Professional Documents

Culture Documents

Stanadyne Lock Timing Perkins

Uploaded by

P.p. Arul IlancheeranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stanadyne Lock Timing Perkins

Uploaded by

P.p. Arul IlancheeranCopyright:

Available Formats

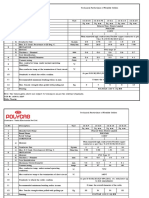

STANADYNE DB4 MODEL PUMP for PERKINS

SUBJECT: LOCKED DRIVE SHAFT TIMING

As a means of improving the installation timing accuracy as well as preventing unauthorized timing

adjustments, Stanadyne has developed a locked drive shaft timing feature for Perkins DB4 pumps.

The system consists of the following features and is pictured in Figure 1.

n

PUMP HOUSING

The locked shaft timing pump housing has holes rather than the traditional "kidney" slots for the

tio

pump-to-engine mounting bolts. This is designed to prevent unauthorized pump to engine timing

adjustments. The housing also has a hole in the face of the flange to accept a timing pin. A threaded

hole in the neck of the housing located between the drive shaft seals is used as a drive shaft locking

screw hole during the pump timing procedure.

ec

I nj

el

Fu

on

DRIVE SHAFT

The drive shaft used with the locked shaft timing arrangement also has no keyway on the tapered

portion allowing the drive hub to be located on the shaft in any position.

g

DRIVE HUB

re

A new drive hub with a slot designed to accept a timing pin but without a keyway on the tapered

inside diameter allows accurate location of the hub on the drive shaft during the timing procedure.

O

IMPORTANT: If a drive shaft hub is removed from the drive shaft, the specific reinstallation steps

require special tools. When the pump is installed on the engine, a timing pin (provided by the engine

manufacturer) is used to properly align the hub with the housing while the gear is attached to the hub.

EUGENE

4036 West 1st Ave.

Eugene, OR 97402

(541) 485-1434

www.oregonfuelinjection.com

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Delphi DP200 Injection Pump John Deere HousingDocument3 pagesDelphi DP200 Injection Pump John Deere HousingGeorge ZormpasNo ratings yet

- Ve Pump Removal and InstallationDocument5 pagesVe Pump Removal and InstallationMiguel MartinezNo ratings yet

- Inline Cummins Pump Removal and InstallationDocument5 pagesInline Cummins Pump Removal and Installationlukman sodiqNo ratings yet

- Fuel Pump Replacement ManualDocument7 pagesFuel Pump Replacement Manualapi-542121636No ratings yet

- Manual Bomba Injectora STANADYNE DB4Document4 pagesManual Bomba Injectora STANADYNE DB4DenisGutierrezNo ratings yet

- .46NX Evolution Engine: User GuideDocument7 pages.46NX Evolution Engine: User GuideJuan Camilo GarciaNo ratings yet

- Dokumen - Tips - John Deere Powertech 68l Diesel Engines Mechanical Fuel Systems Component Service Repair Technical Manual ctm207Document15 pagesDokumen - Tips - John Deere Powertech 68l Diesel Engines Mechanical Fuel Systems Component Service Repair Technical Manual ctm207Valeriy Valkovets100% (1)

- CPCBII 4B3.3 Engine Design FeaturesDocument26 pagesCPCBII 4B3.3 Engine Design FeaturesGowthaman NNo ratings yet

- Engine Timing Tools Renault Dci: Part No. 4076Document4 pagesEngine Timing Tools Renault Dci: Part No. 4076Candace FrankNo ratings yet

- Evolution Engines ManualDocument6 pagesEvolution Engines Manualamalraj1005100% (1)

- 4347 Instructions FRDocument4 pages4347 Instructions FRAllfrNo ratings yet

- Wren 44Document28 pagesWren 44aleminoNo ratings yet

- Manual For Steering Gear. 1 To 4 Rudders (2014)Document12 pagesManual For Steering Gear. 1 To 4 Rudders (2014)RomanNo ratings yet

- Maintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBDocument10 pagesMaintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBAtaa AssaadNo ratings yet

- MERCUR d28l - DtronicDocument8 pagesMERCUR d28l - DtronicAtakan ArıkoğluNo ratings yet

- John Deere Removal and InstallationDocument6 pagesJohn Deere Removal and InstallationMiguel Angel Sancho100% (1)

- 001-049 Timing Pin Housing: Preparatory StepsDocument7 pages001-049 Timing Pin Housing: Preparatory Stepsvictor manuelNo ratings yet

- Mejia Ph-II, 500mw, Vol-1 CepDocument339 pagesMejia Ph-II, 500mw, Vol-1 CepLakshminarayanNo ratings yet

- 211-02 Power SteeringDocument23 pages211-02 Power SteeringMiguel AngelNo ratings yet

- Practical Assignment (Nurridzman)Document3 pagesPractical Assignment (Nurridzman)Naufal NasirNo ratings yet

