Professional Documents

Culture Documents

Injection

Uploaded by

RAHUL SINGH0 ratings0% found this document useful (0 votes)

6 views3 pagesstandard

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentstandard

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesInjection

Uploaded by

RAHUL SINGHstandard

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Manufacturing Process

Injection

Injection molding (British English: molding) is a manufacturing for producing

parts from both thermoplastic and thermosetting plastic materials. Material is

fed into a heated barrel, mixed, and forced into a mold cavity where it cools and

hardens to the configuration of the mold cavity.

After a product is designed, usually by an industrial designer or an engineer,

molds are made by a mold maker (or toolmaker) from metal, usually either steel

or aluminum, and precision-machined to form the features of the desired part.

Injection molding is widely used for manufacturing a variety of parts, from the

smallest component to entire body panels of cars.

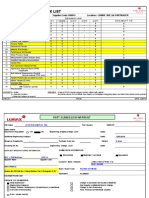

Step 1: Customer Order

When Poly Vision takes an order from a customer, a record will be created and information is

gathered. The order will be submitted for processing after the customer provides the billing address,

shipping address, and payment information. If there are any backorders, predefined discounts or any

other conditions, they are applied to the order.

Step 2: Working Schedule

Material evaluation/Risk assessment is designed to help assess and improve client's product design,

workmanship, functionality, reliability and safety, ensure the injected moulds are meeting your

specifications and relevant international standards or legal regulations of intended market. In the

end, a work schedule is established after the order is confirmed and each department's work is

assigned.

Step 3: Material Purchasing

As soon as the work schedule is arranged, material purchasing is conducted by our procurement

staff. Procurement staff performs all activities related to supply chain management. This includes,

acting in a consultative role between Poly Vision and suppliers to inspect the companies, selecting

optimal suppliers and maintain records of goods ordered and received. In addition, procurement

department is also responsible for researching and evaluating suppliers, maintaining supplier

database with evaluation points based on price, quality, selection, service, support & the supplier's

reputation and history.

Manufacturing Process

Step 4: Granular Plastic Processing

With Injection Molding, granular plastic is fed by gravity from a hopper into a heated barrel. As the

granules are slowly moved forward by a screw-type plunger, the plastic is forced into a heated

Manufacturing Process

chamber, where it is melted. Injection speeds are usually determined by performing viscosity curves.

Process windows are performed varying the melt temperatures and holding pressures.

Step 5: Injection Mould Set Up

Injection mould set up is to install mould tool on mould machine.

Step 6: Data Setting

Mould injection machine's data is set for the first production on this stage. The machine is in

excellent working condition and is capable of processing commodity as well as various plastic

products.

Step 7: First Production Checking

Once the first production is made and the quality is assured, we will start manufacturing them on a

large scale.

Step 8: Mass Production

In the current mould-making industries, the challenge is to shorten the mould lead-time while

maintaining the desired quality. This is one of the main demands from customers so as to maintain a

competitive edge over the competition. During the mass production, mould products are made with

high-standard.

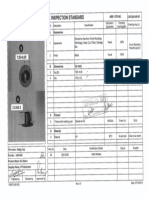

Step 9: Quality Control

The final exam of the products to ensure the quality of each production. Poly Vision's recent

purchase of CMM is to make sure they got the job done properly.

Step 10: Packing

The packing staff check submitted packing sample according customer's packing specification and

perform relevant transportation tests to make sure their products are well protected and shipped

safely. Poly Vision assures your injection moulds are made correctly to your specifications and are

well packed before delivery.

Step 11: Storage

Poly Vision's massive warehouse is one of their advantages which gives clients more options for their

material storage and delivery needs.

