Professional Documents

Culture Documents

International Journal of Engineering Research & Technology (IJERT)

International Journal of Engineering Research & Technology (IJERT)

Uploaded by

Olexiy TchaykovskyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

International Journal of Engineering Research & Technology (IJERT)

Uploaded by

Olexiy TchaykovskyCopyright:

Available Formats

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 06, June-2016

Arc Re-Melting of Ductile Cast Iron After

Mischmetal Fecemg Modification

Dr. Olexiy A. Tchaykovsky,

Senior Professor,

Department of Foundry of ferrous and non-ferrous metals,

National Technical University of Ukraine “KPI”

Kyiv, Ukraine, Peremohy av., 37

Abstract —The sphericity of graphite gradually According to Voloschenko et al. the residual magnesium

disappears after the exposure of the liquid cast iron in the content of castings, which crystallize with the formation of

ladle during casting. This process was previously metastable structures should not be lower than 0,035 %. At

investigated and the influencing factors such as lower magnesium content spherical graphite has irregular or

magnesium content, exposure time and temperature were mixed shape, which is unacceptable [1].

determined. The complete disappearance of the graphite The effect of liquid ductile cast iron exposure on kinetics

sphericity was also observed after ductile cast iron re- of graphite sphericity reduction is given in Table 1.1 [3]. In

melting. The aim of this work was to study the kinetics of this study the initial cast iron with stable chemical

graphite shape transformation in ductile iron treated by composition was smelted in a furnace with basic lining at

mischmetal FeCeMg during the arc re-melting process. 1450...1470 °C and treated with optimal amounts of modifiers.

The effect of heat treatment exposure on the shape of The modified cast iron was kept in the furnace at

graphite inclusions was determined. 1380...1420 °C and the liquid metal probes for analysis were

taken every 3 min.

Keywords — Ductile Iron; Spherical Graphite, Modification,

Based on the results given in Table 1.1 and Figure 1.1 it

Arc Re-Melting, Graphite Nodularity Degree, Graphite Shape,

can be concluded that isothermal exposure of modified cast

Nodular Graphite Mischmetal

iron reduces the sphericity of graphite, but the intensity of this

I INTRODUCTION process depends on the modifier composition. Immediately

after the spheroidizing treatment the sphericity rate was

1.1 Spherical graphite in ductile cast iron 83...93 %, after 10 and 20 min 70...88 % and 32...66 %,

There are many hypotheses regarding to the origin of respectively.

spherical graphite in cast iron, but none of them provides a

complex description of this process. The high temperatures TABLE 1.1 - EFFECT OF DURATION OF EXPOSURE ON THE GRAPHITE SHAPE IN

complicate observations of a number of phenomena that could CAST IRON AFTER MODIFICATION

reveal the mechanism of spherical graphite formation during Modifier Graphite sphericity, % after exposure, min

spheroidizing treatment and the role of magnesium and other Composition

spheroidizers in this process. 0,5 3 6 9 12 15 18 21 24

1 Mg-Ni- 88 88 85 80 65 55 35 35 -

The principal industrial process of ductile cast iron Cu

production is base on using of spheroidizing elements. A 2 Mg-Ni- 90 - 85 80 70 55 40 35 30

range of properties of ductile cast iron is define by graphite REM

sphericity. In turn, the graphite sphericity entirely depends on 3 Mg-Si-Fe 90 - 80 75 60 45 - 30 -

the residual content of spheroidizer, mainly magnesium. 4 Mg-Si- 85 85 - 78 70 60 45 - 30

Residual magnesium content, which gives the spherical Fe-Ca

5 Mg-Ca- 90 90 - 87 85 80 65 50 40

graphite shape, depends on the cooling rate, modification REM-Si-

process parameters and metal matrix structure. The amount of Fe

spheroidizer depends on many factors: the mass of cast iron 6 Mg-Ca- 85 85 83 - 80 73 60 45 35

which is processed, the mold filling time, casting wall REM-Si-

thickness, sulfur content, temperature, cooling rate etc. Fe

7 Mg-Ca- 93 - 83 - 82 - 64 - 45

Based on practice and the results obtained, it can be REM-Si-

concluded that the residual magnesium content which ensure Fe-Ba

the correct spherical shape of graphite in castings with a wall

thickness of 20...80 mm should not be lower than The lack of proportionality between the exposure duration

