Professional Documents

Culture Documents

Omcl Management of Volumetric Glassware PDF

Omcl Management of Volumetric Glassware PDF

Uploaded by

drchughOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Omcl Management of Volumetric Glassware PDF

Omcl Management of Volumetric Glassware PDF

Uploaded by

drchughCopyright:

Available Formats

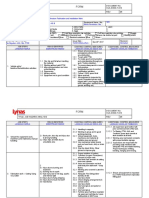

OMCL Network of the Council of Europe

QUALITY MANAGEMENT DOCUMENT

PA/PH/OMCL (15) 16 3R

MANAGEMENT OF VOLUMETRIC GLASSWARE

Full document title and Management of Volumetric Glassware

reference PA/PH/OMCL (15) 16 3R

Document type Recommendation Document

Legislative basis

Date of first adoption 8 January 2016

Date of original entry 15 January 2016

into force

Date of entry into force

of revised document

Previous titles/other

references / last valid

version

Custodian The present document was elaborated by the OMCL Network /

Organisation EDQM of the Council of Europe

Concerned Network GEON

PA/PH/OMCL (15) 16 3R – Management of Volumetric Glassware

Management of Volumetric Glassware

SCOPE

The present document describes the basic principles for the management of volumetric glassware

within an OMCL, with regard to calibration and verification.

INTRODUCTION

The glassware used in a laboratory should be capable of achieving the required accuracy for the

tests performed, in accordance with ISO/IEC 17025:2005. This glassware includes volumetric

flasks, burettes, pipettes or measuring cylinders.

Before being introduced for use, laboratory glassware should be calibrated or checked to

demonstrate that it meets the laboratory’s requirements and complies with the relevant standard

specification. A visual integrity check prior to use and comparison of the certificate with the

laboratory requirements are to be carried out at this stage. Intermediate checks, carried out on a

random sample of glassware according to a defined procedure, may be needed to maintain

confidence in the calibration status of the glassware over the time of use.

Usually, class A and AS volumetric glassware meets the basic accuracy requirements needed in

most quantitative analytical work (for tolerances, please refer to references 1, 2 and 3, for instance).

It is considered that it is generally not necessary to use individually calibrated glassware with an

individual certificate of calibration, since certified glassware usually complies with a certain class and

has a certificate of batch calibration. If the quality or uncertainty of a test result obtained while using

certified glassware is not suitable or consistent, the laboratory should assess whether the glassware

used meets the required tolerance class and/or assess its contribution to the uncertainty of the test.

Class A and AS volumetric glassware is supplied with a batch calibration certificate, where the

tolerance and the error of the material comply with an international standard. Laboratories can also

acquire class A volumetric glassware with individual calibration, as supplied by some brands. The

choice of the type of calibration of volumetric glassware (batch or individual) depends on the

laboratory’s own assessment.

It should be noted that the minimum requirements established by different national accreditation

bodies (NAB) for the volumetric glassware used in a laboratory might differ with regard to the

validity of the calibration and the frequency of the verification of the suitability of the volumetric

glassware after the calibration validity has expired. The initial period of calibration of non-

automatic volumetric glassware can range from 2 to 10 years, according to documentation available

from ILAC, EA, OIML and several NABs.

GENERAL RULES

The tolerance of the glassware being used should be less than the maximum admissible error for

testing. Also, the laboratory should adopt a policy of managing appropriately volumetric glassware,

allowing it to identify the needs for calibration and/or verification and, if deemed necessary, to trace

back to the targeted glassware.

Page 2 of 7 January 2016

PA/PH/OMCL (15) 16 3R – Management of Volumetric Glassware

The laboratory shall ensure that:

- The calibration needs are identified correctly (e.g. need for class A);

- The apparatus that is identified as in need of calibration must be calibrated initially by the vendor or by

the OMCL according to a defined and appropriate level prior to use;

- After purchase and prior to the first use, as well as periodically during use, a careful visual inspection

of the glassware is made to check for signs of deterioration or attack, such as scratches, blurred, broken

or chipped glass, scale or calibration marks not visible. Damaged apparatus must be rejected and

discarded. In the event of aggressive use of the equipment, such as the use of corrosive substances or

thermal or mechanical shock, visual inspections should be performed more frequently.

