Professional Documents

Culture Documents

Visual Acceptance AWS D1.1 Structural

Uploaded by

PamungkasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Visual Acceptance AWS D1.1 Structural

Uploaded by

PamungkasCopyright:

Available Formats

AWS D1 .1/D1 .1M:2020 CLAUSE 8.

INSPECTION

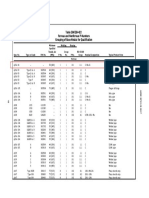

Table ª-·1

Visual lnspection Acceptance Criteria (see ª--9)

Statically Loaded Cyclically Loaded

Nontubular Nontubular

Discontinuity Category and lnspection Criteria Connections Connections

(1) Crack Prohibition

X X

Any crack shall be unacceptable, regardless of size or location.

(2) Weld/Base Metal Fusion

Complete fusion shall exist between adjacent layers of weld metal and between weld X X

metal and base metal.

(3) Crater Cross Section

Ali craters shall be filled to provide the specified weld size, except for the ends of X X

intermittent fillet welds outside of their effective length.

(4) Weld Profiles

X X

Weld profiles shall be in conformance with 1.23.

(5) Time of Inspection

Visual inspection of welds in ali steels may begin immediately after the completed welds

have cooled to ambient temperature. Acceptance criteria for ASTM A514, A517, and X X

A 709 Grade HPS lO0W [HPS 690W] steels shall be based on visual inspection

performed not less than 48 hours after completion of the weld .

(6) Undersized Welds

The size of a fillet weld in any continuous weld may be less than the specified nominal

size (L) without correction by the following amounts (U):

L, u,

specified nominal weld size, in [mm] allowable decrease from L, in [mm]

:<:::3/16 [5] :S 1/16 [2] X X

1/4 [6] :S 3/32 [2.5]

e': 5/16 [8] :S 1/8 [3]

ln ali cases, the undersize portion of the weld shall not exceed 10% of the weld length.

On web-to-flange welds on girders, underrun shall be prohibited at the ends for a length

equal to twice the width of the flange.

(7) Undercut

(A) For material less than 1 in [25 mm] thick, undercut shall not exceed 1/32 in [l mm],

with the following exception: undercut shall not exceed 1/16 in [2 mm] for any accumulated X

length up to 2 in [50 mm] in any 12 in [300 mm]. For material equal to or greater than 1 in

[25 mm] thick, undercut shall not exceed 1/16 in [2 mm] for any length of weld.

(B) ln primary members, undercut shall be no more than 0.01 in [0.25 mm] deep when

the weld is transverse to tensile stress under any design loading condition. U ndercut shall X

be no more than 1/32 in [l mm] deep for ali other cases.

(8) Porosity

(A) CJP groove welds in butt joints transverse to the direction of computed tensile stress

shall have no visible piping porosity. For ali other groove welds and for fillet welds, the

X

sum of the visible piping porosity 1/32 in [l mm] or greater in diameter shall not exceed

3/8 in [10 mm] in any linear inch of weld and shall not exceed 3/4 in [20 mm] in any 12

in [300 mm] length of weld.

(B) The frequency of piping porosity in fillet welds shall not exceed one in each 4 in [100

mm] of weld length and the maximum diameter shall not exceed 3/32 in [2.5 mm] .

Exception: for fi llet welds connecting stiffeners to web, the sum of the diameters of X

piping porosity shall not exceed 3/8 in [10 mm] in any linear inch of weld and shall not

exceed 3/4 in [20 mm] in any 12 in [300 mm] length of weld.

(C) CJP groove welds in butt joints transverse to the direction of computed tensile stress

shall have no piping porosity. For all other groove welds, the frequency of piping porosity

X

shall not exceed one in 4 in [100 mm] of length and the maximum diameter shall not

exceed 3/32 in [2.5 mm].

Note: An "X" indicates app licabi lity for the connection type; a shaded area indicates non-applicability.