0,041...0,042 %. Spheroidizing treatment technology of cast of liquid modified cast iron and the graphite sphericity rate is

iron must guarantee satisfactory assimilation of magnesium in typical for all investigated modifiers. The graphite sphericity

liquid metal. reduction is slow for short durations of exposure and increases

with time (Fig. 1.1).

IJERTV5IS060638 www.ijert.org 495

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 06, June-2016

Repeated iron re-melting in argon at various cooling rates

within 20-1000 degree/min, shown that nodular graphite keeps

its shape for speed 40 degrees/min. At lower speeds

spheroidal graphite disappears (fig1.2 and 1.3) [3].

Nodularity graphite raition, %

Exposure time after modification, min Fig 1.2 Graphite inclusions in specimens cooled at a speed 1000

degrees/min under argon and hydrogen.

Fig. 1.1 Effect of exposure duration of liquid modified cast iron on graphite

sphericity

Thus, in any case, the spheroidizing effect disappears and

duration of exposure in liquid state is the key parameter of this

process.

Therefore, the re-melting of ductile iron castings leads to

complete disappearance of spherical graphite and further

spheroidizing treatment required.

Special attention was dedicated to mechanism and kinetics

of dissolution of spherical graphite at 700...1100 °C. It was

established that the heating over the eutectoid transformation Fig 1.3 Graphite inclusions in specimens cooled at a speed 20 degrees/min

temperature significantly affects the spherical graphite under argon and hydrogen.

dissolution kinetics. Lower overheating temperatures inhibit

the carbon diffusion from graphite throughout the austenite to The aim of this study is to fill the existing gap in literature

ferrite. and to investigate the graphite sphericity reduction during the

arc re-melting of ductile cast iron modified by mischmetal

Carbon diffusion occurs directly in the ferrite grains as FeCeMg.

well as at the ferrite grain boundaries. The continuous transfer

of carbon atoms to austenite creates the gap at the boundary 2 EXPERIMENTAL METHODOLOGY

between graphite and the metal matrix. Graphite dissolution in 2.1. Cast iron smelting

ferrite phase is uneven process and occurs with continuous Base cast iron was melted in core-less induction furnace

acceleration. The carbon dissolution rate in austenite increases with acidic lining crucible, containing 60 kg. The charge

as the temperature increases. Graphite dissolves quickly at

consists of pig iron and steel scrap. The chemical composition

temperatures above 950 °C [2].

of pig iron is given in table 2.1.

Thus, there is lot of studies dedicated to the influence of TABLE 2.1 - CHEMICAL COMPOSITION OF PIG IRON

technological parameters on the shape graphite in cast iron, Element C Si Mn S P

however the comprehensive data regarding to the kinetics of Content, % 4,3 1,65 0,6 <0,03 <0,1

graphite sphericity reduction are very limited.

TABLE 2.2 - CHEMICAL COMPOSITION OF STEEL SCRAP

The use of mischmetal (consisting of cerium) gives Element C Si Mn S P

positive results of graphite spheroidizing. Content, % 0,03 0,3 0,06 0,01 0,1

Research and industrial tests mischmetal used for

processing nickel-carbon and iron-carbon alloys have shown For the cast iron spheroidizing treatment used mischmetal

that spherical graphite formed at high cooling rates and low FeCeMg-5. Mischmetal FeCeMg-5 chemical composition is

sulfur content [3]. given in Table 2.3.

Research on re-melting samples of nickel-carbon alloy, Cast iron temperature before pouring into molds was

pre-treated by spheroidizing elements, showed that the most measured tungsten- rhenium thermocouple VR5/20 paired

effective cerium [3, 4]. with a digital potentiometer A565.

