Professional Documents

Culture Documents

Mechanical Properties of Plastics

Uploaded by

Vainin WiselinkCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Properties of Plastics

Uploaded by

Vainin WiselinkCopyright:

Available Formats

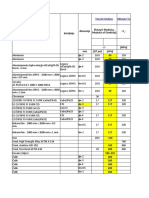

Mechanical Properties of Plastic Materials

Material Formula Abrasive Coefficient of Compression Compressive Compressive Elongation Hardness - Izod Poisson's Tear Tensile Tensile

resistance - friction set after 24 hr modulus strength at break Rockwell impact ratio strength modulus strength

ASTM D1044 at 175C GPa MPa % strengt N mm-1 GPa MPa

mg/1000 % h

-1

cycles Jm

Cellulose Acetate CAB - - - - - 60 99 260 - - 0.3-2.0 20-60

Butyrate

Ethylene- E-CTFE 5 0.07-0.08 - - - 200 R95 <1000 - - 1.4-1.6 48

Chlorotrifluoroethylene

copolymer

Ethylene- ETFE - - - - - 250-350 R50 >1000 - - 0.8 28-48

Tetrafluoroethylene

Copolymer

Fluorinated Ethylene FEP - 0.27-0.67 - - - 150-300 R25-45, No 0.48 - 0.5 - 0.6 14 - 30

Propylene Copolymer 60 Shore break

D

Polyacrylonitrile- ABS - 0.5 - - - 45 R100-110 200- 0.35 - 2.1-2.4 41-45

butadiene-styrene 400

Polyamide - Nylon 6 PA 6 5 0.2-0.3 - - - - M82 30-250 0.39 - 2.6-3.0 78

Polyamide - Nylon 6, 6 PA 6,6 3-5 0.2-0.3 - - - - M89 40-110 0.41 - 3.3 82

Polyamide - Nylon 6, 6 - PA 6, 6 - 30% - - - - - 2 - - - - 24 260

30% Carbon Fiber CFR

Reinforced

Material Formula Abrasive Coefficient of Compression Compressive Compressive Elongation Hardness - Izod Poisson's Tear Tensile Tensile

resistance - friction set after 24 hr modulus strength at break Rockwell impact ratio strength modulus strength

ASTM D1044 at 175C GPa MPa % strengt N mm-1 GPa MPa

mg/1000 % h

-1

cycles Jm

Polyamide - Nylon 6, 6 - PA 6,6 30% GFR - - - - - 5 M100 120 - - 10-11 160-210

30% Glass Fiber

Reinforced

Polyamide - Nylon 12 PA 12 - - - - - 290-300 R84-107 - - - - 50-55

Polyamide/imide PAI - - - - 170-220 7-15 E72-86 60-140 0.38 - 4.5-6.8 110-190

-

notche

d

Polybenzimidazole PBI - 0.19-0.27 - 6.2 400 3 K115 590 0.34 - 5.9 160

unnotc

hed

Polybutylene PBT - - - - - 250 M70 60 - - 2 50

terephthalate

Polycarbonate PC 10-15 0.31 - - >80 100-150 M70 600- 0.37 - 2.3-2.4 55-75

850

Polycarbonate - 30% PC - 30% CFR - - - - - 2 - - - - 18 170

Carbon Fiber Reinforced

Polycarbonate - 30% PC - 30% GFR - - - - - 3 - - - - 5.8 70

Glass Fiber Filled

Polycarbonate - PC - - - - - 5-9 - - - - ~3.8 60-70

Conductive

Polychlorotrifluoroethyle PCTFE - - - - 9-12 80-250 R75-112 D75-90 267 - - 1.3-1.8

ne - Shore

- - - - - - D75-90 - - - - - -

Shore

Polyetheretherketone PEEK - 0.18 - - - 50 M99 85 0.4 - 3.7-4.0 70-100

Polyetherimide PEI 10 - - 2.9 140 60 R125 50 0.44 - 2.9 85

Material Formula Abrasive Coefficient of Compression Compressive Compressive Elongation Hardness - Izod Poisson's Tear Tensile Tensile

resistance - friction set after 24 hr modulus strength at break Rockwell impact ratio strength modulus strength

