Professional Documents

Culture Documents

(22847197 - Journal of Applied Engineering Sciences) Calculation of Heat Loss Through The Pipes of The Interior Central Heating System

Uploaded by

Theod S. VilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(22847197 - Journal of Applied Engineering Sciences) Calculation of Heat Loss Through The Pipes of The Interior Central Heating System

Uploaded by

Theod S. VilaCopyright:

Available Formats

JOURNAL OF APPLIED ENGINEERING SCIENCES VOL.

5(18), ISSUE 2/2015

ISSN: 2247-3769 / e-ISSN: 2284-7197 ART.188, pp. 29-36

CALCULATION OF HEAT LOSS THROUGH THE PIPES OF THE INTERIOR

CENTRAL HEATING SYSTEM

I. Giurca

Technical University of Cluj-Napoca, Faculty Building Services Engineering, Building Services Engineering Department,

B-dul. 21 Decembrie 1989, no. 128-130, Cluj-Napoca, Romania, e-mail: giurca_ioan@yahoo.com

Received: 15.09.2015 / Accepted: 10.10.2015 / Revised: 24.10.2015 / Available online: 15.12.2015

DOI: 10.1515/jaes-2015-0018

KEY WORDS: central heating, residential buildings, thermal energy, energy audit

ABSTRACT:

The article presents aspects related to the calculation of heat loss through the pipes of the interior central heating system. The

purpose of the article is to detail the local heat losses in case of central heating systems. Based on the conclusions of the article, we

propose the modification of the calculation methodology related to the building energy audit.

1. INTRODUCTION 1.2. General Considerations

1.1. Context The thermal calculation of the pipe networks represents a

calculation related to the heat transfer between two fluids,

As climate is changing and fossil fuel deposits are separated by a wall. The purpose of the thermal

constantly diminishing, lowering energy calculation is either to determine the necessary width in

consumption has become an important objective of order to satisfy certain imposed requirements (regulated

the European Union states, including Romania. In values imposed to heat and temperature losses or certain

order to achieve this goal, a series of legislative values of the temperature at the surface of the thermal

measures have been developed, their target being to insulation), or to determine the heat and temperature

limit energy consumption (Ionescu, 2011). losses for a certain thermal insulation (Athanasovici,

1981).

Buildings are responsible for 40-45 % of the total

energy consumption in Europe and China (and for This paper represents a continuation of the study

about 30-40 % worldwide) (Day, 2009). conducted by the author (Giurca, 2006, 2009; Naghiu,

2014) in the field of energetic audit.

It is well known that a major objective of all states is

to decrease the energy consumption in order to 1.3. The purpose presented in the article

protect the natural resources, and directly related to

this aspect, to decrease the CO2 emissions in the The article presents aspects related to the calculation of

atmosphere. These are also the objectives set in heat loss through the pipes of the interior central heating

Directive no. 2010/31/UE on the energetic system.

performance of buildings. This directive was

transposed into the Romanian legislation in Law no. The purpose of the article is to detail the local heat losses

372/2005 (Constantinescu, 2008), (Law 372, 2005). in case of central heating systems.

29

Unauthentifiziert | Heruntergeladen 03.02.20 11:52 UTC

JOURNAL OF APPLIED ENGINEERING SCIENCES VOL. 5(18), ISSUE 2/2015

ISSN: 2247-3769 / e-ISSN: 2284-7197 ART.188, pp. 29-36

1.4. The added value of the present article of the linear heat losses, and those respective values are

presented in a table (see table no. 1).

Based on the conclusions of the article, we propose

the modification of the calculation methodology K coefficient for

related to the building energy audit. Pipe

supported by pipes in enclosed pipes in open

rooms air

2. MATERIALS AND METHODS hanging 1.10 1.15

propping 1.15 1.20

2.1. Calculation of total heat losses of a pipe

Table 1. Values of the K coefficient for determining heat

The total amount of heat that a pipe loses in the losses through the supporting elements of the pipes

environment is determined with the formulas: (Athanasovici, 1981; Carabogdan, 1986)

Qh = q · L + ∑ Qloc (1)

2.2.2. Determining heat losses through the valves’

or

body, including through the joining flanges

Qh = qech · Le = qech · (k · L + l) (2)

where: For losses through valves’ bodies, including the flanges,

Qh = stands for the pipe’s heat loss; the equivalent length taken into account depends on the

q = unitary heat losses of a thermally insulated thermal insulation degree. This value shall be added to

pipe; the length of the pipes (Mc 001/2, 2006).

