Professional Documents

Culture Documents

2003F SuperDuty 6.0L HardStart NoStart1 PDF

2003F SuperDuty 6.0L HardStart NoStart1 PDF

Uploaded by

Alberto GutierrezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2003F SuperDuty 6.0L HardStart NoStart1 PDF

2003F SuperDuty 6.0L HardStart NoStart1 PDF

Uploaded by

Alberto GutierrezCopyright:

Available Formats

-NOTE-

F-Super Duty/Excursion 2003 IF CONCERN IS FOUND, SERVICE AS

REQUIRED. IF THIS CORRECTS THE

6.0L Power Stroke Diesel Engine CONDITION, IT IS NOT NECESSARY TO

Hard Start/No Start Diagnostic Guide COMPLETE THE REMAINDER OF THE

DIAGNOSTIC PROCEDURE.

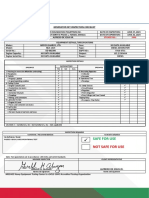

CUSTOMER NAME DEALER NAME P&A ODOMETER

CODE

MODEL YEAR VEHICLE SERIAL N0.(VIN) ENGINE SERIAL NUMBER TRANSMISSION

CHASSIS STYLE VEHICLE GVW 1863 CLAIM NUMBER AMBIENT TEMP. DATE

CUSTOMER CONCERNS (Please list in this box)

TYPE OF SERVICE PERSONAL COMMERCIAL

6005E2 6005E5

7. Perform KOEO On-Demand Self Test 11. Glow Plug System Operation

NOTE: A hard start/no start concern with EOT

• Use scan tool. DTC's set during this test are current faults GPCM Operation

Temp. below 60F perform step 10 first.

Diagnostic • Glow Plug ON time is dependent on oil temperature

6005E

1. Visual Engine/Chassis Inspection Trouble Codes and altitude. The Glow Plug Control Module (GPCM)

6005E3

Fuel Oil Coolant Electrical Hoses Leaks 8. Retrieve Continuous Trouble Codes comes on between 1 and 120 sec., and does not come

Method Check • Use the scan tool. on at all if oil temp is above 131 F.

Visual • DTC's retrieved during this test are historical faults. • Using a scan tool , check Continuous and KOEO DTC's.

Diagnostic If codes are present go to Pinpoint Test AF.

6005E

2. Check Engine Oil Level Trouble Codes • Verify B+ voltage is being supplied to GPCM.

• Check for contaminants (fuel, coolant). 9. KOEO Injector Self Test (Click Test) 6005E3

• Using the scan tool GPCTM and EOT pids, verify

• Correct Grade/Viscosity. • Use scan tool. Injector DTC's will be displayed at test end. glow plug "on" time .

• Miles/Hours on oil ,correct level. • All injectors will momentarily click, then each injector will • Turn key to run position, measure voltage ("on"time)

Method Check click in sequence 1-8. Sequence repeats three times. (Dependent on oil temperature and altitude)

Visual Injector Relay on time Spec. Measurement

Trouble Codes 1 to 120 B+

6005E

3. Intake/Exhaust Restriction » If self test codes are retrieved, go to appropriate PPT test. seconds

6005E4

• Inspect air filter and inlet ducts. 10. Scan Tool - Data List Monitoring Wait to Start Lamp "on" time is independent from g/p "on" time

• Inspect exhaust system. • Scan tool may reset below 9.5 volts. Glow Plug Resistance

• Check if air filter minder indicator has been illuminated • Select the parameters indicated from the scan tool • Disconnect the 4-pin connector at front of valve cover

Method Check parameter list and monitor while cranking engine. • Measure each Glow Plug resistance to Bat. ground.

