Professional Documents

Culture Documents

Defining Intervention

Uploaded by

DanielCastilloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Defining Intervention

Uploaded by

DanielCastilloCopyright:

Available Formats

THE DEFINING SERIES

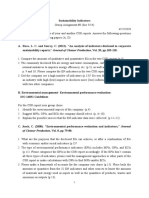

Well Intervention— Guide arch

Maintenance and Repair (gooseneck)

Rick von Flatern CT string

Senior Editor Reel

Injector

head

Few oil and gas wells perform efficiently and produce uninterrupted from Stripper

BOP

initial production to abandonment. Moving parts and seals wear out, tubu-

lars develop leaks, sensors fail and formation pressures decline. To address

these and other problems, operators rely on well intervention specialists.

Interventions fall into two general categories: light or heavy. During light

interventions, technicians lower tools or sensors into a live well while pres- > Coiled tubing unit. Coiled tubing (CT) is flexible pipe that may be spooled

sure is contained at the surface. In heavy interventions, the rig crew may on and off a large reel using an injector head. The hydraulically driven

need to remove the entire completion string from the well to make major injector head uses a series of slips to grip and pull the tubing off the reel or

from the well and through an arched guide called a gooseneck. The

changes to the well configuration, which requires killing the well by stop- gooseneck bends the tubing toward the wellhead or for spooling back onto

ping production at the formation. the reel. The coiled tubing enters and exits the wellbore through a stripper

blowout preventer (BOP), which contains components that seal against the

tubing to contain well pressure. A second set of sealing rams (not shown) in

the BOP may be closed against the coiled tubing to provide a pressure

barrier alternative in the event the stripper BOP fails.

Sheave

The Lighter Side

Pressure- Well service personnel typically perform light interventions using slickline,

control wireline or coiled tubing. These systems may allow operators to clear the

equipment

well of sand, paraffin, hydrates or other substances that may form blockages

and reduce or completely halt production. Operators also use light interven-

tions to change or adjust downhole equipment such as valves or pumps and

to gather downhole pressure, temperature and flow data. In many cases,

because light interventions are relatively inexpensive and require minimal

equipment, they are included in routine well maintenance programs.

A slickline is a single strand of thin wire that conveys tools and sensors

into and out of the well (left). Slickline-based interventions include remov-

Lubricator ing sand and paraffin, running or retrieving subsurface control valves and

running sensors into a well to record bottomhole temperatures and pres-

sures. Slickline is reeled on and off a hydraulically driven drum. A heavier

Wireline

valve cable may be deployedOilfield

from a Review

second drum when the tensile strength

required to complete an Winter

operation08/09

exceeds the rating of the slickline cable.

Wireline also conveys ACTive fig. 1tools and sensors on wire; the advan-

downhole

Sheave ORWin08/09-ACTV Fig. 1

tage to wireline is that downhole data can be delivered to the surface in

Wireline or near real time. The wireline cable acts as a conduit for electric power and

slickline drum

data transfer between the surface and downhole tools and sensors. After a

well has been put on production, wireline may be used to run production

logs or other sensors.

Christmas Coiled tubing also conveys tools downhole, but its primary use is as a con-

Load cell

tree duit for fluid (above). Engineers use coiled tubing to wash out production-

inhibiting sand or scale that has built up inside production tubing or to place

acid or other treatments at precise locations within the well. Because coiled

> Basic slickline or wireline rig-up. A wire or cable runs from the drum to tubing has some rigidity, it may be more effective at pushing slickline or wire-

the lower sheave, which redirects it upward toward a second sheave. The line tools, which typically depend on gravity or tractors to move downhole in

sheave at the top of the pressure-control equipment turns the wire 180° high-angle wells. When real-time data are desired, a wire may be inserted in

and feeds it into the well. The wireline valve above the Christmas tree

contains opposing rams (not shown) that may be closed to seal against the coiled tubing and connected to a sensor being conveyed downhole.

each other without having to remove the wire, thus providing a pressure Light intervention systems usually include a mechanism that ensures well

barrier alternative in the event the pressure-control equipment higher in the pressures are contained as the slickline, wireline or coiled tubing passes

system fails.

through it into the wellbore. Slickline and wireline system seals are maintained

via equipment above the wellhead. Coiled tubing systems use a self-contained

Oilfield Review Winter 2014/2015: 26, no. 4.

pressure-control system that allows the tubing to pass into the wellhead.