Procedures should be defined for the cleaning of glassware, either by washing machine or by hand.

Cleaning validation is advisable given the possibility of poor/deficient washing or cross contamination

with cleaning agents, such as detergents.

Cleaning procedures, storage, and segregation of volumetric equipment may be critical, particularly for

trace analyses where leaching and adsorption can be significant. The laboratory shall ensure that

products or processes employed in washing and decontamination do not alter the state of glassware. The

laboratory may decide to perform periodic validation of the cleaning of glassware, either by determining

relevant chemical parameters in the wash water (such as conductivity and total organic content, TOC),

testing cleaning on different surfaces with the worst case product or by a specific detailed procedure

(see example in Annex 2), if it is found that checking of blanks is not enough for the needs of the

laboratory.

Washing and drying glassware for volumetric purposes should be a temperature that takes into account

the chemical nature of the glass. Above 150°C there may be significant changes in the volumetric

capacity of borosilicate glass and above 90°C for the soda-lime glass. According to ISO 4787, it is

recommended that volumetric instruments should not be heated significantly above 180 °C.

CALIBRATION

Performance of assays and limit tests require the use of calibrated volumetric glassware with acceptance

criteria according to at least class A and/or AS. Special care should be taken when volumetric glassware

is used for a direct reading of the result, without any comparison with a standard (such as a volumetric

burette in an assay by titration).

Prior to use, the compliance of the volumetric glassware to the required class is demonstrated via

calibration as follows:

- external calibration, by an accredited entity (batch certificate or individual calibration certificate by

supplier/producer, when needed);

- internal calibration, in cases where no batch certificate is available or superior quality requirements

have to be fulfilled. In those cases calibration must be performed according to a clearly defined

procedure.

The frequency of calibration of volumetric instruments depends on their characteristics, the type and

frequency of their use and previous calibrations history. The laboratory should decide the suitable

frequency for calibration of all its volumetric glassware, taking into account the use.

If no previous reference exists, initial intervals of annual calibration could be adopted, and adjusted

afterwards, depending on the use and history of the glassware. An intermediate verification may be

performed, if needed.

January 2016 Page 3 of 7

PA/PH/OMCL (15) 16 3R – Management of Volumetric Glassware

If the initial certificate expires or the volumetric glassware has been exposed to environmental or

analytical conditions that could jeopardise calibration, a verification of the suitability of the equipment

may be performed, if found to be necessary. The laboratory can also decide to perform internal or

external calibration, depending on the use.

For volumetric glassware which produces a direct result, such as burettes used in volumetric titrations,

re-calibration of the equipment should be carried out within the schedule established by the laboratory

or, alternatively, new calibrated volumetric glassware should be introduced, taking into account the

laboratory requirements and needs.

VERIFICATION

Procedures for verification of volumetric glassware are to be implemented by the laboratory. In all cases

a careful visual inspection of the glassware is made annually to check for scratches, blurred glass,

broken glass, chipped glass and poorly visible scale or calibration marks. Initially, a yearly analytical

assessment of glassware could be performed on a representative sample and number of items of

glassware in use. Based on the results of the verification, the frequency can be prolonged: in cases

where all test results are in compliance with the acceptance criteria in consecutive years, a re-

verification may be performed after five years.

Procedures for verification of volumetric glassware are described in several documents, issued either by

ISO, EA, OIML or NIST. In general, all of them describe a gravimetric verification procedure for the

volumetric capacity. The amount of water that the vessel contains, or delivers at a measured

temperature, is accurately weighed, and the volume calculated in cubic centimetres at standard

temperature and pressure. All of these documents state that special care must be taken to ensure that the

glassware is clean and, in particular, grease free.

REFERENCES

1. ISO 385:2005 “Laboratory glassware – Burettes”

2. ISO 648:2008 “Laboratory glassware -- Single-volume pipettes”

3. ISO 1042:1998 “Laboratory glassware -- One-mark volumetric flasks”

4. ISO 4787:2010 “Laboratory glassware -- Volumetric instruments -- Methods for testing of

capacity and for use”

5. OIML R 43 Edition 1981 (E) “Standard graduated glass flasks for verification officers”

6. OIML D 26 Edition 2010 (E) “Glass delivery measures - Automatic pipettes”

7. ILAC P10:01/2013 “ILAC Policy on Traceability of Measurement Results”

8. UKAS LAB15 EDITION 2 (June 2009) “Traceability: Volumetric Apparatus”

9. ISO 17025:2005 “General requirements for the competence of testing and calibration

laboratories”

ANNEXES

In this section, examples are given in order to help laboratories with the implementation of some of the

tasks which have been described in the core document, namely:

- how to perform the verification of glassware in Annex 1, in accordance to an OIML standard;

- how to perform the validation of the cleaning of glassware in Annex 2.

