

3 to2 in, aise 1250

Over? ose 0375

Maximum Size of Acceptable Maximum

Rounded indication, mm Size of

Indication,

‘Thickness [Link] Random __Ieolated tom

ase han 3 ae he “ht

5 19 160 38

6 160 zat 038

5 198 zee 078

0 231 aaa 078

au ar aot 078

B ne az 078

o 261 aa 078

16 395 535 079

w 396 sae 078

194950 nc 396 638, ore

over 0 396 983 160

ASME HPVEL.2017

EL 0 aa] © BEE Ha] a FBT OF 790 WHS LON WARNED

by

=

suope>ipul papunoy paubyry

Tere ose-v ainbia

266

; Sy dno ayo wr -BLON WAND

> waa) ew) we BLO

‘pevenjene (une

U0} (uu 5)

a1 oun 517 910408 16 (uu 61)

1 | 5 He

suoy2>1pu papunoy paubjny yo sdnosg

TreosT-y aunbLy

267

ASME BPVC.-2017

a7 Figure A-250.3.6-1

Charts for t % in. (3 mm) to % in. (6 mm), Incl

ae Pa aaee eaves -

. : : °

(@} Random Rounded Indications (tote |3))

Fotis amma] [etm 25mm}

(rotted ination Noe te\ouster

nares

(1) Typical concentration and size permed in any 6 in (150 mm) length of weld

(2) Maximum size per Table A.25033.2.

Figure A-250.3.6-2

Charts for t Over Yq in. (6 mm) to % in. (10 mm), Inclusive

Terre : Sean

: es: oe: ‘ eens

BR dcr Aeesiet) . e °

e

Fete. asm] fet. 26 mmo]

(6) Isoated indication [Note (2) (e) Cluster

(2) Typ eonceneation and sve permite in any 6 in (250 mm) length of weld

(2) Minimum size per Table A-250:32

268

ASME BPVCA-2017

Figure A-250.3.6-3,

Charts for t Over % in. (10 mm) to % in. (19 mm), Inclusive

fe ate e

(: cee e

(2c.

fetin 25mm] fern asm]

ores

(2) Types concentection and sine permitted in any 6 in (150 mam) Int of wel

(2) Minium size per Table A2503.2

Figure A-250.3.6-4

Charts for ¢ Over % in. (19 mm) to 2 in, (50 mm), Inclusive

O oof,

Jetin25mm—] — fetin. 25mm]

ores:

[1) Typical concentration and size permitted in any 6 in (150 mm) length of weld

[2) Minimum sire per Table 4250.32,

269

igure A-250.3.6:

(100 mm), Inclusive

CCharts for t Over 2 in, (50 mm) to 4

+e ee

.@ ete

° : :

ra

{a} Random Rounded Indeations [Note |1))

1 i

cgi ve

e . z

. o ae

Fina mma] Ft ae mm

0) oat Indeaton Note) (orcuster

ores

(2) Types concentration and size permitted in any 6 in. (350 mm) length of wel

(2) Minimum sie per Table A2503.2

ASME BPUCI-2017

Figure A-250.3.6-6

Charts for t Over 4 in. (100 mm)

Foimaoom—] Feinasnm]

(etd neaton Net (o-cster

(1) Typ concentration and size permitted in any 6 in. (150 mem) length of weld

(2) Minioum size per Table 425032

an

ASME BPVCH-2017

METHODS FOR MAGNETIC PARTICLE

EXAMINATION (MT)

A260

A-260.1 Scope. This Appendix provides for prove-

dures that shall be followed whenever magnetic particle

examination is required by PG-63. The detailed examina

‘ton method of Section V, Article 7 shall be used with the

acceptance erteria specified in this Appendix. Magnetic

particle examination shall be performed in accordance

with a writen procedure, demonstrated to the satisfac

tion of the Inspectar, and certified by the Manufacturer

to be in accordance with the requirement of Section V,

Subsection A, Article 1, T-150(a) or T-150(),

4-260.2 Certification of Personnel. The Manufac

turer shall certify that each magnetic particle examiner

meets the following requirements:

(a) The examiner has vison, with correction if neces

sary, to enable him to read a Jaeger Type No. 2 Standard

Chart ata distance of nat less than 12 n. (300 ram) and is

‘capable of distinguishing and differentiating contrast be-

tween colors used. These capabilities shall be checked

anally.

(b) The examiner is competent inthe techniques ofthe

magnetic particle examination method for which he is

certified, including making the examination and inter

preting and evaluating the results, except that where

‘the examination method consists of more than one apera

tion, he may be certified as being qualified only for one or

more ofthese operations.

‘A-260.3 Evaluation of Indications. Indications will

be revealed by retention of magnetic particles. All uch in

dications are not necessarily imperfections, however,

since excessive surface roughness, magnetic permeability

variations (such as at the edge of heat-affected zones),

ete, may produce similar indications.