Copyright © 2015 Schlumberger.

www.slb.com/defining

Heavy Lifting Operators are sometimes reluctant to use kill weight mud to perform

To perform heavy interventions, or workovers, rig crews remove the wellhead heavy interventions because the dense fluid may permanently damage pres-

and other pressure barriers to allow full access to the well. Crews fill the well sure-depleted formations. One option is to perform the heavy intervention

with kill weight mud to contain the formation pressure during an interven- with the well under pressure, as in light interventions, using a snubbing

tion. Kill weight mud is a dense fluid that creates a hydrostatic pressure at the unit. Snubbing operations use a hydraulic jack to snub, or push, joints of

formation that is greater than the formation’s pore pressure. pipe into a live well against well pressure. Although snubbing operations are

Heavy interventions require a rig to remove and reinstall the completion similar to coiled tubing operations, the former use joints of stiff tubing or

hardware. In many cases, the operator’s objective is to replace leaking or casing and can be performed in wells with significantly higher pressures

worn-out parts. Typically, this requires replacing only the failed parts and than are possible with coiled tubing. Because snubbing equipment is more

running the completion equipment back into the hole. In some cases, how- robust than that used in coiled tubing operations, it can be employed to

ever, operators perform workovers to adapt the completion to reservoir con- perform nearly all operations that typically require use of a drilling rig.

ditions that have changed as a result of production. These changes may

include the onset of water and sand production or formation pressure that Offshore Work

has fallen too low to push fluids to the surface. Assuming the formation has Since the introduction of subsea wells in the 1970s, service companies have

reserves with economic potential, an operator may make adjustments that been developing methods to perform light interventions without costly off-

shut off water production, deploy sand control equipment or run artificial shore drilling units. Using specially designed vessels, service companies

lift systems into the well. perform slickline, wireline and coiled tubing operations through subsea

Operators may perform a special type of workover option—a recomple- wellheads using riserless or riser-based methods (below left).

tion—to abandon one zone and open and complete another zone that was Riserless interventions deploy wireline and slickline tools from a subsea

tested and left behind pipe when the well was drilled. In some cases, slick- intervention vessel to a subsea pressure-control package on the wellhead.

line may be used to shut off the first zone by running in the hole with a These open-water operations are currently limited to relatively shallow

special tool to close a sliding sleeve that had been placed across the perfora- waters of less than about 400 m [1,300 ft]. Use of coiled tubing in open-water

tions as part of the original completion. Slickline is then used to open a operations is restricted almost exclusively to operations requiring hydraulic

sleeve to allow production from a secondary zone. interventions such as placing kill weight mud or performing stimulation or

Typically, however, because of initial well conditions, sleeves are not a flow assurance treatments.

viable completion option and operators must first abandon the primary pro- Subsea interventions may also be performed through a riser, or casing

ducing zone by placing a cement plug across it. They then install new com- string, that connects the subsea wellhead to a surface system. Because ris-

pletion equipment with which to produce from the secondary zone. ers must be deployed from offshore drilling rigs, this method is more expen-

sive than riserless methods. However, the riser effectively extends the

wellbore to the surface, which permits engineers to use all light and heavy

Wireline or slickline

intervention options available.

Coiled tubing

To Intervene or Not to Intervene

Interventions are an economic choice; operators must balance the cost of

the operation against the value of potential additional production. Decisions

to intervene may be made as early as the planning stage when, for instance,

operators include sliding sleeves in the completion. Or engineers may con-

Control Guidelines ROV umbilical

umbilical clude that potential secondary zone production justifies installing an intel-

Coiled tubing, ligent well completion equipped with permanent sensors and remotely

slickline or

wireline actuated sliding sleeves that require little or no intervention to reach known

reserves behind pipe.

Operators’ decisions are also influenced by new or enhanced interven-

ROV tether tion methods. For example, engineers have developed a slickline that

Well enables digital two-way communication and may be deployed using a stan-

intervention ROV dard slickline unit. This digital slickline confirms tool depth and operations

package

as they are performed and allows operators to conduct numerous operations

that were at one time available using only heavier and larger wireline units.

Subsea BOP The greatest intervention challenges and opportunities are offshore.

Subsea wellhead Recovery from subsea wells is as low as 20% compared with about 50% to

60% from land-based and platform wells. The difference lies in the economic

> Riserless light well intervention rig-up. Using a monohull vessel with dynamic decision-making process. Because subsea well interventions in water depths

positioning capabilities, service providers perform riserless wireline and greater than 400 m must be performed from expensive offshore rigs, expected

slickline interventions. A remotely operated vehicle (ROV) may be used to view production gains often do not justify the cost of an intervention. By increas-

the operation and to monitor and guide the landing of the well intervention

ing depth capability of much less expensive light interventions, experts

package onto the subsea wellhead. The well intervention package includes

the pressure-control hardware and the subsea BOP. A control umbilical allows believe they can increase deepwater ultimate recovery in some fields by

technicians to manipulate the BOP and subsea tree valves from the surface. 15% to 30%.