ASTM D1044 at 175C GPa MPa % strengt N mm-1 GPa MPa

mg/1000 % h

-1

cycles Jm

Polyethersulfone PES 6 - - - - 40-80 M88 85 0.4 - 2.4-2.6 70-95

Polyethylene - High HDPE - 0.29 - - - - D60-73 - 20-210 0.46 - 0.5-1.2 15-40

density Shore

Polyethylene - Low LDPE - - - - - 400 D41-46 - >1000 - - 0.1-0.3 5-25

Density Shore

Polyethylene - U.H.M.W. UHMW PE - 0.1-0.2 - - - 500 R50-70 >1000 0.46 - 0.2-1.2 20-40

Polyethylene Polyester, PET, - 0.2-0.4 - - - - M94-101 13-35 0.37- - 2-4 80, for

terephthalate PETP 0.44(orie biax film

nted) 190-260

Polyimide PI - 0.42 - - - 8-70 E52-99 80 - - 2.0-3.0 70-150

Polymethylmethacrylate PMMA, Acrylic - - - - - 2.5-4 M92-100 16-32 0.35 - - 2.4-3.3 80

0.4

Polymethylpentene TPX® - - - - - 15 R85 49 - - 1.5 25.5

Polyoxymethylene - Acetal - - - - - - 15 - 40 M80 70-80 0.35 - 2.3 - 2.8 60-70

Copolymer Copolymer POMC

Polyoxymethylene - Acetal - - 0.2 - 0.35 - - - 40 - 75 M94 75 - 0.35 - 2.9 - 3.1 70

Homopolymer Homopolymer 130

POMH

Polyphenyleneoxide PPO (modified), 20 0.35 - - - 50 M78/R115 200 0.38 - 2.5 55-65

PPE (modified)

Polyphenyleneoxide PPO 30% GFR 35 - - - - 2-3 L108 80 0.27 - 8-9 100-120

(modified), 30% Glass

Fiber Reinforced

Polyphenylenesulfide - PPS - 40% GFR - - - - - 1.2 R123 75-80 - - 7.6-12.0 124-160

40% Glass Fiber

Reinforced

Polyphenylsulfone PPSu - - - - - 30 M80 - - - 2.5 76

Material Formula Abrasive Coefficient of Compression Compressive Compressive Elongation Hardness - Izod Poisson's Tear Tensile Tensile

resistance - friction set after 24 hr modulus strength at break Rockwell impact ratio strength modulus strength

ASTM D1044 at 175C GPa MPa % strengt N mm-1 GPa MPa

mg/1000 % h

-1

cycles Jm

Polypropylene PP 13-16 0.1-0.3 - - - 150-300, R80-100 20-100 - - 0.9-1.5, 25-40, for

for biax for biax biax film

film >50 film 2.2- 130-300,

4.2,

Polystyrene PS - - - - - 1.6 M60-90 19-24 0.35 - 2.3-4.1 30-100

Polystyrene - Conductive High Impact - - - - - 36 - no - - 1.6 27

Conductive break

Polystyrene

Polystyrene - Cross- PS - X - Linked 60-100 - - - - 3-5 R110-120 - - - 1.65 55-70

linked

Polysulphone PSu - - - - - 50-100 M91 69 - - 2.48 70

Polytetrafluoroethylene PTFE - 0.05-0.2 - - - 400 D50-55 - 160 0.46 - 0.3-0.8 10-40

Shore

Polytetrafluoroethylene PTFE 25% GF - 0.08-0.10 - - - 100-300 D60-70 - 144 - - 1.7 7-20

filled with Glass Shore

Polyvinylchloride - UPVC - - - - - 60 R106-120 20- - - 2.5-4.0 25-70

Unplasticized 1000

Polyvinylfluoride PVF - - - - - 90-250 D80 - 180 0.4 130-200 2.1 - 2.6 55-110

Shore (initial)

Polyvinylidenefluoride PVDF 24 0.2-0.4 - - - 50 R77-83 120- 0.34 - 1.0-3.0 25-60

320

Silicone Elastomer MQ /VNQ /PMQ /P - - - - - - 60 - - - - 6.5

VMQ degrees

Shore A

Tetrafluoroethylene- PFA. Teflon PFA. - - - - - 300 - - - - - 25

perfluoro(alkoxy vinyl

ether) - Copolymer

All information and technical data are given as a guide only. Although every effort has been made to ensure that the information is correct, no warranty is given as to its completeness or

accuracy.

