Professional Documents

Culture Documents

2017 Dec CASE Biodiesel Guildline PDF

Uploaded by

JUNA RUSANDI SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2017 Dec CASE Biodiesel Guildline PDF

Uploaded by

JUNA RUSANDI SCopyright:

Available Formats

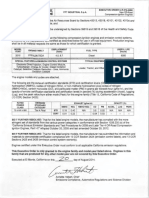

Service Bulletin

BINDER: Construction Equipment PAGE:1 / 18

FILE UNDER: General Information DATE: 01 December 2017

ISSUE NUMBER: ISSUED BY: Quality & Product Support

REPLACES: 2014 - 011 CASE I SB BULLETIN NUMBER: 2017 - 048 CASE A SB

MODELS AFFECTED: ALL Construction Equipment

GROUP - SUBGROUP - 10 AAA

DEFECT:

SUBJECT: UPDATED GUIDELINES FOR THE USE OF FAME

BIODIESEL BLENDS AND APPROVAL LIST

DESCRIPTION

Biodiesel in CASE CONSTRUCTION products.

Summary of the content:

1. Introduction to Fatty Acid Methyl Ester (FAME) biodiesel:

A. Biodiesel types

B. Type of biodiesel blends

C. Comparison with pure diesel fuel (positive features and negative features)

2. Biodiesel specification:

A. Biodiesel types and their effects on the engine performance

B. General topics on the use of biodiesel and the biodiesel effects

■ Biodiesel fuel storage

■ Vehicle storage

■ Maintenance

3. Biodiesel usage conditions

A. Original equipment

B. Retrofitted units, Tier 3 and older

C. Blends up to B7

D. Blends greater than B7 up to B20

E. Blends greater than B20 through B100

4. Warranty on Fuel Injection Equipment (FIE) – update

5. Biodiesel usage in previous models / out of production units

6. Attachment A to determine the type of engine in each vehicle application and the approved biodiesel blend.

1 01 December 2017 CNHi internal user EN

1. Introduction to FAME biodiesel

FAME biodiesel consists of a family of fuels derived from methyl-esters treated vegetable oils. We refer to Fame

biodiesel as biodiesel in this document.

A. Biodiesel types

There are two main types of biodiesel:

○ RME - Rapeseed Methyl Ester (or a blend of rapeseed and sunflower methyl ester), which is the preferred

crop in Europe.

○ SME - Soybean Methyl Ester, which is the preferred crop in North America.

B. Type of blends

You can use biodiesel fuel to run diesel engines in blends with standard EN 590 diesel:

○ B5 indicates a blend of 5 % biodiesel fuel and 95 % diesel fuel.

○ B7 indicates a blend of 7 % biodiesel fuel and 93 % diesel fuel.

○ B20 indicates a blend of 20 % biodiesel fuel and 80 % diesel fuel.

○ B100 indicates pure or 100 % biodiesel fuel.

NOTICE: CASE CONSTRUCTION does NOT APPROVE B100 for its equipment. B20 is the maximum

approved biodiesel fuel blend on Tier 2, Tier 3, and Tier 4a construction equipment. The Tier 4b engines

with Selective Catalytic Reduction (SCR) system are compatible ONLY up to B7 . Refer to attachment

A for the maximum allowed biodiesel blend.

C. Comparison with pure diesel fuel

○ Positive features:

Biodiesel has several positive features in comparison with pure diesel

■ Biodiesel fuel adds lubricity to the fuel, which is beneficial in many circumstances, particularly as there is no

sulfur or aromatics in the fuel.

■ Biodiesel has a greater cetane number and burns cleaner.

■ Biodiesel produces less particulate matter and reduces smoke emissions.

■ Biodiesel is fully biodegradable and non-toxic.

○ Negative features

Biodiesel has several drawbacks in comparison with pure diesel:

■ Biodiesel is an organic blend which means that it is subject to degradation over time. The degradation of the

biodiesel will eventually generate algae, bacteria, fungi, and spores, which can damage the fuel circuit and/

or the components of the fuel injection equipment. Normal stability of biodiesel blends greater than B7 is 3

months, and biodiesel blends B7 or less is 6 months.

■ Biodiesel is hygroscopic and tends to collect water at a higher rate than standard diesel fuel.

■ It is critical to perform a biodiesel quality control to ensure the current EN14214 standard. The quality control

ensures that there are no harmful quantities of chemical elements such as - P (Phosphorus), Ca (Calcium),

Mg (Magnesium), Na (Sodium), and K (Potassium), which may pollute the after-treatment catalytic system.

Pollution of the after-treatment catalytic system jeopardizes the reliability of both the Tier 4a and the Tier 4b

Selective Catalytic Reduction (SCR) after-treatment systems.

■ Biodiesel increases NOx emissions which as a consequence, increases the DEF/AdBlue® consumption in

the case of Tier 4a as well as Tier 4b SCR applications.

■ Biodiesel can dilute the engine lube oil and cause inadequate engine lubrication when you exceed the rec-

ommended oil change intervals on Tier 4a applications with a Diesel Particle Filter (DPF).

2 01 December 2017 CNHi internal user EN

2. Diesel and biodiesel fuel specifications:

The following standard covers the diesel fuel specifications up to B7 :

• European diesel fuel specification EN 590 allows up to 7 % biodiesel since 2009. European fuel suppliers can

use up to B7 ( 7 % ) biodiesel fuel that meets specification EN14214 .

The standards below cover the requirements for pure biodiesel ( B100 ):

• EN14214 - Automotive fuels. Fatty Acid Methyl Ester (FAME) for diesel engines, requirements and test methods

• DIN V 51606 – German standard for biodiesel

In order to convert raw oil into usable biodiesel fuel, the raw oil must undergo transesterification to remove glycerides.

During the transesterification process, the raw oil reacts with an alcohol to separate the glycerine from the raw oil. This

process leaves behind two products: methyl ester (the chemical name for biodiesel) and glycerine (a side product

usually sold for use in soaps or other products).

NOTICE: CASE CONSTRUCTION only allows transesterified biodiesel fuels that comply with standard EN14214

or standard DIN V 51606 , except when we state differently in the guidelines below.

NOTE: CASE CONSTRUCTION does NOT approve the use of unrefined vegetable oils, such as home-made/

purchased cold-pressed biodiesel, cold-pressed oil, Straight Vegetable Oil (SVO). These fuels normally come from

oil seed rape, or similar high oil containing crops. These are non-transesterified fuels that do NOT fulfil the current

standard EN14214 or standard DIN V 51606 requirements. There is no recognized standard available for these

types of fuel, as such, there are no quality standards.

NOTE: CASE CONSTRUCTION Warranty will NOT cover any engine nor fuel injection system from CASE CON-

STRUCTION equipment that ran with any blend of NON-APPROVED fuel (Fuel that does not meet the specifications

of standard EN14214 or standard DIN V 51606 ).

A. Biodiesel types and their effects on the engine performance

We can summarize the effects of biodiesel on the engine performances as follows:

○ Up to B7 : no effect on performance

○ Up to B20 : up to 5 % reduction in power / torque

○ Up to B100 : up to 20 % reduction in power / torque

NOTICE: CASE CONSTRUCTION does NOT APPROVE B100 for its equipment. B20 is the maximum

approved biodiesel fuel blend.

When you agree to use biodiesel, you MUST accept the reduced power and an increase in fuel consumption as

this is normal with the use of biodiesel.

In order to recover any reduced performance, Do NOT modify:

○ any part of the engine

○ any part of the injection pump

○ the engine management settings

○ the settings of the engine management system (for example: data set, ECU, fuel pump injectors, sensors, etc.)

If the engine performance continues to deteriorate over time, immediately contact your dealer to verify the integrity

and / or possible clogging of either the low pressure or high pressure fuel circuit.