Visual Parameter Spec. Measurement • Measure engine harness resistance to GPCM

V PWR Glow Glow Plug Harness to

6005E6

4. Sufficient Clean Fuel FICMLPWR 8 volt min. Plug to Ground GPCM connector

• Check if the WATER IN FUEL lamp has been FICMVPWR Number .1 to 2 ohms 0 to 1 ohms

illuminated. RPM 100 RPM #1

• After verifying that there is fuel in the tank, drain a minimum #3

sample from fuel control module. ICP 3.5 mPa min. #5

• Cetane rating between 40-50 is recommended for (500 PSI) #7

optimum start. ICP volts .80 V min. #2

Method Check FUEL PW 500 uS - 2 mS #4

Visual FICMSYNC Yes/No #6

A - V PWR - If low voltage condition is present, check battery, #8

6005E7

5. Electric Fuel Pump Pressure charging system, or power/gnd circuits to the PCM.

140

• Verify that the fuel pump has voltage and gnd. At key on. B - FICMLPWR - No/low voltage indicated could be caused

• Measure fuel pressure at engine fuel filter housing test by 12-way connector issue or logic power fuse. 120

port with a (0-160 PSI) gauge at key on. Refer to Pinpoint S for detailed 12-way conn. diagnostics 100

Time (seconds)

Fuel pump runs for 20 sec. at key on and pressure C - FICMVPWR - No or low voltage indicated could be caused 80

falls after key off. by 12-way connector issues. 60

Instrument Spec. Measurement D - RPM - Low RPM can be caused by starting/charging

40

0-160 PSI 45 PSI min. system issues. No RPM indicated while cranking could be

20

Gauge CMP or CKP faults.

0

If pressure fails low go to next step to verify no restriction E - ICP - A minimum of 500 PSI (3.5 mPa) is required for

0 20 40 60 80 100 120 140

6005E8

6. Electric Fuel Pump Inlet Restriction the injectors to be enabled. No or low oil in the system, EOT (F)

• Measure restriction at fuel pump inlet. system leakage, injector O-Rings, faulty IPR, or high

Instrument Spec. Measurement pressure pump could cause low pressure. • Add 5 seconds to glow plug on time when above

0-30 " Hg 6" Hg MAX IPR duty cycle defaults to 14 % (300 PSI) w/o CKP signal. 7000 feet in altitude, but not to exceed 120 seconds.

vacuum F - ICP V - Voltage reading below spec indicates low ICP

» If > 6" Hg restriction, check lines between pump and fuel tank. during crank.

» If < 6" Hg, inspect both fuel filters. If filters are OK, check fuel G - FUEL PW - Pulse width defaults to 0 w/o CKP signal

regulator. If regulator and filters are OK, replace fuel pump. H - FICMSYNC- No sync could be caused CMP or CKP faults.

» Refer to PC/ED section 4 for detailed test procedures.

See PC/ED manual, Section 4 for more detail on all of the above test steps.

When troubleshooting a Hard Start / No Start or Performance concern, this form must be filled out to the point of repair and returned, to receive warranty credit for diagnostic time

for the parts listed below.

Fuel Injectors (9E527), regulator-injection control pressure (9C968), pump assembly-high pressure oil (9A543), turbo charger assembly (6K682), fuel control module (9G282), FICM (12B599), PCM (12A650), EGR valve (9P452),

CKP sensor (6C315), CMP sensor (12K073), GPCM (12B533), and Glow Plugs (12A342).

Some labor operations are listed in more than one test step. Those operations include time for all occurrences and can be claimed only once.

What problems were found and what repairs were performed?

List Part Name, Number and Serial Number of parts replaced.

You might also like

- Manuals 7 3L Power Stroke ManualDocument78 pagesManuals 7 3L Power Stroke ManualuriealNo ratings yet

- Nissan Atlas F23 Workshop ManualDocument1,177 pagesNissan Atlas F23 Workshop Manualcamclarkson520083% (6)

- Technical Service Information: Automatic Transmission Service GroupDocument2 pagesTechnical Service Information: Automatic Transmission Service GroupRepuestos Maceira100% (2)

- 2017 COE EngineDocument648 pages2017 COE EngineWolfang Ferney Gomez Cardenas100% (2)

- 6.0 Late 2004 Hardstart - Nostart - DiagnosticsDocument1 page6.0 Late 2004 Hardstart - Nostart - DiagnosticsvixentdNo ratings yet