Page 4 of 7 January 2016

PA/PH/OMCL (15) 16 3R – Management of Volumetric Glassware

ANNEX 1

OIML (reference 5) describes the following procedure for the verification of glassware:

“OIML R 43 Edition 1981 (E) “Standard graduated glass flasks for verification officers

(…)

APPENDIX A: VERIFICATION OF STANDARD GRADUATED GLASS FLASKS”

A.1. Test liquid.

A. 1.1. Water: distilled or deionized of high purity, in accordance with the following requirements when

tested immediately before use: it must be free from dissolved gases, and heavy metals, in particular

copper, as shown by the dithizone test, the specific conductivity must not exceed 1 × 104 S × m-1 at 20

°C, and it must be neutral to methyl red.

A.2. Instruments.

A.2.1. Scales: of suitable maximum capacity, having an accuracy at least equal to that of nonautomatic

weighing machines of the high accuracy class (or possibly special accuracy class).

3.2.2. Thermometer: with appropriate measurement range, suitable for the measurement of temperature

with error not exceeding ± 0.1 °C.

A.3. Method.

A.3.1. Determination of the « contained » capacity (capacity « In »).

A.3.1.1.

— clean and dry the flask,

— weigh the flask empty,

— allow the temperature of flask and water used for testing to equalize,

— record the water temperature,

— place the flask on a flat horizontal surface, and fill it with water to a point a few millimetres

below the mark indicating the nominal capacity « In »,

— add more water slowly, to bring the meniscus carefully to the scale mark concerned,

— check that the outside surface of the flask, and its internal surface above water level are dry, and

that neither bubbles or foam are present in the water,

— weigh the flask and its contents.

A.3.1.2.

From the difference between the results of weighing the flask when full and the flask when empty, and

allowing for correction of the displaced air, the mass of the quantity of water corresponding to nominal

« contained » capacity is obtained.

Knowing the temperature of the water in the flask, and using tables for the density of water as a function

of the temperature, the volume of the water contained in the flask may be determined.

From this volume and the coefficient of cubic expansion of the glass, the conventional true capacity of

the flask is determined for the scale mark corresponding to nominal « contained » capacity, at the

chosen reference temperature (20 °C or 27 °C).

A.3.1.3.

Repeat the procedure for filling and weighing the filled flask as in point A.3.1.1., and calculate as in

point A.3.1.2., for four other scale marks, including both the highest and lowest scale marks.

A.3.1.4.

The error on the « In » capacity for any scale mark, is equal to the difference between the « In »

capacity indicated by a mark, and the conventional true capacity corresponding to this mark, determined

by the method described in points A.3.1.1. to A.3.1.3.

The error on the « In » capacity between any two scale marks, is equal to the difference between:

— the difference between the capacities indicated by the marks and,

January 2016 Page 5 of 7

PA/PH/OMCL (15) 16 3R – Management of Volumetric Glassware

— the difference between the conventional true capacities determined by the method given in points

A.3.1.1. to A.3.1.3.

A.3.2. Determination of the « delivered » capacity (capacity « Ex »)

A.3.2.1.

— clean the flask,

— equalize the temperature of the flask and the water used for testing,

— record the water temperature,

— fill the flask with water to a few millimetres below the scale mark indicating the nominal capacity

« Ex »,

— empty the flask, and allow to drain for 2 to 3 minutes,

— refill the flask as above, adding the water slowly so as to bring the meniscus carefully to the scale

mark concerned,

— check that the outside surface of the flask, and its internal surface above water level are dry, and

that neither bubbles or foam are present in the water,

— weigh the flask and its contents,

— empty the contents into a container,

— hold the flask in an inverted position to drain for 30 seconds,

— remove the last drop adhering to the lip of the neck, by bringing the lip into contact with the

internal wall of the container,

— weigh the empty flask.