B. General topics on the use of biodiesel and biodiesel effects

○ Biodiesel fuel storage

■ Water in fuel:

Biodiesel is hygroscopic and tends to collect more water than pure diesel fuel. To limit the amount of air as

well as water vapors inside the biodiesel storage tanks, it is essential to keep the biodiesel storage tanks as

full as possible. Drain the water on a regular basis (at least once a week).

■ Growth of microbes and algae:

3 01 December 2017 CNHi internal user EN

Use a biocide additive in the biodiesel storage tank to prevent problems with bacterial growth (bacteria, fungi,

spores, yeast, …) as well as to prevent the formation of algae in the system. The biocide has also cleansing

properties.

NOTE: To avoid potential damage to the after-treatment systems on all Tier 4 engines, use only biocide

additives that CASE CONSTRUCTION recommends.

■ Biodiesel storage tank:

It is a requirement to protect the storage tank and the handling system against both direct sunlight and frost.

■ Tank cleaning and biodiesel fuel storage:

It is a requirement to completely clean the whole on-site biodiesel handling system as well as the biodiesel

storage tanks. Use a fuel filter and water separator. Make sure that the fuel storage tanks, fuel lines, and

fittings are compatible with biodiesel. As there is risk of potential oxidation as well as biodiesel related sta-

bility problems, do NOT store biodiesel fuel in on-site storage tanks for more than:

– three months for blends higher than B7

– six months for B7 blends or less

NOTE: You cannot use biodiesel fuel after longer storage for your diesel engine. Usage of this biodiesel

fuel will:

– endanger the engine reliability

– void the warranty

○ Vehicle storage

■ Growth of microbes and algae:

The growth of microbes and algae strongly relates to vehicle storage time as well as to high ambient temper-

atures. Do NOT store vehicles with biodiesel in the fuel system for:

– more than three months with biodiesel blends greater than B7

or

– more than six months with biodiesel blends of B7 or less.

For longer storage time it is a strong suggestion to only use pure diesel fuel.

■ Vehicle long storage:

It is a requirement to run the engine on pure diesel fuel for 20 hours (NOT gasoline, or kerosene blends)

prior to long vehicle storage.

■ Long vehicle storage = more than three months in case of blends above B7 .

■ Long vehicle storage = more than six months in case of blends B7 or below.

■ Cold start:

As biodiesel has a higher cloud point than conventional diesel, the minimum operating temperature limit is

-9 °C ( 16 °F ) for blends greater than B7 and up to B20 .

■ Biodiesel leak:

Clean up any spillage of biodiesel blend immediately before it causes damage to the paint work of the ma-

chine.

○ Maintenance and check

■ Maintenance intervals:

■ It is a requirement to check the items below, every 150 hours or every 3 months (whichever comes first):

■ all the fuel system hoses

■ the fuel system connections

■ the fuel system gaskets

■ Replace the fuel filters, the oil, and the oil filters when the customer switches back from biodiesel fuel to pure

diesel fuel, or after long storage, even if this falls between routine service intervals.

■ Check the engine oil dipstick daily to ensure that the engine oil level stays between the normal minimum and

maximum oil level. If the engine oil level rises above the maximum, verify that this rise is not due to the overfill

of the engine. If the rise is not due to overfill, shorten the engine oil change intervals by 25 % . If the overfill

continues, do NOT use the machine. Immediately contact your CASE CONSTRUCTION dealer.

4 01 December 2017 CNHi internal user EN

On engines where the use of biodiesel blends greater than B7 through B20 is approved, in some cases shorter

maintenance intervals are required.

○ For all machines using Tier 4a NEF or Cursor engines and SCR after-treatment, the engine oil and filter

change interval is reduced to 300 hours.

○ For all machines using Tier 4a F5C engines and DPF after-treatment, the engine oil and filter change interval

is reduced to 300 hours.

○ For all machines using Tier 4b F5C engines and a DOC or PM catalyst, the engine oil and filter change inter-

val is reduced to 300 hours

○ For all machines using ISM engines where biodiesel blends greater than B7 through B20 is approved, the en-

gine oil and oil filter change interval is reduced to 150 hours

○

○ Please refer to the maintenance intervals specified in the Operator Manual for other engines.

3. Biodiesel usage conditions

You must stringently follow the biodiesel fuel usage conditions.

Incorrect biodiesel fuel usage could lead to severe damage of:

• the engine

• the fuel injection equipment

• the after-treatment system

A. Original equipment

○ The main concerns that relate to the operation with biodiesel blends are:

■ Filter clogging and/or damage to the components of the Fuel Injection Equipment (FIE) by organic deposits

due to intrinsic fuel instability and microbial growth (microbes).

■ Wear and/or corrosion of the internal FIE components due to water content.

■ Deterioration of not-compatible rubber sealing compounds

■ Biodiesel oxidation that can lead to the formation of deposits

■ Degradation of the after-treatment system (SCR, DPF, PM catalyst etc) due to pollutants that are potentially

present in the biodiesel blends. Due to emissions non-compliance, the degradation of the after-treatment

system can cause an engine “de-rate code” or a “fault code”.

NOTE: CASE CONSTRUCTION Warranty will NOT cover any concern with the engine, the engine fuel

injection equipment, and after-treatment systems when the non-compliance to the following conditions for the

biodiesel fuel handling and biodiesel fuel maintenance causes the concern.

B. Retrofitted after-treatment devices

For Tier 3 and older machines that have exhaust after-treatment devices from the aftermarket, such as Diesel

Particulate Filters (DPF) or Selective Catalytic Reduction (SCR), consult the device supplier to determine if the

device is compatible with biodiesel.

C. Blends up to B7 :

CASE CONSTRUCTION approves the use of Biodiesel blends up to B7 in all past and current production CASE

CONSTRUCTION engines. For CASE CONSTRUCTION engines please see Attachment A of this bulletin. For

non- CASE CONSTRUCTION engines follow the engine manufacturers guidelines for biodiesel blends.

Biodiesel blend specifications:

■ The European diesel fuel specification EN 590 allows up to 7 % biodiesel since 2009. Fuel suppliers can

use up to B7 ( 7 % ) biodiesel fuel to supply the network.

5 01 December 2017 CNHi internal user EN

NOTE: The stock of biodiesel blend must meet either the current EN14214 specifications or the

DIN V 51606 specifications. The fuel supplier must maintain good fuel quality.

Identification of the engine type and the after-treatment system:

■ Refer to Attachment A to determine the type of the fitted engine, the after-treatment system (if applicable) for

all machine models, and the maximum allowable biodiesel blend.

D. Blends greater than B7 up to B20 :

CASE CONSTRUCTION allows the use of biodiesel blends above B7 up to B20 for most of its models when

you stringently follow all the requirements for biodiesel usage in the present paragraph, and when you take

the provision in paragraph “Warranty on FIE” in consideration. Please refer to the Attachment A of this bulletin.

Attachment A specifies the machine and engine compatibility with biodiesel as well as the required fuel filter

upgrade kits you must install (if necessary) to allow the use of biodiesel blends greater than B7 up to B20 .

NOTE: CASE CONSTRUCTION Tier 4b engines with Selective Catalytic Reduction (SCR) are compatible

ONLY up to B7 . Refer to Attachment A for the maximum allowable biodiesel blend .

Follow the engine manufacturer’s guidelines for biodiesel blends in case of non- CASE CONSTRUCTION

engines.

CASE CONSTRUCTION warranty will NOT cover any engine nor fuel injection system from CASE CON-

STRUCTION equipment that ran with any blend of NON-APPROVED fuel.

Biodiesel blend specifications:

When the Attachment A allows the use of biodiesel blends above B7 up to B20 , this will not void the CASE

CONSTRUCTION engine warranty as long as you stringently adhere to the following conditions for biodiesel

fuel handling as well as maintenance:

■ For machines with Tier 2 and Tier 3 engines (NEF/F5C/CURSOR):

■ The biodiesel blend stock MUST meet the fuel specifications ( standard EN14214 or standard DIN V

51606 )

■ Upgrade the selected FIE components, according to Attachment A. This will guarantee biodiesel robust-

ness.