- Overhaul of PurifierDocument37 pagesOverhaul of PurifierSayem kaif100% (2)

- G45ME-C9 - 5 Project Guide PDFDocument358 pagesG45ME-C9 - 5 Project Guide PDFAlexandru Pazargic0% (1)

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- F Series 2002Document4 pagesF Series 2002mario rosasNo ratings yet

- Cummings Parts Catalog PM QSB6 7 GBDocument92 pagesCummings Parts Catalog PM QSB6 7 GBFany Armenta100% (2)

- SUN Inductive Timing LightDocument8 pagesSUN Inductive Timing LightWongstorn DamrongmaneeNo ratings yet

- Training Material For OperatorsDocument360 pagesTraining Material For OperatorsBui Vanluong100% (1)

- Irc Gov in 090 2010Document96 pagesIrc Gov in 090 2010Elumalai Srinivasan86% (7)

- (BP Process Safety Series) BP Safety Group-Safe Furnace and Boiler Firing-Institution of Chemical Engineers (IChemE) (2005) PDFDocument86 pages(BP Process Safety Series) BP Safety Group-Safe Furnace and Boiler Firing-Institution of Chemical Engineers (IChemE) (2005) PDFHugh MantaNo ratings yet

- Calibration Certificate FormDocument1 pageCalibration Certificate Formel_sharkawy2011100% (2)

- BAT - For Emission of RefineriesDocument185 pagesBAT - For Emission of Refineriesbiondimi66No ratings yet

- Scania DEC2 Control System: Industrial & Marine EnginesDocument10 pagesScania DEC2 Control System: Industrial & Marine EnginesGleison Gomes100% (2)

- Methanol As A Marine Fuel - Final - 2021-03-02Document6 pagesMethanol As A Marine Fuel - Final - 2021-03-02AVINASH ANAND RAONo ratings yet

- Combustion Theory Boiler Efficiency and Control - PpsDocument72 pagesCombustion Theory Boiler Efficiency and Control - PpsRantau SilalahiNo ratings yet

- Co-Cracking of Mixed C4 S and LPG With N PDFDocument14 pagesCo-Cracking of Mixed C4 S and LPG With N PDFCindy GallosNo ratings yet

- MMPX 403 Parametr ListDocument30 pagesMMPX 403 Parametr ListOğuz Kağan ÖkdemNo ratings yet

- M32C Technical Files and On Board NOx Verification ProceduresDocument27 pagesM32C Technical Files and On Board NOx Verification Procedureshihihi50% (2)

- SUN Dwell / TachDocument8 pagesSUN Dwell / TachWongstorn DamrongmaneeNo ratings yet

- Reporting PPM D155A-6 Baskhara Sinar SaktiDocument9 pagesReporting PPM D155A-6 Baskhara Sinar SaktiCandy 888No ratings yet

- MEPC.282 70 SEEMP GuidelinesDocument19 pagesMEPC.282 70 SEEMP GuidelinesFarich FirmansyahNo ratings yet

- 2004 6.0L F-Error de ArranqueDocument1 page2004 6.0L F-Error de ArranqueAlejandraNo ratings yet

- Breakdown Analysis Motor Inching Z2M13PMDocument6 pagesBreakdown Analysis Motor Inching Z2M13PMmaherianto 29No ratings yet

- Analog Million Mega Ohm MeterDocument2 pagesAnalog Million Mega Ohm Meterdeepanshu singh vishenNo ratings yet

- Genset 5649Document2 pagesGenset 5649Mac-Ross CordovaNo ratings yet

- Kge12e PDFDocument9 pagesKge12e PDFmuftah76No ratings yet

- Eged290 1Document2 pagesEged290 1eng_hamada_4uNo ratings yet

- Sony GDM-F500 F500T9 N3P Revised @Document60 pagesSony GDM-F500 F500T9 N3P Revised @StefanNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Automatic Engine Control For Diesel/Gas Engines: ECU®-88LDocument2 pagesAutomatic Engine Control For Diesel/Gas Engines: ECU®-88LAnderson MagoNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- J7A Series InverterDocument44 pagesJ7A Series InverterAbanoub Badawi MasryNo ratings yet