IJERTV5IS060638 www.ijert.org 496

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 06, June-2016

TABLE 2.3 – CHEMICAL COMPOSITION OF MISCHMETAL FESCEMG-5 Melting was conducted with carbon electrode.

Element Mg Ce La Nd Pr Fe Determining the sample melting point occurs at 1130 °C, i.e.

Content, % 4…5 40…45 18…25 10…12 5…7 ≤6

at a temperature slightly above the solidus. The temperature

was kept in two ranges 1130 °C…1320 °C and

The amount of modifier was 3% of metal weight. Cast iron

1050 °C…1100 °C during a specified time.

temperature before modification was 1400...1420 °C.

For cast iron treatment and molds pouring was used lade

with volume of 10 kg. After filling, the molds cool to room

temperature.

2.2. Sample preparation

The initial casting with 12 samples (Fig. 2.1) was

produced in dry sand mold.

Fig 2.3 Schematic diagram of the experimental mold: 1 – sample; 2 – sand-

Fig. 2.1 Casting with samples clay mixture; 3 – thermocouple 1; 4 – thermocouple; 2 5 – contact; 6 –

carbon electrode

The molten and superheated to the temperatures 1450 °С

cast iron was treated with mischmetal FeCeMg-5 in the After re-melting and exposure sample cooled in mold to

amount of 3% by weight of metal. The molds were poured room temperature.

with modified cast iron, and cooled to room temperature

The sample was purified by residues of molding mixture

In each ductile iron sample with the sizes of (fig. 2.4), and polished for metallographic research.

70 × 10 × 10 mm three through holes with diameter 3 mm

were made (Fig. 2.2).

Fig 2.4 Samples after partial re-melting and holding for a specified time.

2.3 Metallographic analysis

Determination of graphite nodularity degree (GND)

conducted by the method, developed IPL of Academy of

Sciences of Ukraine. To determine the amount of graphite

Fig 2.2 Research sample scheme

inclusions in cast iron used Hlaholeva point method.

Two holes required for installation of thermocouples, and The structure of the metal matrix, graphite nodularity rate

the third (lower) to supply contact. (GNR) [3], the amount and average size of graphite inclusions

Sample was molded in mold-box with diameter of 200 mm were defined by means of light optical microscopy (LOM).

and a height of 300 mm. Schematic diagram of the 3 EXPERIMENT

experimental mold is shown in Fig. 2.3.

3.1 Nodular iron samples structure characteristics after

Thermocouples 3, 4 is set in the holes for temperature mischmetal FeCeMg-5 modification.

recording at two points during the sample heating and melting For research were produced samples with 70 mm length

of the. Thermocouple 3 was set at the upper part of the and a 10 mm width (a square cross-section). Cast iron was

sample, where the heating and melting occur, for control the treated with mischmetal FeCeMg-5 and pureed into dry sand

desired temperature. Thermocouple 4 was installed at the mold. After samples separation the high-temperature

bottom of the sample, is designed to control temperature of annealing was carried out at a temperature 960...980 °C

solid iron. followed by cooling in the furnace.

IJERTV5IS060638 www.ijert.org 497

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 06, June-2016

The results of metallographic studies found, that graphite Nodular graphite observed in all sample area that was re-

nodularity degree of base ductile iron modified by mischmetal melted. In general, the size of graphite inclusions decreased

FeCeMg-5 is 90...95 %, the average graphite size is in the from 3...7 m to 1,5...2 m, graphite inclusions nodularity

range of 3...7 m and the graphite inclusions quantity is in the degree decreased from 90...95 tо 65...85 % and the amount of

range 120...140 pcs/mm2 (fig. 3.1, а). graphite inclusions decreased from 80..120 to 5...15 pcs/mm2

(fig. 3.3). In the melting area there are some graphite

Graphite inclusion features of base ductile iron and metal inclusions that have partially broken shape. The size of some

matrix structure shown in the table 3.1. graphite inclusions is increased considerably to range

25...50 m (fig. 3.4). This nodular graphite size is bigger than

TABLE 3.1 – CHARACTERISTICS OF THE BASE NODULAR IRON STRUCTURE in base ductile iron. The amount of such inclusions is in range

AFTER TREATMENT AND HIGH-TEMPERATURE ANNEALING.

from 5 to 10 pcs/mm2 (fig. 3.4).