Oilfield Review

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- ReportDocument26 pagesReportDanielCastilloNo ratings yet

- SI Assignment2Document2 pagesSI Assignment2DanielCastilloNo ratings yet

- The Are Including Kun-Yen See The Web Page at For More DetailsDocument3 pagesThe Are Including Kun-Yen See The Web Page at For More DetailsDanielCastilloNo ratings yet

- Assignment 3 For Four Papers 4 22 2020Document5 pagesAssignment 3 For Four Papers 4 22 2020DanielCastilloNo ratings yet

- Course Outlines of Spring 2021 Sustainability IndicatorsDocument2 pagesCourse Outlines of Spring 2021 Sustainability IndicatorsDanielCastilloNo ratings yet

- Course Outlines of Spring 2021 Sustainability IndicatorsDocument2 pagesCourse Outlines of Spring 2021 Sustainability IndicatorsDanielCastilloNo ratings yet

- 07-Absorption For HAP and VOCcontrolDocument118 pages07-Absorption For HAP and VOCcontrolNitin RautNo ratings yet

- 03 Catalyst CharacterizationDocument39 pages03 Catalyst CharacterizationMegan TorresNo ratings yet

- Fracking en Ecuador SPE152596Document19 pagesFracking en Ecuador SPE152596DanielCastilloNo ratings yet

- Defining Coiled TubingDocument2 pagesDefining Coiled TubingAmin DehghaniNo ratings yet

- Statement of Purpouse ExampleDocument2 pagesStatement of Purpouse ExampleDanielCastilloNo ratings yet

- Informative Essay ExampleDocument2 pagesInformative Essay ExampleDanielCastilloNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Petro FullDocument239 pagesPetro FullOhol Rohan BhaskarNo ratings yet

- Ytg PDFDocument2 pagesYtg PDFHarshitShuklaNo ratings yet

- Portable GeneratorDocument2 pagesPortable Generatorramsi17No ratings yet

- Prepared By: Ahmed Mohamed Elshora Under The Supervision Of: U-104 Process TeamDocument38 pagesPrepared By: Ahmed Mohamed Elshora Under The Supervision Of: U-104 Process TeamAhmed ElShoraNo ratings yet

- Workover OperationsDocument19 pagesWorkover Operationslaaliauto100% (4)

- Bins Am Suri 2010Document32 pagesBins Am Suri 2010FarahNo ratings yet

- ZW250 1 Workshop Manual (W4GC E 00)Document582 pagesZW250 1 Workshop Manual (W4GC E 00)Dragan83% (6)

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Increasing Pipeline Deliveries of Heavy Crude OilDocument21 pagesIncreasing Pipeline Deliveries of Heavy Crude Oilferperez90No ratings yet

- Basic Guide To Explosives.Document8 pagesBasic Guide To Explosives.Seng BoucherNo ratings yet

- Fire Prevention PowerpointDocument11 pagesFire Prevention PowerpointSean kelsey Sandoval100% (1)

- White PaperDocument41 pagesWhite PaperParnasree ChowdhuryNo ratings yet

- Flash & Fire Point Test For Asphalt by Cleveland Open Cup Tester.Document8 pagesFlash & Fire Point Test For Asphalt by Cleveland Open Cup Tester.Shaheer AhmadNo ratings yet

- Website Docs To Be Pasted.23-24Document2 pagesWebsite Docs To Be Pasted.23-24paulBennetts2yNo ratings yet

- Industrial Fluid Power PDFDocument141 pagesIndustrial Fluid Power PDFchidambaram kasi33% (3)

- Prime CoatDocument2 pagesPrime CoatPanchadcharam PushparubanNo ratings yet

- Oxygen Tanks and Gas RegulatorDocument2 pagesOxygen Tanks and Gas RegulatorLarry MicksNo ratings yet

- Technical and User Manual For LG Washing Machines.Document52 pagesTechnical and User Manual For LG Washing Machines.lucaNo ratings yet

- Fyrite Classic User Manual Rev.13Document44 pagesFyrite Classic User Manual Rev.13luroguita-1No ratings yet

- Racor Fuel Filtration - GreenMAX - RSL0145Document8 pagesRacor Fuel Filtration - GreenMAX - RSL0145Jorge PerezNo ratings yet

- Fire Safety TrainingDocument44 pagesFire Safety TrainingIbnu Wirawan100% (1)

- Ds Pf8v71tDocument2 pagesDs Pf8v71tEsteban Medina LemosNo ratings yet

- Ajay Kumar Tiwari: Lead EngineerDocument2 pagesAjay Kumar Tiwari: Lead EngineerAJAY1381No ratings yet

- ALKANESDocument9 pagesALKANESPatricia Theresa Ira IlustreNo ratings yet

- Brochure 2055GDocument23 pagesBrochure 2055GObydur RahmanNo ratings yet

- RefrigerationDocument16 pagesRefrigerationKundan sharma100% (1)

- 0653 w16 QP 22Document24 pages0653 w16 QP 22yuke kristinaNo ratings yet

- Soft Corporate Offer: General Trading - Import Export of General GoodsDocument3 pagesSoft Corporate Offer: General Trading - Import Export of General GoodsABELL INDONESIA100% (1)

- 02-Petroleum GeologyDocument48 pages02-Petroleum GeologyWaqas Sadiq100% (2)

- Ratiometric BurnersDocument4 pagesRatiometric BurnersAli ZafarNo ratings yet