L = length of the pipe, in m;

∑ Qloc = local heat losses; Further on, we shall present the data related to the way of

qech = equivalent thermal flow; determining heat losses through the valves’ body,

Le = equivalent pipe length, in m; including through the joining flanges, according to the

k = coefficient taking into account Romanian legislation in force, as well as in accordance

supplementary heat losses through the pipe’s with the specialized papers published in Romania,

supporting elements (see table no. 1); Germany, Belgium or France.

l = length of the thermally insulated pipe,

equaling the heat losses through the closing In table no. 2 we presented the equivalent length for the

elements and through the pipe’s joints, in m casings, in accordance with the Romanian calculation

(Carabogdan, 1986). methodology, namely Mc 001/2-2006- Part II.

2.2. Key Determining heat losses through the Valves also Equivalent

related elements including the Equivalent length [m] length [m]

attachment ND ≤ 100 mm ND ≥ 100

When referring to heat losses of a pipe system one

flanges mm

must take into account not only the losses that

not insulated 4.0 6.0

correspond to the pipes, but also those corresponding

to the related elements (valves, fittings, bases that insulated 1.5 2.5

are not insulated, etc.). In order to be able to take

into account the related elements, one must consider Table 2. Equivalent length for casings (Mc 001/2, 2006)

an equivalent length (Mc 001/2, 2006).

2.2.1. Determining the supplementary heat In table no. 3 we presented the length of the thermally

losses through the supporting elements of insulated pipe which represents the heat losses through

the pipe the closing and joining elements, according to the

Romanian specialized papers.

Supplementary heat losses through the supporting

elements of the pipe are represented as percentages

Pipes in enclosed rooms Pipes in open air

Element

t = 100 oC t = 400 oC t = 100 oC t = 400 oC

Casings Di = 100 mm 2.3 4.8 4.5 6.2

Di = 500 mm 3.0 7.5 5.5 8.5

Joints through flanges 1 – 1.5

Table 3. Values of the “l’’ coefficient, the length of the thermally insulated pipe which represents the heat losses through

the closing and joining elements, in m (Athanasovici, 1981; Carabogdan, 1986)

30

Unauthentifiziert | Heruntergeladen 03.02.20 11:52 UTC

JOURNAL OF APPLIED ENGINEERING SCIENCES VOL. 5(18), ISSUE 2/2015

ISSN: 2247-3769 / e-ISSN: 2284-7197 ART.188, pp. 29-36

According to the Romanian specialized papers (Voinescu, Equivalent

1964), the “l” coefficient for the pipes located in enclosed Name pipe length

rooms is the following: -m-

- flange thermally not insulated, 3 m; Valves not insulated

- flange thermally insulated, 0.5 m; 1.7

- cock or valve thermally not insulated, 5-7 m; Insulated valves (6 cm of

0.17

- cock or valve thermally insulated, 3 m. padding)

Pair of flanges not insulated 0.9

In table no. 4 we presented the equivalent length Pair of flanges not insulated (6

0.06

corresponding to valves and flanges thermally not cm of padding)

insulated, according to the specialized papers from

Germany. Table 5. Equivalent pipe length for heat losses through

valves and flanges (source: AIB, cited in paper (Energie+, nd.a.)

Water temperature

Name ND

50 °C 100 °C If the value of the “l” coefficient is not determined, the

25 0.5 m 1.0 m values of the “K” coefficient shall be increased with 0.05

Valves 100 1.2 m 2.5 m (Carabogdan, 1986).

300 3.0 m 6.0 m

25 0.2 m 0.4 m Heat losses through pipes may be represented directly as

Flanges 100 0.5 m 1.0 m values, and therefore in table no. 6 we presented these

300 1.5 m 3.0 m values in accordance with the French specialized papers.

Table 4. Thermally equivalent lengths of the valves and In table no. 7 we presented the values corresponding to

flanges thermally not insulated, in equivalent meters of heat losses through valves, according to the Belgian

pipe (Recknagel, 1996; Energie+, nd.b.) scholarly literature.