Step 12: Delivery

Poly Vision's delivery team performs effectively. After plastic productions are delivered, we continue

to provide our services until the first vehicle rolls off the line.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- April StatementDocument2 pagesApril StatementRAHUL SINGH50% (2)

- Ansi b151.1 RG-687Document13 pagesAnsi b151.1 RG-687luisulloaimNo ratings yet

- EWM WhseDocument26 pagesEWM WhseShaik Khwaja Nawaz SharifNo ratings yet

- Merchandise MixDocument7 pagesMerchandise MixANSHU KUMARINo ratings yet

- Walmart CaseDocument2 pagesWalmart CaseIliaskzNo ratings yet

- Chopra scm5 Tif ch12Document24 pagesChopra scm5 Tif ch12Madyoka Raimbek100% (1)

- Accounting For Merchandising Operations LongDocument32 pagesAccounting For Merchandising Operations Longgk concepcionNo ratings yet

- Life Cycle Assessment of Wood Pellet: Siyu ChenDocument82 pagesLife Cycle Assessment of Wood Pellet: Siyu Chentopollillo24No ratings yet

- Strategic ProcurementDocument74 pagesStrategic ProcurementRaluca UngureanuNo ratings yet

- Solid Waste and By-Products Processing: Laboratory Practical Report Group 1Document42 pagesSolid Waste and By-Products Processing: Laboratory Practical Report Group 1RAHUL SINGHNo ratings yet

- Resources, Conservation and RecyclingDocument11 pagesResources, Conservation and RecyclingRAHUL SINGHNo ratings yet

- Life Cycle Assessment - Opportunities For Forest Products SectorDocument13 pagesLife Cycle Assessment - Opportunities For Forest Products SectorRAHUL SINGHNo ratings yet

- The Future of Mining?: Group Project InformationDocument11 pagesThe Future of Mining?: Group Project InformationRAHUL SINGHNo ratings yet

- Life-Cycle Analysis of Lithium-Ion Battery Production and RecyclingDocument18 pagesLife-Cycle Analysis of Lithium-Ion Battery Production and RecyclingRAHUL SINGHNo ratings yet

- Articles +doll2010 Article ChemicalVaporDepositionAndAtomDocument7 pagesArticles +doll2010 Article ChemicalVaporDepositionAndAtomRAHUL SINGHNo ratings yet

- Determination of Size and Concentration of Gold Nanoparticles From UV/vis Spectra'Document7 pagesDetermination of Size and Concentration of Gold Nanoparticles From UV/vis Spectra'Umar IjazNo ratings yet

- Project Power Shoe: Piezoelectric Wireless Power Transfer - A Mobile Charging TechniqueDocument33 pagesProject Power Shoe: Piezoelectric Wireless Power Transfer - A Mobile Charging TechniqueRAHUL SINGHNo ratings yet

- Wood Pellet and Wood LogDocument10 pagesWood Pellet and Wood LogRAHUL SINGHNo ratings yet

- BP-1, Business PlanDocument1 pageBP-1, Business PlanRAHUL SINGHNo ratings yet

- Mechanical and Chemical Recycling of Solid Plastic Waste PDFDocument35 pagesMechanical and Chemical Recycling of Solid Plastic Waste PDFTapu mojumderNo ratings yet

- PSWDocument1 pagePSWRAHUL SINGHNo ratings yet

- Sorting of Plastic Waste For Effective Recycling: January 2015Document9 pagesSorting of Plastic Waste For Effective Recycling: January 2015PurushothamNo ratings yet

- Cosmo Account LedgerDocument2 pagesCosmo Account LedgerRAHUL SINGHNo ratings yet

- RAHUL SINGH, AMIR Master 2020-2022 - 1st Application Period (2020)Document4 pagesRAHUL SINGH, AMIR Master 2020-2022 - 1st Application Period (2020)RAHUL SINGHNo ratings yet

- Bulb Lock PlateDocument1 pageBulb Lock PlateRAHUL SINGHNo ratings yet

- 2428Document4 pages2428RAHUL SINGHNo ratings yet

- Dispatch DetailDocument1 pageDispatch DetailRAHUL SINGHNo ratings yet

- Data20 21Document2 pagesData20 21RAHUL SINGHNo ratings yet

- JOURNALOFMECHANICALENGINEERINGANDDocument10 pagesJOURNALOFMECHANICALENGINEERINGANDRAHUL SINGHNo ratings yet