■ For machines with Tier 4a engines that have either SCR or DPF after-treatment systems and Tier 4b en-

gines using a PM catalyst:

■ The stock of biodiesel blend MUST meet the latest fuel specification EN14214 .

■ Take special precautions when you use the biodiesel blend stock to standard DIN V 51606 to ensure

that the biodiesel blend stock fully complies with the following special requirements:

■ Group I Metals content (sodium + potassium) is ≤ 5 mg/kg per biodiesel specification EN14108 .

■ Group II Metals content (calcium + magnesium) is ≤ 5 mg/kg per biodiesel specification EN14538 .

■ A phosphorus level that is lower than the specified value is mandatory. Phosphorus must not exceed 4

mg/kg per standard EN14107 .

■ The resulting blend (greater than B7 through B20 ) must not exceed 1 mg/kg for Group I Metals (Sodium

+ Potassium), Group II Metals (Calcium + Magnesium), and Phosphorus content.

NOTE: For machines that use Tier 4a engines with SCR and/or DPF after-treatment in regions where

the supplied biodiesel blend stock is according to the standard DIN V 51606 , it is essential that you

obtain evidence of compliance to the above specified special limits for Group I Metals, Group II Metals,

and the reduced phosphorus content on every delivery of fuel from the fuel supplier. Failure to comply with

this requirement can result in damage to the after-treatment system which CASE CONSTRUCTION will

not cover under warranty.

6 01 December 2017 CNHi internal user EN

■ Fuel hose upgrades for B20 on ISM powered machines:

■ To permit the use of up to B20 biodiesel on some ISM powered machines, a field update

kit is available to update the engine. Find the part numbers of the fuel hose upgrade kit in

Attachment A, column “ B20 Engine kit part number”. Update the fuel hose(s) on the en-

gine as follows:

■ For the engine fuel hose SBA068209621 , replace the old engine fuel hose

SBA068204112 with the new engine fuel hose SBA068209621 , available from CASE

CONSTRUCTION service parts

■ For the engine fuel hose SBA068209622 , replace the old engine fuel hose

SBA068204112 with the new engine fuel hose SBA068209622 , available from CASE

CONSTRUCTION service parts

■ Refer to the ISM engine (or vehicle) service manual for specific info for the removal and

the installation of the fuel hose.

NOTE: The application chart at the end of this service bulletin includes the column that shows

the required fuel hose upgrade kits for B20 usage on ISM Engines.

E. Blends greater than B20 through B100 :

CASE CONSTRUCTION does NOT APPROVE B100 for its equipment. B20 is the maximum biodiesel fuel

blend approved and only on the Tier 2, Tier 3, Tier 4a and Tier 4b PM catalyst machines so indicated in Ap-

pendix A. Tier 4b engines that have the SCR after-treatment system are NOT approved for use with biodiesel

blends greater than B7, unless otherwise noted.

4. Warranty on Fuel Injection Equipment

Even though CASE CONSTRUCTION approves of the use of greater biodiesel blends according to the list on At-

tachment A, diesel FIE manufacturers allow B7 as the maximum blend. FIE service may reject any warranty claim for

equipment failure due to the use of biodiesel in blends greater than B7 . In these cases, forward the warranty claim

directly to CASE CONSTRUCTION .

CASE CONSTRUCTION will consider the warranty claim only if you strictly follow all of the specified requirements

in these guidelines for:

• biodiesel fuel type

• biodiesel quality

• biodiesel handling

• biodiesel storage

• vehicle maintenance

5. Biodiesel usage in previous models / out of production models

For machines with engines that precede compliance to the Tier 2 emissions regulations and for machines that are

out of production, more generally for all earlier machines not in the following list, the only approved blends are up

to, and including B7 .

There are no evaluations on the use of greater biodiesel blends in previous models and their engines. Biodiesel

deteriorates old type rubber, seals, etc, and there are no conclusive tests on older engines.

CASE CONSTRUCTION will NOT cover any engine on a CASE CONSTRUCTION vehicle (with an existing warranty)

which ran with a biodiesel blend greater than B7 if the vehicle is not present in Attachment A (previous model or

out of production model)

WARRANTY STATUS

Service Bulletins DO NOT constitute warranty authorization to update units, unless stated otherwise.

7 01 December 2017 CNHi internal user EN

Biodiesel approval list

Biodiesel Approval Guidelines

Case Construction - Europe

Revision Z - December 2017

Approval Codes:

A = Approved with no conditions

AC = Approved with conditions - follow Case Guidelines for Biodiesel Blends above 5%

M = Follow Engine Manufacturer's Guidelines for Biodiesel Blends

N/R = Not Required

N/A = Not Approved

Af- BioDiesel

Rating Displace- Approval B20 Engine

Model Engine tertreat-

kW(HP) ment (L) Kit Number.

ment B7 B20

Articulated Truck

235

327 B (Case Fam IV) Iveco Cursor 10.3L NONE A AC N/R

(315)

260

330 B (Case Fam IV) Iveco Cursor 10.3L NONE A AC N/R

(349)

306 (Case Fam IV)

335 B 12.9L NONE A AC N/R

(410) Iveco Cursor 13

340 (Case Fam IV)

340B 12.9L NONE A AC N/R

(456) Iveco Cursor 13

Backhoe Loaders

580 Super R 71 (95) NEF445T/M2 4.5L NONE A AC N/R

580 R Series 3 72 (97) NEF445TA/M3 4.5L NONE A AC N/R

580 Super R Se-

72 (97) NEF445TA/E3 4.5L NONE A AC N/R

ries 3

580 Super R+

72 (97) NEF445TA/E3 4.5L NONE A AC N/R

Series 3

590 Super R 82 (110) NEF445TA/M2 4.5L NONE A AC N/R

590 Super R Se-

82 (110) NEF445TA/E3 4.5L NONE A AC N/R

ries 3

695 Super R 82 (110) NEF445TA/M2 4.5L NONE A AC N/R

695 Super R Se-

82 (110) NEF445TA/E3 4.5L NONE A AC N/R

ries 3

580T 72 (97) CNH 445TA/ML5 4.5L NONE A AC N/R

580ST 72 (97) CNH 445TA\EEA 4.5L NONE A AC N/R

590ST 82 (110) CNH 445TA\EGH 4.5L NONE A AC N/R

695ST 82 (110) CNH 445TA\EGH 4.5L NONE A AC N/R

STAGE

580ST 72 (97) CASE 434T/E 3.4L A AC N/R

IIIB

STAGE

590ST 82 (110) CASE 434T/E 3.4L A AC N/R

IIIB

8 01 December 2017 CNHi internal user EN

STAGE

695ST 82 (110) CASE 434T/E 3.4L A AC N/R

IIIB

Compact Track Loaders (SSL)

420CT Series 3 55 (74) 432T/M3 3.2L NONE A AC N/R

440CT Series 3 67 (89) 445T/M3 4.5L NONE A AC N/R

445CT Series 3 61 (82) 432T/M3 3.2L NONE A AC N/R

TR270 55 (74) 432T/M3 3.2L NONE A AC N/R

TR320 67 (90) 432T/M3 3.2L NONE A AC N/R

TV380 67 (90) 432T/M3 3.2L NONE A AC N/R

STAGE

TR320 67 (90) FPT F5C 3.4L A AC N/R

IIIB

STAGE

TV380 67 (90) FPT F5C 3.4L A AC N/R

IIIB

STAGE

TR270 55 (74) FPT F5C 3.4L A N/A* N/R

IIIB

STAGE

TR310 55 (74) FPT F5C 3.4L A N/A* N/R

IIIB

STAGE

TV380 67 (90) FPT F5 3.4L A N/A N/R

IV

Crawler Dozers

1150K XLT WT

97 (130) 667TA/E3 6.7L NONE A AC N/R

LGP

116

1650K 667TA/E3 6.7L NONE A AC N/R

(156)

