Professional Documents

Culture Documents

Fci 70 PDF

Fci 70 PDF

Uploaded by

Anonymous V5UYBUMaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fci 70 PDF

Fci 70 PDF

Uploaded by

Anonymous V5UYBUMaCopyright:

Available Formats

ANSI/FCI 70-2-2006

AMERICAN NATIONAL STANDARD

Control Valve Seat Leakage

1. PURPOSE 3.4 Rated Travel. The valve travel at which the

manufacturer's rating is established.

1.1 This standard establishes a series of seat

leakage classes for control valves and defines the test 3.5 Seat Leakage. The quantity of test fluid

procedures. passing through an assembled valve in the closed

position under the test conditions as defined.

2. SCOPE & LIMITATIONS

4. LEAKAGE SPECIFICATIONS & CLASSES

2.1 Selection of a leakage class is not restricted as

to valve design, but acceptable values for various 4.1 The maximum allowable seat leakage as

commercially available designs are suggested for specified for each class shall not exceed the seat

each class under Section 4. leakage in Table 1 using the test procedure as defined

in Section 5. For Classes II through VI each and

2.2 The standard cannot be used as a basis for every valve shall be tested.

predicting leakage at conditions other than those

specified. 4.2 Leakage Classes

2.3 This standard is similar to IEC 60534-4, 4.2.1 CLASS I. A modification of any Class II,

except that no provision is made for Class IV-S1 and III or IV valve where design intent is the same as the

the standard is applicable for valves with a Cv value basic class, but by agreement between user and

less than 0.1. The air leakage test and allowable leak supplier, no test is required.

rates for Class V are equivalent to the water test and

allowable water leakage rates for a water test 4.2.2 CLASS II. This class establishes the

performed at a nominal temperature of 60ºF. maximum permissible leakage generally associated

with commercial double-seat control valves or

3. DEFINITIONS balanced single-seat control valves with a piston ring

seal and metal-to-metal seats. Use test procedure

3.1 Control Valve Type A.

3.1.1 A valve with a power positioning actuator 4.2.3 CLASS III. This class establishes the

for moving a closure member to any position relative maximum permissible leakage generally associated

to a valve seat or seats in response to and in with Class II (4.2.2), but with a higher degree of seat

proportion to an external signal. The energy for a and seal tightness. Use test procedure Type A.

control valve actuator is derived from an independent

source. 4.2.4 CLASS IV. This class establishes the

maximum permissible leakage generally associated

3.1.2 Control valve body subassemblies on with commercial unbalanced single-seat control

which an actuator is to be mounted at some later date valves and balanced single-seat control valves with

are within the intent of this definition. extra tight piston rings or other sealing means and

metal-to-metal seats. Use test procedure Type A.

3.2 Cv - An experimentally determined valve

4.2.5 CLASS V. This class is usually specified

sizing coefficient. (Ref. ISA S75.01, ISA S75.02 and for critical applications where the control valve may

FCI Standard 84-1). be required to be closed, without a blocking valve,

for long periods of time with high differential

3.3 Rated Valve Capacity. The quantity of test pressure across the seating surfaces. It requires

fluid (air or water) that would pass through the valve special manufacturing, assembly and testing

at rated travel under the stated pressure conditions as techniques. This class is generally associated with

determined by the appropriate equations and metal seat, unbalanced single-seat control valves or

manufacturer's ratings. balanced single-seat designs with exceptional seat

You might also like

- CSA C22 2 No 14 Rev 3 1 2018 ED 4 11 2023Document8 pagesCSA C22 2 No 14 Rev 3 1 2018 ED 4 11 2023Karina Elizabeth AyalaNo ratings yet

- AGA 14-3 Meter Tube Pipe LengthsDocument4 pagesAGA 14-3 Meter Tube Pipe LengthsJames Krista CorwinNo ratings yet

- Iecex Certificate of ConformityDocument4 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- Simulationof Single Phase Full Bridge Converter Using PSPICEDocument10 pagesSimulationof Single Phase Full Bridge Converter Using PSPICEDhivya NNo ratings yet

- Sira Atex PosterDocument1 pageSira Atex PosterRiadh2012No ratings yet

- VMSVTDocument363 pagesVMSVTabysslabsNo ratings yet

- Control Valve Test ProcedureDocument5 pagesControl Valve Test ProcedureMark Haizlip100% (2)

- En13445 Vs AsmeDocument46 pagesEn13445 Vs Asmejeff501100% (11)

- Specification Att - 3-18 - 6-51-0032 20rev 205 - Spec For Medium Voltage Induction MotorsDocument15 pagesSpecification Att - 3-18 - 6-51-0032 20rev 205 - Spec For Medium Voltage Induction MotorsAvinash ShuklaNo ratings yet