And in table no. 5 we presented the equivalent pipe length

corresponding to heat losses through valves and flanges,

according to the specialized papers from Belgium.

ND Threaded valve Ball threaded valve 2-way cock with flange 3-way cock with flange

o

mm W/ C W/ oC W/ oC W/ oC

20 0.12 0.11

32 0.17 0.18 1.65

40 2.59

50 0.25 0.32 2.37

65 0.59 3.46 3.63

100 4.27 5.71

Table 6. Heat loss values recommended for a temperature difference of one degree

between the thermal agent and the air (COSTIC, nd)

Inner diameter Outside diameter Not-insulated valve Insulated valve Savings

toli mm W/m2 W/m2 W/m2

½ 21 48 17 31

1 33 88 31 57

1½ 48 124 43 81

2 60 158 55 103

3 89 226 79 147

4 114 292 102 190

5 140 358 125 233

6 169 420 147 273

Table 7. Heat losses through valves (Simon, 2010)

31

Unauthentifiziert | Heruntergeladen 03.02.20 11:52 UTC

JOURNAL OF APPLIED ENGINEERING SCIENCES VOL. 5(18), ISSUE 2/2015

ISSN: 2247-3769 / e-ISSN: 2284-7197 ART.188, pp. 29-36

In Figure 1-4 we presented the heat losses through valves,

as presented by the French association COSTIC in the

paper (COSTIC, nd).

Heat losses, in W

Temperature difference between the thermal agent and the air, in K

Figure 1. Nomogram for determining heat losses through threaded valve

Heat losses, in W

Temperature difference between the thermal agent and the air, in K

Figure 2. Nomogram for determining heat losses through ball valves

Heat losses, in W

Temperature difference between the thermal agent and the air, in K

Figure 3. Nomogram for determining heat losses through flanged ball valves

32

Unauthentifiziert | Heruntergeladen 03.02.20 11:52 UTC

JOURNAL OF APPLIED ENGINEERING SCIENCES VOL. 5(18), ISSUE 2/2015

ISSN: 2247-3769 / e-ISSN: 2284-7197 ART.188, pp. 29-36

Heat losses, in W

Temperature difference between the thermal agent and the air, in K

Figure 4. Nomogram for determining heat losses through 3 way flanged valves

3. CASE STUDY, RESULTS AND DISCUSSION - specialized papers from Belgium;

- specialized papers from France.

3.1. Case Study

Steps pipe heat loss calculation are shown in Figure 5.

Further on, we are presenting a case study concerning

the heat losses that occur in case of an interior central

heating system of a block of flats located in Bucharest

and administered by the Owners’ Association.

The building has a parallelepiped shape, consists of 2

sections, each of these sections being composed of an

underground floor, a first floor and 3 floors. In plan,

the building’s dimensions are 34.90 m x 13.00 m, with

Figure 5. Steps calculation of heat loss through pipes

a total built surface of 1814.88 m2.

The block has 24 flats, namely 3 flats on each floor that

is 12 flats on each section (Mc 001/4, 2009).

Hypotheses:

- the number of yearly heating hours is of 5736

hours/year;

- the average temperature of the heating agent is of 70

o

C;

- the average temperature of the underground floor is of

8.73 oC;

- the average interior temperature is of 20 oC;

- the pipes located in the underground floor are

thermally insulated;

- the pipes located in the apartments are not thermally

insulated.

3.2. Results

Based on the above hypotheses and based on the

calculation methodology, we made the calculations

using the following bibliography in order to determine

the heat losses through the valves:

- Romanian legislation;

33

Unauthentifiziert | Heruntergeladen 03.02.20 11:52 UTC

JOURNAL OF APPLIED ENGINEERING SCIENCES VOL. 5(18), ISSUE 2/2015

ISSN: 2247-3769 / e-ISSN: 2284-7197 ART.188, pp. 29-36

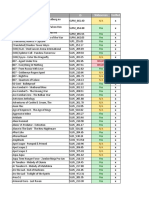

The results of the calculations are synthetically table no. 11.