Call Professional Plastics at (888) 995-7767 or E-Mail sales@proplas.com Order Online at www.professionalplastics.com

You might also like

- Mechanical Properties of PlasticsDocument4 pagesMechanical Properties of PlasticsArul VasanthNo ratings yet

- Thermal Propertiesof Plastic MaterialsDocument4 pagesThermal Propertiesof Plastic MaterialsVincent Qiang ChenNo ratings yet

- 03-Humble Homemade Hifi - HATT Mk-IIIDocument4 pages03-Humble Homemade Hifi - HATT Mk-IIIjns0110100% (1)

- 15 - Vehicle Rollover AnalysisDocument33 pages15 - Vehicle Rollover AnalysisClaudio Rodrigues100% (1)

- Laminar Flow Assignment No 3Document3 pagesLaminar Flow Assignment No 3Ayushi GuptaNo ratings yet

- Cellecta Sound Proofing Solutions GuideDocument24 pagesCellecta Sound Proofing Solutions Guidejamiecellecta2012No ratings yet

- Polymers & Plastics NotesDocument4 pagesPolymers & Plastics NotessaheedvkNo ratings yet

- The Loudspeaker Spec Sheet, John M. RischDocument7 pagesThe Loudspeaker Spec Sheet, John M. RischThomas GrantNo ratings yet

- Lighting CatalogueDocument42 pagesLighting CatalogueWanjiru Kiharah75% (4)

- Technical Textiles - Composites - PDF Test 25 PDocument25 pagesTechnical Textiles - Composites - PDF Test 25 Psayedmorsy100% (1)

- Everyday DetailsDocument116 pagesEveryday DetailsBello kabirNo ratings yet

- Finishing of Technical TextilesDocument3 pagesFinishing of Technical TextilesKaushik BogharaNo ratings yet

- A 976 - 13 PDFDocument5 pagesA 976 - 13 PDFflpNo ratings yet

- NHBB Cevue PlansDocument1 pageNHBB Cevue PlansNewHomeBuildingBrokers0% (1)

- What Is Sound ??Document30 pagesWhat Is Sound ??AditiNo ratings yet

- Avhp 2300 DVDDocument172 pagesAvhp 2300 DVDduver barreraNo ratings yet

- Acoustic Catalog 0109Document63 pagesAcoustic Catalog 0109Socaciu VioricaNo ratings yet

- lt2662 RubberBondGuideDocument70 pageslt2662 RubberBondGuideAhmed Emad AhmedNo ratings yet

- Materials Used in Athletic ApparelDocument8 pagesMaterials Used in Athletic ApparelJorita ManayonNo ratings yet

- Bristile Roofing Technical Manua 21144804379Document107 pagesBristile Roofing Technical Manua 21144804379Anjali AnjuNo ratings yet

- Sandwich Panel SP2D PU For External WallDocument5 pagesSandwich Panel SP2D PU For External WallMujjo SahbNo ratings yet

- Enclosure ModellingDocument35 pagesEnclosure ModellingkanzazzNo ratings yet

- 7-Thermal Properties of MaterialsDocument6 pages7-Thermal Properties of MaterialsaomareltayebNo ratings yet

- Silicone Technical TextilesDocument39 pagesSilicone Technical TextilesRahul Oza100% (4)

- Tyre Flap (Butyl) Specification350 - 83 - SEP - 2016Document5 pagesTyre Flap (Butyl) Specification350 - 83 - SEP - 2016Purchase and Stores Officer Contract Cell-IINo ratings yet

- Lab 1 - Becoming Familiar With Lab Equipment v2Document8 pagesLab 1 - Becoming Familiar With Lab Equipment v2Isella ShoNo ratings yet

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989No ratings yet

- Ecozero PDFDocument12 pagesEcozero PDFvranceanu.ovidiu-1No ratings yet

- Development of An Auto Rickshaw Suspension SystemDocument125 pagesDevelopment of An Auto Rickshaw Suspension Systemmawais15No ratings yet

- Fundamentals of SPFDocument11 pagesFundamentals of SPFsamiw75No ratings yet

- Fan Efficiency ArticlesDocument12 pagesFan Efficiency ArticlesRami GhanemNo ratings yet

