Professional Documents

Culture Documents

Pig Trap Sizing

Uploaded by

zohaib_farooq0 ratings0% found this document useful (0 votes)

18 views1 pageSizing of Pig Trap

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSizing of Pig Trap

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views1 pagePig Trap Sizing

Uploaded by

zohaib_farooqSizing of Pig Trap

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

pressurisation of the vent/flare system is avoided) for controlled depressurisation.

During depressurisation, pig traps in gas service and associated piping may become

cold. Protection of personnel should be by means of operating procedure rather than

insulation.

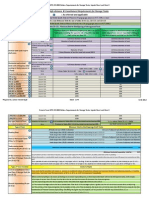

Table 3 Typical Diameters of Pipe work [Ref 1]

Pipeline Bypass Line, mm Kicker Line, Balance Line, Drain Line,

Diameter, mm (inches) mm (inches) mm (inches) mm (inches)

(inches)

200 (8) 100-150 (4-6) 100 (4) 50 (2) 50 (2)

250 (10) 150 (6) 100 (4) 50 (2) 50 (2)

300 (12) 150-200 (6-8) 100 (4) 50 (2) 50 (2)

350 (14) 150-250 (6-10) 100 (4) 50 (2) 50 (2)

400 (16) 200-300 (8-12) 150 (6) 100 (4) 100 (4)

450 (18) 250-300 (10-12) 200 (8) 100 (4) 100 (4)

500 (20) 250-400 (10-16) 200 (8) 100 (4) 100 (4)

600 (24) 300-450 (12-18) 200 (8) 100 (4) 100 (4)

650 (26) 400-500 (16-20) 250 (10) 100 (4) 100 (4)

700 (28) 400-500 (16-20) 250 (10) 100 (4) 100 (4)

750 (30) 400-550 (16-24) 250 (10) 100 (4) 100 (4)

800 (32) 400-600 (16-24) 250 (10) 100 (4) 100 (4)

900 (36) 450-650 (18-28) 300 (12) 100 (4) 100 (4)

950 (38) 500-650 (20-28) 300 (12) 100 (4) 100 (4)

1 000 (40) 500-800 (20-32) 300 (12) 100 (4) 100 (4)

1 050 (42) 500-900 (20-36) 400 (16) 100 (4) 100 (4)

1 200 (48) 600-900 (24-36) 450 (18) 100 (4) 100 (4)

1 400 (56) 800-1 000 (32-40) 500 (20) 100 (4) 100 (4)

2.4.8.8 Orientation

The orientation of branches on the Pig Trap System shall be as follows:

¾ Drains: bottom of pipe (at 180° position)

¾ Vents, pressure gauges, purge connection, thermal relief and pig signaller:

top quadrant of the pipe (at 0° position)

¾ Kicker line, balance line and by-pass line: side of pipe (at 90° position)

The diameters of the branch connections are specified in Table 3.

Project No.: MASTER

DOCUMENT TITLE:

ADCO DOC. NO. 30-99-00-0103-1

REV. 2 DATE :March 07

PIPELINES LAUNCHER & RECEIVER

SYSTEMS PAGE 30 OF 61

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Intro To HAZID of PipelinesDocument30 pagesIntro To HAZID of Pipelineszohaib_farooq100% (3)

- Apex Series 5000 7000 Bill Acceptor Manual PDFDocument17 pagesApex Series 5000 7000 Bill Acceptor Manual PDFFidelRomasantaNo ratings yet

- Fiance & Accounts - Session 1Document3 pagesFiance & Accounts - Session 1zohaib_farooqNo ratings yet

- Sr. Risk Engineer Job DescriptionDocument3 pagesSr. Risk Engineer Job Descriptionzohaib_farooqNo ratings yet

- NamazDocument55 pagesNamazzohaib_farooqNo ratings yet

- HSC Frame WorkDocument5 pagesHSC Frame Workzohaib_farooqNo ratings yet

- The Galaxy Industries Production Problem - A Prototype ExampleDocument25 pagesThe Galaxy Industries Production Problem - A Prototype Examplezohaib_farooqNo ratings yet

- NFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIDocument4 pagesNFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIzohaib_farooqNo ratings yet

- Datasheet of Monitor (Sample)Document4 pagesDatasheet of Monitor (Sample)zohaib_farooqNo ratings yet

- Fiance & Accounts - Session 1Document3 pagesFiance & Accounts - Session 1zohaib_farooqNo ratings yet

- Election MenifestoDocument1 pageElection Menifestozohaib_farooqNo ratings yet

- Solving Linear Programs: The Simplex MethodDocument10 pagesSolving Linear Programs: The Simplex MethodKhalid MalikNo ratings yet

- E GN 000Document90 pagesE GN 000أصلان أصلانNo ratings yet

- ProfileDocument68 pagesProfilezohaib_farooqNo ratings yet

- HAZOP WORKSHEET FOR LIQUID NITROGEN AND OXYGEN SEPARATIONDocument9 pagesHAZOP WORKSHEET FOR LIQUID NITROGEN AND OXYGEN SEPARATIONzohaib_farooqNo ratings yet

- Sharjeel HassanDocument2 pagesSharjeel Hassanzohaib_farooqNo ratings yet

- Mechanics of AirDocument4 pagesMechanics of Airzohaib_farooqNo ratings yet

- Appendix-1 (HAZOPWorksheets)Document37 pagesAppendix-1 (HAZOPWorksheets)zohaib_farooq100% (1)

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Pages From Selection and Sizing of Pressure Relief ValvesDocument1 pagePages From Selection and Sizing of Pressure Relief Valveszohaib_farooqNo ratings yet

- Ehsan Rashid InstrumentDocument1 pageEhsan Rashid Instrumentzohaib_farooqNo ratings yet