presented in table no. 8, table no. 9, table no. 10 and

Unitary heat

Equivalent pipe

losses of a Total

Number length for heat Total loss of Total loss

Pipe di thermally L linear heat l

of valves losses through local heat of heat

destination insulated pipe, loss

valves

q

m kWh/m an m kWh/an pcs. m/pcs. m kWh/an kWh/an

Distribution

pipeline 0.04 76.849 206.28 15,852 6 3 18 1,383 17,236

Columns 0.025 51.828 254.4 13,185 48 3 144 7,463 20,648

Connecting

pipes to

radiators 0.015 58.145 960 55,819 64 6 384 22,328 78,146

Total 1,420.68 84,856 118 546 31,174 116,030

Table 8. Calculation of heat loss through pipes according to literature in Romania

Unitary heat

Equivalent pipe

losses of a Total

Number length for heat Total loss of Total loss

Pipe di thermally L linear heat l

of valves losses through local heat of heat

destination insulated loss

valves

pipe, q

m kWh/m an m kWh/an pcs. m/pcs. m kWh/an kWh/an

Distribution

0.04 76.849 206.28 15,852 6 0.17 1.02 78 15,931

pipeline

Columns 0.025 51.828 254.4 13,185 48 0.17 8.16 423 13,608

Connecting

pipes to 0.015 58.145 960 55,819 64 1.7 108.8 6,326 62,145

radiators

Total 1,420.68 84,856 118 2.04 117.98 6,827 91,684

Table 9. Calculation of heat loss through pipes according to literature in Belgium

Unitary heat

losses of a Total

Number Total loss of Total loss of

Pipe di thermally L linear heat l ∆T tH

of valves local heat heat

destination insulated pipe, loss

q

m kWh/m an m kWh/an pcs. W/ oC K h/year kWh/an kWh/an

Distribution

0.04 76.849 206.28 15,852 6 0.32 61.27 5,736 675 16,527

pipeline

Columns 0.025 51.828 254.4 13,185 48 0.18 50 5,736 2,478 15,663

Connecting

pipes to 0.015 58.145 960 55,819 64 0.11 50 5,736 2,019 57,838

radiators

Total 1,420.68 84,856 118 5,172 90,028

Table 10. Calculation of heat loss through pipes according to literature in France

34

Unauthentifiziert | Heruntergeladen 03.02.20 11:52 UTC

JOURNAL OF APPLIED ENGINEERING SCIENCES VOL. 5(18), ISSUE 2/2015

ISSN: 2247-3769 / e-ISSN: 2284-7197 ART.188, pp. 29-36

Total linear heat Total loss of local Total loss of Linear losses Local losses

Method loss heat heat weight weight

kWh/an kWh/an kWh/an % %

Romania 84,856 31,174 116,030 73.1% 26.9%

Belgium 84,856 6,827 91,684 92.6% 7.4%

France 84,856 5,172 90,028 94.3% 5.7%

Table 11. Values of heat losses

where: - the values obtained for the local heat losses may

di represents the inner diameter of the pipe, differ, depending on the bibliography used when

in m; making the calculations.

∆t - temperature difference between the

thermal agent and the air, in K;

tH - the annual number of hours of heating, 4. CONCLUSIONS

h/year.

a) Conclusions derived from the article:

The results obtained are also presented graphically

(figure 6 and figure 7). - The use of the calculation method presented

above allows us to calculate more precisely the

heat losses through valves, depending on the

constructive type of the valve used and depending

on the temperature difference between the thermal

agent and the air.

- We notice that using different bibliographic

sources may lead to obtaining different local heat

losses, for the same interior central heating

system.

- Considering that the local heat losses may have

Figure 6. Values of heat losses

significant values, we recommend that in the

preliminary calculations, one should supplement

the local heat losses. According to the

recommendations of the Romanian specialized

papers, in case of interior heating systems, the

heat losses through:

- pipe supporting elements represent about 10-

15 % of the linear heat losses;

- closing elements and pipe joints represent

about 5 % of the linear heat losses.

Figure 7. Weight of heat losses

b) Contribution of the present work synthesis:

3.3. Discussion

- The article presents aspects related to the

From the facts presented above, it results that: calculation of heat loss through the pipes of the

interior central heating system.

- local heat losses range between 5.7...26.9 % from

total heat losses; - The purpose of the article is to detail the local heat

losses in case of central heating systems.