157

1850K NEF 667TA/E3 6.7L NONE A AC N/R

(211)

1150M / LT / 103 STAGE

F4HFE613Z 6.7L A AC N/R

WT / LGP (138) IIIB

1650M / XLT / 122 STAGE

F4HFE613Z 6.7L A AC N/R

WT / LGP (164) IIIB

2050M / LT / 173 STAGE

F4HFE613W 6.7L A AC N/R

XLT / WT / LGP (232) IIIB

Excavators - Mini

CX15B 11.3 (15) Mitsubishi L3E-W231KBS 0.95L NONE A N/A N/A

CX15B Series2 11.3 (15) Mitsubishi L3E-W231KBS 0.95L NONE A N/A N/A

CX16B 11.2 (15) Yanmar 1L NONE A N/A N/A

CX17B 11.3 (15) Mitsubishi L3E-W231KBS 0.95L NONE A N/A N/A

CX17B ZTS 11.3 (15) Mitsubishi L3E-W231KBS 0.95L NONE A N/A N/A

CX18B 11.2 (15) Yanmar 1L NONE A N/A N/A

CX18B 11.3 (15) Mitsubishi L3E-W231KBS 0.95L NONE A N/A N/A

CX20B ZTS 17.2 (23) Yanmar 3TNV82A SYB 1.3L NONE A N/A N/A

CX22B ZTS 17.2 (23) Yanmar 3TNV82A SYB 1.3L NONE A N/A N/A

CX26B ZTS 17.2 (23) Yanmar 3TNV82A SYB 1.3L NONE A N/A N/A

CX27B ZTS 17.2 (23) Yanmar 3TNV82A SYB 1.3L NONE A N/A N/A

CX30B ZTS 17.2 (23) Yanmar 3TNV82A SYB 1.3L NONE A N/A N/A

9 01 December 2017 CNHi internal user EN

CX31B ZTS 22.4 (30) Yanmar 3TNV88P PYB 1.6L NONE A N/A N/A

CX35B ZTS 22.4 (30) Yanmar 3TNV88P PYB 1.6L NONE A N/A N/A

CX36B ZTS 22.4 (30) Yanmar 3TNV88P PYB 1.6L NONE A N/A N/A

CX39B ZTS 22.4 (30) Yanmar 3TNV88P PYB 1.6L NONE A N/A N/A

CX40B ZTS 32 (43) Yanmar 4TNV88A XYB 2.2L NONE A N/A N/A

CX45B ZTS 32 (43) Yanmar 4TNV88A XYB 2.2L NONE A N/A N/A

CX50B ZTS 32 (43) Yanmar 4TNV88A XYB 2.2L NONE A N/A N/A

CX55B 32 (43) Yanmar 4TNV88A XYB 2.2L NONE A N/A N/A

12.5

CX17C Kubota D902 0.89L NONE A M N/A

(16.8)

12.5

CX18C Mitsubishi L3E 0.95L NONE A M N/A

(16.8)

18.5

CX26C Kubota D1305 1.3L NONE A M N/A

(24.8)

18.3

CX33C Yanmar 1.6L 1.6L NONE A M N/A

(24.4)

18.2

CX37C Yanmar 3TNV88F 1.6L NONE A M N/A

(24.4)

49.9 STAGE

CX57C Yanmar 4TNV98C 3.3L A N/A N/A

(66.9) IIIB

48.3 STAGE

CX60C Yanmar 4TNV98C 3.3L A N/A N/A

(64.7) IIIB

Excavators - Midi

STAGE

CX75C SR 41 (55) ISUZU AP-4LE2X 2.2L A1 N/A N/A

IIIB

STAGE

CX80C MSR 41 (55) ISUZU AP-4LE2X 2.2L A1 N/A N/A

IIIB

Excavators - Tracked

CX75SR 39.5 (53) Isuzu CC-4JG1 3.1L NONE A1 N/A N/A

CX75SR LR 40 (54) ISUZU AU-4LE2X 2.2L NONE A1 N/A N/A

CX80 38.8 (52) Isuzu CC-4JG1 3.1L NONE A1 N/A N/A

CX80 40 (54) ISUZU AU-4LE2X 2.2L NONE A1 N/A N/A

CX130 69.4 (93) Isuzu BB 4BG1T 4.3L NONE A1 N/A N/A

CX130B LR 71 (95) Isuzu 4JJ1X 3.0L NONE A1 N/A N/A

CX135SR 65.6 (88) Isuzu BB 4BG1T 4.3L NONE A1 N/A N/A

CX135SR 71 (95) ISUZU AJ-4JJ1X 3.0L NONE A1 N/A N/A

CX160 79 (106) Isuzu BB 6BG1T 6.5L NONE A1 N/A N/A

CX160B 89 (119) Isuzu AI-4JJ1X 3.0L NONE A1 N/A N/A

CX180 79 (106) Isuzu DD 4BG1TRA 4.3L NONE A1 N/A N/A

CX180B 89 (119) Isuzu AI-4JJ1X 3.0L NONE A1 N/A N/A

105

CX210 Isuzu BB 6BG1T 6.5L NONE A1 N/A N/A

(141)

117

CX210B MH SL Isuzu AI-4HK1X 5.2L NONE A1 N/A N/A

(157)

10 01 December 2017 CNHi internal user EN

103

CX225SR Isuzu BB 6BG1T 6.5L NONE A1 N/A N/A

(138)

114

CX225SR ISUZU AJ-4HK1X 5.2L NONE A1 N/A N/A

(153)

105

CX230 Isuzu BB 6BG1T 6.5L NONE A1 N/A N/A

(141)

117

CX230B Isuzu AI-4HK1X 5.2L NONE A1 N/A N/A

(157)

124.5

CX240 Isuzu BB 6BG1T 6.5L NONE A1 N/A N/A

(167)

132

CX240B MH SL Isuzu AH-4HK1X 5.2L NONE A1 N/A N/A

(177)

140

CX290 Isuzu CC 6BG1T 6.5L NONE A1 N/A N/A

(188)

154

CX290B Isuzu AH-6HK1XYSS 7.8L NONE A1 N/A N/A

(207)

185

CX330 Isuzu AA 6HK1XQB 7.8L NONE A1 N/A N/A

(248)

202

CX330 Isuzu AH-6HK1XYSS 7.8L NONE A1 N/A N/A

(271)

185

CX350 Isuzu AA 6HK1XQB 7.8L NONE A1 N/A N/A

(248)

202

CX350 Isuzu AH-6HK1XYSS 7.8L NONE A1 N/A N/A

(271)

202

CX350B Isuzu AH-6HK1XYSS 7.8L NONE A1 N/A N/A

(275)

202

CX350B Isuzu AH-6HK1XYSS 7.8L NONE A1 N/A N/A

(275)

202

CX370B Isuzu AH-6HK1XYSS 7.8L NONE A1 N/A N/A

(275)

250

CX460 Isuzu AA 6SD1XQB 9.8L NONE A1 N/A N/A

(335)

245

CX460 Isuzu AH-6UZ1XYSS 9.8L NONE A1 N/A N/A

(329)

270

CX470B Isuzu AH-6UZ1XYSS 9.8L NONE A1 N/A N/A

(367)

345

CX700 Isuzu AH-6WG1X 15.7L NONE A1 N/A N/A

(462)

345

CX700B/ ME Isuzu AH-6WG1X 15.7L NONE A1 N/A N/A

(462)

331

CX800 Isuzu 6WG1TC 15.7L NONE A1 N/A N/A

(444)

369

CX800 Isuzu AH-6WG1X 15.7L NONE A1 N/A N/A

(495)

369

CX800B Isuzu AH-6WG1TC 15.7L NONE A1 N/A N/A

(495)

397

CX800B / ME Isuzu AH-6WG1XYSS-02 15.7L NONE A1 N/A N/A

(532)

