Professional Documents

Culture Documents

Tecfloor Ec 100

Uploaded by

Sean HarshaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tecfloor Ec 100

Uploaded by

Sean HarshaCopyright:

Available Formats

®

TECFLOOR EC 100

High performance, solvent based epoxy resin based floor coating

®

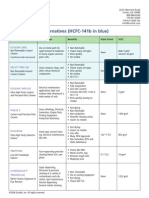

Tecfloor EC 100 is a two part solvent based, epoxy Properties

resin coating system supplied in pre-weighed packs

ready for on-site mixing and use. The values given below are average figures achieved

The cured film forms a hard but flexible coating with in laboratory tests at 35°C. Actual values obtained

excellent adhesion to clean concrete, sand/cement and onsite may show minor variations from those quoted.

granolithic screeds, and certain metal surfaces. It cures

to a semi-gloss,impervious finish which is easily cleaned.

The product is available in a range of standard colours Mix Density : 1.22-1.28 gm/cc

and is also available in a clear grade. 2

Adhesive Bond : 2 N/mm (concrete failure)

Uses Strength with concrete

(ASTMD 4541)

To provide a hard wearing, easily cleaned, attractive floor

coating in areas where high resistance to chemical attack Shore D Hardness : 80

is required. It is suitable for use in production assembly (ASTMD2240)

areas, workshops, dairies, soft drinks production and

bottling plants, kitchens, showrooms etc. It is particularly Water absorption : <1%

suitable in wet working areas and where chemical

spillage is likely, e.g. plating shops, processing plants, Pot life @ 35°c : 20 - 30 min

dye works etc.

Tack free time : 2-4 hrs

It can also be used as a final coating and sealer for

epoxy floor screeds to provide a more durable and easily

Time between coats : 8-12 hrs

cleaned surface where high impact is desirable.

Benefits Full cure : 7 days

· Hard wearing - durable, low maintenance costs Total dry film

thickness(2 coats) : 100 microns

· High resistance - to a wide range of industrial

chemicals

· Hygienic - impervious finish provides easily cleaned Note: After the pot life has expired, the material,

surface although not hardened, increases in viscosity

and the characteristics of the product change.

· Attractive - available in a range of colours to Excess material should be discarded after this

improve the working environment point.

Technical support Chemical properties

Thermax offers a comprehensive range of high ®

Tecfloor EC 100 is resistant to a wide range of

performance, high quality flooring, jointing and repair chemicals. Few of them are listed below. Specific data

products for both new and existing floor surfaces. In will be available upon request.

addition, the company offers a technical support service

to specifiers, end users and contractors. It is also able to

offer on-site technical assistance, in locations all over the

country. Citric Acid (10%) : Resistant

Hydrochloric Acid (10%) : Resistant

Standards compliance Lactic Acid (10%) : Resistant

® Sulphuric Acid (10%) : Resistant

Tecfloor EC 100 complies with BS 476, Part 7:1971

Class 1, spread of flame.

Design criteria

Good housekeeping is essential in areas where

®

Tecfloor EC 100 is designed for application in two coats chemical spillage is likely to occur. It is especially

to achieve a total dry film thickness of 100 microns. important that such spillage should not be allowed to

Substrates should be dry and not suffer, or be likely to dry since very much higher concentrations of chemicals

suffer, from rising dampness. If necessary, suitable will then result.

damp-proof membranes should be installed to prevent

this. Substrates should not have a relative humidity

greater than 75% at the time of application.

Sustainable Construction Solutions

®

TECFLOOR EC 100

Specification together. The entire contents of the hardener container

should be poured into the base container and the two

Epoxy floor coating materials mixed thoroughly, for at least 3 minutes. The

®

use of a heavy-duty slow speed, flameproof or air

The floor coating shall be Tecfloor EC 100, a two driven drill fitted with a Mixing Paddle is desirable. Mix

component epoxy suitable for application by spray, brush these components in the quantities supplied taking

or lambs wool roller. The coating shall be applied in two care to ensure all containers are scraped clean. Do not

coats to achieve a total dry film thickness of 100 microns. add solvent thinners at any time.

Instructions for use Application

®

The mixed Tecfloor EC 100 must be applied to the

Surface preparation prepared surface using airless spray, brush or lambs

®

It is essential that Tecfloor EC 100 is applied to cleaned wool roller. Ensure that the area is completely coated

and dry substrates in order to achieve maximum and that 'ponding' of the material does not occur.

adhesion between the floor coating and substrate.

The second coat may be applied as soon as the first

®

Because Tecfloor EC 100 is a relatively thin coating, coat has initially dried (typically 8 to 12 hours). The

the substrate must be fine textured. Any surface time will be dependent on the type of surface and the

irregularities may show through causing excessive wear ambient conditions.

on high spots and changing the perceived colour of the

Maintenance

coating.