A.3.2.2. From the difference between the results of weighing the flask when full and when empty, and

allowing for correction of the displaced air, the mass of the quantity of water corresponding to the

«delivered » capacity is obtained.

Knowing the temperature of the water in the flask, and using tables for the density of water as a function

of the temperature, the volume of the water delivered can be determined.

From this volume and the coefficient of cubic expansion of the glass, the conventional true capacity of

the flask for the scale mark corresponding to « Ex » nominal capacity, at the chosen reference

temperature (20 °C or 27 °C) may be determined.

A.3.2.3. Repeat the procedure for filling, draining and weighing as in point A.3.2.1., and calculate as in

point A.3.2.2., for four other scale marks, including both the highest and lowest scale marks.

A.3.2.4. The error on the « Ex » capacity for any scale mark, is the difference between the « Ex »

capacity indicated by a mark, and the conventional true capacity corresponding to this mark, determined

by the method given in points A.3.2.1. to A.3.2.3.

The error on the « Ex » capacity between any two scale marks, is equal to the difference between:

— the difference between the capacities indicated by these marks, and

— the difference between the conventional true capacities determined by the method given in points

A.3.2.1. to A.3.2.3.”5

Page 6 of 7 January 2016

PA/PH/OMCL (15) 16 3R – Management of Volumetric Glassware

ANNEX 2

Example of validation of a cleaning procedure for volumetric glassware using a glassware

washing machine (source: CY – Workshop for auditors October 2015)

1. The procedure can be used during the IQ-OQ of the new glassware washing machine and for

PQ (e.g. every 6 months);

2. The laboratory chooses an available “difficult to clean” API;

3. From the volumetric flasks described in the testing method of the selected API, two of

the lower and two of the maximum nominal volume flasks are selected (e.g. 2 x 5ml

and 2 x 100ml volumetric flasks);

4. A reference solution of the API is prepared as described in the testing method;

5. Each of the selected volumetric flasks is filled to about 10% of its nominal volume with this

reference solution, closed and shaken so the inner walls of the flasks will be covered by the

liquid. They are emptied and allowed to dry;

6. The 4 flasks are then washed alone in the washing machine using the defined washing

instructions (Empty Load);

7. The same procedure is performed with the maximum number of volumetric flasks that can

be washed in the washing machine (Full Load);

8. All the flasks are filled with the solvent solution used for the preparation of the Reference

Standard Solution and analysed with the HPLC testing method of the API used (the method

is validated and the validation parameters, e.g. LOD, LOQ etc. are used);

9. No traces of the API above the LOD of the method should be detected.

January 2016 Page 7 of 7

You might also like

- Ethylene Oxide Sterilization Validation ProtocolDocument25 pagesEthylene Oxide Sterilization Validation ProtocolUlisses V A Campos100% (5)

- HW3 SolutionsDocument15 pagesHW3 Solutionsellie<3100% (1)

- 531-Autoclave Inspection and Routine Maintenance - SOP-finalDocument8 pages531-Autoclave Inspection and Routine Maintenance - SOP-finalIcee SinlapasertNo ratings yet

- 10 Main Personal Protective EquipmentDocument7 pages10 Main Personal Protective EquipmentDaniel CastilloNo ratings yet

- Management of Volumetric GlasswareDocument7 pagesManagement of Volumetric GlasswareTashdiq AnwarullohNo ratings yet

- US Environmental Protection Agency Office of Pesticide ProgramsDocument20 pagesUS Environmental Protection Agency Office of Pesticide Programsanandhra2010No ratings yet

- Autoclaving GuidelinesDocument5 pagesAutoclaving GuidelinesImr RaNo ratings yet

- DRI Guidelines For Autoclave Use: or Items That Have Come in Contact With Biological MaterialsDocument5 pagesDRI Guidelines For Autoclave Use: or Items That Have Come in Contact With Biological Materialscshinson60No ratings yet

- Autoclaves - Proper Operation and ValidationDocument7 pagesAutoclaves - Proper Operation and Validationgrace holmNo ratings yet

- C675 91 (2016)Document2 pagesC675 91 (2016)werrteNo ratings yet

- Annex 8 Qualification of Balances PDFDocument11 pagesAnnex 8 Qualification of Balances PDFzilangamba_s4535No ratings yet