Indicator Value

Graphite inclusion size, m 3…7

Graphite inclusion quantity, pcs/mm2 120…140

Graphite nodularity degree, % 90…95

Ferrite/Perlite quantity, % 30/70

a b

Fig. 3.1 Structure of base nodular iron modified by mischmetal FeCeMg-5. а

– not etched; b – etched

The longitudinal sample cross-sections were taken for

microstructure analysis.

3.2 Graphite inclusions characteristics after nodular iron re-

melting

3.2.1 Re-melting ductile iron modified mischmetal FeCeMg-5

at high temperature and short-term exposure conditions.

The sample was re-melted by carbon electrode electric arc.

Graph of heating, exposure and cooling mode are presented in

Fig. 3.2. Samples from nodular iron heated to a temperature

1270...1300 °C and exposure during 27...30 seconds. The total

time during which part of the sample was in liquid state is 35-

40 seconds.

1500

Temperature, оС

1000

Melting zone

500

Solid zone

0

39 42 45 48 51 55 58 61 65 68 72 75

Time, sec

Fig 3.3 Graphite inclusions on the sample length after melting at the

Fig 3.2 Graph of ductile iron high temperature heating and short term temperature 1270...1300 °C and exposure time 35...40 seconds: а - 0 mm

exposure mode (base ductile iron); b - 3 mm; c - 6 mm; d -9 mm; e - 12 mm.

After heating, melting, exposure, and cooling the Metal matrix structure along the length of the sample

characteristics of graphite inclusions in the sample part, that changes from ferrite-pearlite, in solid part to cement and

was re-melted, were investigated. Metallographic analysis ledeburite in apart, which was re-melted (fig. 3.5).

conducted by 3 mm – in direction from temperature control

point to melting bath (fig.3.1).

IJERTV5IS060638 www.ijert.org 498

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 06, June-2016

TABLE 3.2 − GRAPHITE INCLUSIONS CHARACTERISTICS IN THE RE-MELTED

SAMPLE AREA OF DUCTILE IRON MODIFIED BY MISCHMETAL FECEMG-5.

Distance, mm Diameter, m GND, % Average graphite

amount,%

initial 3…7 90…95 80...120

3 1,5…3 85…90 80...120

6 1,5…3 85…90 60..80

9 1,5…3 85…90 10…20

12 1,5…2(25…50) 65…80 10…15(5-10)

Metallographic analysis showed that the spherical graphite

includes is present in ductile iron that was modified by

mischmetal FeCeMg-5 after re-melting, which began to lose

spherical graphite shape and includes of flake graphite.

The characterization of re-melted ductile iron modified by

mischmetal FeCeMg-5 is shown in table 3.3.

TABLE 3.3 – THE CHARACTERIZATION OF RE-MELTED DUCTILE IRON

MODIFIED BY MISCHMETAL FECEMG-5

Temperature mode Re-melting

Ductile iron matrix structure cement and ledeburite

Graphite inclusions shape nodular, flake

Fig. 3.5 The metal matrix structure (different field of view) on the length of

re-melted sample area at the re-melted temperature 1270...1300 °C and

exposure time 35...40 seconds.

3.2.2 Re-melting ductile iron modified mischmetal FeCeMg-5

at low temperature and long term conditions.

a

Fig. 3.4 Graphite inclusion (different field of view) in the sample molten

Sample modified by mischmetal FeCeMg-5, was heated to

area. the temperature.1050...1100 °C (near magnesium boiling

point) and exposure during 5 min 35 second (fig.3.13).