- VEDAFEU Fire Barrier SystemsDocument32 pagesVEDAFEU Fire Barrier SystemsShyam AwalNo ratings yet

- Foam TypesDocument12 pagesFoam TypesRolaxNo ratings yet

- Brochure GreenWall - Uk - 2016-ADocument46 pagesBrochure GreenWall - Uk - 2016-ASelena SabrinaNo ratings yet

- Flaktwoods SilencersDocument14 pagesFlaktwoods SilencersBenjamín AlainNo ratings yet

- BLH Design ArticleDocument16 pagesBLH Design ArticleDebajyoti GhoshNo ratings yet

- Airox Presentation - 248Document36 pagesAirox Presentation - 248mino pharm0% (1)

- MTB Suspension Basics v2Document9 pagesMTB Suspension Basics v2Kyle Walter100% (1)

- Silencer Spark Arrestor CatalogueDocument10 pagesSilencer Spark Arrestor CatalogueBasem TamNo ratings yet

- Muffler Design For Automotive Exhaust Noise Attenuation - A ReviewDocument4 pagesMuffler Design For Automotive Exhaust Noise Attenuation - A ReviewStylishrockerPradeepNo ratings yet

- Product Design of MufflerDocument16 pagesProduct Design of MufflernaniNo ratings yet

- FeltDocument8 pagesFeltadhityaNo ratings yet

- Most Mikro ACM® - Air Classifying Mill SystemsDocument12 pagesMost Mikro ACM® - Air Classifying Mill SystemsCesar EnochNo ratings yet

- Acoustic Absorption Characterization and Prediction of Natural Coir FibersDocument11 pagesAcoustic Absorption Characterization and Prediction of Natural Coir FibersUty VictoriaNo ratings yet

- High Performance PlasticsDocument6 pagesHigh Performance PlasticsAlok MallickNo ratings yet

- Stroud 2015Document6 pagesStroud 2015Dhananjay SargarNo ratings yet

- Trelleborg Users Chart 2011Document13 pagesTrelleborg Users Chart 2011hemontoyNo ratings yet

- 02UP Product Record (En)Document8 pages02UP Product Record (En)Mohamed NabilNo ratings yet

- Acoustical Design of Halls and StudiosDocument8 pagesAcoustical Design of Halls and StudiosAnqa ParvezNo ratings yet

- Noise Reduction Coefficient of Recycled Textile and Waste Paper Composite As Compared To Rigid Polyurethane FoamDocument6 pagesNoise Reduction Coefficient of Recycled Textile and Waste Paper Composite As Compared To Rigid Polyurethane FoamJohn Mark TicarNo ratings yet

- Suspension Assembly of BAJA ATVDocument4 pagesSuspension Assembly of BAJA ATVInfogain publicationNo ratings yet

- Bituminous WaterproofingDocument5 pagesBituminous WaterproofingJatinder BhatiaNo ratings yet

- Hi-Vi Re Search Loud Speak ErsDocument11 pagesHi-Vi Re Search Loud Speak ErsDomingo AngelNo ratings yet

- Onkyo A800 Leaflet BlackDocument2 pagesOnkyo A800 Leaflet Blackmttw010No ratings yet

- BD Systems Brochure 2016 05Document164 pagesBD Systems Brochure 2016 05Rajat KatyalNo ratings yet

- Application of Polypropylene in Technical TextilesDocument11 pagesApplication of Polypropylene in Technical TextilesDr Muhammad Mushtaq Mangat100% (1)

- Audaxcatalog 2Document15 pagesAudaxcatalog 2bogdanlcNo ratings yet

- ASSIGNMENT 1 2012 Insulation PDFDocument4 pagesASSIGNMENT 1 2012 Insulation PDFPrasanna KumarNo ratings yet

- Product Technical Specification-Polypropylene (POLYTAM)Document1 pageProduct Technical Specification-Polypropylene (POLYTAM)Axel Mahya AvichenaNo ratings yet

- Materijali I NabavkaDocument9 pagesMaterijali I NabavkaSonja KostićNo ratings yet

- Dna Replication Lecture Notes 2011Document46 pagesDna Replication Lecture Notes 2011Suliman GarallehNo ratings yet