- DBB CatalogueDocument28 pagesDBB CatalogueHeri SetyantoNo ratings yet

- 2019 Formica Asia Residential Collection - en PDFDocument52 pages2019 Formica Asia Residential Collection - en PDFKornumaNo ratings yet

- ASTM C764 Mineral Fiber Loose-Fill InsulationDocument5 pagesASTM C764 Mineral Fiber Loose-Fill InsulationMike DukasNo ratings yet

- Conect OresDocument44 pagesConect OresManoloEskobarNo ratings yet

- TES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)Document19 pagesTES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)BetoCostaNo ratings yet

- Is 778 1984 Gate, Globe and Check Valves For Water Works Purposes (Fourth RevisionDocument32 pagesIs 778 1984 Gate, Globe and Check Valves For Water Works Purposes (Fourth Revisionyesvvn100% (1)

- User Guide FlowscannerDocument137 pagesUser Guide FlowscannerJDavid NavaNo ratings yet

- Ref 17Document11 pagesRef 17Gabriel BatistaNo ratings yet

- FADPC Amphenol 1820416Document113 pagesFADPC Amphenol 1820416Omar Alfredo Del Castillo QuispeNo ratings yet

- Valves and Regulators - Turndown RatioDocument3 pagesValves and Regulators - Turndown RatioklashincoviskyNo ratings yet

- KITZ ProductDocument44 pagesKITZ Productkingathur26681No ratings yet

- Geh 6737Document92 pagesGeh 6737Lyman ConnorNo ratings yet

- Regulator VNN-505 - DN50Document25 pagesRegulator VNN-505 - DN50aminNo ratings yet

- Gas Power Plant - Layout and Operation PPT (1) Electrical Seminar TopicsDocument5 pagesGas Power Plant - Layout and Operation PPT (1) Electrical Seminar Topicsdeepanshi2100% (1)

- Emission Characteristics of Hydrogen Oxygen FlamesDocument8 pagesEmission Characteristics of Hydrogen Oxygen FlamesRaghavNo ratings yet

- DS 099 Rev01 Zinc Anode 304 MZDocument2 pagesDS 099 Rev01 Zinc Anode 304 MZsojeckNo ratings yet

- ZonesDocument19 pagesZonesVaidheeshwar VetrivelNo ratings yet

- Prysmian - Instrumentation Cables CatalogueDocument2 pagesPrysmian - Instrumentation Cables Cataloguebharatsehgal00100% (1)

- Solenoid Valve S06Document28 pagesSolenoid Valve S06korpaapNo ratings yet

- ABB Rota Bsics PDFDocument26 pagesABB Rota Bsics PDFAvik BhaiNo ratings yet

- Gasket Paking ListDocument1 pageGasket Paking ListIrwansyah MuchtarNo ratings yet

- Lcie Bureau Veritas Atex Poster PDFDocument1 pageLcie Bureau Veritas Atex Poster PDFAncaOniscuNo ratings yet

- Air Valve BrochureDocument27 pagesAir Valve Brochuredamith030No ratings yet

- DLT 5210.5-2009 - Part 5 Piping & SystemDocument147 pagesDLT 5210.5-2009 - Part 5 Piping & SystemecsuperalNo ratings yet

- Product Date Sheet - Swagelok BrocureDocument6 pagesProduct Date Sheet - Swagelok BrocurejulianpirahNo ratings yet

- G81 - 2 Housing Materials PDFDocument17 pagesG81 - 2 Housing Materials PDFHassan SaeedNo ratings yet

- Manual de Monitoramento de Condições LCM20 - EN PDFDocument41 pagesManual de Monitoramento de Condições LCM20 - EN PDFRafael G OliveiraNo ratings yet

- Fisher LP-Gas Regulators and Equipment Application Guide d450104t012Document87 pagesFisher LP-Gas Regulators and Equipment Application Guide d450104t012Alfredo Castro FernándezNo ratings yet

- Iec TS 60079-46-2017Document20 pagesIec TS 60079-46-2017Philip JonesNo ratings yet

- SGT - Le.05 Eye BoltsDocument1 pageSGT - Le.05 Eye BoltsryangillespieNo ratings yet

- Autodesk AutoCAD Plant Design Essentials Training SyllabusDocument6 pagesAutodesk AutoCAD Plant Design Essentials Training SyllabusPRASHANT INGALENo ratings yet

- Astm G 96 PDFDocument10 pagesAstm G 96 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Klinger Kammprofiles Austr PDFDocument5 pagesKlinger Kammprofiles Austr PDFAnonymous nw5AXJqjdNo ratings yet