239

Copyright American Welding Society

Provided by IHS Markil under license with AWS

No reproduction or networking permitted without license Iram IHS Not for Resale, 01 /31 /2020 02:35:12 MST

You might also like

- Astm A143a143m.20Document4 pagesAstm A143a143m.20safak kahramanNo ratings yet

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 pagesNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNo ratings yet

- Scan Plan For Weldolet Connection-RevisedDocument2 pagesScan Plan For Weldolet Connection-Revisedsnndhk50% (2)

- Appendix 1 - Visual Inspection PlateDocument4 pagesAppendix 1 - Visual Inspection PlateLaith Salman100% (1)

- Air Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsDocument4 pagesAir Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsTim WilsonNo ratings yet

- 25 Macro Micro ExaminationDocument14 pages25 Macro Micro ExaminationAdhanom G.100% (1)

- Amse PiDocument5 pagesAmse PiNnamdi Celestine NnamdiNo ratings yet

- 20 Astm A672 A672m-2014Document7 pages20 Astm A672 A672m-2014FYNo ratings yet

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNo ratings yet

- ASTM E746-07 (2014) Standard Practice For Determining Relative Image Quality Response of Industrial Radiographic Imaging SystemsDocument7 pagesASTM E746-07 (2014) Standard Practice For Determining Relative Image Quality Response of Industrial Radiographic Imaging SystemsnationalfoxNo ratings yet

- Armco UTTG ProcedureDocument10 pagesArmco UTTG ProcedureSurajit Singha100% (2)

- Mpi Acceptance Criteria Aws D1.1ziuhjhdsbhdebhdbdDocument2 pagesMpi Acceptance Criteria Aws D1.1ziuhjhdsbhdebhdbdsandeep100% (1)

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyNo ratings yet

- Robotic WeldingDocument21 pagesRobotic WeldingJuan BarronNo ratings yet

- Part 68 Tack WeldingDocument4 pagesPart 68 Tack Weldingravindra_jivaniNo ratings yet

- Astm A239Document4 pagesAstm A239Ngô Trung NghĩaNo ratings yet

- Calibration ValidationDocument12 pagesCalibration ValidationAlberto LobonesNo ratings yet

- RT Technique Evaluation Dwsi of 1 Inch Dia PipeDocument3 pagesRT Technique Evaluation Dwsi of 1 Inch Dia Pipemusaismail8863No ratings yet

- MT PROCEDURE - TEST BENCH WET FLOURESCENT-Draft 2Document18 pagesMT PROCEDURE - TEST BENCH WET FLOURESCENT-Draft 2Doan Van TienNo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Cswip 3 1 Macro PDFDocument36 pagesCswip 3 1 Macro PDFtheNo ratings yet

- Radiographic Inspection of Corrosion and Deposits in Pipes by X - and Gamma Rays Tangential Radiographic Inspection Technique (ISO 20769)Document16 pagesRadiographic Inspection of Corrosion and Deposits in Pipes by X - and Gamma Rays Tangential Radiographic Inspection Technique (ISO 20769)Sergey KichenkoNo ratings yet

- Radiography Test Procedure Part - 1Document21 pagesRadiography Test Procedure Part - 1Ahmed Lepda100% (1)

- Tack Welding ProcedureDocument3 pagesTack Welding Procedureiftekhar ahmed0% (1)

- 18.in House Calibration ProcedureDocument1 page18.in House Calibration ProcedureSAKTHIVEL ANo ratings yet

- 4260Document10 pages4260Lipika GayenNo ratings yet

- RTFI-weld-defect-repairs-twiDocument61 pagesRTFI-weld-defect-repairs-twismsunil12345No ratings yet

- API 1104 ComplateDocument24 pagesAPI 1104 ComplateAwale UdinNo ratings yet

- Method of Shearing Test For Fillet Weld Joint: Nissan Engineering StandardDocument5 pagesMethod of Shearing Test For Fillet Weld Joint: Nissan Engineering StandardRicardo F.A.No ratings yet

- Procedure Progress ISO 3834 2 PDFDocument3 pagesProcedure Progress ISO 3834 2 PDFKumar DNo ratings yet

- Weld Penetration Procedure NewDocument4 pagesWeld Penetration Procedure NewJm VenkiNo ratings yet

- G8s-5034-02-Bubble Leak TestDocument4 pagesG8s-5034-02-Bubble Leak TestmaheshNo ratings yet

- MT ReportDocument11 pagesMT Reportel_sharkawy2011100% (1)

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- Weld Joint Preparation ISO 9692Document46 pagesWeld Joint Preparation ISO 9692biancogallazziNo ratings yet