- CT - PT MQPDocument12 pagesCT - PT MQPGnanavel GNo ratings yet

- Fire Water Motor Engine PMDocument5 pagesFire Water Motor Engine PMShamsuddin SoomroNo ratings yet

- QSV81G Data SheetsDocument6 pagesQSV81G Data SheetsSaban Sang Petualang Return100% (1)

- 5 Engine ArrangementDocument98 pages5 Engine Arrangementhendra hardyNo ratings yet

- Sims Report c18 PT Dendymarker Indah Lestari So 8600445523Document1 pageSims Report c18 PT Dendymarker Indah Lestari So 8600445523Teguh Prabowo CenaNo ratings yet

- GSSC - Case Study - BI3 - All Warning Lights On in The ClusterDocument8 pagesGSSC - Case Study - BI3 - All Warning Lights On in The ClusterSantosh SridharNo ratings yet

- Machine Condition Report WA 380-3: Data SheetDocument9 pagesMachine Condition Report WA 380-3: Data Sheetnanda adisNo ratings yet

- User Manual: Hand in Hand Heading For The Future!Document5 pagesUser Manual: Hand in Hand Heading For The Future!Emir HarismiNo ratings yet

- Standard Specifications: Powered byDocument3 pagesStandard Specifications: Powered bysarahlawaNo ratings yet

- Ambac Ec 5010 ManualDocument2 pagesAmbac Ec 5010 ManualGonzalo DominguezNo ratings yet

- Engine Temperature Control Actuator - N493-, CHECKING: General DescriptionDocument3 pagesEngine Temperature Control Actuator - N493-, CHECKING: General Descriptionbyungchul kimNo ratings yet

- Lube Oil Console Functional Test ProcedureDocument10 pagesLube Oil Console Functional Test Proceduremohamedsaib438No ratings yet

- Technical Service Bulletin: Service Action: Inspection For Noise From Engine Under Specific Conditions (Sa 141)Document5 pagesTechnical Service Bulletin: Service Action: Inspection For Noise From Engine Under Specific Conditions (Sa 141)Diego Fabian Vega AlpizarNo ratings yet

- Dealing With That Annoying Ratio Code!: F4E-III/FN-4AELDocument8 pagesDealing With That Annoying Ratio Code!: F4E-III/FN-4AELperezmigl92No ratings yet

- TAT I O Manual Rev3 9-14Document16 pagesTAT I O Manual Rev3 9-14Amin AminNo ratings yet

- Automotive Vehicles - Integral Power Steering Gear - Method of - TestDocument9 pagesAutomotive Vehicles - Integral Power Steering Gear - Method of - TestMr. AimeNo ratings yet

- 713 DFHBDocument4 pages713 DFHBTBDSNo ratings yet

- Form MCR PC2000-8Document2 pagesForm MCR PC2000-8Dwi IswantoNo ratings yet

- 1540 PDFDocument6 pages1540 PDFOscar Fernando Guerrero RomeroNo ratings yet

- Maintenance Chart For QSM15 POWER CAR - Updated - Latest - Final - 1Document2 pagesMaintenance Chart For QSM15 POWER CAR - Updated - Latest - Final - 1SSE ACCNo ratings yet

- ASM720P: Programming Switches Mode Control Engine StartingDocument4 pagesASM720P: Programming Switches Mode Control Engine Startingdargom salamanNo ratings yet

- ITR ExampleDocument15 pagesITR ExampleCarlos Rossemberg Cubas AlcántaraNo ratings yet

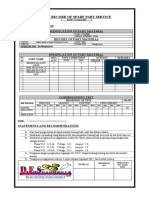

- Test Record of Spare Part Service: Spesification of Part Material History of Part MaterialDocument4 pagesTest Record of Spare Part Service: Spesification of Part Material History of Part MaterialKhalidperkasaNo ratings yet

- Engine Generator Engine Generator: SDG Series SDG SeriesDocument8 pagesEngine Generator Engine Generator: SDG Series SDG SeriesVũ Nguyễn MinhNo ratings yet