- ASME InterpretationDocument4 pagesASME Interpretationhrh_pogcNo ratings yet

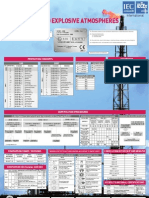

- A Guide To Hazardous Locations & Product Certification PDFDocument1 pageA Guide To Hazardous Locations & Product Certification PDFImdad PeshimamNo ratings yet

- BS 470 Entry PVDocument8 pagesBS 470 Entry PVbonnicoNo ratings yet

- Iecex FMG 12.0022XDocument6 pagesIecex FMG 12.0022XFrancesco_CNo ratings yet

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepNo ratings yet

- Afv TDB 9610.6 Capacity TablesDocument24 pagesAfv TDB 9610.6 Capacity TablesJorge BaronNo ratings yet

- Calculated Motor Pump SizeDocument6 pagesCalculated Motor Pump SizeRicky Ocktavi RizkyNo ratings yet

- Sheet 3Document2 pagesSheet 3Ayman EsaNo ratings yet

- Accessories Cosasco Two Inch SystemDocument4 pagesAccessories Cosasco Two Inch SystemWong Chung MengNo ratings yet

- E71278 PowerPlus D2L Panels Compliance LetterDocument1 pageE71278 PowerPlus D2L Panels Compliance Letterandersson benito herrera100% (1)

- Fisher 2500 249 Pneumatic Controllers Transmitters en 127050Document16 pagesFisher 2500 249 Pneumatic Controllers Transmitters en 127050GOKUL PRASADNo ratings yet

- M624 MBATech Electrical Subrat Sharma Final ReportDocument64 pagesM624 MBATech Electrical Subrat Sharma Final ReportJosef MorganNo ratings yet

- FEA On ThermowellDocument4 pagesFEA On Thermowellvaisakp777No ratings yet

- Jai Balaji Limit Switches PDFDocument2 pagesJai Balaji Limit Switches PDFSuresh kannanNo ratings yet

- Modern Developments in the Mechanics of ContinuaFrom EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziNo ratings yet

- Boiling Heat Transfer: Modern Developments and AdvancesFrom EverandBoiling Heat Transfer: Modern Developments and AdvancesR.T. Lahey Jr.No ratings yet

- ANSI - Control Valve Seat LeakageDocument4 pagesANSI - Control Valve Seat Leakagerenjithv_4No ratings yet

- Ansi Fci70-2Document3 pagesAnsi Fci70-2RafaelNo ratings yet

- Cuel CPT ReportDocument103 pagesCuel CPT ReportIkhsan Ly100% (1)

- Turnkey Boiler Burner SolutionsDocument5 pagesTurnkey Boiler Burner SolutionsIkhsan LyNo ratings yet

- Term of Coating FailuresDocument21 pagesTerm of Coating FailuresIkhsan LyNo ratings yet

- Magnetic Effects of Stainless SteelDocument2 pagesMagnetic Effects of Stainless SteelIkhsan LyNo ratings yet

- Tafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TDocument4 pagesTafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TIkhsan LyNo ratings yet

- Reliability Block DiagramDocument9 pagesReliability Block DiagramIkhsan Ly100% (1)

- Preparation Steel Substrates Before Paints and Related Products Specifications For Metallic Blast-Cleaning AbrasivesDocument25 pagesPreparation Steel Substrates Before Paints and Related Products Specifications For Metallic Blast-Cleaning AbrasivesIkhsan LyNo ratings yet

- Neles Seat Leakage SpecDocument9 pagesNeles Seat Leakage SpecIkhsan Ly100% (1)

- ASME Training Programs: For Engineers and Technical ProfessionalsDocument28 pagesASME Training Programs: For Engineers and Technical ProfessionalsIkhsan LyNo ratings yet

- DGS Test Transformer OilDocument18 pagesDGS Test Transformer OilIkhsan LyNo ratings yet

- Author Manuscript: Performance of Metal and Polymeric O-Ring Seals During Beyond-Design-Basis Thermal ConditionsDocument18 pagesAuthor Manuscript: Performance of Metal and Polymeric O-Ring Seals During Beyond-Design-Basis Thermal ConditionsIkhsan LyNo ratings yet

- Belajar Menghitung ReliabilityDocument103 pagesBelajar Menghitung ReliabilityIkhsan LyNo ratings yet

- K 1000Document2 pagesK 1000Ikhsan LyNo ratings yet

- 3star GasketDocument16 pages3star GasketIkhsan LyNo ratings yet

- Pctfe (Polychlorotrifluoroethylene) : PhysicalDocument1 pagePctfe (Polychlorotrifluoroethylene) : PhysicalIkhsan LyNo ratings yet