‘An indication ofan imperfeetion may be larger than the

Imperfection that causes it; however, the sizeof the indi

cation is the basis for acceptance evaluation. Only indica

tions that have any dimension greater than "yg in

(15 mm) shall be considered relevant

(a) linear indication is one having a length greater

than three times the width,

(6) A rounded indication is one of circular or elliptical

shape with a length equal to oF less than three times its

width

(c) Any questionable or doubtful indications shall be

reexamined to determine whether or not they are

relevant.

4-260.4 Acceptance Standards. All surfaces to he

examined shall be free of

(a) relevant linear indications

(b}relevant rounded indications greater than %e in

(6 mm)

(6) four oF more relevant rounded indications ina line

separated by "hy in. (15 mn) of less, edge to edge

2m

METHODS FOR LIQUID PENETRANT

EXAMINATION (PT)

NOTE: Satisfactory application of this method of examination re

‘ules special sil inthe techniques involved! and in Interpreting

the resule The requiremente specified herein presume application

by suitably experienced personnel

A-270

A-270.1 Scope. This Appendix provides for proce:

dures that shall be followed whenever liquid penetrant

examination is required by PG-93, The detailed examina

tion method of Section V, Article 6 shall be used with the

acceptance criteria specified in this Appendix. Liquid pen

etrant examination shal be performed in accordance with

a written procedure, demonstrated to the satisfaction of

the Inspector, and certified by the Manufacturer to be in

accordance withthe requirement of Section V, Subsection

A, Artile 4, T-150(a} or -150(b),

A-270.2 Certification of Personnel. Tine Manufse:

turer shall certify that each liquid penetrant examiner

‘meets the following requirements:

(a) The examiner has vision, with correction if neces-

sary, to enable him to read a Jaeger Type No. 2 Standard

Chart at a distance of not less than 12 in, (300 mm) and is

capable of distinguishing and differentiating contrast be-

tween colors used. These capabilities shall he checked

annually.

(b) The examiner is competent in the techniques of the

Liquid penetrant examination method for which he is cer-

ted, including making the examination and interpreting

and evaluating the results, except that where the exam

nation method consists of more than one operation, he

may be certified as being qualified only for one or more

of these operations.

-270.3_ Evaluation of indications. An indication of

an imperfection may be larger than the imperfection that

causes it; however, the size of the indication is the basis

for acceptance evaluation. Only indications that have

any dimension greater than "yg in. (1.8 mm) shall be con

sidered relevant.

(a} 4 linear indication is one having a length greater

than three times the width

(b} A rounded indication is one of circular or elliptical

shape with a length equal to or less than three times its

width

(] Any questionable or doubtful indications shall be

reexamined to determine whether or not they are

relevant,

A-270.4 Acceptance Standards. ll surfaces to be ex

amined shall be free of

(q) relevant linear indications

(b) relevant rounded indications greater than in

(mm)

(¢) four or more relevant rounded indications in line

separated by ‘hg in. (1.5 mm) or less, edge to edge

You might also like

- PW-11 Volumetric Examination of Welded Butt JointsNo ratings yetPW-11 Volumetric Examination of Welded Butt Joints1 page

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)No ratings yetFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)1 page

- Anexo ASME BPVC Sec VIII UW12 Eficiencia de JuntaNo ratings yetAnexo ASME BPVC Sec VIII UW12 Eficiencia de Junta10 pages

- ASTM A 422 64 R85 Butt Welds in Still Tubes For Refinery ServiceNo ratings yetASTM A 422 64 R85 Butt Welds in Still Tubes For Refinery Service2 pages

- TVL-SMAW 12 - Week 5 - Lesson 2 - Acceptable Criteria For Completed WeldsNo ratings yetTVL-SMAW 12 - Week 5 - Lesson 2 - Acceptable Criteria For Completed Welds10 pages

- Páginas DesdeAWS D1.1-D1.1M-2015 - Structural Welding Code-SteelNo ratings yetPáginas DesdeAWS D1.1-D1.1M-2015 - Structural Welding Code-Steel1 page

- Welding Procedure & Quality Control GuideNo ratings yetWelding Procedure & Quality Control Guide17 pages

- ASME UW-33 Welding Requirements OverviewNo ratings yetASME UW-33 Welding Requirements Overview18 pages

- SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure Vessel100% (1)SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure Vessel15 pages

- Visual Inspection Acceptance Criteria (See: Prohibition33% (3)Visual Inspection Acceptance Criteria (See: Prohibition1 page

- ASME BPVC 2019 Section VIII Div. 1 RT-UTNo ratings yetASME BPVC 2019 Section VIII Div. 1 RT-UT3 pages

- Weld Defect Guidelines for Pressure VesselsNo ratings yetWeld Defect Guidelines for Pressure Vessels6 pages

- Nondestructive Testing Materials & ProcessesNo ratings yetNondestructive Testing Materials & Processes1 page