- Umm Shaif - Ppef881cDocument26 pagesUmm Shaif - Ppef881czohaib_farooqNo ratings yet

- A Guide To Refinery ProcessDocument35 pagesA Guide To Refinery ProcessBalamurugan100% (3)

- Factor de UnidadesDocument81 pagesFactor de Unidadesyoly10No ratings yet

- CryogenicDocument19 pagesCryogeniczohaib_farooq100% (1)

- Study Results For Process in Fig. 3-1: T-L Damage To Pump LIA-1, Can Reagent ReactDocument1 pageStudy Results For Process in Fig. 3-1: T-L Damage To Pump LIA-1, Can Reagent Reactzohaib_farooqNo ratings yet

- Packinox Catalytic ReformingDocument2 pagesPackinox Catalytic Reformingzohaib_farooqNo ratings yet

- Number Name Description Halal StatusDocument16 pagesNumber Name Description Halal Statuszohaib_farooqNo ratings yet

- Refinery Process Design Notes - For IITGDocument193 pagesRefinery Process Design Notes - For IITGLakshmi Devineni100% (3)

- A Review of Air Separation Technologies and Their Integration With Energy Conversion Processes PDFDocument20 pagesA Review of Air Separation Technologies and Their Integration With Energy Conversion Processes PDFtiara arlettaNo ratings yet

- SAP PM T - CodesDocument4 pagesSAP PM T - CodesBujjibabu Katta0% (1)

- Readings: Decision AnalysisDocument44 pagesReadings: Decision AnalysisPierre Moreno SotoNo ratings yet

- SC-9790AV SX-9790: Service ManualDocument80 pagesSC-9790AV SX-9790: Service ManualBRAULIO GARCIA SANTIAGONo ratings yet

- EECE 210 Electric Circuits Simple Resistive CircuitsDocument32 pagesEECE 210 Electric Circuits Simple Resistive CircuitsDaniaNo ratings yet

- What Makes A Planet Habitable?Document3 pagesWhat Makes A Planet Habitable?Willie WilliowNo ratings yet

- Hkimo 2022 Heat Round - p4Document5 pagesHkimo 2022 Heat Round - p4Marsella NadjamoeddinNo ratings yet

- AP Music Theory - Summer Work Packet (Ada)Document28 pagesAP Music Theory - Summer Work Packet (Ada)pj.sulls1234No ratings yet

- Product Details for 42CrMo4 SteelDocument2 pagesProduct Details for 42CrMo4 SteelGABRIEL IORDACHINo ratings yet

- Stress Corrosion Cracking in Stainless SteelDocument3 pagesStress Corrosion Cracking in Stainless Steelmavis16No ratings yet

- VB Toolbar Tutorial: Create a Toolbar in Visual BasicDocument25 pagesVB Toolbar Tutorial: Create a Toolbar in Visual BasicRizemmaNo ratings yet

- F321 Module 1 Practice 2: Balancing Equations & Calculating MolesDocument7 pagesF321 Module 1 Practice 2: Balancing Equations & Calculating Moles11pearcerNo ratings yet

- Cat ThermoMETER InfraredDocument56 pagesCat ThermoMETER InfraredspyrosNo ratings yet

- Eobd FacileDocument22 pagesEobd FacileGabi NitaNo ratings yet

- Dissolving Cellulose from Different Sources in NaOH/UreaDocument11 pagesDissolving Cellulose from Different Sources in NaOH/Ureajitendra kumarNo ratings yet

- Alexandra Elena Plesu (Bonet Ruiz) PHD ThesisDocument278 pagesAlexandra Elena Plesu (Bonet Ruiz) PHD ThesisThắng MinerNo ratings yet

- Ashpasol SupremeDocument2 pagesAshpasol SupremeAlex K.No ratings yet

- 000 N EE 0020003 Rev1 Acoustic Insulation SpecificationDocument18 pages000 N EE 0020003 Rev1 Acoustic Insulation Specificationonur gunesNo ratings yet

- Kinetics of Hexamine Crystallization in Industrial ScaleDocument8 pagesKinetics of Hexamine Crystallization in Industrial ScaleAnggit Dwi WNo ratings yet

- Indc CCP 432Document182 pagesIndc CCP 432SteveAbonyiNo ratings yet

- On The Quantum Well and Multi DimensionaDocument19 pagesOn The Quantum Well and Multi DimensionaGianna Barcelli FantappieNo ratings yet

- YSCA Brochure22 York Pared Con SEER 10Document2 pagesYSCA Brochure22 York Pared Con SEER 10san cadejoNo ratings yet

- Activity DiagramsDocument26 pagesActivity Diagramskant.beleNo ratings yet

- BROADLEAF 6 ManualDocument109 pagesBROADLEAF 6 ManualBaseCubica ArquitectosNo ratings yet

- Thesis SummaryDocument31 pagesThesis Summary2007.Restidar SoedartoNo ratings yet

- 1st Q Math 10Document2 pages1st Q Math 10Mari Zechnas Osnola100% (1)

- Papper Maths Class 8thDocument5 pagesPapper Maths Class 8thAbdul Basit KhanNo ratings yet

- Metering Devices IQ DP-4000: Cutler-HammerDocument4 pagesMetering Devices IQ DP-4000: Cutler-HammerArif KhanNo ratings yet

- The Impact of Content, Context, and Creator On User Engagement in Social Media MarketingDocument10 pagesThe Impact of Content, Context, and Creator On User Engagement in Social Media MarketingNG NoviardhiNo ratings yet

- Phylogenetic studies of Mammillaria provide new insightsDocument13 pagesPhylogenetic studies of Mammillaria provide new insightsA Man ZedNo ratings yet