- NABL 106 - Specific Criteria For Fluid Flow Testing Laboratories PDFDocument13 pagesNABL 106 - Specific Criteria For Fluid Flow Testing Laboratories PDFzilangamba_s45350% (1)

- Micro-10-QA-002 (1) (1)Document13 pagesMicro-10-QA-002 (1) (1)Tahir IbrahimNo ratings yet

- D7160 16Document7 pagesD7160 16ertfgbdfbNo ratings yet

- Gauging Manual Rev 1.6Document22 pagesGauging Manual Rev 1.6ابوالحروف العربي ابوالحروفNo ratings yet

- Integrity Testing FactsheetDocument9 pagesIntegrity Testing Factsheetamirreza_eng3411No ratings yet

- Gulfstream G650Er: Maintenance ManualDocument6 pagesGulfstream G650Er: Maintenance ManualLena BatboldNo ratings yet

- SAQAM-Lab TestingDocument13 pagesSAQAM-Lab TestingMohammed BndawdawNo ratings yet

- Moist Heat SterilizatiojnDocument16 pagesMoist Heat Sterilizatiojnajitjoshi950No ratings yet

- SOP For Operations & Calibration of Laboratory Glasswares (Volumetric, Micro, Chemical, Analytical)Document3 pagesSOP For Operations & Calibration of Laboratory Glasswares (Volumetric, Micro, Chemical, Analytical)Dolly BijaniNo ratings yet

- Guide Mqa 011 007Document13 pagesGuide Mqa 011 007Ian G. Walker100% (2)

- Inspection of BoilersDocument13 pagesInspection of BoilersLuis MenaNo ratings yet

- EUROLAB Cook BookDoc No 3 Handling of Untestable Deviating SamplesRev2017Document2 pagesEUROLAB Cook BookDoc No 3 Handling of Untestable Deviating SamplesRev2017nedkovbgNo ratings yet

- EQ-17 StackDocument6 pagesEQ-17 StackSangam SharmaNo ratings yet

- UKAS Traceability of Volumetric ApparatusDocument11 pagesUKAS Traceability of Volumetric ApparatusHasan SozeriNo ratings yet

- TS TVS TFS ProtocolsDocument16 pagesTS TVS TFS ProtocolsTaulehia Pulefou SemisiNo ratings yet

- ESCRDocument3 pagesESCRAvelino Sobrevega Pinuela Jr.No ratings yet

- Autoclave Calibration and Validation - Astell UKDocument4 pagesAutoclave Calibration and Validation - Astell UKALSIN Technology ServicesNo ratings yet

- Autoclave Expansion of Portland Cement: Standard Test Method ForDocument4 pagesAutoclave Expansion of Portland Cement: Standard Test Method ForSebastián RodríguezNo ratings yet

- Gsbme Autoclave Training v3Document43 pagesGsbme Autoclave Training v3madosb5133No ratings yet

- Plant Inspection Guideline ManualDocument36 pagesPlant Inspection Guideline ManualAcid Burns100% (1)

- C200 ManualDocument42 pagesC200 ManualMohd Masri A. RazakNo ratings yet

- FIA Guidance On Regular Testing of Fire Fighting Foam Concentrates and Discharged Foam SolutiosnDocument21 pagesFIA Guidance On Regular Testing of Fire Fighting Foam Concentrates and Discharged Foam Solutiosnluckystrike9008No ratings yet

- Thermal Validation Information Manual & GuideDocument10 pagesThermal Validation Information Manual & Guideviethuong96No ratings yet

- Astm D5094 D5094M 09Document2 pagesAstm D5094 D5094M 09hassen.benachoureNo ratings yet

- SPE International Symposium & Exhibition On Formation Damage Control - Otc20820 - Taking The Gas Lift Valves To A New Level of Realiability PDFDocument5 pagesSPE International Symposium & Exhibition On Formation Damage Control - Otc20820 - Taking The Gas Lift Valves To A New Level of Realiability PDFGláucia SantosNo ratings yet

- Clean Room Requirements As Per Iso 14644 PDFDocument8 pagesClean Room Requirements As Per Iso 14644 PDFAnkur100% (1)

- Integrity Testing of Aboveground Storage TanksDocument43 pagesIntegrity Testing of Aboveground Storage TanksMakhfud Edy100% (1)