- BS 7072 Offshore ContainersDocument17 pagesBS 7072 Offshore ContainersStandards Procedures100% (1)

- IQIDocument9 pagesIQIalouisNo ratings yet

- List of NDT StandardsDocument3 pagesList of NDT Standardskiki270977No ratings yet

- 00.ISO 9712 Scheme SGNDTDocument41 pages00.ISO 9712 Scheme SGNDTVuong Tran VanNo ratings yet

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitNo ratings yet

- SNIS UT 578 - Steel PlatesDocument14 pagesSNIS UT 578 - Steel PlatesShailesh DeshmukhNo ratings yet

- Fluorescent Magnetic TestingDocument29 pagesFluorescent Magnetic TestingAlzaki Abdullah100% (1)

- 1434529014349-Welding DefectsDocument61 pages1434529014349-Welding DefectsJayaneela PrawinNo ratings yet

- Sample Procedure For The Ultrasonic Testing of Steel Castings To ASTM A609/ASME B16.34Document5 pagesSample Procedure For The Ultrasonic Testing of Steel Castings To ASTM A609/ASME B16.34Mark Brailsford100% (2)

- As 2062-1997 Non-Destructive Testing - Penetrant Testing of Products and ComponentsDocument8 pagesAs 2062-1997 Non-Destructive Testing - Penetrant Testing of Products and ComponentsSAI Global - APACNo ratings yet

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraNo ratings yet

- WPS Flow Proceess Chart PDFDocument1 pageWPS Flow Proceess Chart PDFSatish KeskarNo ratings yet

- Kerosene Leak TestDocument3 pagesKerosene Leak TestsapkotamonishNo ratings yet

- Interview QuestionsDocument13 pagesInterview QuestionsWalter RuedaNo ratings yet

- Daytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryDocument6 pagesDaytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryEnriqueVeNo ratings yet

- Outside Micrometer CalibrationDocument2 pagesOutside Micrometer CalibrationJJNo ratings yet

- Destructive Test With Tensile BendDocument20 pagesDestructive Test With Tensile BendRohit MalhotraNo ratings yet

- IACS Rec-69-Rev2-Oct-2020-Ul (NDT)Document21 pagesIACS Rec-69-Rev2-Oct-2020-Ul (NDT)Al aminNo ratings yet

- Appendix 1 Part 4 Radiographic Interpreter 5th Edition February 2016 PDFDocument6 pagesAppendix 1 Part 4 Radiographic Interpreter 5th Edition February 2016 PDFRizwan NazirNo ratings yet

- Tube To Tubesheet WeldsDocument1 pageTube To Tubesheet Weldsramzi5ben5ahmedNo ratings yet

- Ut ProcedureDocument7 pagesUt Procedurearavindan100% (1)

- WP-8.5.1-02 Role of RWCDocument3 pagesWP-8.5.1-02 Role of RWCNitin SharmaNo ratings yet

- Performance Characteristics: Acceptance / Rejection CriteriaDocument1 pagePerformance Characteristics: Acceptance / Rejection CriteriaFadhilah QomariyantoNo ratings yet

- Hardness Testing Power Point TrainingDocument33 pagesHardness Testing Power Point Trainingamol1321No ratings yet

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- E9018 G Welding ElectrodeDocument1 pageE9018 G Welding ElectrodeSai PrasathNo ratings yet

- Chevron Biodiesel 1Document31 pagesChevron Biodiesel 1PamungkasNo ratings yet

- TDS Interthane® 990aliphatic PolyurethaneDocument4 pagesTDS Interthane® 990aliphatic PolyurethaneSyamsul MaripNo ratings yet

- RD CocDocument1 pageRD CocPamungkasNo ratings yet

- Table 127.4.2 Reinforcement of Girth and Long. Butt Welds & Table 127.4.4Document2 pagesTable 127.4.2 Reinforcement of Girth and Long. Butt Welds & Table 127.4.4PamungkasNo ratings yet

- Table 10Document1 pageTable 10PamungkasNo ratings yet

- Pipe TolerancesDocument1 pagePipe TolerancesPamungkasNo ratings yet

- Visual Examination B31.1Document2 pagesVisual Examination B31.1PamungkasNo ratings yet