- Rover V8 DIS Kit Instructions 1.4Document25 pagesRover V8 DIS Kit Instructions 1.4enquiries7922No ratings yet

- Mode - 17 Edited AddedDocument44 pagesMode - 17 Edited AddedHimanshu TiwariNo ratings yet

- Super Tigre ManualDocument32 pagesSuper Tigre ManualtamanogNo ratings yet

- Stanadyne DB2 and DB4 Pump Removal and InstallationDocument3 pagesStanadyne DB2 and DB4 Pump Removal and InstallationJoseph100% (1)

- Rover V8 DIS Kit Instructions 1.3Document31 pagesRover V8 DIS Kit Instructions 1.3enquiries7922No ratings yet

- Unit5&6 CW Pump AssemblyDocument14 pagesUnit5&6 CW Pump Assemblyrashm006ranjanNo ratings yet

- Fuel Injection Timing: Engine Setup and AdjustmentsDocument28 pagesFuel Injection Timing: Engine Setup and AdjustmentsDaniel PaisNo ratings yet

- Vortex InstructionsDocument8 pagesVortex InstructionsRenee CamilleNo ratings yet

- Section 5. Overhead Valve Engine Carburetors: Carburetor Servicing Throttle ShutterDocument3 pagesSection 5. Overhead Valve Engine Carburetors: Carburetor Servicing Throttle ShutterStephanie CandyNo ratings yet

- Iom Manual 250 Series Centrifugal Pump: M15794, Rev 0Document17 pagesIom Manual 250 Series Centrifugal Pump: M15794, Rev 0hebert perez50% (2)

- EngineDocument79 pagesEngineEdi Ianto100% (2)

- Jet Kit InstallDocument2 pagesJet Kit InstallmihaisimoNo ratings yet

- Bronze Rotary Gear Pumps Installation, Operation, and Maintenance InstructionDocument4 pagesBronze Rotary Gear Pumps Installation, Operation, and Maintenance InstructionGlenn Bryan AntonioNo ratings yet

- SECTION 4.05: Cylinder Head AssemblyDocument8 pagesSECTION 4.05: Cylinder Head AssemblyLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Resealing The VE Injector PumpDocument20 pagesResealing The VE Injector PumpFayez AlnamarnehNo ratings yet

- Wren 44i Gold Thrust Instructions - 2016Document27 pagesWren 44i Gold Thrust Instructions - 2016AurangzebNo ratings yet

- dp200 Pump Timing Instructions PDFDocument3 pagesdp200 Pump Timing Instructions PDFTodd PowersNo ratings yet

- 1076 Cpi EinstDocument2 pages1076 Cpi EinstSaverioNo ratings yet

- HRD Sherco Ignition Timing Manual 03-04Document16 pagesHRD Sherco Ignition Timing Manual 03-04Per ForsbergNo ratings yet

- Manual de Servicio Sauer DanfossDocument2 pagesManual de Servicio Sauer DanfossCristian100% (1)

- Replace Rocker Arm Cover Gasket - ctm415 - Service ADVISOR™Document5 pagesReplace Rocker Arm Cover Gasket - ctm415 - Service ADVISOR™Fernando Aguilar100% (1)

- Serrage CulasseDocument2 pagesSerrage CulasseJulien VervaekeNo ratings yet

- Th60dh WW CycloneDocument12 pagesTh60dh WW CycloneWILY EBER VIDAL RUIZNo ratings yet

- Valve and Valve AdjustmentsDocument18 pagesValve and Valve Adjustmentsgillian marbebeNo ratings yet

- Installation ManualDocument6 pagesInstallation ManualBEARNo ratings yet

- C and L Series Weekly ReportDocument13 pagesC and L Series Weekly Reportvoice of voicelessNo ratings yet

- Vertical Turbine Firefighting Pump InstallationDocument4 pagesVertical Turbine Firefighting Pump InstallationWahid HusainNo ratings yet

- Assembly and Disaassembly of PumpsDocument5 pagesAssembly and Disaassembly of Pumpsshin deiru100% (1)

- Stanadyne de Pump Timing InstructionsDocument1 pageStanadyne de Pump Timing Instructionskonstantin chekan100% (1)

- Stanadyne de Pump Timing Instructions PDFDocument1 pageStanadyne de Pump Timing Instructions PDFSMITINo ratings yet

- Mantenimiento ShaferDocument12 pagesMantenimiento ShaferMauricio RoldanNo ratings yet

- EP Camshaft Installation Manual - Rev1.0Document10 pagesEP Camshaft Installation Manual - Rev1.0Paweł TopolewiczNo ratings yet

- BUDA-Service Manual 6DT389Document58 pagesBUDA-Service Manual 6DT389ferdockmNo ratings yet

- Magnum .61 4TDocument8 pagesMagnum .61 4TJoseAlfredoCarneiroDosSantosNo ratings yet