The service life of a floor can be considerably extended

New concrete floors by good housekeeping practices. Regular cleaning of

®

These should normally have been placed for at least 28 Tecfloor EC 100 may be carried out using a rotary

day sand have a moisture content of less than 5%. scrubbing machine with a water miscible cleaning

Floors should be sound and free from contamination agent or by hot water washing at temperatures up to

such as oil and grease, mortar and paint splashes or

50°C.

curing compound residues. Excessive laitence can be

removed by the use of mechanical methods. Dust and Cleaning

other debris should then be removed by vacuum ®

cleaning. Tecfloor EC 100 should be removed from tools and

equipment with cleaning Solution immediately after

Old concrete floors use. Hardened material can only be removed

mechanically.

A sound, clean substrate is essential to achieve

maximum adhesion. As for new concrete floors dry Limitations

removal of laitance by use of mechanical methods is

preferable. Oil and grease penetration should be ®

removed by the use of a proprietary chemical degreaser · Tecfloor EC 100 must not be applied onto surfaces

or by hot compressed air treatment. known to or are likely to suffer from rising dampness

or have a relative humidity greater than 75% as

Any damaged areas or surface irregularities should be measured in accordance with BS 8203 Appendix A

repaired using epoxy repair mortar. or by Protimeter thermohygrometer

Steel substrates · Thermax does not recommend acid etching as a

method of floor preparation. If it is used, the method

Steel substrates should be grit blasted to surface quality should be approved by the project consultant.

SA 2½ (BS 4232: Second Quality) and primed with a ®

®

single coat of Tecfloor PR. · The durability of Tecfloor EC 100 in foot traffic are

as reduced in areas of very heavy traffic such as

Epoxy screeds around workbenches, drinks machines etc. It is

advisable to either :

® 1. specify additional coats in such areas or,

Tecfloor EC 100 can be applied to epoxy resin screeds.

2. specify a higher build system such as Tecfloor

its high spots or trowel marks should be rubbed down EC 100 in such areas.

and dust and other debris removed by vacuum cleaning. ®

· Tecfloor EC 100 should not be applied to

Mixing asphalt floors or PVC tiles or sheet.

The base and hardener components of Tecfloor EC

® · In common with all epoxy materials some slight

100 must be thoroughly stirred before the two are mixed shade changes may be experienced over the long

term when placed in adverse exposure conditions

Any such change in shade is not regarded as

being detrimental to performance.

Sustainable Construction Solutions

®

TECFLOOR EC 100

®

· Tecfloor EC 100 should not be installed at temperatures below 5°C.

Health and safety Instructions

Thermax Limited

® ® Environment House, Plot No.90-92

Tecfloor EC 100, and Tecfloor PR and cleaning Solution should not come into

BG Block, MIDC, Bhosari,

contact with skin and eyes or be swallowed. Ensure adequate ventilation and Pune 411 026, India.

avoid inhalation of vapours. Some people are sensitive to resins, hardeners and Tel: +91-20-67156000

solvents. Wear suitable protective clothing, gloves, and eye protection. If working Fax: +91-20-27120206

Customer Care: 18002090115 (India

in confined areas, suitable respiratory protective equipment must be used. The toll free)

use of barrier creams provide additional skin protection. Email : enquiry@thermaxglobal.com

In case of contact with skin, rinse with plenty of clean water, then cleanse with

soap and water. Do not use solvent. Incase of contact with eyes, rinse

immediately with plenty of clean water and seek medical advice. If swallowed, Ahmedabad

seek medical attention immediately - do not induce vomiting. Tel: +91-79-26575408 • Fax: +91-79-65577270

Fire

®

Tecfloor EC 100, Cleaning Solution are flammable. Keep away from sources of

ignition. No smoking. In the event of fire, extinguish with CO2 or foam. Do not use Bengaluru

a water jet.

Tel: +91-80-22371721 • Fax: +91-80-22371726

Flash points

Tecfloor EC 100 : 23°C Chennai

Cleaning Solution : 33°C Tel: +91-44-24303400 • Fax: +91-44-24353841

Storage

Delhi

Shelf life

® Tel: +91-11- 46087200 • Fax: +91-11- 26145311

Tecfloor EC 100 and solution have a shelf life of 12 months if kept in a dry store

between 5°C and 30°C in the original, unopened packs.

Hyderabad

Storage conditions Tel: +91-40-23253700 • Fax: +91-40-23253799

All products should be stored in accordance with local regulations.