- Autoclave Expansion of Portland Cement: Standard Test Method ForDocument3 pagesAutoclave Expansion of Portland Cement: Standard Test Method ForHumberto GutierrezNo ratings yet

- 017 - Who - PQS - E005 - PCMC VP0.1Document9 pages017 - Who - PQS - E005 - PCMC VP0.1ageng djakmanNo ratings yet

- Metal Can Defects CFIADocument210 pagesMetal Can Defects CFIARichard Miranda RomeroNo ratings yet

- Example Baghouse Agency Operation & Maintenance PlanDocument8 pagesExample Baghouse Agency Operation & Maintenance Plankashifbutty2kNo ratings yet

- Autoclave Qualification Some Practical AdviceDocument4 pagesAutoclave Qualification Some Practical AdviceVitalis MbuyaNo ratings yet

- EU - Quality ControlDocument3 pagesEU - Quality Controlapi-3859063No ratings yet

- QSTC2012Document87 pagesQSTC2012masterix7No ratings yet

- Autoclave Validation - What Is Really RequiredDocument4 pagesAutoclave Validation - What Is Really Requiredwadhwa_shailNo ratings yet

- Astm D6934 22Document3 pagesAstm D6934 22akmalzainal.onlineNo ratings yet

- HOKLAS - SC-20 Procedure For Validation MethodDocument17 pagesHOKLAS - SC-20 Procedure For Validation MethodAgeng Wahyu PatrianitaNo ratings yet

- F 2227 - 02 RjiymjcDocument4 pagesF 2227 - 02 RjiymjcfrostestNo ratings yet

- Containment Testing For Underground Storage Tanks (Usts) : WWW - Dep.State - Pa.UsDocument1 pageContainment Testing For Underground Storage Tanks (Usts) : WWW - Dep.State - Pa.Uskishore2285No ratings yet

- Q/SQR: Enterprise Standard of Chery Automobile Co., LTDDocument10 pagesQ/SQR: Enterprise Standard of Chery Automobile Co., LTDDiego CamargoNo ratings yet

- How To Validate An AutoclaveDocument3 pagesHow To Validate An AutoclaveqhpuongNo ratings yet

- Intertek Confinement ASHRAE 110 1995Document31 pagesIntertek Confinement ASHRAE 110 1995Linh NgoNo ratings yet

- Notice To Surveyors, Shipowners, Managers and Classification SocietiesDocument36 pagesNotice To Surveyors, Shipowners, Managers and Classification SocietieskdimosNo ratings yet

- Standard Operating Procedure: Safe Autoclave OperationsDocument7 pagesStandard Operating Procedure: Safe Autoclave OperationsvivoNo ratings yet

- FDA Inspections PDFDocument52 pagesFDA Inspections PDFMajdi Hasan Ayoub100% (1)

- Safety Issues On DryerDocument5 pagesSafety Issues On Dryerareej athirahNo ratings yet

- Environmental ConditionDocument7 pagesEnvironmental ConditionTammam AbourshaidNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Adiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringFrom EverandAdiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringNo ratings yet

- LIC Nomination Form OnlineDocument2 pagesLIC Nomination Form Onlinedrchugh0% (1)

- Registration Guidelines 1Document85 pagesRegistration Guidelines 1drchughNo ratings yet

- Jai Hind College: AutonomousDocument57 pagesJai Hind College: AutonomousdrchughNo ratings yet

- Cancellation Refund PolicyDocument2 pagesCancellation Refund PolicydrchughNo ratings yet

- Integrated Application Form 97 2003 Compatible PDFDocument15 pagesIntegrated Application Form 97 2003 Compatible PDFdrchughNo ratings yet

- SOP For Environmental Monitoring of Aseptic Area by Air Sampling For Viable Count Using Air SamplerDocument4 pagesSOP For Environmental Monitoring of Aseptic Area by Air Sampling For Viable Count Using Air SamplerdrchughNo ratings yet

- Indian Oil Xtrarewards CatalogueDocument6 pagesIndian Oil Xtrarewards CataloguedrchughNo ratings yet

- Career Opportunities in Indian IT IndustryDocument9 pagesCareer Opportunities in Indian IT IndustrydrchughNo ratings yet