STAGE

CX130C SR 75 (100) Isuzu AM-4JJ1X 3.0L A1 N/A N/A

IIIB

11 01 December 2017 CNHi internal user EN

STAGE

CX145C SR 75 (100) Isuzu AM-4JJ1X 3.0L A1 N/A N/A

IIIB

STAGE

CX160C 92 (124) Isuzu AM-4JJ1X 3.0L A1 N/A N/A

IIIB

STAGE

CX180C 92 (124) Isuzu AM-4JJ1X 3.0L A1 N/A N/A

IIIB

119 STAGE

CX210C / LR Isuzu AI-4HK1X 5.2L A1 N/A N/A

(160) IIIB

119 STAGE

CX230C Isuzu AM-4HK1X 5.2L A1 N/A N/A

(160) IIIB

119 STAGE

CX235C SR Isuzu AM-4HK1X 5.2L A1 N/A N/A

(160) IIIB

132 STAGE

CX250C / LR Isuzu AH-4HK1X 5.2L A1 N/A N/A

(177) IIIB

154 STAGE

CX300C Isuzu AL-6HK1X 7.8L A1 N/A N/A

(207) IIIB

198 STAGE

CX350C Isuzu AL-6HK1X 7.8L A1 N/A N/A

(266) IIIB

198 STAGE

CX370C Isuzu AL-6HK1X 7.8L A1 N/A N/A

(266) IIIB

270 STAGE

CX470C / ME Isuzu AL-6UZ1X 9.8L A1 N/A N/A

(367) IIIB

STAGE

CX75C SR 41 (55) Isuzu AP-4LE2X 3.1L A1 N/A N/A

IIIB

STAGE

CX80C SR MSR 41 (55) Isuzu AP-4LE2X 3.1L A1 N/A N/A

IIIB

78.5 STAGE

CX130D Isuzu AR-4JJ1X 3.0L A1 N/A NA

(105) IV

STAGE

CX160D 86 (115) ISUZU AR-4JJ1X 3.0L A1 N/A NA

IV

STAGE

CX180D 86 (115) ISUZU AR-4JJ1X 3.0L A1 N/A NA

IV

124 STAGE

CX210D Isuzu AR 4HK1X 5.2L A1 N/A NA

(166) IV

124 STAGE

CX230D Isuzu AR 4HK1X 5.2L A1 N/A NA

(166) IV

124 STAGE

CX240D Isuzu AR 4HK1X 5.2L A1 N/A NA

(166) IV

140 STAGE

CX250D Isuzu AQ 4HK1X 5.2L A1 N/A NA

(188) IV

161 STAGE

CX300D Isuzu AQ-6HK1X 7.8L A1 N/A NA

(216) IV

210 STAGE

CX350D Isuzu AQ-6HK1X 7.8L A1 N/A NA

(282) IV

210 STAGE

CX370D Isuzu AQ-6HK1X 7.8L A1 N/A NA

(282) IV

270 STAGE

CX490D ISUZU AQ-6UZ1X 9.84L A1 N/A NA

(362) IV

382 STAGE

CX750D ISUZU AH-6WG1X 15.7L A1 N/A NA

(512) IV

12 01 December 2017 CNHi internal user EN

78.5 STAGE

CX145D SR Isuzu AR-4JJ1X 3.0L A1 N/A NA

(105) IV

124 STAGE

CX245D SR Isuzu AR 4HK1X 5.2L A1 N/A NA

(166) IV

Excavator - Special Applications

74.9 STAGE

CX130C LR ISUZU 3.0L A1 N/A NA

(100) IIIB

124 STAGE

CX210D LR ISUZU AR-4HK1X 5.2L A1 N/A NA

(166) IV

140 STAGE

CX250D LR ISUZU AQ-4HK1X 5.52L A1 N/A NA

(188) IV

140 STAGE

CX290D SL / MH ISUZU AQ-4HK1X 5.52L A1 N/A NA

(188) IV

270 STAGE

CX500D ME ISUZU AQ-6UZ1X 9.84L A1 N/A NA

(362) IV

382 STAGE

CX750D ME ISUZU AH-6WG1X 15.7L A1 N/A NA

(512) IV

Excavator - Wheeled

WX 95 74 (99) NEF 439T/M2 3.9L NONE A AC N/R

WX 95 Series2 74 (99) NEF 445TA/M3 4.5L NONE A AC N/R

WX 125 87 (117) NEF 439TA/M2 3.9L NONE A AC N/R

WX 125 Series2 84 (113) NEF 445TA/M3 4.5L NONE A AC N/R

WX145 87 (117) NEF 439TA/M2 3.9L NONE A AC N/R

WX 145 Series2 90 (121) NEF 445TA/M3 4.5L NONE A AC N/R

WX148 90 (121) F4GE9484D 4.5L NONE A AC N/R

105

WX 165 NEF 659TA/M2 5.9L NONE A AC N/R

(141)

WX 165 90 (121) NEF 445TA/M3 4.5L NONE A AC N/R

WX 165 Light 93 (125) NEF 445TA/M3 4.5L NONE A AC N/R

105

WX 165 Series2 NEF 667TA/M3 6.7L NONE A AC N/R

(141)

105

WX168 F4GE9684F 6.7L NONE A AC N/R

(141)

118

WX 185 NEF 659TA/M2 5.9L NONE A AC N/R

(158)

118

WX 185 Series2 NEF 667TA/M3 6.7L NONE A AC N/R

(158)

118

WX188 F4GE9684E 6.7L NONE A AC N/R

(158)

129

WX 210 NEF 659TA/M2 5.9L NONE A AC N/R

(173)

129

WX 210 Series2 NEF 667TA/M3 6.7L NONE A AC N/R

(173)

129

WX 210 IND NEF 667TA/M3 6.7L NONE A AC N/R

(173)

129

WX218 F4GE9684G 6.7L NONE A AC N/R

(173)

13 01 December 2017 CNHi internal user EN

129

WX 240 NEF 659TA/M2 5.9L NONE A AC N/R

(173)

129

WX 240 Series2 NEF 667TA/M3 6.7L NONE A AC N/R

(173)

129

WX 240TND NEF 667TA/M3 6.7L NONE A AC N/R

(173)