35

Unauthentifiziert | Heruntergeladen 03.02.20 11:52 UTC

JOURNAL OF APPLIED ENGINEERING SCIENCES VOL. 5(18), ISSUE 2/2015

ISSN: 2247-3769 / e-ISSN: 2284-7197 ART.188, pp. 29-36

c) The possibility of practical use of the study Teză de doctorat, Universitatea Tehnică de ConstrucŃii

results: Bucureşti, Bucureşti, p. 6.

Naghiu, G. S., Giurca, I., 2014. Considerations related to

- The conclusions of this study are useful both for

economic efficiency indices in case of energy audit for

the specialists who want to obtain the energy auditor buildings. Annals of the „Constantin Brâncuşi”

license for buildings as well as for elaborating University of Târgu Jiu. Economy Series, Issue 5, pp. 92-

energy audit projects for buildings. 97.

d) Outlook: Recknagel, H., Sprenger, E., Schramek, E-R., 1995.

Taschenbuch főr heizung + klimatechnik. Oldenbourg,

- Based on the conclusions of the article, we 94/95, pp. 824.

propose the modification of the calculation

methodology related to the building energy audit. Simon, D., 2010. Cahier technique no9. Economies

d’énergie dans l’industrie. Service public de Wallonie, p.

4.

5. REFERENCES Voinescu, V., Niculescu, N., Lăzărescu, L., 1964.

Îndrumătorul instalatorilor (Plumbers’ Guide). Editura

Athanasovici, V., Muşatescu, V., Dumitrescu, I., S., Tehnică, Bucureşti, pp. 506-509.

1981. Termoenergetică industrială şi termoficare

(Industrial thermoenergetics and thermofication). Editura *** COSTIC, nd. Developpements. ,,DEV. 6 -

Didactică şi Pedagogică, Bucureşti, pp. 290-291; 295. L'optimisation des circuits de chaufferies’’.

Carabogdan, I., G., 1986. Manualul inginerului *** Energie+, nd.a. Évaluer l'efficacité énergétique de la

termotehnician. Volumul III (Manual of the thermo- distribution de chaleur. Louvain, Belgique

technician engineer. Volume III). Editura Tehnică, http://www.energieplus-lesite.be/index.php?id=10904

Bucureşti, pp. 696-697. (view at 9 Sep. 2015).

Constantinescu, D., Perianu, C., Petran, H., Petcu, C., *** Energie+, nd.b. Les pertes de chaleur des conduites et

2008. Estimarea analitică a performanŃei energetice a vannes non isolées Louvain, Belgique

clădirilor de locuit existente - metoda simplificată http://www.energieplus-lesite.be/index.php?id=11002

(Analytical Assessment of the Energy Performance of (view at 9 Sep. 2015).

Existent Residential Buildings - the Simplified Method).

Revista ConstrucŃii, no. 2, p. 26. *** Legea nr. 372, 2005. Lege privind performanŃa

energetică a clădirilor (Law 372/2005 on the energy

Day, AR., Ogumka, P., Jones, PG., Dunsdon, A., 2009. performance of buildings).

The use of the planning system to encourage low carbon

energy technologies in buildings. Renewable Energy, *** Mc 001/2, 2006. Metodologia de calcul al

Volume 34, Issue 9, pp. 2016-2021. performanŃei energetice a clădirilor. Partea a II-a -

PerformanŃa energetică a instalaŃiilor din clădiri

Giurca, I., 2006. Analiza economică a măsurilor de (Calculation methodology of the energy performance of

modernizare energetică a clădirilor existente (Economic buildings. Part II – Energy performance of installations

analysis of measures to modernize the existing building from buildings), pp. 34-35.

energy). În: ConferinŃa „ŞtiinŃa Modernă şi Energia”,

EdiŃia a XXV-a; 18-19 mai 2006, Cluj-Napoca, România. *** Mc 001/4, 2009. Metodologie de calcul al

Risoprint, Cluj-Napoca, pp. 347-350. performanŃei energetice a clădirilor. Partea a IV-a -

Breviar de calcul al performanŃei energetice a clădirilor şi

Giurca, I. 2009. ContribuŃii privind alimentarea cu apartamentelor (Calculation methodology of the energy

energie termică a ansamblurilor de locuinŃe, utilizând performance of buildings. Part IV - Calculation for the

agenŃi termici cu parametri scăzuŃi (Contributions to energy performance of buildings and apartments), p. 84.

thermal energy supplies of building assemblies by using

thermal agents with low parameters), Teză de doctorat,

Universitatea Tehnică din Cluj-Napoca, Cluj-Napoca.