- Natural and Synthetic RubbersDocument35 pagesNatural and Synthetic RubbersAnoop Kumar SainiNo ratings yet

- Arkema F and VulCup Grades 2022Document14 pagesArkema F and VulCup Grades 2022Alejandro JassoNo ratings yet

- Biopolymers of Microbial Origins PDFDocument4 pagesBiopolymers of Microbial Origins PDFManish SoniNo ratings yet

- DNA Replication WorksheetDocument2 pagesDNA Replication WorksheetMaktoumNo ratings yet

- ASTM International - BOS Volume 08.01 - 2017 ContentsDocument5 pagesASTM International - BOS Volume 08.01 - 2017 Contentspedro serranoNo ratings yet

- Process of Dna ReplicationDocument3 pagesProcess of Dna ReplicationLaiba AsimNo ratings yet

- Thermoforming Workbook DraftDocument118 pagesThermoforming Workbook DraftJaved Iqbal100% (5)

- Polymers Engineering5Document18 pagesPolymers Engineering5Hizbullah SattiNo ratings yet

- F3Document132 pagesF3Catalin OajdeaNo ratings yet

- Internship Report: TM Rubber (PVT.) LTDDocument6 pagesInternship Report: TM Rubber (PVT.) LTDsaudNo ratings yet

- RNA and Protein SynthesisDocument14 pagesRNA and Protein SynthesisFelicia Landon-HicksNo ratings yet

- Module-3 Additive Manufacturing 18 SchemeDocument62 pagesModule-3 Additive Manufacturing 18 SchemeSANTOSHNo ratings yet

- Marking of Polymeric Parts: Nissan Engineering StandardDocument14 pagesMarking of Polymeric Parts: Nissan Engineering StandardKarthic BhrabuNo ratings yet

- DNA, RNA and Protein Synthesis (Part 1) : Lesson 6Document69 pagesDNA, RNA and Protein Synthesis (Part 1) : Lesson 6Febbie IbatuanNo ratings yet

- Chapter 3 Synthetic Fibres and PlacticsDocument7 pagesChapter 3 Synthetic Fibres and PlacticsDhyani PanchalNo ratings yet

- Materials GuideDocument1 pageMaterials GuideggudayakumarNo ratings yet

- A Brief History of PlasticsDocument2 pagesA Brief History of PlasticsAntSWNo ratings yet

- Novel ABS-based Binary and Ternary Polymer Blends For Material Extrusion 3D PrintingDocument8 pagesNovel ABS-based Binary and Ternary Polymer Blends For Material Extrusion 3D PrintingSagnik ChowdhuryNo ratings yet

- HPCJUL10IM XperionCCMProcessLayoutDocument7 pagesHPCJUL10IM XperionCCMProcessLayoutglgardinerNo ratings yet

- DNA - The Moldecule of HeredityDocument36 pagesDNA - The Moldecule of HeredityRemiel MarticioNo ratings yet

- STPM Biology DNA Structure and Replication Question BankDocument6 pagesSTPM Biology DNA Structure and Replication Question BankMichele Goh100% (4)

- Chloroprene Rubber CR Selection Guide The Chloroprene Rubber (CR) Used in General Industrial Rubber ProductsDocument2 pagesChloroprene Rubber CR Selection Guide The Chloroprene Rubber (CR) Used in General Industrial Rubber ProductsPhuong The Nguyen100% (1)

- Taapma Diary - 2016Document70 pagesTaapma Diary - 2016ravi sharma100% (1)

- ThreeDotZero Filament ComparisonDocument1 pageThreeDotZero Filament Comparison3D MESHNo ratings yet

- DNA ReplicationDocument51 pagesDNA Replicationkk_bt67% (3)

- Module 5 Molecular Basis of HeredityDocument23 pagesModule 5 Molecular Basis of HeredityJohn Ray GasparNo ratings yet

- Liquid Process Piping, Part 3 Miscellaneous Piping Design PDFDocument23 pagesLiquid Process Piping, Part 3 Miscellaneous Piping Design PDFosama alabsiNo ratings yet

- Transcription & Translation ColoringDocument2 pagesTranscription & Translation ColoringBesty MaranathaNo ratings yet

- Dna and Rna Grade 10 TopicsDocument16 pagesDna and Rna Grade 10 TopicsJewel Tan100% (1)