Graders

836C / 836C 115 STAGE

NEF6 6.7L A N/A N/A

AWD (156) IV

856C / 856C 142 STAGE

NEF6 6.7L A N/A N/A

AWD (190) IV

Skid Steer Loaders

410 38 (51) ISM N844L 2.2L NONE A AC SBA068209622

410 44 (59) ISM N844LT 2.2L NONE A AC SBA068209622

410 S3 45 (60) ISM N844LT 2.2L NONE A AC SBA068209622

420 44 (59) ISM N844LT 2.2L NONE A AC SBA068209622

420 55 (74) 432T/M3 3.2L NONE A AC N/R

420 S3 55 (74) F5C F5AE9454E*A 3.2L NONE A AC N/R

430 60 (80) NEF 445/M2 4.5L NONE A AC N/R

430 61 (82) 432T/M3 3.2L NONE A AC N/R

430 S3 61 (82) F5C F5AE9454E*A 3.2L NONE A AC N/R

435 58 (78) NEF 334T/M2 3.4L NONE A AC N/R

435 61 (82) 432T/M3 3.2L NONE A AC N/R

435 S3 61 (82) F5C F5AE9454E*A 3.2L NONE A AC N/R

440 66 (89) NEF445T/M2 4.5L NONE A AC N/R

440 67 (90) NEF 445T/M3 4.5L NONE A AC N/R

440 S3 67 (90) NEF F4GE9454C*J 4.5L NONE A AC N/R

445 60 (80) NEF 445/M2 4.5L NONE A AC N/R

445 61 (82) 432T/M3 3.2L NONE A AC N/R

445 S3 61 (82) F5C F5AE9454E*A 3.2L NONE A AC N/R

SR130 34 (46) ISM N844T 2.0L NONE A AC N/R

SR130 36 (49) ISM N844L 2.2L NONE A AC N/R

SR150 39 (52) ISM N844T 2.0L NONE A AC N/R

SR175 45 (60) ISM N844LT 2.2L NONE A AC N/R

SR200 55 (74) FPT F5C 3.2L NONE A AC N/R

SR220 61 (82) Case 432T/ M3 3.2L NONE A AC N/R

SR250 67 (90) Case 432T/ M3 3.2L NONE A AC N/R

SV185 45 (60) ISM N844LT 2.2L NONE A AC N/R

SV250 61 (82) Case 432T/ M3 3.2L NONE A AC N/R

SV300 67 (90) Case 432T/ M3 3.2L NONE A AC N/R

STAGE

SR160 45 (60) ISM N844LT 2.2L A AC N/R

IIIB

STAGE

SR175 50 (67) ISM N844LTA 2.2L A AC N/R

IIIB

14 01 December 2017 CNHi internal user EN

STAGE

SV185 45 (60) ISM N844LTA 2.2L A AC N/R

IIIB

STAGE

SR 250 67 (90) FPT F5C 3.4L A AC N/R

IIIB

STAGE

SV 300 67 (90) FPT F5C 3.4L A AC N/R

IIIB

STAGE

SR 210 55 (74) FPT F5C 3.4L A N/A* N/R

IIIB

STAGE

SR 240 55 (74) FPT F5C 3.4L A N/A* N/R

IIIB

STAGE

SV280 55 (74) FPT F5C 3.4L A N/A* N/R

IIIB

Telescopic Handlers

TX130-30 60 (80) NEF 445/M2 4.5L NONE A AC N/R

TX130-33 71 (95) NEF 445T/M2 4.5L NONE A AC N/R

TX130-33 74 (99) NEF 445TA/M3 4.5L NONE A AC N/R

TX130-40 82 (110) NEF 445TA/M2 4.5L NONE A AC N/R

TX130-40 88 (118) NEF 445TA/M3 4.5L NONE A AC N/R

TX130-43 82 (110) NEF 445TA/M2 4.5L NONE A AC N/R

TX130-43 88 (118) NEF 445TA/M3 4.5L NONE A AC N/R

TX130-45 82 (110) NEF 445TA/M2 4.5L NONE A AC N/R

TX130-45 88 (118) NEF 445TA/M3 4.5L NONE A AC N/R

TX140-43 82 (110) NEF 445TA/M2 4.5L NONE A AC N/R

TX140-45 88 (118) NEF 445TA/M3 4.5L NONE A AC N/R

TX140 88 (118) NEF 445TA/M3 4.5L NONE A AC N/R

TX170-45 88 (118) NEF 445TA/M3 4.5L NONE A AC N/R

TX170 88 (118) NEF 445TA/M3 4.5L NONE A AC N/R

Wheel Loaders

21D 40 (54) Deutz F4M2011 3.1L NONE A M N/A

21E Series 3 41 (54) 432T/M3 3.2L NONE A AC N/R

121D 44 (59) Deutz F4M2011 3.1L NONE A M N/A

121E Series 3 48 (64) 432T/M3 3.2L NONE A AC N/R

221D 45 (60) Deutz F4M2011 3.1L NONE A M N/A

221E Series 3 55 (74) 432T/M3 3.2L NONE A AC N/R

321D 56 (75) Deutz BF4M2011 3.1L NONE A M N/A

321E Series 3 61 (82) 432T/M3 3.2L NONE A AC N/R

521D 82 (110) NEF 445TA/M2 4.5L NONE A AC N/R

521E 96 (129) NEF 445TA/EGE 4.5L NONE A AC N/R

521E XT 96 (129) NEF 445TA/EGE 4.5L NONE A AC N/R

100

621D NEF 667TA/M2 6.7L NONE A AC N/R

(134)

116

621E NEF 667TA/EBD 6.7L NONE A AC N/R

(156)

15 01 December 2017 CNHi internal user EN

116

621E XT NEF 667TA/EBD 6.7L NONE A AC N/R

(156)

116

621E XR NEF 667TA/EBD 6.7L NONE A AC N/R

(156)

127

721D NEF 667TA/E2 6.7L NONE A AC N/R

(170)

136

721E NEF 667TA/EED 6.7L NONE A AC N/R

(182)

136

721E XT NEF 667TA/EED 6.7L NONE A AC N/R

(182)

136

721E XR NEF 667TA/EED 6.7L NONE A AC N/R

(182)

143

821C CDC 6TAA-830 8.3L NONE A AC N/R

(192)

157

821E NEF 667TA/EBD 6.7L NONE A AC N/R

(210)

157

821E XR NEF 667TA/EBD 6.7L NONE A AC N/R

(210)

157

821E XT NEF 667TA/EBD 6.7L NONE A AC N/R

(210)

202

921C Cummins QSM 10.8L NONE A AC N/R

(271)

216

921C Cummins QSM 10.8L NONE A AC N/R

(290)

221

921E Cummins QSM 11 10.8L NONE A AC N/R

(297)

221

921E XR Cummins QSM 11 10.8L NONE A AC N/R

(297)

272

1221E Cummins QSM 11 10.8L NONE A AC N/R

(365)

250

1221E XT Cummins QSM 11 10.8L NONE A AC N/R

(335)

250

1221E XR Cummins QSM 11 10.8L NONE A AC N/R

(335)

250

1221E EXR Cummins QSM 11 10.8L NONE A AC N/R

(335)

106 STAGE

521F F4HFE413J 4.5L A AC N/R

(142) IIIB

128 STAGE

621F / WH F4HFE613Z 6.7L A AC N/R

(172) IIIB

145 STAGE

721F / WH F4HFE613Y 6.7L A AC N/R

(195) IIIB

145 STAGE

721F XT F4HFE613Y 6.7L A AC N/R

(195) IIIB

145 STAGE

721F XR F4HFE613Y 6.7L A AC N/R

(195) IIIB

172 STAGE

821F F4HFE613X 6.7L A AC N/R

(230) IIIB

172 STAGE

821F XR F4HFE613X 6.7L A AC N/R

(230) IIIB

16 01 December 2017 CNHi internal user EN

190 STAGE

921F F4HFE6131 6.7L A AC N/R

(255) IIIB

180 STAGE

921F XR F4HFE6131 6.7L A AC N/R

(242) IIIB

239 STAGE

1021F FPT Cursor F2CFE614C 8.7L A AC N/R

(320) IIIB

216 STAGE

1021F XR FPT Cursor F2CFE614C 8.7L A AC N/R

(290) IIIB

259 STAGE

1121F FPT Cursor F2CFE614B 8.7L A AC N/R

(347) IIIB

235 STAGE

1121F XR FPT Cursor F2CFE614B 8.7L A AC N/R

(315) IIIB

145 STAGE

721F / 721F WH NEF N67 6.7L A N/A N/A

(195) IV

172 STAGE

821F NEF N67 6.7L A N/A N/A

(230) IV

190 STAGE

921F NEF N67 6.7L A N/A N/A

(255) IV

239 STAGE

1021F CURSOR 9 8.7L A N/A N/A

(320) IV

259 STAGE

1121F CURSOR 9 8.7L A N/A N/A

(347) IV

105 STAGE

521G FPT NEF 4 4.5L A N/A N/R

(142) IV

120 STAGE

621G / WH FPT NEF 6 6.7L A N/A N/R

(160) IV

146 STAGE

721G / WH FPT NEF 6 6.7L A N/A N/R

(195) IV

169 STAGE

821G FPT NEF 6 6.7L A N/A N/R

(225) IV

183 STAGE

921G FPT NEF 6 6.7L A N/A N/R

(244) IV

216 STAGE

1021G FPT Cursor 9 8.7L A N/A N/R

(288) IV

235 STAGE

1121G FPT Cursor 9 8.7L A N/A N/R

(313) IV

Wheel Loaders - Compact

STAGE

21F 43 (58) FPT F5C 3.4L A N/A* N/R

IIIB

STAGE

121F 48 (64) FPT F5C 3.4L A N/A* N/R

IIIB

STAGE

221F 55 (74) FPT F5C 3.4L A N/A* N/R

IIIB

STAGE

321F 55 (74) FPT F5C 3.4L A N/A* N/R

IIIB

Additional Notes:

A 1 = Isuzu approves B5 BioDiesel Fuel compliant with EU EN14214

N/A* = Not approved only for the models equipped with DOC only aftertreatment

17 01 December 2017 CNHi internal user EN

Global Product Support

CASE CONSTRUCTION

You might also like

- 2017 Dec CASE Biodiesel Guildline PDFDocument18 pages2017 Dec CASE Biodiesel Guildline PDFJUNA RUSANDI S100% (1)

- JAMA Seminar 2019 LCM WG - Final PDFDocument37 pagesJAMA Seminar 2019 LCM WG - Final PDFgilar herliana putraNo ratings yet

- McCormick C-MAX RPS Tier 3 (2008-) - RS24 - 100 Tractor Service Repair Manual PDFDocument30 pagesMcCormick C-MAX RPS Tier 3 (2008-) - RS24 - 100 Tractor Service Repair Manual PDFfjkkekmdmNo ratings yet

- After Sales Service Training: New Holland EngineDocument52 pagesAfter Sales Service Training: New Holland EngineAminadavNo ratings yet

- Common Rail Diagnosis - V6108-Tie3 - M128XDocument251 pagesCommon Rail Diagnosis - V6108-Tie3 - M128XRadek Babuszkiewicz100% (2)

- Our Milling MachinesDocument43 pagesOur Milling MachinesWill Front100% (3)

- Skid Steer Loader KOHLER Diesel KDIDocument204 pagesSkid Steer Loader KOHLER Diesel KDIAstrit Strati100% (1)

- 12Document35 pages12ED JO MenmarNo ratings yet

- NOx Conversion Is LowDocument13 pagesNOx Conversion Is LowNir PeledNo ratings yet

- Lubricantes JCBDocument24 pagesLubricantes JCBNoe GarciaNo ratings yet

- 310J, 310SJ, 315SJ, 325J, 410J, 310SJ TMC and 410J TMC Engines 4045DT060, 4045HT054, 4045TT094, and 4045TT095Document2 pages310J, 310SJ, 315SJ, 325J, 410J, 310SJ TMC and 410J TMC Engines 4045DT060, 4045HT054, 4045TT094, and 4045TT095Tomas GomezNo ratings yet

- AirOil Separator AS2496Document5 pagesAirOil Separator AS2496Victor Zhicay100% (1)

- Catalogo 2009Document110 pagesCatalogo 2009marciorga50% (2)

- Service Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Document5 pagesService Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Milorad Zelenovic100% (1)

- Yanmar 4TN88Document3 pagesYanmar 4TN88Alfonso RectificadorNo ratings yet

- Cursor 770 c13 Ent m77Document226 pagesCursor 770 c13 Ent m77jvega_534120No ratings yet

- Kioti Daedong DK451 Tractor Operator Manual PDFDocument19 pagesKioti Daedong DK451 Tractor Operator Manual PDFfjjsekfkskemeNo ratings yet

- Mini 05 03M V3 PDFDocument75 pagesMini 05 03M V3 PDFMiguel Chacon100% (1)

- 12 PDFDocument35 pages12 PDFED JO Menmar100% (1)

- Volvo WB 1 Bulletins TransWay WB PDFDocument2 pagesVolvo WB 1 Bulletins TransWay WB PDFmhan imanNo ratings yet

- V-ACT D16E Brochure 22 A 100 3523 - 2007-07Document2 pagesV-ACT D16E Brochure 22 A 100 3523 - 2007-07Rolando Mancilla FloresNo ratings yet

- Dieselmax - 444 - I t3 Tcae 97Document4 pagesDieselmax - 444 - I t3 Tcae 97juanNo ratings yet

- Perkins 400 Series: Workshop ManualDocument6 pagesPerkins 400 Series: Workshop ManualDella AstariNo ratings yet

- 1 Standard Parts, ServiceDocument149 pages1 Standard Parts, ServiceAriánCalderaNo ratings yet

- Kubota 05 Series d1005 E3b SpecificationsDocument2 pagesKubota 05 Series d1005 E3b SpecificationsVol VasylkevychNo ratings yet

- Sa6d125e-2a-7 SN 60721-UpDocument189 pagesSa6d125e-2a-7 SN 60721-UpHelioNo ratings yet

- SleeveDocument21 pagesSleeveAnonymous 5tkF5bFwONo ratings yet

- Cummins Nta855 Engine: Parts CatalogDocument106 pagesCummins Nta855 Engine: Parts Catalogmery100% (1)

- 420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónDocument7 pages420F Backhoe Loader SKR00001-UP (MACHINE) POWERED BY C4.4 Engine (SEBP5986 - 55) - DocumentaciónRosa ChNo ratings yet

- HCR1200 DS3Document8 pagesHCR1200 DS3Hodumi JosefNo ratings yet

- Deutz Engines Service CentresDocument198 pagesDeutz Engines Service Centreszulu800% (1)

- 06 Aeraid Flywheel ManualDocument108 pages06 Aeraid Flywheel ManualBen HammonNo ratings yet

- Operator Training16-35Document21 pagesOperator Training16-35ODM rachmanzNo ratings yet

- NH Sslctlrange Anz GB LQDocument16 pagesNH Sslctlrange Anz GB LQmiab1No ratings yet

- Og Gas Hauler1200x 21sept 2011Document82 pagesOg Gas Hauler1200x 21sept 2011Forklift Systems IncorporatedNo ratings yet

- DX420LCA-K: Construction EquipmentDocument15 pagesDX420LCA-K: Construction EquipmentHaidar SareeniNo ratings yet

- Engine: SpecificationsDocument124 pagesEngine: SpecificationsZawminn Htut100% (1)

- Manual For Metal Detector Fisher f2Document16 pagesManual For Metal Detector Fisher f2Nicolaie FlorinNo ratings yet

- N45ENT 104kW E PDFDocument3 pagesN45ENT 104kW E PDFSecret64No ratings yet

- 273243957-DENSO-Common-Rail-Isuzu-6HK1-6SD1-Service-Manual-Pages Backup PDFDocument9 pages273243957-DENSO-Common-Rail-Isuzu-6HK1-6SD1-Service-Manual-Pages Backup PDFjwd100% (1)

- Transmission Pressure TestDocument7 pagesTransmission Pressure Testandi gamersNo ratings yet

- Repairmanual C078ensm20 C078entm30!50!55 P3d32c001e Jun07Document254 pagesRepairmanual C078ensm20 C078entm30!50!55 P3d32c001e Jun07Luis Eduardo Corzo Enriquez100% (1)

- Effect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsDocument9 pagesEffect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsNgocTinhPhamNo ratings yet

- Engine Characteristics (DV15T/DV15TIS) - Technical Tips For MaintenanceDocument14 pagesEngine Characteristics (DV15T/DV15TIS) - Technical Tips For MaintenanceBùi Xuân ĐứcNo ratings yet

- Comparacion Articulado Best PDFDocument26 pagesComparacion Articulado Best PDFrolex21No ratings yet

- WD12. Каталог запасных частейDocument43 pagesWD12. Каталог запасных частейSergeyNo ratings yet

- Diesel Generator Set QSX15 Series Engine: Power GenerationDocument4 pagesDiesel Generator Set QSX15 Series Engine: Power GenerationsdasdNo ratings yet

- 2005 Engine Manual - S5-UJ05E04CDocument394 pages2005 Engine Manual - S5-UJ05E04CHS it50% (2)

- 33Document150 pages33mandy johnNo ratings yet

- FPT F4DFE613M U-R-015-0290Document3 pagesFPT F4DFE613M U-R-015-0290Goran MatovicNo ratings yet