- Service BulletinDocument11 pagesService BulletinDave Green100% (1)

- E360 Low Engine Oil Pressure Event Code TroubleshootingDocument2 pagesE360 Low Engine Oil Pressure Event Code TroubleshootingYosephBerhanuNo ratings yet

- Neon P0016Document5 pagesNeon P0016Carlos Awo OsaureNo ratings yet

- Wednesday, March 11, 2009Document2 pagesWednesday, March 11, 2009steve413100% (2)

- Summary Vehicle Health Monitoring System: Model Unit C/N Engine Model S/NDocument3 pagesSummary Vehicle Health Monitoring System: Model Unit C/N Engine Model S/NJokoNo ratings yet

- P1128-Closed Loop Fueling Not Achieved - Bank 1Document10 pagesP1128-Closed Loop Fueling Not Achieved - Bank 1Jorge RaulNo ratings yet

- 0181830sby (1) Gereac GasolinaDocument4 pages0181830sby (1) Gereac GasolinaRobertoHerediaJacoboNo ratings yet

- Service Report: General InformationDocument3 pagesService Report: General Informationjerald noblezaNo ratings yet

- Generac Stand ByeDocument5 pagesGenerac Stand ByeMiguel Angel Pavon CarbonellNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- VTG Iom 2011 0919Document86 pagesVTG Iom 2011 0919Cak AndiNo ratings yet

- 05-Oimb-Philippine National Standards and Its Importance MCCCM Final April242018 PDFDocument44 pages05-Oimb-Philippine National Standards and Its Importance MCCCM Final April242018 PDFrasper pascualNo ratings yet

- Omc Performance Statistics January-April 2021Document68 pagesOmc Performance Statistics January-April 2021TONU YAW KUMA BIDUKINo ratings yet

- Batch Asphalt Mixing Plants Brochure Ppb-1591-04-En 221009Document17 pagesBatch Asphalt Mixing Plants Brochure Ppb-1591-04-En 221009Mohammad Rabnawaz imamNo ratings yet

- Manual de Calderas Cleaver Brooks 250-Hp 300-Hp 350-HpDocument194 pagesManual de Calderas Cleaver Brooks 250-Hp 300-Hp 350-HpAlexis CruzNo ratings yet

- 12+ +list+of+availability of Compliant Fuels in SingaporeDocument2 pages12+ +list+of+availability of Compliant Fuels in SingaporeArne OlsenNo ratings yet

- 08 Yanbu Industrial PortDocument11 pages08 Yanbu Industrial PortMohammed IrfanNo ratings yet

- Diesel Engine - Britannica Online EncyclopediaDocument9 pagesDiesel Engine - Britannica Online Encyclopediaali universityNo ratings yet

- Sulphur Emission Control Area (SECA) - Entry GuideDocument2 pagesSulphur Emission Control Area (SECA) - Entry GuideChristine SullivanNo ratings yet

- D6728-16 Spectroil - Determination ContaminantsDocument7 pagesD6728-16 Spectroil - Determination ContaminantsFatimazahra SahriNo ratings yet

- ML12300A122Document14 pagesML12300A122Rizqi PriatnaNo ratings yet

- 1Document2 pages1art attackNo ratings yet

- BS&WDocument2 pagesBS&Wnikhil guptaNo ratings yet

- SEC v. U. S. Sustainable Energy Corp Et Al Doc 102 Filed 15 Oct 12Document88 pagesSEC v. U. S. Sustainable Energy Corp Et Al Doc 102 Filed 15 Oct 12scion.scionNo ratings yet

- Refinery Presentation On 07th July 07Document83 pagesRefinery Presentation On 07th July 07meenuNo ratings yet

- WPC 20 2866Document8 pagesWPC 20 2866annasitNo ratings yet

- Siwes Report at Danmarna Oil DepotDocument28 pagesSiwes Report at Danmarna Oil DepotForscherNo ratings yet

- Apag 20190422Document21 pagesApag 20190422Ghasem BashiriNo ratings yet