IJERTV5IS060638 www.ijert.org 499

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 5 Issue 06, June-2016

TABLE 3.3 − GRAPHITE INCLUSIONS CHARACTERISTICS IN THE RE-MELTED

1200 SAMPLE AREA OF DUCTILE IRON MODIFIED BY MISCHMETAL FECEMG-5

(EXPOSURE TEMPERATURE 1050...1100°C, TIME 5 MINUTES 35 SECONDS).

1000

Temperature, оС

Distance, Diameter, GND, % Average graphite

800 Melt zone mm m amount,%

initial 3…7 90…95 80...120

600

1 3…7 90…95 80...120

Solid zone 2 3…7 90…95 80...120

400

3 3…7 90…95 80...120

200 4 3…7 90…95 80...120

8 3…7 90…95 80...120

0 9 3…7 90…95 80...120

155 201 247 294 342 391 438 487 11 3…7 90…95 80...120

Time, с 12 3…7 90…95 80...120

Fig. 3.6 Graph of ductile iron low temperature heating and long term

exposure mode Graphite nodularity degree is 90...95 %, the average

graphite size is 3...7 m, the graphite inclusion amount is

Metallographic analysis showed that after nodular iron 120...140 pcs/mm2, that is no different from the baseline

heating, re-melting and exposure at 1050...1100 °C, during characteristics of ductile iron graphite, which is not melted.

5 minutes 35 seconds, in the area of the sample that has been

re-melted, there were no changes in the shape of graphite 4 CONCLUSIONS

inclusions (fig. 3.14). There are no complete destruction nodular graphite

inclusions.in the liquid phase during ductile iron

modified by mischmetal FeCeMg-5 re-melted at the

temperature 1270...1300 °C during 35...40 seconds. There

is a decrease their size from 7 m to 2 m, and decrease

GND to 65...85 %. At the same time, there has been a

sharp increase the diameter of individual nodular graphite

inclusions to 25-50 mcm. This inclusions is situated near

small one and evenly spaced in ductile iron.

At ductile iron modified by mischmetal FeCeMg-5 re-

melting at the temperature 1100°C (near magnesium

boiling point) during 5 minutes 35 seconds, the of nodular

graphite inclusions shape changing were not found. The

size, amount and GND remain unchanged and fully

conform to the characteristics of the basic ductile iron.

REFERENCES

[1] Voloschenko M.V., Toropov A.I., Influence of residual magnesium

on the graphite shape. // Foundry. Manuf. - 1961. - № 5. - S. 30..

[2] Yakovlev F.I, About the mechanism of dissolution of graphite during

induction heating of the nodular iron casts. // Foundry. Manuf. - 1978. -

№ 3. - S. 3-5..

[3] Yuji Kato, Ying Zou, Hideo Nakae. Influence of Melting Conditions on

Graphite Morphology in Spheroidal Graphite Cast Iron Using Ni-C

Alloys. Key Engineering Materials Vol. 457 (2011) pp 37-42

[4] Y. Tatsuzawa, S. Jung, H. Nakae Cooling curve and graphite

morphology in Ni–C alloys International Journal of Cast Metals

Research 2008 Vol 21 No 1–4 pp 17-22.

Fig. 3.7 Graphite inclusions in the ductile iron re-melted area

(various view sight) at the temperature 1050...1100°C, by 1 mm

IJERTV5IS060638 www.ijert.org 500

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 4.3 Reaction Rates and Reversible ReactionsDocument18 pages4.3 Reaction Rates and Reversible ReactionsVictor VC100% (6)

- The Number of Geometrical Isomers ForDocument3 pagesThe Number of Geometrical Isomers ForGajendran PandiNo ratings yet

- N10120045 - Putri Aswariyah Ramli - Laporan Praktikum Penilaian Status GiziDocument5 pagesN10120045 - Putri Aswariyah Ramli - Laporan Praktikum Penilaian Status GiziPutri Aswariyah RamliNo ratings yet