- Detroitdiesel MHDD A2900174 7d7-5d1 0d20-0d01Document3 pagesDetroitdiesel MHDD A2900174 7d7-5d1 0d20-0d01Erick RodriguesNo ratings yet

- g930 g940 g946 g960 en (c48)Document24 pagesg930 g940 g946 g960 en (c48)Deddy ChristianNo ratings yet

- Fuel Supply Pump Installation: Introduction Safety Information ReferenceDocument9 pagesFuel Supply Pump Installation: Introduction Safety Information ReferenceMiguel CevallosNo ratings yet

- Hatz Diesel D Series BrochureDocument8 pagesHatz Diesel D Series BrochureColdbloodedbiker100% (1)

- Dynapac CA 250/252/262 Workshop Manual: Converting Drum STD/D To P/PDDocument11 pagesDynapac CA 250/252/262 Workshop Manual: Converting Drum STD/D To P/PDJonhNo ratings yet

- SERVICE MANUAL TNE Series (1) OCR PDFDocument136 pagesSERVICE MANUAL TNE Series (1) OCR PDFfranklinaresNo ratings yet

- Mercedes Benz Biodiesel Brochure PDFDocument18 pagesMercedes Benz Biodiesel Brochure PDFkshepard_182786911No ratings yet

- Biodiesel Information For Mercedes-Benz Vehicles 2014 EditionDocument19 pagesBiodiesel Information For Mercedes-Benz Vehicles 2014 EditionSumathi SrinivasNo ratings yet

- Alternative Fuels L120G VolvoDocument3 pagesAlternative Fuels L120G Volvokianoush Volvo construction equipmentNo ratings yet

- Mercedes Benz Biodiesel - Rev5Document11 pagesMercedes Benz Biodiesel - Rev5wurtukukNo ratings yet

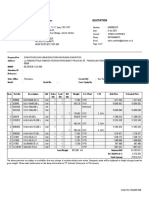

- PT Trakindo Utama: QuotationDocument2 pagesPT Trakindo Utama: QuotationJUNA RUSANDI SNo ratings yet

- Junarusandi 2019-03-06 16.16.24Document10 pagesJunarusandi 2019-03-06 16.16.24JUNA RUSANDI SNo ratings yet

- CC 900 Instructions Manual Icc900g Cn1en PDFDocument96 pagesCC 900 Instructions Manual Icc900g Cn1en PDFJUNA RUSANDI S100% (1)

- T PDFDocument4 pagesT PDFJUNA RUSANDI SNo ratings yet

- Ex 100 3 Troubleshooting Manual PDFDocument207 pagesEx 100 3 Troubleshooting Manual PDFJUNA RUSANDI SNo ratings yet

- Cat 120K: Motor GraderDocument2 pagesCat 120K: Motor GraderJUNA RUSANDI SNo ratings yet

- Ex 100 3 Troubleshooting Manual PDFDocument207 pagesEx 100 3 Troubleshooting Manual PDFJUNA RUSANDI SNo ratings yet

- Fuel ConsumptionDocument1 pageFuel ConsumptionJUNA RUSANDI SNo ratings yet

- Chemistry Investigatory Project: Formation of Bio DieselDocument15 pagesChemistry Investigatory Project: Formation of Bio DieselHardik RohitNo ratings yet

- Performance Analysis of Shell and Tube As Preheater Fuel For BiodieselDocument6 pagesPerformance Analysis of Shell and Tube As Preheater Fuel For BiodieselAchmad WijayaNo ratings yet

- Alternate Fuels: EthanolDocument11 pagesAlternate Fuels: Ethanolkadam saicharanNo ratings yet

- Run Your Car On Waste Vegetable OilDocument12 pagesRun Your Car On Waste Vegetable Oilad14100% (2)

- Waste Vegetable Oil As A Diesel Replacement FuelDocument19 pagesWaste Vegetable Oil As A Diesel Replacement Fuelapi-19662887No ratings yet

- SRS 003 Ijreamv04i0642035 PDFDocument3 pagesSRS 003 Ijreamv04i0642035 PDFSatish ShahNo ratings yet

- Iocl Tender Bio-DieselDocument21 pagesIocl Tender Bio-DieselHussain Shaikh100% (1)

- Thesis On Biofuel ProductionDocument5 pagesThesis On Biofuel Productionaflpaftaofqtoa100% (2)

- Power Alcohol and BiodieselDocument12 pagesPower Alcohol and BiodieselVenkatesh Perumal MNo ratings yet

- Applied Energy: Lin Lin, Zhou Cunshan, Saritporn Vittayapadung, Shen Xiangqian, Dong MingdongDocument12 pagesApplied Energy: Lin Lin, Zhou Cunshan, Saritporn Vittayapadung, Shen Xiangqian, Dong MingdongLacramioara Iuliana VladulescuNo ratings yet

- Biofuels Formal Lab Report RevisedDocument9 pagesBiofuels Formal Lab Report RevisedVeronica ChangNo ratings yet

- Combustion of Vegetable Oils Under Optimized Conditions of Atomization and Granulometry in A Modified Fuel Oil BurnerDocument6 pagesCombustion of Vegetable Oils Under Optimized Conditions of Atomization and Granulometry in A Modified Fuel Oil BurnerThiago ValenteNo ratings yet

- PROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoDocument36 pagesPROCEEDINGAPTECS2011ITS TheBio FuelPressureStoveFueledbyWasteCookingOil SjaffriadiNugrohoAdiSasongkoJoanna Marie SimonNo ratings yet

- Castor (Ricinus Communis) : Potential of Castor For Bio-Fuel ProductionDocument17 pagesCastor (Ricinus Communis) : Potential of Castor For Bio-Fuel ProductionfnielsenNo ratings yet

- Production of Biodiesel From Used Vegetable OilDocument4 pagesProduction of Biodiesel From Used Vegetable OilEmmanuelNo ratings yet

- Research ProposalDocument10 pagesResearch ProposalGNo ratings yet

- Data Collection On Modified Engines On PureDocument50 pagesData Collection On Modified Engines On PurecoralonsoNo ratings yet

- 2008 RenewableEnergyDocument6 pages2008 RenewableEnergyJoanna Marie SimonNo ratings yet

- How Diesel Engines WorkDocument23 pagesHow Diesel Engines WorkBabu Stunner100% (1)

- A Critical Review of Bio-Diesel As A Vehicular FuelDocument15 pagesA Critical Review of Bio-Diesel As A Vehicular Fueldann07No ratings yet

- Biobased Diesel 1222Document48 pagesBiobased Diesel 1222Марина НурмагомедоваNo ratings yet

- Sub Control System HY-AM-10Document64 pagesSub Control System HY-AM-10mohamed hamedNo ratings yet

- Run Your Diesel Vehicle On Biofuels PDFDocument250 pagesRun Your Diesel Vehicle On Biofuels PDFedalzurcNo ratings yet

- Jawahar Navodaya Vidyalaya, Naultha (Panipat) : Biodiesel FormationDocument12 pagesJawahar Navodaya Vidyalaya, Naultha (Panipat) : Biodiesel Formationharsh poonia100% (1)

- Gas TurbineDocument6 pagesGas TurbineAditya GuptaNo ratings yet

- Biodiesel - A Fuel of FutureDocument5 pagesBiodiesel - A Fuel of FutureYashad JoshiNo ratings yet

- UCO Biodiesel Indonesia 20180919Document26 pagesUCO Biodiesel Indonesia 20180919mareNo ratings yet

- Titration: The ProcessDocument2 pagesTitration: The ProcessDALITSO CHIKOYANo ratings yet

- Comparison of Renewable Diesel vs. BiodieselDocument6 pagesComparison of Renewable Diesel vs. BiodieselmbrancovNo ratings yet

- Lecture - (Unit-5) - Rating and Convetional-Alternative FuelsDocument41 pagesLecture - (Unit-5) - Rating and Convetional-Alternative FuelsraviNo ratings yet