Ionescu, A. M., 2011. Cercetări privind consumul de

energie pentru climatizarea clădirilor (Research works on

the energy consumption for buildings’ acclimatization),

36

Unauthentifiziert | Heruntergeladen 03.02.20 11:52 UTC

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Thermo 12Document19 pagesThermo 12Jess Ryan Olayon100% (2)

- WebpdfDocument276 pagesWebpdfprateekvNo ratings yet

- ISO 20000-1 Gap Analysis QuestionaireDocument15 pagesISO 20000-1 Gap Analysis QuestionaireUsman Hamid67% (6)

- Solution PDFDocument20 pagesSolution PDFVard FarrellNo ratings yet

- Fire Alarm SymbolsDocument6 pagesFire Alarm Symbolscarlos vasquezNo ratings yet

- CEA Thermodynamics UpdatedDocument5 pagesCEA Thermodynamics UpdatedTheod S. VilaNo ratings yet

- Productflyer - 978 3 540 89748 4Document1 pageProductflyer - 978 3 540 89748 4Theod S. VilaNo ratings yet

- Development of A Reviewer Manual in Mechanical Engineering With Theories and 5,001 Solved Problems and Answered Questions (Elements) : For Computerized Mechanical Engineering Licensure Examination PDFDocument13 pagesDevelopment of A Reviewer Manual in Mechanical Engineering With Theories and 5,001 Solved Problems and Answered Questions (Elements) : For Computerized Mechanical Engineering Licensure Examination PDFTristan Tabago Consolacion33% (3)

- Productflyer - 978 3 540 89748 4Document1 pageProductflyer - 978 3 540 89748 4Theod S. VilaNo ratings yet

- Fluid Mechanics My Book PDFDocument38 pagesFluid Mechanics My Book PDFAniket BabutaNo ratings yet

- Steam QualityDocument3 pagesSteam Qualitydurga_85100% (1)

- Steam QualityDocument3 pagesSteam Qualitydurga_85100% (1)

- Centrifugalfansr00john PDFDocument120 pagesCentrifugalfansr00john PDFTheod S. VilaNo ratings yet

- Centrifugalfansr00john PDFDocument120 pagesCentrifugalfansr00john PDFTheod S. VilaNo ratings yet

- Opt PDFDocument32 pagesOpt PDFTheod S. VilaNo ratings yet

- Adi Nsps 9900003Document1 pageAdi Nsps 9900003John Jonel CasupananNo ratings yet

- Adi Nsps 9900003Document1 pageAdi Nsps 9900003John Jonel CasupananNo ratings yet

- Section 11Document57 pagesSection 11Hermogenes L. Jr MejiaNo ratings yet

- Solution 1330895172 PDFDocument1 pageSolution 1330895172 PDFTheod S. VilaNo ratings yet

- Don VI Ap SuatDocument2 pagesDon VI Ap SuatPham ThienNo ratings yet

- Testing of Air Compressor 2 PDFDocument5 pagesTesting of Air Compressor 2 PDFTheod S. VilaNo ratings yet

- CH 07Document59 pagesCH 07Theod S. VilaNo ratings yet

- Engineering Thermodynamics35MDocument876 pagesEngineering Thermodynamics35MTara Collier100% (4)

- Types of Shafts: 1. Transmission Shafts. These Shafts Transmit PowerDocument9 pagesTypes of Shafts: 1. Transmission Shafts. These Shafts Transmit PowerTheod S. VilaNo ratings yet

- Testing of Air Compressor 2 PDFDocument5 pagesTesting of Air Compressor 2 PDFTheod S. VilaNo ratings yet

- Testing of Air Compressor 2 PDFDocument5 pagesTesting of Air Compressor 2 PDFTheod S. VilaNo ratings yet

- Thermodynamics 2 Problem W Solution PDFDocument67 pagesThermodynamics 2 Problem W Solution PDFTheod S. VilaNo ratings yet