- Formulation of Dosage Forms - Pre Formulation FactorsDocument10 pagesFormulation of Dosage Forms - Pre Formulation FactorsdrchughNo ratings yet

- Otc Medicine Monograph Bromhexine HydrochlorideDocument9 pagesOtc Medicine Monograph Bromhexine HydrochlorideAndreas SimanjuntakNo ratings yet

- YEMA User Guide Dive Watches Eta2824 Sellitasw200 enDocument11 pagesYEMA User Guide Dive Watches Eta2824 Sellitasw200 enAndrei TomaNo ratings yet

- Reduction Potential - WikipediaDocument28 pagesReduction Potential - WikipediaBabar AliNo ratings yet

- Distillation Column DesignDocument17 pagesDistillation Column DesignMazan ShaviNo ratings yet

- 02 Jsa Structure Work - Spray Tower (Bi)Document10 pages02 Jsa Structure Work - Spray Tower (Bi)Mohd KhaidirNo ratings yet

- TMP7000 PDFDocument40 pagesTMP7000 PDFhdaamirNo ratings yet

- General and Dilution Ventilation PDFDocument15 pagesGeneral and Dilution Ventilation PDFSeunNo ratings yet

- Astm D6038 - 2014Document4 pagesAstm D6038 - 2014alferedNo ratings yet

- Unit 8B AP Chem - ElectrochemistryDocument11 pagesUnit 8B AP Chem - ElectrochemistryAnivia12100% (1)

- High-Performance Cutting and Grinding Technology For CFRP (Carbon Fiber Reinforced Plastic)Document7 pagesHigh-Performance Cutting and Grinding Technology For CFRP (Carbon Fiber Reinforced Plastic)Dongxi LvNo ratings yet

- Unit-V Investment Casting of SuperalloysDocument36 pagesUnit-V Investment Casting of SuperalloysJ JhansibaiNo ratings yet

- Injection Molding Lab Manual UpDocument3 pagesInjection Molding Lab Manual UpAnonymous asGPbPNo ratings yet

- Victrex PEEK 450FE20: Conditions Test Method Units Typical ValueDocument2 pagesVictrex PEEK 450FE20: Conditions Test Method Units Typical ValueRohan KulkarniNo ratings yet

- Bop RepairDocument13 pagesBop Repairnjava1978100% (1)

- Ch. 7 redox-22-23-IGDocument16 pagesCh. 7 redox-22-23-IGvfdfdNo ratings yet

- AssiDocument3 pagesAssiScott BoothNo ratings yet

- Trends in The Therapeutic Drug Delivery System For The Management of Glaucoma A ReviewDocument8 pagesTrends in The Therapeutic Drug Delivery System For The Management of Glaucoma A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Tugas PPM Deny Saputro Arifin 113170039Document9 pagesTugas PPM Deny Saputro Arifin 113170039Vira IrnandaNo ratings yet

- Performance Grinder Brochure US1069 051616ADocument4 pagesPerformance Grinder Brochure US1069 051616AJonathan DouglasNo ratings yet

- 7 Production Technology of Liquid Bio FertilizerDocument20 pages7 Production Technology of Liquid Bio FertilizersmileyNo ratings yet

- Cysteine HPLC MethodDocument6 pagesCysteine HPLC MethodYuxiong HuangNo ratings yet

- Application of CFD QuenchDocument42 pagesApplication of CFD Quenchluigi_mazzuccoNo ratings yet

- Molykotel 1605 FGDocument7 pagesMolykotel 1605 FGMayur PattanshettiNo ratings yet

- Soil Mechanics Assighnment 1Document3 pagesSoil Mechanics Assighnment 1EVANS KIPNGETICHNo ratings yet

- Silicone Conformal Coating Intro-GatedDocument29 pagesSilicone Conformal Coating Intro-GatedknajikNo ratings yet

- Cdu Overhead Afc Failure Rev1Document286 pagesCdu Overhead Afc Failure Rev1rajivNo ratings yet

- EDM KTU AMT Notes Module 4Document37 pagesEDM KTU AMT Notes Module 4Safeer MNo ratings yet

- 03 Reference Material HMT ME302 Steady Heat Conduction PDFDocument38 pages03 Reference Material HMT ME302 Steady Heat Conduction PDFhimanshu singhNo ratings yet