- Bendix NA-R9A, B Stromberg Float Carburetor InstructionDocument12 pagesBendix NA-R9A, B Stromberg Float Carburetor InstructionWilfredo Díaz GonzalezNo ratings yet

- CV Carb TuningDocument7 pagesCV Carb Tuningmark_dayNo ratings yet

- Technical Service Manual: Heavy Duty Pumps SERIES 4195 and 495 Series GG - Al Section TSM 144 1 Issue BDocument9 pagesTechnical Service Manual: Heavy Duty Pumps SERIES 4195 and 495 Series GG - Al Section TSM 144 1 Issue BRoshan ShanmughanNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- ECM Calibration Download Instructions PDFDocument11 pagesECM Calibration Download Instructions PDFArtemio Garcia BarrientosNo ratings yet

- 128 - GS Level Industrial Level Sensor - LD4174-M Issue 2Document2 pages128 - GS Level Industrial Level Sensor - LD4174-M Issue 2P.p. Arul IlancheeranNo ratings yet

- 128 - GS Level Industrial Level Sensor - LD4174-M Issue 2Document2 pages128 - GS Level Industrial Level Sensor - LD4174-M Issue 2P.p. Arul IlancheeranNo ratings yet

- Polycab Cables Pricelist (New)Document8 pagesPolycab Cables Pricelist (New)P.p. Arul IlancheeranNo ratings yet

- Land Market Solutions: Drawworks Rotary TablesDocument2 pagesLand Market Solutions: Drawworks Rotary TablesP.p. Arul IlancheeranNo ratings yet

- 3 CementsDocument43 pages3 CementsChan Pisith de Phal100% (1)

- 0 5PX1CBLKFLX100Document4 pages0 5PX1CBLKFLX100P.p. Arul IlancheeranNo ratings yet

- Agri Price List 01jan2019 PDFDocument32 pagesAgri Price List 01jan2019 PDFParas VaghasiyaNo ratings yet

- Coolant Filter, Spin-On Sca Plus: AttributesDocument2 pagesCoolant Filter, Spin-On Sca Plus: AttributesP.p. Arul IlancheeranNo ratings yet

- ECU 100, GCU 100, Engine Communication, 4189340804 UKDocument60 pagesECU 100, GCU 100, Engine Communication, 4189340804 UKJoaquin Andres Boilet Huerta100% (1)

- 056-017 PC Configuration Interfacing PDFDocument2 pages056-017 PC Configuration Interfacing PDFCarlitos MenesNo ratings yet

- 2 X1.3TAA G7 - 20kVA - Rev 2Document4 pages2 X1.3TAA G7 - 20kVA - Rev 2P.p. Arul IlancheeranNo ratings yet

- Koel AmfDocument4 pagesKoel AmfChetan GuptaNo ratings yet

- 15LD400 GBDocument4 pages15LD400 GBP.p. Arul IlancheeranNo ratings yet

- Ojus Ol 5d Portable Genset PDFDocument2 pagesOjus Ol 5d Portable Genset PDFP.p. Arul IlancheeranNo ratings yet

- Pluggable and Miniature Relays PDFDocument10 pagesPluggable and Miniature Relays PDFP.p. Arul IlancheeranNo ratings yet

- Specification BurdenDocument3 pagesSpecification BurdensarokrisNo ratings yet

- GSM Motor Model 2Document2 pagesGSM Motor Model 2P.p. Arul IlancheeranNo ratings yet

- Diesel Trouble PDFDocument5 pagesDiesel Trouble PDFzona amrullohNo ratings yet

- Analog Timer1Document4 pagesAnalog Timer1P.p. Arul IlancheeranNo ratings yet

- GSM Security System Ac230v New PDFDocument3 pagesGSM Security System Ac230v New PDFP.p. Arul IlancheeranNo ratings yet

- GSM 2 RELAY v3Document2 pagesGSM 2 RELAY v3P.p. Arul IlancheeranNo ratings yet

- 2011-08-04 114144 Fl70cumisbiscwiring PDFDocument6 pages2011-08-04 114144 Fl70cumisbiscwiring PDFVM Elliott II100% (1)

- ECU 100, GCU 100, Engine Communication, 4189340804 UKDocument60 pagesECU 100, GCU 100, Engine Communication, 4189340804 UKJoaquin Andres Boilet Huerta100% (1)

- CTS2 5unDocument3 pagesCTS2 5unP.p. Arul IlancheeranNo ratings yet

- Vashi Electricals BrochureDocument26 pagesVashi Electricals BrochureP.p. Arul Ilancheeran100% (1)

- Diesel Trouble PDFDocument5 pagesDiesel Trouble PDFzona amrullohNo ratings yet

- 2-Basic - Feb 12 ONGC - Cleaned PDFDocument36 pages2-Basic - Feb 12 ONGC - Cleaned PDFP.p. Arul Ilancheeran100% (1)

- GSM 6 Relay Switch 2019Document2 pagesGSM 6 Relay Switch 2019P.p. Arul IlancheeranNo ratings yet