Packing Kolkata

® Tel: +91-33-66070800 • Fax: +91-33-66070999

Tecfloor EC 100 : 4.5 litre packs

®

Tecfloor PR : 1 and 4 litre packs

Mumbai

Cleaning Solution : 5 litre tins

Tel: +91-22-67542222 • Fax: +91-22-22040859

® 2

Coverage Tecfloor EC 100 : 45 m /pack @ 100 microns WFT per coat

(2 coat application recommended) Thermax World-wide

® 2

Tecfloor PR : 5.5 - 6.5 m /litre UK, USA, UAE, Germany, Belgium, Denmark,

Russia, Saudi Arabia, Thailand, Malaysia,

Note : Coverage figures given are theoretical - due to wastage factors and the Bangladesh, Sri Lanka, China, Philippines,

Peru, Chile, Kenya, Nigeria, Brazil, Indonesia

variety and nature of substrates, practical coverage figures may be reduced,

this will vary with site and application conditions. Website: www.thermaxglobal.com

Thermax Business Portfolio

Chemicals

Absorption Cooling

Other segments :

Air Pollution Control

● Concrete Admixtures ● Surface Treatments ● Grouts & Anchors ● Repair & Rehabilitation

● Protective Coatings ● Industrial Flooring ● Waterproofing ● Sealants ● Adhesives Boilers & Heaters

Disclaimer: The information contained in this document is true and accurate to the best of our knowledge and is based on our Power

experience & test results. It is always the Company's endeavor to give true and accurate information however as it does not have any

direct and/or continuing control on the use of the Products , the Company cannot accept any liability , direct or indirect as a consequence

of the use of Products. In the event of any doubt upon any critical parameter it is advisable to seek clarification from our technical

representative. Water & Waste Solutions

We reserve the right to amend any product details without notice. Copyright© Thermax Limited Edition: (TCC/TDS/0219)

Solar

You might also like

- Adobe Scan 02-Sep-2021Document4 pagesAdobe Scan 02-Sep-2021Sean HarshaNo ratings yet

- Crystalline Durability Admixture PDFDocument1 pageCrystalline Durability Admixture PDFSean HarshaNo ratings yet

- Maxflex PSDocument3 pagesMaxflex PSSean HarshaNo ratings yet

- Maxshield Hdpe SFDocument3 pagesMaxshield Hdpe SFSean HarshaNo ratings yet

- Maxshield SBS: Self-Adhesive, Modified Bitumen Waterproofing Membrane With Cross Laminated PE FilmDocument2 pagesMaxshield SBS: Self-Adhesive, Modified Bitumen Waterproofing Membrane With Cross Laminated PE FilmSean HarshaNo ratings yet

- Sustainable Construction Solutions: Thermax LimitedDocument2 pagesSustainable Construction Solutions: Thermax LimitedSean HarshaNo ratings yet

- Mandatory Testing of Crystalline Durability AdmixtureDocument1 pageMandatory Testing of Crystalline Durability AdmixtureSean HarshaNo ratings yet

- Waterproof 6 2 1Document11 pagesWaterproof 6 2 1rowatersNo ratings yet

- Flowfresh Esd HFDocument2 pagesFlowfresh Esd HFSean HarshaNo ratings yet

- Podium NTCB-005-CB-4018-OF02-00202 - 08Z PDFDocument8 pagesPodium NTCB-005-CB-4018-OF02-00202 - 08Z PDFSean HarshaNo ratings yet

- Basf Ime 1315Document3 pagesBasf Ime 1315Sean HarshaNo ratings yet

- MS For Lift Pit Water ProofingDocument18 pagesMS For Lift Pit Water ProofingaruanNo ratings yet

- Foundation Waterproofing For FoundationDocument1 pageFoundation Waterproofing For FoundationSean HarshaNo ratings yet

- Ucrete MF: Heavy Duty Polyurethane Hybrid Flooring SystemDocument3 pagesUcrete MF: Heavy Duty Polyurethane Hybrid Flooring SystemSean HarshaNo ratings yet

- Brushbond (M) : Acrylic Polymer Modified Cementitous Waterproofing Coating For Concrete and Masonry SurfacesDocument4 pagesBrushbond (M) : Acrylic Polymer Modified Cementitous Waterproofing Coating For Concrete and Masonry SurfacesSean HarshaNo ratings yet

- Statistical Analysis of LTPP SPS-3 Experiment On Preventive Maintenance of Flexible PavementsDocument14 pagesStatistical Analysis of LTPP SPS-3 Experiment On Preventive Maintenance of Flexible PavementsSean HarshaNo ratings yet

- Fosroc Waterproofing BrochureDocument12 pagesFosroc Waterproofing BrochureAgung RahmadiNo ratings yet

- Changing Playfield-07-Milind Despande FinalDocument13 pagesChanging Playfield-07-Milind Despande FinalSean HarshaNo ratings yet