- ABS NDI - Guide Section 8 Acceptance Criteria For Hull Welds 5.Document3 pagesABS NDI - Guide Section 8 Acceptance Criteria For Hull Welds 5.Dagoberto AguilarNo ratings yet

- A 36Document1 pageA 36PamungkasNo ratings yet

- Part 1 - ABS Approval TierDocument2 pagesPart 1 - ABS Approval TierPamungkas50% (2)

- Cement and Steel Rates For The Month of March 2013Document1 pageCement and Steel Rates For The Month of March 2013Guru PrasadNo ratings yet

- Valvulas Cryogenicas SWValveDocument56 pagesValvulas Cryogenicas SWValveecarsfipNo ratings yet

- The Future of Productivity: Wire Arc Additive Manufacturing: 3dprintDocument4 pagesThe Future of Productivity: Wire Arc Additive Manufacturing: 3dprintItziarNo ratings yet

- MECCOCT18-12582: Investigation of The Electrochemical Properties of An Economical Lean Duplex Stainless Steel AlloyDocument12 pagesMECCOCT18-12582: Investigation of The Electrochemical Properties of An Economical Lean Duplex Stainless Steel AlloyMikeNo ratings yet

- Guide To Aluminium WeldingDocument3 pagesGuide To Aluminium WeldingManish SharmaNo ratings yet

- Is 15560 - 2005Document12 pagesIs 15560 - 2005kalpanaadhiNo ratings yet

- ASTM A 962 - 16aDocument12 pagesASTM A 962 - 16aMarcos Verissimo Juca de Paula100% (2)

- Technical Supply Conditions For Threaded Steel Fasteners: IS: 1367 (Part VII) - 1980Document3 pagesTechnical Supply Conditions For Threaded Steel Fasteners: IS: 1367 (Part VII) - 1980somnath senNo ratings yet

- H2 Family of Chokes: For Pressure and Flow ControlDocument16 pagesH2 Family of Chokes: For Pressure and Flow ControlDEATH ASSASSIN GAMERNo ratings yet

- Uddeholm Qro90supremeDocument12 pagesUddeholm Qro90supremeDarwin Anderson GNo ratings yet

- Steel Grating WeightDocument4 pagesSteel Grating WeightCane CirpoNo ratings yet

- C7-1 ADocument79 pagesC7-1 AAnonymous 24lnhhNo ratings yet

- E.M.D Chapter - 01Document72 pagesE.M.D Chapter - 01Adityasingh ChauhanNo ratings yet

- EFCO Valve Repair ProductsDocument20 pagesEFCO Valve Repair Productsjay_rajeshirkeNo ratings yet

- UNS S32760 Superduplex Stainless Steel For Wet FGD Air Pollution SystemsDocument15 pagesUNS S32760 Superduplex Stainless Steel For Wet FGD Air Pollution SystemsdsoNo ratings yet

- U1. T2. Activity 1. Heat Treatments of SteelDocument11 pagesU1. T2. Activity 1. Heat Treatments of SteelTygaNo ratings yet

- Literature - 220 Ancra CatalogDocument116 pagesLiterature - 220 Ancra Catalogvinurules20No ratings yet

- Nasa STD 5008bDocument72 pagesNasa STD 5008bVitor TavaresNo ratings yet

- SteelDocument1 pageSteelgego2No ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- Mem 22343Document2 pagesMem 22343ajit buradeNo ratings yet

- 01-Samss-046 10302013Document11 pages01-Samss-046 10302013Anonymous jKuXWubR8No ratings yet

- Q3, Module 2, Lesson 4Document8 pagesQ3, Module 2, Lesson 4Jerome A. Gomez100% (1)

- Thermal Expansion For The MetalsDocument15 pagesThermal Expansion For The MetalsJuan OchoaNo ratings yet

- Specialty Steels FM Alloy: Material's General CatalogDocument16 pagesSpecialty Steels FM Alloy: Material's General Catalogyadu kumar singhNo ratings yet

- Self Blocking Rail ClampsDocument18 pagesSelf Blocking Rail ClampsGogyNo ratings yet

- Aws WJ 201409Document166 pagesAws WJ 201409spineyro1500No ratings yet