- FansDocument5 pagesFansTheod S. VilaNo ratings yet

- Abdullah's Feet: Hafid BouazzaDocument13 pagesAbdullah's Feet: Hafid BouazzaTheod S. VilaNo ratings yet

- Testing of Air Compressor 2 PDFDocument5 pagesTesting of Air Compressor 2 PDFTheod S. VilaNo ratings yet

- Engineering Thermodynamics35MDocument876 pagesEngineering Thermodynamics35MTara Collier100% (4)

- Enterpreneurship Assignment 2Document8 pagesEnterpreneurship Assignment 2Khusbu JaiswalNo ratings yet

- Which Will Weigh The Least Without AnswerDocument7 pagesWhich Will Weigh The Least Without AnswerumeshNo ratings yet

- Laser Diffraction Physics Project: Submitted By, Disha DineshDocument11 pagesLaser Diffraction Physics Project: Submitted By, Disha DineshNidaleeNo ratings yet

- Chapter 15 - Leukocyte Migration and Inflammation - The IS Relies Upon The Continual Circulation of Leukocytes Through The BodyDocument12 pagesChapter 15 - Leukocyte Migration and Inflammation - The IS Relies Upon The Continual Circulation of Leukocytes Through The BodyEmad ManniNo ratings yet

- One Plan Student 1Document7 pagesOne Plan Student 1api-465826207No ratings yet

- Addressing Diversity Through The Years Special and Inclusive EducationDocument6 pagesAddressing Diversity Through The Years Special and Inclusive EducationJiezel SurinNo ratings yet

- Empowerment TechnologyDocument15 pagesEmpowerment Technologysxhan gwenNo ratings yet

- KV Class 3 Half Yearly Previous Year Question Paper 2019 ComputerDocument2 pagesKV Class 3 Half Yearly Previous Year Question Paper 2019 Computer02 Aanya Gupta VII CNo ratings yet

- Rule Based ClassificationsDocument14 pagesRule Based ClassificationsAmrusha NaallaNo ratings yet

- WideScreen Code For PS2 GamesDocument78 pagesWideScreen Code For PS2 Gamesmarcus viniciusNo ratings yet

- History of Computer ReviewerDocument10 pagesHistory of Computer ReviewerNeil Andrew Aliazas78% (9)

- Anger Management: Gaurav Sharma 138Document21 pagesAnger Management: Gaurav Sharma 138gaurav_sharma_19900No ratings yet

- Parkinson S Disease Detection Based On SDocument5 pagesParkinson S Disease Detection Based On SdaytdeenNo ratings yet

- Cooling and Sealing Air System: Gas Turbine Training ManualDocument2 pagesCooling and Sealing Air System: Gas Turbine Training ManualVignesh SvNo ratings yet

- SFN ProfileDocument4 pagesSFN Profiledinesh panchalNo ratings yet

- Structure and Operation: 3. Electronic Control Unit Connection DiagramDocument16 pagesStructure and Operation: 3. Electronic Control Unit Connection DiagramAung Hlaing Min MyanmarNo ratings yet

- Summative 1Document4 pagesSummative 1Nean YsabelleNo ratings yet

- Data Migration Good DocumentDocument16 pagesData Migration Good Documentsambit76No ratings yet

- Himachal Pradesh Staff Selection Commission Hamirpur - 177001Document2 pagesHimachal Pradesh Staff Selection Commission Hamirpur - 177001Verma JagdeepNo ratings yet

- A Brief Tutorial On Studio MonitorsDocument18 pagesA Brief Tutorial On Studio MonitorsCurtis O'BrienNo ratings yet

- Formal Report Expt 5Document6 pagesFormal Report Expt 5AnonymouscatNo ratings yet

- Cocoon 8002 PDFDocument24 pagesCocoon 8002 PDFaxisNo ratings yet

- PP in Ii 001Document15 pagesPP in Ii 001Dav EipNo ratings yet

- BFISDocument1 pageBFISEverestNo ratings yet

- 01.introduction To Earth ScienceDocument29 pages01.introduction To Earth ScienceIshan Chua100% (1)

- Bhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Document37 pagesBhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Anu RsNo ratings yet