- 534Document1 page534RAHUL SINGHNo ratings yet

- Measurement Analysis PKDocument2 pagesMeasurement Analysis PKRAHUL SINGHNo ratings yet

- Stud Pin Comp HL Yg4Document16 pagesStud Pin Comp HL Yg4RAHUL SINGHNo ratings yet

- Book 1Document4 pagesBook 1RAHUL SINGHNo ratings yet

- Personal ContactDocument2 pagesPersonal ContactRAHUL SINGHNo ratings yet

- Safety cap-LISDocument1 pageSafety cap-LISRAHUL SINGHNo ratings yet

- 09 X07 C Responsibility Accounting and TP Variable Costing & Segmented ReportingDocument8 pages09 X07 C Responsibility Accounting and TP Variable Costing & Segmented ReportingAnnaNo ratings yet

- Final Slides Supply ChainDocument33 pagesFinal Slides Supply ChainghaziaNo ratings yet

- Supply Chain of Automotive Industry V/S Suplly Chain of FMCG IndustryDocument9 pagesSupply Chain of Automotive Industry V/S Suplly Chain of FMCG IndustryMuhammad Umar KhanNo ratings yet

- Case Study - Dell Vs LenovoDocument5 pagesCase Study - Dell Vs Lenovostudyhotels50% (2)

- Department of Management Studies - Doc FFDocument32 pagesDepartment of Management Studies - Doc FFRamasudhakarreddy MedapatiNo ratings yet

- Supply Chain Coordination - The Bullwhip Effect: 3/14/2019 Rakesh V - IIM Lucknow 1Document11 pagesSupply Chain Coordination - The Bullwhip Effect: 3/14/2019 Rakesh V - IIM Lucknow 1neha bhatiaNo ratings yet

- Certification in Humanitarian Supply Chain Management (CHSCM) Competence Model. Final Version 2007Document28 pagesCertification in Humanitarian Supply Chain Management (CHSCM) Competence Model. Final Version 2007Kareem AqeelNo ratings yet

- Tugas-Kasus - 4.12Document3 pagesTugas-Kasus - 4.12niti dsNo ratings yet

- Supply Chain Management - MGMT614Document4 pagesSupply Chain Management - MGMT614Syed Abdul Mussaver ShahNo ratings yet

- PGPM Ex BrochureDocument13 pagesPGPM Ex Brochureprakhar singhNo ratings yet

- Production Theory & Law of Variable ProportionsDocument17 pagesProduction Theory & Law of Variable ProportionssanaNo ratings yet

- 3626 Protecnica 11291Document2 pages3626 Protecnica 11291Paula GonzalezNo ratings yet

- Make or Buy, Insourcing, and OutsourcingDocument17 pagesMake or Buy, Insourcing, and OutsourcingAseel TurjomanNo ratings yet

- Supplier Evaluation and Selection: South-Western Cengage LearningDocument45 pagesSupplier Evaluation and Selection: South-Western Cengage LearningRahil AndleebNo ratings yet

- PALL Gas Filter BroDocument20 pagesPALL Gas Filter BroClaudio TurlherNo ratings yet

- Bol 717985078Document3 pagesBol 717985078Mike YeeNo ratings yet

- Dalpk201031 Grobogan HwabDocument1 pageDalpk201031 Grobogan HwabWidus AirportNo ratings yet

- Panalpina FCR: (Forwarder's Certificate of Receipt)Document1 pagePanalpina FCR: (Forwarder's Certificate of Receipt)LoganNo ratings yet

- Turban 2008 Instructor’s Manual Chapter 1 OverviewDocument14 pagesTurban 2008 Instructor’s Manual Chapter 1 OverviewTâm HuỳnhNo ratings yet

- USPS Price ListDocument68 pagesUSPS Price Listbrent.chong9398No ratings yet

- Shams Group of Companies BrochureDocument16 pagesShams Group of Companies BrochureSajjadul MawlaNo ratings yet

- Tema de Inventarios Oziel FloresDocument7 pagesTema de Inventarios Oziel FloresOziel FloresNo ratings yet

- Service ManualDocument33 pagesService ManualJongchan Jason MoonNo ratings yet