- PTFEDocument1 pagePTFEIkhsan LyNo ratings yet

- Tafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TDocument4 pagesTafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TIkhsan LyNo ratings yet

- KMT Stellite Alloys Brochure FINALDocument15 pagesKMT Stellite Alloys Brochure FINALIkhsan LyNo ratings yet

- Pilot Opereted Relief ValveDocument2 pagesPilot Opereted Relief ValveIkhsan LyNo ratings yet

- Maintenance Manual SRV Consolidated Type 1900Document53 pagesMaintenance Manual SRV Consolidated Type 1900Ikhsan Ly100% (1)

- IS 3370 (Part 3) 1967 R 1999Document14 pagesIS 3370 (Part 3) 1967 R 1999Nayag Singh100% (1)

- Sizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04Document71 pagesSizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04zbyszko201234No ratings yet

- RGB Color ModelDocument15 pagesRGB Color ModelkavitaNo ratings yet

- YEAR 9 SCIENCE Exam Sample Quesyions On SHCDocument13 pagesYEAR 9 SCIENCE Exam Sample Quesyions On SHCAlayna ChattooNo ratings yet

- Ixis CS8 08io2Document3 pagesIxis CS8 08io2onafetsNo ratings yet

- Gis AssignmentDocument3 pagesGis AssignmentBajyambere LéandreNo ratings yet

- Process Control & Instrumentations CEV 544 PrelabDocument9 pagesProcess Control & Instrumentations CEV 544 PrelabFaradilah Binti Ajma'inNo ratings yet

- Esas 44-86Document20 pagesEsas 44-86Ej ParañalNo ratings yet

- Introduction To Quantum MechanicsDocument28 pagesIntroduction To Quantum MechanicsTayeb TchikouNo ratings yet

- Conditioning Ultramid Moldings: Technical InformationDocument16 pagesConditioning Ultramid Moldings: Technical Informationsuhas110No ratings yet

- 105 5 四技二專 外語群英語類專二試題 (選)Document6 pages105 5 四技二專 外語群英語類專二試題 (選)happycity2No ratings yet

- Neural Network Based Closed Loop Speed Control of DC Motor Using Arduino UnoDocument4 pagesNeural Network Based Closed Loop Speed Control of DC Motor Using Arduino UnoMuhammad Yusuf ThauziriNo ratings yet

- Astmd1259non Volatile Contentpdf - CompressDocument6 pagesAstmd1259non Volatile Contentpdf - Compressubaid_nedianNo ratings yet

- Optical Cavity Resonator PDFDocument4 pagesOptical Cavity Resonator PDFIjaz TalibNo ratings yet

- Caterpillar Master Glossary Spanish Spain PDFDocument102 pagesCaterpillar Master Glossary Spanish Spain PDFjoelNo ratings yet

- Drilling Fluids With AphronDocument7 pagesDrilling Fluids With Aphronsaa6383No ratings yet

- Behaviour of Laterally Loaded Piles in Cohesionless SoilsDocument3 pagesBehaviour of Laterally Loaded Piles in Cohesionless SoilsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Itc-100 Manual v1 1w57Document9 pagesItc-100 Manual v1 1w57mei krismahariyantoNo ratings yet

- Denso Protal 7900HTDocument2 pagesDenso Protal 7900HTalbertojanetaNo ratings yet

- Topic 1 Pages From A Level Physics 2022 Paper 1Document9 pagesTopic 1 Pages From A Level Physics 2022 Paper 1KhanheduNo ratings yet

- Tda 2611aqDocument13 pagesTda 2611aqban4444No ratings yet

- Nikah UrduDocument20 pagesNikah UrduMuhammad SahalNo ratings yet

- IGCSE Grade 6 PhysicsDocument5 pagesIGCSE Grade 6 PhysicsSathya MarieNo ratings yet

- Rla DescriptiveDocument22 pagesRla Descriptivesurya892No ratings yet

- BS en Iso 29661 - 2017Document44 pagesBS en Iso 29661 - 2017Tamara Silvana CárcamoNo ratings yet

- Soil StructureDocument5 pagesSoil StructureFeras TemimiNo ratings yet

- Bio Trial SPM 2007 Paper 3Document4 pagesBio Trial SPM 2007 Paper 3cmeeflyNo ratings yet

- Eggshell in Concrete PDFDocument3 pagesEggshell in Concrete PDFGil L. Garnatcha Ill100% (1)

- 269-314900 - Rev A - FTIR - IG50 - LASER AND POWER SUPPLY - IGDocument30 pages269-314900 - Rev A - FTIR - IG50 - LASER AND POWER SUPPLY - IGIndhu VaratharajanNo ratings yet