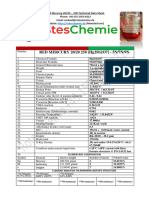

- Red Mercury 2020 Technical Data SheetDocument2 pagesRed Mercury 2020 Technical Data SheetThe UniversNo ratings yet

- 1-Poll ChemistryDocument3 pages1-Poll Chemistryamanrana98128No ratings yet

- Chemistry of Salt, Acid, Base and Metal: ChemicalDocument6 pagesChemistry of Salt, Acid, Base and Metal: ChemicalrezadNo ratings yet

- What Is A Metal?Document46 pagesWhat Is A Metal?Akweri OyunguNo ratings yet

- 12 - WBM Contamination & Treatment BMS 2013Document87 pages12 - WBM Contamination & Treatment BMS 2013Slim.BNo ratings yet

- Empirical and Molecular FormulaDocument2 pagesEmpirical and Molecular FormulaHanum100% (1)

- Chemistry Question Bank 1 - FinalDocument27 pagesChemistry Question Bank 1 - FinalKim LeeNo ratings yet

- Using Solubility Rules To Predict Precipitates in ReactionDocument3 pagesUsing Solubility Rules To Predict Precipitates in ReactionRaiel AlvaroNo ratings yet

- Acta Ciencia Indica First0001Document6 pagesActa Ciencia Indica First000195 vkjNo ratings yet

- PDF SPM Chemistry Form 4 Notes DLDocument10 pagesPDF SPM Chemistry Form 4 Notes DLJames SimNo ratings yet

- Nickel and Nickel AlloysDocument0 pagesNickel and Nickel Alloysidien100% (1)

- Protons, Neutrons, and Electrons Practice WorksheetDocument3 pagesProtons, Neutrons, and Electrons Practice WorksheetMelerose Dela SernaNo ratings yet

- Lakhmir Singh Solutions For Class 9 Chemistry Chapter 4Document56 pagesLakhmir Singh Solutions For Class 9 Chemistry Chapter 4Premshankar RajbharNo ratings yet

- ASSIGNMENT NotesDocument10 pagesASSIGNMENT Notesnm.ananya2008No ratings yet

- Ion Test PDFDocument11 pagesIon Test PDFAnderson XiaoNo ratings yet

- Chapter 9 Manufactured Substances in IndustryDocument10 pagesChapter 9 Manufactured Substances in IndustryEric ChewNo ratings yet

- Infrared Studies On Synthetic Oxygen Carriers - K. Ueno and A. E. Martell PDFDocument6 pagesInfrared Studies On Synthetic Oxygen Carriers - K. Ueno and A. E. Martell PDFrennan_ps499No ratings yet

- PST-05 SolutionDocument16 pagesPST-05 Solutionritpal365No ratings yet

- 9701 s07 QP 2Document15 pages9701 s07 QP 2G M Ali KawsarNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/63Document12 pagesCambridge IGCSE: CHEMISTRY 0620/63afyNo ratings yet

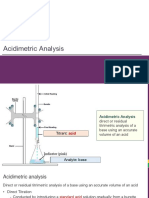

- Acidimetric AnalysisDocument31 pagesAcidimetric AnalysisFedelyn Mae AcaylarNo ratings yet

- DLL SCIENCE 9 Dec 9-13Document49 pagesDLL SCIENCE 9 Dec 9-13Raiza Lainah MianoNo ratings yet

- Fertilizer WorksheetDocument4 pagesFertilizer WorksheetJohn Rey LayderosNo ratings yet

- 316 LVMDocument1 page316 LVMMetehan AgacaNo ratings yet

- Atomic StructureDocument31 pagesAtomic StructureudaysrinivasNo ratings yet

- Comparitive Study of Commercial AntacidsDocument30 pagesComparitive Study of Commercial AntacidsPranjali Prashant DurgeNo ratings yet

- Redox ReactionsDocument44 pagesRedox ReactionsAnanthakrishnan Tinneveli VNo ratings yet