- TDS Nitoflor SL2000 India PDFDocument4 pagesTDS Nitoflor SL2000 India PDFSean HarshaNo ratings yet

- Nitofill EPLVDocument2 pagesNitofill EPLVSean Harsha100% (1)

- CBR Test ManualDocument6 pagesCBR Test ManualmmNo ratings yet

- Kamran Majeed KhanzadaDocument130 pagesKamran Majeed KhanzadaSean HarshaNo ratings yet

- Biogas Purification and Methane-Enrichment For Industrial Use - Mr. Sanjay Sharma, PSADocument15 pagesBiogas Purification and Methane-Enrichment For Industrial Use - Mr. Sanjay Sharma, PSASean HarshaNo ratings yet

- Cement and HydrationDocument10 pagesCement and HydrationmohammedzeeshanNo ratings yet

- Intelligent Transportation SystemDocument32 pagesIntelligent Transportation SystemSean HarshaNo ratings yet

- Intelligent Transport System (1) NewDocument5 pagesIntelligent Transport System (1) NewSean HarshaNo ratings yet

- PFRCDocument24 pagesPFRCSean HarshaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Clark SM 717 Service ManualDocument20 pagesClark SM 717 Service Manualtom100% (22)

- Belzona 1391Document2 pagesBelzona 1391AsadAliNo ratings yet

- Nitomortar TC2000 PDFDocument3 pagesNitomortar TC2000 PDFtalatzahoor100% (2)

- Loctite PC 7210-ENDocument4 pagesLoctite PC 7210-ENYuvarajNo ratings yet

- STP538 Eb.1415051 1 PDFDocument239 pagesSTP538 Eb.1415051 1 PDFpaola100% (2)

- EnviroPeel StripperDocument3 pagesEnviroPeel StripperAhmed ElghmatiNo ratings yet

- Stepan Formulation 1205Document2 pagesStepan Formulation 1205ricardo navarreteNo ratings yet

- TVL Cookery: Quarter 1 - Module 2: (WEEK 2)Document17 pagesTVL Cookery: Quarter 1 - Module 2: (WEEK 2)BiZayangAmaZona100% (6)

- S2.04.3 Primer Surfacer EP APACDocument8 pagesS2.04.3 Primer Surfacer EP APACWawan BudiantoNo ratings yet

- Cleaning and SanitizingDocument13 pagesCleaning and SanitizingErlyn AlcantaraNo ratings yet

- Technical Data BookletDocument53 pagesTechnical Data Booklettracy8763No ratings yet

- Product GuideDocument5 pagesProduct GuidemehoNo ratings yet

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocument1 pageLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNo ratings yet

- Jet-Lube Clean-Up AerosolDocument1 pageJet-Lube Clean-Up AerosolDon HowardNo ratings yet

- SHOC & SW Awareness SlideDocument41 pagesSHOC & SW Awareness SlideNadiatul AishahNo ratings yet

- Ufgs 09 97 13.15Document43 pagesUfgs 09 97 13.15Tim KearneyNo ratings yet

- Manual B1012 EDocument24 pagesManual B1012 ERPNo ratings yet

- Fosroc Acid EtchDocument2 pagesFosroc Acid EtchVenkata RaoNo ratings yet

- Belzona 1511 Instruction For UseDocument2 pagesBelzona 1511 Instruction For UseNitin AggarwalNo ratings yet

- pt522msds PDFDocument2 pagespt522msds PDFSkySupplyUSANo ratings yet

- 50101-000rev K PDFDocument48 pages50101-000rev K PDFRiki Rijaludin100% (1)

- Por 15 CatalogDocument56 pagesPor 15 CatalogPOR 1567% (3)

- Protective Coatings and LiningsDocument67 pagesProtective Coatings and LiningsYang HUng86% (7)

- Method Statements WebsiteDocument24 pagesMethod Statements WebsitemullerNo ratings yet

- Fosroc Acid EtchDocument2 pagesFosroc Acid EtchtalatzahoorNo ratings yet

- LLP Catalogue PDFDocument27 pagesLLP Catalogue PDFManish GoyalNo ratings yet

- Sanitation Standard Operating Procedures LoxDocument15 pagesSanitation Standard Operating Procedures LoxSherry Salazar100% (1)

- 2012 Organic Finishing Guidebook IssueDocument332 pages2012 Organic Finishing Guidebook IssueGabriel MedeirosNo ratings yet

- Weldtite Catalogue 2016Document43 pagesWeldtite Catalogue 2016Martin LewisNo ratings yet

- Powerrail 2013 Catalog Emd CompletoDocument96 pagesPowerrail 2013 Catalog Emd CompletoSaMuell San100% (2)